-

Posts

1,232 -

Joined

-

Last visited

-

Days Won

17

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Radarsonwheels

-

Cabbage Hauler - WD-21 Build Thread

Radarsonwheels replied to Jomani's topic in Mopar Flathead Truck Forum

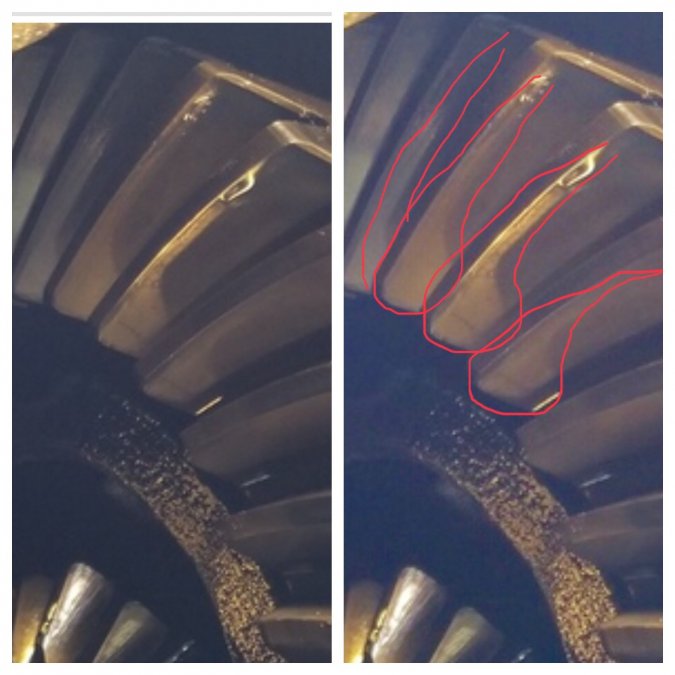

This is what I was looking at. Actually accel not decel right? Interested to see what the actual pattern is once you get her marked -

Cabbage Hauler - WD-21 Build Thread

Radarsonwheels replied to Jomani's topic in Mopar Flathead Truck Forum

Never a bad idea to throw some yellow marking grease on there and see what the pattern looks like. On the 60 you need a spreader and shims? Pain in the butt but worth it. The 9.25 in my truck has screw adjusters to move the ring gear left and right for lash and the pattern fell in nicely after I tightened the lash back to the middle of spec. I am just learning about rear set up myself mine was the first one I did without help. I already had a good starett dial and base just needed to make a three foot long male hex socket with a lip instead of buying $$$ one. The last few rear setups I had pro mechanic friends do and was lucky to be able to look over their shoulder and ask questions. Those guys have huge shim collections and mortgaged full snap on toolboxes with a blow molded clamshell full of any tool they need- hard won and expensive luxuries. -

Cabbage Hauler - WD-21 Build Thread

Radarsonwheels replied to Jomani's topic in Mopar Flathead Truck Forum

Neat! I’ve worked on rear gears before but never a dana 60- I guess that is what the axle end looks like on a truck dually axle? That 9.75 will certainly take some abuse and come back for more! -not an expert- but does the decel pattern look a little close to the inside of the teeth? -

1942 Dodge pickup WC Civilian drive train

Radarsonwheels replied to 1942DodgeWC's topic in Mopar Flathead Truck Forum

Wheel hop is when the springs wrap up into an S shape due to torque vs. traction, then when the spring tension gets too strong it snaps back to a natural curved shape. This can happen quickly in a violent oscillation. My ‘09 stickshift challenger does it if I give too much gas to plant the tires but not enough to smoke them. I’d see if she’ll do a burnout- that will rule out a clutch problem. If it is the clutch chattering due to glazing or whatever you can either keep driving and hope it smooths out as the parts wear or take it apart for a flywheel resurfacing and new fiber disc. Sometimes a little brakleen up in there will help but oil soaked frictions are kind of a losing battle. Good luck! radar -

I am restoring my MōPār model 65 TRUCK MASTER heater. I was thinking about putting a resistor or potentiometer inline with it but the choices are kind of staggering and none are exactly ideal. I can probably just run my 6v heater real fast till it gives up or put a 70s ignition ballast resistor in there where it will get some cooling from the airflow but why plan to replace it later if I have it totally disassembled now? I’d love to find a 12v motor that can accept the stock hamster wheel/blade fan combo and just run off a simple on off switch. With the brain trust here there is no need to re-invent the wheel and I figured there is a good chance somebody has a part number for something that will work? If not no big deal and in that case can anyone confirm my suspicion that since I am running 12v negative ground I should apply 12v+ to the wire which was formerly grounded out on the heater body so it will blow and not suck? Any options experiences or advice is definitely welcome! Thanks fellas Radar

-

Wow how bout this MōPār model 65 TRUCK MASTER heater? What a nice unit. I wonder if I can’t just get a 12v potentiometer to put before it and run this 6v fan motor? I remember the motor was good when I made the truck 12v but I tried one of those resistors on it off ebay and it just ran way too slow and I didn’t bother messing with it again. The design is so tight and nice- instead of just a hamster wheel like a modern heater it has a regular fan that blows out the front and a centrifugal style behind that to run the defroster vents or open the door and shoot hot air at the passenger. This thing is really neat. Now that I cleaned three pounds of mud wasp homes out of it I will test it, wire it up and get it ready to re-install. It definitely needs disassembly, some blasting and paint. I kinda want to leave it as-is but it will start to really rot if I don’t clean and protect it. Sure wish the paint on the inside of the front was how the whole thing still looked!

-

Spent a couple hours today making patterns for the rest of the firewall and passenger toe board. I’m getting close to having it figured out in paper. I want to make it with the least number of pieces possible without losing any usable space and keeping generous pockets around the heads for maintainance. I am not sure about doing access panels or a removable section- I might not need it.

-

Hey I have a C-series. The fenders bolt through the front of the door jams with fine thread bolts. Mine doesn’t have a gasket. My nose/grille/rad support was long ago molded to my fenders which is not cool but it is what it is. The hood (bonnet- you’re british and say boot instead of trunk too?) has four bolts that go down into tapped holes. Also fine thread. No gaskets. It’s all so so simple but I am sometimes flabbergasted by simple tasks when I don’t have experience so no judgment here good luck!

-

Cabbage Hauler - WD-21 Build Thread

Radarsonwheels replied to Jomani's topic in Mopar Flathead Truck Forum

Nice work! I had my kingpin bushings reamed at the same machine shop that does my block boring and decking- didn’t realize how lucky I am. -

I see nobody answered this and since I am clueless about towing my inclination is to leave it alone but if nobody wants to step up with hard earned knowledge here’s my worthless opinion: Swapping the frame to modern running gear is great but not easy. It is a ton of work. You will gain modern brakes which is probably the biggest improvement in my opinion. Our trucks came with solid front and rear axles on leafs which aren’t really too different from many modern heavy duty set ups? If everything is in good working order and not beat up you might come out ahead to just refresh everything and weld up a tow bar to the frame. Now is it a good idea and can you trust other people to act in a way that will keep you out of trouble no matter how carefully you drive? And will truck enforcement and highway patrol think your antique tow rig is as cool as I would? Sorry for more questions than answers! Good luck and hopefully folks with better info will chime in to help.

-

you did it wrong. campbells soup cans are the professional way to do it. if you use hormel chili the red cap from the can can also be used as a tail light lense edit: I added a pic of my ramcharger exhaust- this can was goya black beans and lasted a few months before I swapped to headers and new duals! also please note my pebble beach level of fit and finish- the clamps are clocked the same as are the slots in the screws. Professional.

-

1951 Fargo 400cid on Dakota chassis

Radarsonwheels replied to f_armer's topic in Mopar Flathead Truck Forum

Farmer- with that engine mounted solid you might want to keep some chewing gum around to keep your teeth from rattling and buy stock in loctite. I had solid mounts on my 72 demon for about a week after getting tired of ripping stock anchor brand mounts in half all the time with a healthy smallblock. The solid mounts felt great under power but at idle it was like being in a paint shaker. I had some fuses in my ashtray- it sounded like a maraca. I went to a thru bolted ‘mag mount’ in a hurry. Maybe the rag joint will make the wheel have a smoother feel? The mild engine might help too. I’m not trying to be negative- it’s a hotrod after all and a little shakin’ will be part of it’s badass personality. -

1951 Fargo 400cid on Dakota chassis

Radarsonwheels replied to f_armer's topic in Mopar Flathead Truck Forum

Oh and the cam I am using is a comp but very similar to the 509 cam from their test -

1951 Fargo 400cid on Dakota chassis

Radarsonwheels replied to f_armer's topic in Mopar Flathead Truck Forum

Nice! I've read that 440 article before- amazing what can be squeezed out of a smog motor. I know our 400 low decks have the strongest block and biggest bore of any stock big block mopar ever made, but that they also had really low hp and torque ratings like 300 ft/lbs 220hp or something? Hopefully yours gets a nice wake up with the '68 cam! I'm sure it will sound good and move you along nicely. Plus you don't seem afraid to tear into it so if you get bored with the power you can always throw some pistons and heads on it to get closer to 1hp/cid. -

1951 Fargo 400cid on Dakota chassis

Radarsonwheels replied to f_armer's topic in Mopar Flathead Truck Forum

Thanks for the detailed response Farmer. I see that rag joint- I thought they were pretty solid and were more for vibration than angle. I used a small diameter dual diaphram booster on mine- I'm surprised you can fit the big dakota booster. I am planning on finishing my inner fenders a little to keep mud out and also for additional mounting surface for MSD & relays and such- my firewall is already getting cluttered and full. That OEM fuel pump should kick butt for a long time even though my 89 truck ran but had no fuel pressure- bad pump- the v6 would crank up if you spilled a little gas down the throat. The plastic Dak tank is really nice I thought about using mine but gave it away instead when I was still planning on using a round tank in the bed. I am happy with my boat filler in the rear fender though. About the cam- I think a little bigger would be fun without killing the street manners but you should have 400lbs of torque and 300hp right? For normal driving and an occasional rip or smokeshow I think that motor will do the job. I had a 408 smallblock with edelbrock heads, 10:1cr and a hydraulic flat tappet in the 230s @.050. That motor made 350hp/400 tq to the wheels but it was a stick shift- if it was an auto it would have needed a high stall converter to smooth out the crappy off idle performance and the jerk when the cam came on at 2200. I am not any kind of expert but I enjoy swapping cams and messing around with motors to see how the personality changes. A healthy 400 cid motor will be fun and all that torque will make use of your big tires for sure. I don't remember what gear you are running in the rear but I suspect that your fun will be from 2500-4000 rpm and there will be no hard pull in the upper revs- time to shift to get back into the power. Hopefully you have 3.73 or 3.55 even better. I have always gone with 4.10 rears but this time I think my big block will pull 3.21 juuust fine. I'm angling for a similar street type motor but I couldn't help making it a little more hotrodded since I was replacing everything but the block anyway. I have the forged bottom end to safely rev but I suspect my stealth heads won't keep feeding 512 inches much past 5k rpm. I went with a cam just over a 1/2" of lift so I could keep the stock (cheap) rockers and in the 240s duration so it would still have some power to rip above 3000. The big displacement will tame the duration some. First time I drove a stock chevy 454 (legendary!) I was disappointed it felt like a well geared modern 4 cylinder- nice hard bump to get moving but no hard pull unless you shifted gears down to 1800rpm. It's always good to make all the parts work together so with a low CR cast crank motor you are absolutely right to keep the cam mild. It will sound good and drive smooth for sure! -

1951 Fargo 400cid on Dakota chassis

Radarsonwheels replied to f_armer's topic in Mopar Flathead Truck Forum

If you only have two universals and they don't bind do you need the spherical bearing for the middle? I saved all my dakota wiring too but ended up using none of it- too crusty. Is that the stock Dak fuel pump? That alternator bracket came out really nice! The lights and whole back view is awesome too What cam did you go with? It's still a low compression motor right? -

I took about ten feet of bailing wire out of my 3 on the tree shift linkage...

-

I made the console out of poster board and blue tape then flattened it out into the fewest pieces possible which ended up being three- two little guys and one big crazy shape. I don’t have a brake so I bent it by hand and with a body hammer over a plate clamped to my table. It actually fit pretty well and only needed minor trimming before marking and cleaning the metal all up and welding it in. I have been lamenting my failure to tap the shifter mounting plate holes when I originally made it, thinking that I would need a helper underneath to install the shifter with nuts & bolts or maybe I could weld nuts under it all uncomfortable and out of position which makes for bad welds. Duh! There is no reason the shifter needs to be flat on that plate! It just has to bolt down solid and flat to the mounting surfaces. I am going to cut out rectangular lugs from heavy plate, drill and tap those 1/4”-20, and have a nice amount of metal to weld that’s away from the threads and sticking out from under the shifter body where I can see them to tack them in. Then after they thread through the lugs the bolts can stick down through the generous holes drilled in the existing plate. Anyway, the console is done and I can continue fabricating sheetmetal up to the firewall the next good day I get. It was 7° this morning but I had to go do to work till around 1:00 so by the time I got in the driveway it was a comfortable 10° with a balmy high of 14°. A 60° garage is sounding pretty nice right now but the world really disappears when you’re welding so it wasn’t too bad

-

I haven’t tried to re-gasket the cowl vent yet and my door seals are just scraps hanging on by a thread and my floor is coming along but still fred flintstone style. Somehow I still get moisture in the cab?! Haha well these problems are all on the list to get done- the sheetmetal first, then the cowl vent gasket, then eventually the door seals. In the meantime I am contemplating floor treatments. Nothing has the comfort or luxury of a nice carpet over dynamat but for now I think I’m gonna go with a nice sheet of rubber flooring and no underlay. I ordered some tonite off amazon that looks like it will have a cool vintage work truck vibe and be easy to maintain. With my console I am able to do it in two sides that don’t meet in the middle and I measured just under 5’x3’ for each piece. Should give a finished look and some small amount of protection and insulation.