-

Posts

1,232 -

Joined

-

Last visited

-

Days Won

17

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Radarsonwheels

-

Yup the little bars are definitely a sweet detail! I already have two big grill opening bars- unfortunately my bottom bar is the worse of the two but no big deal. Mine are painted solid and don’t have the cool chrome centers though. My truck came without them and I scoured junkyards and the web for a few years before I found them

-

My truck’s front panel was bondo molded on (maybe leaded? I never dug in to find out and who knows how long ago). With this piece installed my truck would be totally free of bondo sculptured panels and all steel. Maybe someday I’ll find a clean windshield- the 54 is a one year only piece of glass since 55 wraps around the corners more and 53 is still the split B series...

-

So probably like a lot of you I haunt craigslist and more recently facebook marketplace looking for gems and keeping my thumb on the pulse of junk prices. I see the usual cast of decent looking trucks ruined with chevy motors and camaro clips that people want 10k for, and rusted out beaters worth 2500 that list for 5500- usually no juicy part-outs or reasonable parts trucks. but- I found this grille for reasonable and fingers crossed I’m supposed to go get it on monday! It’ll go in the attic until I get around to body work but I’m stoked on the find

-

1951 Fargo 400cid on Dakota chassis

Radarsonwheels replied to f_armer's topic in Mopar Flathead Truck Forum

Ha! That’s awesome congratulations man -

Haha nope I am at work today and it snowed last nite. I could just stick the heater hoses to each other and fire up the motor but I have waited this long. I figure I’ll finish fixing up the heater and making the passenger inner fender & mudflap first. That way if everything goes smoothly on breakin I can just top off the coolant. I have a crossed off to-do list a mile long. I feel like I can see the end of it but there are still some big jobs. If I get busy this week maybe I can fire up in a couple wednesdays...

-

Thanks fellas for the encouragement and ribbing. I really hope I don’t have to look at the h20 temp too often. A hotrod that overheats in traffic is no fun. Fingers crossed on that one! EHAdams post up some pics when you get done in the garage! I got the front all wired up- high & low beams and front turns. The old harness was in super sorry shape- rotten cloth, bare wires with green and black patina on the copper, y’all know the deal with ancient wiring. I was gifted some beautiful four strand loomed wire that was new old stock off a lull crane or something. It’s got a thick black sheath, hefty red white black and green wires with soft flexible insulation, and even talc or something inside the loom. I used it in a bunch of spots and I was able to do ground turn hi & low beam to each side of the front. The headlight backers/cups got new rubber grommets and everything has weatherpack disconnects for service. Now the wiring is totally done except the heater blower motor and the wideband sensor & gauge. I did get a three way switch for the heater and a ballast resistor to drop the voltage for low fan. Time to buy some antifreeze on the way home from work tonite!

-

There are two styles of smallblock mount from the muscle car years up to the magnum 5.2/5.9. There is the early biscuit style that looks like a rubber pack of cards with a stud sticking out of the top and bottom flats, and the spool style that has a metal sleeve suspended in rubber. They both work but the biscuit style is probably going to be better represented in the aftermarket due to the golden years of muscle cars being popular. With a lot of power the biscuit mounts tend to seperate/rip in half. Especially new manufacture parts- the rubber from india just ain’t what 1970s USA rubber was. You can get solid metal ones that will loosen your fillings, thru-bolted ‘mag mounts’ from mancini, or make your own limiters. If it’s a stock 318 you shouldn’t have any problems! The spool mounts are really nice but slightly harder to fabricate from scratch. I used modified spool mounts from a late 80s v6 to accept the late 70s big block spool mounts on my ‘54 project. The bolts go front to back and the trick part is that the frame side brackets are open on top so the bolts just drop right in, then there is a lip on the top which captures the washers when you tighten it up. Stock spools are weak too and people often pour polyurethane in them to fill the voids or just replace the rubber with poly inserts.

-

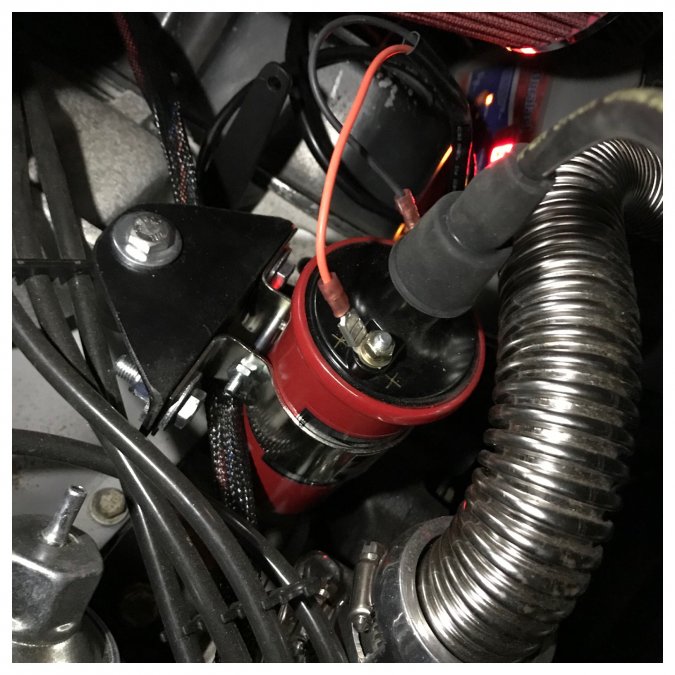

It sure is tight in this engine bay! I finished up the driver’s side front inner fender in metal with a generous rubber mudflap covering the area over the upper control arm. I installed the horn (Aaaaaooogah!), regulator, ignition box, fan controller, and grounds. The rear turns, tail lights, and right side brake light work. The high beam and turn indicator LEDs on the dash all work too. Hopefully the L brake light just needs a new 1157 bulb. The gauges all light up and the new battery still reads over 11 volts on the dash gauge after sitting a couple months- could use a trickle charge before startup. I gave the key a clockwise bump and the starter motor gave a quick grunt so that is working too. The gas gauge reads empty which is correct. I’m going to get a one gallon and a five gallon jug to get aquainted with how those amounts look on the gauge. I still have to install the coil, the O2 sensor, bung, and gauge, make a front lamp harness, and figure out why my fan doesn’t spin when I turn the controller down. It does click when I go past ambient temp so thats a good sign. I’ll jump it to see if it spins and make sure the controller wires are on the right terminals and getting juice, and possibly check the fuse. The negative battery disconnect switch under the bed works flawlessly. I’m glad I did that!

-

Dang! Page 21 and hundreds of posts on here! It’s almost like I’ve been working on this thing steady for months and months now Working outside is starting to make me feel like I’m sharing the southeastern Pennsylvania weather report as much as my truck progress. It’s been super super windy here for a couple days- trees down all over and feeling colder than it really is. There is no way to weld outside and keep the shielding gas where it needs to go and I’m not doing sheetmetal work with the stick welder or running flux mig wire. Tomorrow is my day off- hopefully I’ll have a chance to weld up at least the driver’s inner fender. In the meantime I got the cab wiring almost finished- I still need a three position switch for the heater blower and I have to mount and wire in the AFR gauge. I decided to just make a black plate On the motor side of the firewall the engine bay is done. All the connectors and terminals are on. I have a nice loomed cable that goes to the headlights and turns in the front but I still need to make the harness section that will live over the grille and have the pigtails for the bulbs. Once my inner fender is solid I can populate it with the msd ignition box, regulator, horn, and fan controller and plug those in. I also need to mount the coil- probably on the intake. Gettin closer to fireup!

-

Cabbage Hauler - WD-21 Build Thread

Radarsonwheels replied to Jomani's topic in Mopar Flathead Truck Forum

Thanks Jomani I always wanted to do an engine setback even though I’ve read that the engine setback has a minimal effect on front to rear weight distribution unless it’s getting into mid-engine territory. On the other hand with a lot of power and the light rear end of a pickup every bit helps and my heavy wood bed will give some ‘bag of sand in the trunk’ effect. I’m sure with all the weight of your tires and your wide wide contact patch a burnout will be a greater challenge for you than a dead hook. Neither of us are building race cars though! I think a lot of race classes are limited to lining up the first sparkplug with the front wheel centerline- mine is more like #3 plug lined up so it’s a pretty mild setback but I was limited depth wise by wanting to keep my cowl intact and height wise by my deep oil pan and deciding to keep my dakota motor crossmember. Your trans x-member notch is not a deal breaker at all- that would be easy to put back to stock. Are you going to box it in? Probably doesn’t need more strength since it still has the top corners on it. I can’t see giving up double the horsepower and less valvetrain maintainance to go back to stock. Plus with that dual axle & v8 you can haul safes up mountains in modern traffic! Those motor mounts look stout and the junkyards are still full of 318s and 360s if you ever hurt this motor and wanted to be back on the road in a weekend. Flatheads are super cool though... -

Windshield Wiper Positioning

Radarsonwheels replied to jcnida52's topic in Mopar Flathead Truck Forum

I have to mess with mine soon- so they are not pushed onto a splined stub like on a modern car? Edit: meaning the wiper arm itself on the cowl- I know inside are levers and linkages. -

Cabbage Hauler - WD-21 Build Thread

Radarsonwheels replied to Jomani's topic in Mopar Flathead Truck Forum

I don’t know what you mean? Fabricating a setback firewall and floor is totally easy you don’t need three weeks, four packs of poster board, and a whole 4’x8’ sheet of steel or anything Good decision on the engine location. That thing is gonna haul so much cabbage and you won’t even need to wash it before eating it! -

The price isn’t bad at all and rtv or weatherstrip adhesive sounds like the way to go. I am just so far from that kind of detail work. The major areas that will need metal work are the door skins, passenger door to fender gap, driver’s running board, front bottom bedside corners below the stake pockets, and my driver’s turn signal/headlight area has a lot of bondo sculpture going on. Right now I am trying to get cleaned up and wired under the hood so I can start my fresh motor and test my driveline work (first auto transmission build!). Finding and eliminating the water leaks into the cab is a pretty big priority though- it comes before making it pretty. I think I’m going in the right order though to make it safe and solid to have fun and get back out on the road quickly. It will be less fun if I need to get it all perfect before I can rip around in it. You can lead a horse to water, but you can’t make him drink. I do appreciate the info on the stock way to do it though. I wish my truck was in good enough shape to make me want to put it back stock! It being so far gone made me feel good about butchering it up. I am trying to be respectful to the original design but I’m going for more ‘fun hotrod’ than the ‘factory should have done it like this’ kustom. Really my vision for the truck kind of went off the rails a little with the streetrod/EFI tuner intake... I’m rambling now but I did just get a tig welder and I am not amazing but I managed to weld up a 4” 16g cube that holds water. I bet I could make some kind of cool air cleaner that would at least look space age....

-

Manifold Stud Replacement

Radarsonwheels replied to Matt Wilson's topic in Mopar Flathead Truck Forum

That’s great! -

Lets see pic of your trucks

Radarsonwheels replied to Ken_Hart's topic in Mopar Flathead Truck Forum

Roger1 I agree your truck is stunning- looks like a better than stock restoration. I don’t want to steal any of your thunder but just wanted to note the similarity to my truck- I used to have the same parking brake ? -

Seatbelts! I swapped out the evil kenieval blue seatbelts for some nice simple black ones with airplane buckles. I haven’t wasted too much $ buying stuff I didn’t use but I’m really really good with the decision to not put garish five point harnesses in there. The footprint gas pedal could have stayed though if it fit better

-

I just sat in the cab like I was driving and put it a little above the comfy places to put my left foot. I usually end up with my heel at the bottom of the ‘wheel well’ curved floor section and I wear size 14 shoes so it’s out of the way but not hard to hit. The part of the floor that got a rubber mat got extended forward to a 90° corner on the drivers side instead of having the stock angled toe board. This was mostly to give more room for brake pedal travel without having it too high at rest. But there isn’t much room there for two feet!