-

Posts

824 -

Joined

-

Last visited

-

Days Won

44

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by timkingsbury

-

Transmission Overhaul - 1935-1939 page 1 of 4

timkingsbury commented on timkingsbury's gallery image in Individual Member Photo Albums

Hi Dan - Well here is my blog entries on our adapter plate that allows someone to hook an A833 overdrive 4 speed to a mopar bell housing. My Dad 1st took a 1974 a833 in 1975 and bolted it up to a Dodge 265 ci flathead 6 in a 1956 Fargo (Dodge) pickup. On my blog you will see the bell housings and I know that our adpater plate will work for the early hemi bell housings and in the case of the mopar situation you use your stock flywheel, stock pressure plate, stock throw out bearing. Its only the clutch you need to change as the A833 uses a fine spine clutch. But the Offenhauser 5272 or 5174 (chevy to flathead adapter) or Offenhuser 401 Bell, I know nothing about them, sorry. But if you have an early mopar hemi, the original mopar bell housing our adapter plate likely will work just fine. Adapter plates to utilize a modern floor shift A833 4 speed overdrive on most Mopar Flathead Cars (ready to ship) - Keeping Up with the AoK boys - P15-D24.com and Pilot-house.com (p15-d24.com) Solving the Modern Overdrive with a Floor Shift using Mopar Parts - Keeping Up with the AoK boys - P15-D24.com and Pilot-house.com (p15-d24.com) -

The Worlds Greatest Intakes - AoK

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Well folks - A little progress report. After getting our customer orders locked in with the foundry we got a load of casting Aluminum from Alcan in Hamilton Ontario Canada on its way to California. The foam cores ( the yellow piece in the picture above) were produced and the foundry are now scheduled to have the intake casting finished next week. They will then be off to be heat treated and then shipped to Pennsylvania where we will have carb side and block side of the manifold all machined. Then for most the carb mounts drilled and tapped before they are packed up and shipped out to customers. This turned out to be a large order with over 150 intakes (duals and triples) , with a lot of linkage and customer carbs rebuilt by George to wrap up what is likely our last run of AoK intakes, at least for the foreseeable future. For those kicking themselves for not ordering one, we have a tiny bit of good news. There are two AoK triples for the 25 1/2" motor and two AoK dual carb intakes for the 23 1/2" motors available as of today - December 8th 2020. Its too long of a story how we will wind yo with 2 extra or each and as George and I both said - who cares if we sell them because we likely should put the $2,400 into the pot and keep them. But.. instead of hoarding them we will open it up to the public. The expected shipping will be early in 2021. A side item - if you have surplus Carter Ball and Ball carbs that are 3 bolt bases (center to bottom carb sections) that you can part with please let us know. Were looking for good rebuijdable cores for custoners, Thanks Tim -

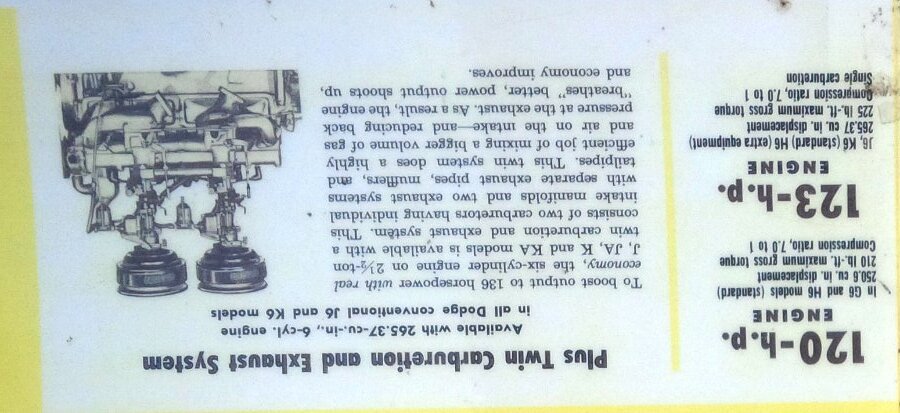

Hi Folks - After several emails i best weigh in. The factory dual carb , dual exhaust setup for the 25 1/2" motor was unveiled at the 1951 municipal show and was introduced 1st in the 1952 model year with the 1st delivery to Wellington County in Ontario Canada. Attached was the dealer poster that was sent to them in late November 1951, showing the introduction of both the hemi and the factory dual carb/ dual exhaust setup. At that time Chrysler Detroit marketing wanted the HP rating of the 265 engine scaled back as the plan was to push the hemi v9 which actually cost less to produce. The 1st ones were what in Canada we call 4 ton trucks because that is the weight haulage. By April 1952 they were coming out in 2 1/2 ton and heavier trucks. It was also the 1st introduction of the 5 speed and 5 speed with overdrive in the bigger trucks. In 1954 the dual carb setup was optional on the 250 ci motor and in 1956 it was optional on any model truck. My Grandfather bought a 1956 Fargo pickup with a 265 and factory dual carbs and exhaust and gave it to my Mother for her 18th birthday Yes i have the line ticket, internal bill of sale and the truck is still in the family. It was long ago posted on p15d24. It was a Chrysler internal bill of sale because he worked as the GM of the Windsor Engine Plant. The dual carb dual exhaust setup was technically available as a factory option up until 1959 whoever it was more often a dealer add on and you could buy the setup from any dealer who sold Dodge or Fargo trucks. I have the engineering, and shop manuals from 1936 to 1971 and you can clearly see the setup appearing in the 1952 documentation. I will attach a marketing poster picture and the Chrysler documentation. In terms of welding, between my Dad, our buddy George Asche (the other part of AoK Racing) and I we have restored more than 50 of the setups including welding up some exhausts or intakes that people would have said that we restorable. Some of those now have more than 100,000 miles on them and are over 50 years old and never needed another restoration/ Tim Tim Kingsbury

-

Hi folks - The good news folks, is that the AoK Boys will be making another run of our AoK Intakes; The bad news is this will likely the last run we do... More at the end of this note, but as requested by many, a look back at how the intakes came to be... It was over 20 years ago that George Asche Jr and Eddy Kingsbury (both Feb 1932 babies) we hanging out at Chrysler Carlisle, or The All Chrysler Nationals. Along with George's son Rob and Ed's Son Tim, there was a few trips down memory lane from George's 142 mph run in 1954 on Daytona Beach in the Flying Mile to Eddy building a Legendary Top Fuel Engine that would Rock the World setting the 1st of many World Record runs, to Tim's 1971 Challenger that he and his Two Grandfathers would build, for Tim to Campaign in what would be the Pro Stock division and leaving behind all time Track Records at more than 1 strip. Of course having a Legendary Chrysler Engineer as a Grandfather whose best friends ranged from Eddy Edmunds to Al Sharp never hurts a build either. It would be during the "Bull Session" that idea of building a 1/4 mile dragster was hatched. During the next few hours every body style was discussed and of course what type of power plant would it have was a key topic. Sure Eddy could go into the shop and go crazy on some Top Fuel Hemi monster, but that just seemed to be a case of "same old same old". Of course it didnt take long before the conversation swung to - "I wonder how much power we could make in a Chrysler Flathead.... and.... what are the things we would need that we really dont have access to or potentially have never been made. The big 3 items became - 1) A wild cam with lots of torque, lots of rev and lots of power. 2) Light weight top fuel grade pistons with modern rings 3) A few delivery system.... lol An Intake The 1st one, well that became a case of digging into the Chrysler experimental archives, pulling out the Asche archives , put everything in a blender, pour it over ice, do a bit of tweaking and well a Big Ass Wild Cam was born. #2, well that is call - 1-800 ask Shirley Muldowney for a set of .125 over bore Venola Top Fuel grade coated pistons and Plasma Moly Rings. The 3rd, well that would take a bit of work. 1st we looked at, flowed and tested a huge variety of intakes. From triple carb intakes from the Legend Eddy Edmunds, to other after market intakes, to over a dozen custom intakes, to fuel injection, hell we pulled out turbo and blower intakes that were squirrelled away in the AoK archives and over 2000 man hours later we had an encyclopedia of fuel delivery systems. A few times we circled back to Eddy Edmunds - "Edmunds Racing" Triple intake and a one off intake that was made at the Chrysler Engine Plant in Windsor in the early 1950s. Next a good friend of Tim's that he went to School with who would be known of the best modern intake designers alive today, was talked into, or conned into helping so that we could play the game of -"What would Eddy Edmunds and/or Tim's Grandfather have created if they had modern design, testing, simulation and casting technology". Out of all of that and several alpha and beta versions, we created 10 - AoK Racing triple carb intakes. Now to be very honest, there was never any intention for any of these to ever leave the Kingsbury or Asche Families. It would be while Eddy Kingsbury was playing with one on his "Olde School" flow bench that he speculated what the AoK racing triple would be like on the Family Relic. That would be a 1936 Fargo pickup which would be one of the 1st 100 trucks to have a new 25 1/2" engines from the Windsor Engine Plant. Two hundred and one, massive cubic inches or Chrysler flathead.. lol Ok.. while that engine would sport a forged steel crank balanced to the gram, balanced rods, a pressurized oil system and bearing inserts coated with a new formulation that would eventually be known as Clevite 77 coating, it would lot make 100 hp. For its day, in 1936 compared to Henry Ford or Chevrolet it was quite something, but compared to a later 265 ci engine with factory dual carbs and headers, well it was pretty tame. The 201 ci motor was still rock stock, never bored, stock cam, really as stock as it gets. On went an AoK racing triple. Eddy and George had to figure out mounding a pivot point on the intake for the pickup, and a matched set of 3 carbs and a set of headers made from a stock exhaust manifold. What happened was incredible and honestly I wished both my Grandfathers had been alive to see the results. The Rock Stock 201 gained 25% more HP to the rear wheels and taking it for a 60 mile trip the fuel economy improved by 7 miles to the gallon. That was the "Ah hah" moment when it became obvious that the intake was just the most fuel efficient delivery system ever made and what you stacked on top of the triple carb intake obviously depended on how many cubic inches of engine, how many RPMs you were going to be spinning, with how much horsepower and how much torque your producing. From that point forward, I think 7 of those 10 intakes wound up and engines that were stock, to fairly modest performance engines. Certainly nothing wild. The response was through the roof positive. More Power, Better Fuel Mileage, More Torque and the complaint were simple - "Why dont you make an AoK intake for the USA 23 1/2" Engine".. It would be over a decade later when we asked the Mopar Hobbiest what they would like to see - a Triple for the Small Block or a Dual Carb intake. Overwhelmingly the response was to great a dual carb intake that took everything learned with the AoK Triple for the 25 1/2" engine and apply it to a dual carb intake for the 23 1/2" engine as well as make it so it can easily be used on car pre and post WW2 cars as well as trucks. Tim would take it upon himself to name this AoK intake as the "AoK - George Asche Jr Limited Edition" intake. It was actually not intended to show up until the production intakes were rolling out of the foundry, although some how the 1st Sample that arrived for George to look over, had his name on it. Since then we made a few runs of the AoK dual carb intake for the 23 1/2" engine and to be honest I have lost count how many runs of the AoK Triple carb intake for the 25 1/2" motor that we have made. I know between the two, they have been in over 50 countries. In the last few year the foundry which we originally started with, has seen its owner retire and his business passed on to another. Cost increases from the foundry, need for mold and tooling changes, cost increases to heat treat, cost increases to machine castings, have moved this from a labor of love project where would shoot to break even to a loss on every intake sold. We have looked at alternatives for every step along the way to produce intakes and while we have made some changes, both costs and minimum order numbers have increased. We will be emailing those on our waiting list as well as anyone from here to see if we are within striking distance of the minimum order quantities The cost of the AoK triple intakes (for the 25 1/2" big block made in Canada) is going to be $620.00 usd plus shipping. On the AoK - George Asche Jr limited edition dual carb intake for the 23 1/2" USA small block they too will be will be $605.00 usd plus shipping. * We had hoped with North America being far from hot economies that we would be able to get pricing closer to what it has been in the past, but its just not there. Everything is up and these are priced so close to cost no one would remotely consider this a business adventure. It is strictly to give those who have been on a waiting list a long time, plus a few that have had AoK intakes and want more for a current or future project(s). Linkage will range depending upon what is required, but the standard 3 carb linkage with linkage that can be hooked up to linkage coming across the head will be $195.00 and the Dual Carb Linkage with be $175.00 That is stainless linkage hand made by George Asche for Carter Ball and Ball Carbs. If you need linkage for a truck or pre-ww2 car you will need to supply a pivot point which is on your original intake for those vehicles. Carbs, are going to be a problem for us to supply rebuilt carbs. If you have cores and need them rebuilt we may be able to help but we can not supply carbs for all of the intakes. * Note: realistically with several suppliers involved in the production of these, some effected by the Coronavirus, the realistic target for shipping should start by the end of March 2021. For customers wanting linkage or their Carter ball and ball carbs rebuilt and everything mounted and setup it will depend on what linkage George needs to make and/or carbs he needs to rebuild. Obviously if we get them sooner they will be shipped sooner. If your interested in either and not already on our waiting list, drop us a note and we will happy to discuss your project(s). Well can accept USA postal money orders, a check/cheque drawn in a USA or Canadian bank or PayPal (sent as friends and family cash transfer) Thanks Tim Kingsbury and George Asche Jr fargopickupking@yahoo.com Attached is pictures of the AoK triple with inboard linkage (across the head) and for the AoK dual intake for the 23 1/2" motor, linkage both on the outboard

-

Hey guys - after several messages, I have made it even easier and put up the specifications of the most popular cams we either cut, or in a the case of a couple, guys are just just curious what the cam spec is. Their all up there, from mild to out of this world wild! Enjoy! Tim Kingsbury - George Asche Jr The AoK Boys

-

The all Mighty Cam - Flathead Style

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Since I have been asked by a few for specifications for some of our more popular cam grinds, or in a couple of cases, people are curious as to what the specifications are, here they are.... While a lot hide behind names of the cam they sell, honestly, happy to hand out the cam details. If you can find a computerized cam grinder you should be able to cut any of these from the detail... so as my Grandfather would say - knock yourself out! 1) .380 - Mild and we likely sell the most of these. It would be a .380 lift cam which is going to give you 4500 rpm. It’s closest comparison would be to the Isky 3/4 mile cam. It’s been around a long time and has a quicker rev over stock. It was historically for stock car racing. For most guys this is where George steers them, because most guys think they want power.. but they want to start their car and not hear it running. Tons of guys call this cam a race cam.. It’s far from that. The tech side = 242 duration and .380 lift 2) 400 - Higher lift and increased duration cam, which was use for drag racing in the later 50s and early 60s. Your starting to get a little lumpy at idle, it will idle down but you need a fresh rebuild as this is the point where your starting to test the limits of a flathead This is a modified version of the Scholler full race cam - stock car racing - Higher lift and increased duration (Intake - open at 18 degrees, closes at 54 degree. Exhaust opens at 54 degrees and closes at 18 degrees - duration is 252 and lift is 400 3) 435 - Tim’s 49 Plymouth & Harry Heins #90 cam. It is a little lumpy and still streetable, but it is definitely aggressive, with a .435 lift,so it will crank to over 6000rpm. This was a cam was developed from tweaking a full race cam from the 1950s and 1960s and was what Harry Hein #90 used at the end of his career. Harry is in the NASCAR hall of fame and George's uncle. Tech info - intake open 20 degrees closes at 58, exhaust opens at 58 and closes at 20 degrees. 258 duration .435 lift 4) 375 ½ mile “1023”- this was a stock car cam or the modified .375 cam increasing duration instead of lift, which will give you a more rev taking you to the 6000-6500 rpm range. It was for quick bursts coming out of the corners at stock car tracks. Barely idles at 1000rpm. Not for street use although it has been used by some on the street.. aka Harry Hein’s personal car. It was designed for use on ½ mile and longer tracks. tech specs - intake opens at 20 degrees and closes at 50 degrees, and exhaust opens at 57 degrees and closes at 13 degrees, Duration .250 and lift is .375. Stock lift (which is 375) and played with the duration and the intake and exhaust opening. If you ever decide to go blower, this isn't a bad cam. 5) 430 - Briggs and Stratton – Tractor Pull Grind was born out of looking at cams from different manufactures and believe it or not Briggs and Stratton made a high lift higher torque cam. Thus was born from using other performance Mopar cams and the Briggs and Stratton cam. Its an extreme lift cam, with big torque pattern at slightly higher rev than a stock Mopar truck cam. It is here where the engine modification has an effect on engine vacuum. 320 duration 430 lift. This cam would likely be questionable to putting it on the street. 6) 446 – This is the most extreme cam likely ever made for a Flathead Mopar - We call if the AoK Velociraptor Grind . It is tough to get it to idle below 22-2300 rpm, and we have with a ton of work gotten our dragster to idle around 2000 rpm. It will rev to 7200 + rpm and we have tossed almost 1500 cfm of carburation at it. You can run an engine on alcohol and will need 3 carbs and need to shift to 6 exhaust pipes for at least 42” and if it’s going into an exhaust system it will need to be large duals after the 42”s of 1 ½’ pipes. Tech info - intake opens 30 degrees and closes at 70 degrees, and exhaust opens at 70 and closes at 30 degrees, 280 duration and 446 lift If your running 3,4,5 or 6 - you may want to print yourself off this bumper sticker! -

Im honestly not sure about a 1979 dodge van. I know long ago when we were doing them here was the this of the a833's we had researched as working. I will attach that document. The overdrive configuration with a 23-spline input appeared in these vehicles: o 1975 to 1979 Valiant, Duster, Dart, Scamp, Swinger, Volare, Aspen (3.09:1 ratio first gear) o 1975 to 1987 Dodge light-duty pickups and Dodge and Plymouth Vans (3.09:1 ratio first gear) o 1977 to 1979 Diplomat and LeBaron (3.09:1 ratio first gear) A p20 bell housing should be just fine Unfortunately I do not have an adapter plate with me to check the hole size of it either.. Ill send you a pm and try and work through this for you. Chrysler a833 4speed.docx

-

since I keep being asked for the technical breakdown of T5 transmissions I will cave and post it here even though its clearly not what this blog is about. This is the splits of the average mopar 3 speed Plymouths 1936 – 1940 1st 2.57 2nd 1.55 3rd 1.00 Plymouths 1941 1st 2.57 2nd 1.83 3rd 1.00 Plymouth 1942 -1954 1st....2.57 2nd...1.83 3rd...1.0 reverse 3.48 T-5 Transmission Application Chart (attached) overdrive info - including a833 and t5 information.docx

-

there are the splits of the aluminum a833 4 speed with overdrive and comparing to the earlier Plymouths factory 3 speed (without overdrive) Plymouths 1936 – 1940 1st 2.57 2nd 1.55 3rd 1.00 Plymouths 1941 1st 2.57 2nd 1.83 3rd 1.00 Plymouth 1942 -1954 1st....2.57 2nd...1.83 3rd...1.0 reverse 3.48 So here is the a833 primer stuff ! Aluminum cased a833's with overdrive started part way into 1975 thru mid 1987 Gear splits 1st: 3.09:1, 2nd: 1.67:1 3rd: 1:1 4th: 0.73:1 (Trucks used a 0.71:1 fourth) The overdrive configuration with a 23-spline input appeared in these vehicles: o 1975 to 1979 Valiant, Duster, Dart, Scamp, Swinger, Volare, Aspen (3.09:1 ratio first gear) o 1975 to 1987 Dodge light-duty pickups and Dodge and Plymouth Vans (3.09:1 ratio first gear) o 1977 to 1979 Diplomat and LeBaron (3.09:1 ratio first gear)

-

George update, and AoK Intake updates

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Hi Folks - I likely should have updated this back before Christmas. 100% of the AoK triples are sold out. The 1st batch of those came out in 2000 and there has been 5 or 6 runs of them done. The triple is for the 25 1/2:" Canadian engine which starting in 1936 was on Chryslers, Desoto, heavier Dodge trucks and in Canada, add Dodge Cars, Plymouth cars (other than convertibles), all Dodge and Fargo trucks unless you were talking the super big block that is a series of 331ci, 377ci and later 413ci. The AoK dual carb intake for the USA 23 1/2" block has been out a few years and there are 2 or 3 batches of those made. Unfortunately the foam core casting supplier has changed from our original supplier. He retired after his wife passed away. The next supplier has gone up in costs, needed significant molding enhancements before they took over and now want even more changes. So until we resolve that situation, or find a new supplier were sitting sold out. We have a waiting list right now. It costs nothing to be on it. If we run off another round of both, then we will get people to firm up. I hate to say never, but it is possible a next run is a last run. From rock stock engines, right back to 1936 engines on the 25 1/2" front to full blown race engines, the AoK triple has proven its the best intake ever made for the Chrysler based flathead. The AoK dual will now around 5 years experience has shown in the field to be what our tests of over 25 intakes, from flow bench to dyno testing showed. It to is the best dual carb intake ever made for the 23 1/2" USA flathead Mopar and honestly there is nothing close. So if you want on our waiting list, please email me at fargopickupking@yahoo.com As a final note, right now we have 52 triples and 70 dual intakes on that waiting list that we started early last fall -

The Serial Number is for a 1954 Chrysler Windsor which engine was made in the Windsor Ontario Engine Plant and the car came from the Windsor Assembly plant. It was a 265 ci motor when it left the factory . 3 7/16" bore and 4 3/4" stroke That being said the serial as 55 Fargo point out on another one, was not applied at the factory. The factory used a jig which held all numbers, letters and any special character together so when the serial number was applied they were absolutely in a straight line. This is a restamped block. 1954 was the 1st year the Windsor had a v8 in it, although at least in Canada the 265 was an option. The part number that is cast into the block -1400229-1 was actual a part number used for the 238, 250 and 265 ci engines and was a block number casted from oct 1951 until 1955 actually. If you looked inside the block you would notice its been carved on the side which allows for the long stroke 265 crank and rods to have clearance. That same carving was done in advance of it being known which ci motor it would be. If you look closer to the oil filler tube, but down by the oil pan you will likely see a Letter (likely a D and then a number (1 or 2 digets) and then another number (1 or 2 digets) . That will allow us to figure out when the block was casted. You can also look up a little higher and see a clock face cast in the block and a code for what shift it was casted on. The USA engines are a lot easier to determine the casting date that the later Canadian 25 1/2" engines, but thats a long story that really doesnt help in this discussion Good eye... 55 Fargo your 100% correct. while the t137 is an excellent resource it really is, it is not without its gaps and Canadian engines are often part of that gap. A classic example would be looking at a 1949 Plymouth you will see a p18 shown as a 218. Without getting into a big debate, it really was known within Chrysler as a 217. The Canadian 25 1/2" engine was a 218. However the real point is I have a 1949 Plymouth that my great aunt bought brand new. Its a p18 serial number. It was neither a 217 or 218... In canada they were 228 ci 25 1/2" blocks. On the t137 site it would show the 1954 chrysler 6 cylinder as c62 and that is correct... Correct for engines which were shipped to the USA for assembly into a 1954 Chrysler. For engines that were going to the Canadian assembly plant in Windsor, they were marked c54. Hope that helps

-

Anything with a date after august 1951 is the best blocks made. A bypass oil filter does a better job of filtering oil, but a full flow starting in 1954 model years will see all the oil passed through a filter. You can drill into a by pass block and put on a full flow on it. Here its done on a 1949 Canadian Plymouth block, which started its life as a 228 and is now 125 thou over bored 265. You can run both a bypass and a full flow if you like. There are 265s with either configuratons that you can consider as durable as anything ever made. All of the Canadian engines after ww2 in the 25 1/2" series are all forged cranks, balanced to 1 gram, forged pistons (from the factory unless ordered by a secondary manufacturer) and balanced assemblies of crank, rods and pistons. You will see lots referring to combines and industrial engines. You can get into engines that are purpose build, maybe with sodium valves and low rev cams. Often industrial engines have cams to meet a specific hp configuration but also a per hour fuel consumption number will have a specialty cam. It is the cam which a lot miss and there are a huge catalogue of cams that were ground for the 25 1/2" engines. The whole topic can be an explosive one and everyone has an opinion. Sadly I find a lot of opinions can be without any experience or expertise behind them. As I have read your posts you talk durability, but then I see the thread going in the supercharger and other directions. I will take a slight tangent here to say, that once you move any engine into a turbo or super charger arena, a cam with a certain number of degrees of separation between when an intake closes and exhausts opens, and visaversa on exhausts closing and intakes opening, become critical if you doing much more than using them as jewelry. By that I mean if your just putting it on with a tiny boost as many have ok.. In those cases I can get way way more power out of a naturally aspirated engine. But if your going to start cranking up pressure, you need separation and no stock cam was ever cam with such seperation. We are happy to provide without charge the specs for at least a couple of cams for superchargers or turbo charges. After that, drop me a note any time.. fargopickupking@yahoo.com and happy to discuss further.

-

Well you make some interesting observations. On HP your numbers are not quite correct and what was published was for the 265 coming out in 1952 under valued and with a purpose. I have uploaded many times and can send it to you, the 1952 poster which was the start of the 265 and as well the start of dual carbs and factory dual exhaust, but also 241 dodge hemi. The Hemi for what they called the medium tonnage field was primarily municipalities and contractors, dump trucks etc. It w4 ould come out at 133 hp. The 265 for the truck with the truck cam and dual carbs and dual exhaust was 155hp. That not a guess, thats a fact. But marketing said if you say that we will never sell the hemi, so we want it cranked back. At one point the poster was the hemi at 133 and the 6 and 132, but when it hit the dealers in December of 1951 the 6 was tucked into the corner and was shown at 136 hp. Pure marketting. No difference to the 1964 426 hemi being called 425 hp with a single 4 barrel, and in 1966 with a wilder cam, 2 4 barrels it was still 425 hp. That of course was for insurance purposes. In any case I digress. The 265 from the factory with a chrysler car 265 cam in it, was the most hp of the 23 1/2" or 25 1/2" engines. But connecting rods.. You are correct, the shorter the rod the bigger the angle. Now its the balanced crank, rods and pistons that offset your concerns it really does. Think about it.. GM, FORD, you name the manufacturer.. Who else had forged cranks balanced to a gram.. answer no one.. Back to your point.. Let me just say that in the 238/250/265 series engines, they are all exactly the same bore.. 3 7/16" If your having custom made forged pistons made well what you do is take a 238 rod, and raise the pin placement on the pistons. Longer rod and better angle. It doesnt work with a 218 and a 201 is smaller rods bearings so not relevant. The point being on that one point your correct.. long the rod the better.. if.. key word if you not negatively effecting displacement. As so many would tell you, there is no replacement for displacement.

-

Hi - Well in the 25 1/2" block engines.. the 201 you maybe referring to was moved from USA production to the Windsor Ontario Canada plant when it opened in 1935 for the 1936 model year. that engine was produced for 14 months out of that plant. Among other things you may wish to consider.. The crank has smaller journals, the water jackets, are smaller. the oil galleys are smaller.. It really would be the weakest of all engines ever produced out of the Canadian Plant. When I say that I am quoting my Grandfather who would be the GM of that engine plant when it opened in 1935, reporting directly to Walter Chrysler (and not the VP of production) and he would still be in charged of the engine plant when the very last 25 1/2" engine rolled out of the plant on Nov 11 1959. The 230 was 23 1/2" block so not relevant to the big block discussion, beyond the small block has offset rods. With the 218 and I am assuming your are referring to the Canadian 25 1/2" 218 and not the USA small block 23 1/2" engine that are 217 that are often called 218s. The next generation block would actually be a changed version of the 228 ci motor which started in Windsor in early 1936. That is often referred to as a generation 2 block. Definately better than the 201 engine, but there would be a number of changes to the engine blocks and internal configurations. Even the 1946 250 ci motor has a different block than would a 250 ci motor made after August 1951. It would be that later block which has the best water jackets, best oil circulation, reworking of oil passages and on and on. By that point you could get a 218, 228 or the series of 3 7/16" bore which would be the 238, 250 and 265 ci motors. The difference is the stroke which is accomplished by changing rods, and cranks. 4 1/4" being a 238, 4 1/2" being a 250 and 4 3/4" being a 265. But there is no question the best ever flathead engines ever built are those generations. Among other things and I could give you a laundry list.. Your talking forged cranks balanced to 1 gram, forged pistons, rods, pistons and cranks as an assembly balanced to 1 gram. That never existed with any other flathead engine anywhere in the world. In fact my Grandfather often said - I defy anyone to find a more balanced engine in the planet that came out of my plant. So if stroke becomes where you wish to draw your battle line.. best try with the 238, 250 and 265 motors.. But by 1953 the vast majority of all orders for heavy trucks, commercial vehicles, municipal vehicles, industrial engines, for welders, water pumps, combines, and on and on were 265s. One can point ot military orders of 250s and I would suggest the reduction in price was the factor. They didnt want to pay the extra $. One last one, of total production of any single motor the 265 was produced in a volume larger than any other single motor configuation from the Windsor Engine plant. From 1946 until the end of the flatheads, the Windsor engine plants warranty numbers as a % of production was not only the smallest of any Chrysler engine plant by over 98% but the smallest of any engine plant in North America. The reason was simple.. Build it better, balance it better and you will get less back. Tim Kingsbury

-

Well after my 7th note from someone I guess I will wade in. I have no idea what Don's picture is or what the story line there is, but here Here is the answer to your question. Yes, every single dual carb dual exhaust manifold that came from the factory was equipped with govenors and balance tubes. You could buy the intake assembly which was the intake and balanced tube, the exhaust maifolds (front or back) as individual assemblies from dealers. Lots of stock car builders would drop the govenors. If you also drop the balance tube as many do, you will find you loose torque and hp. You will gain rpm if you are simply removing the balance tube from the truck engine that it came from the factory with. But and here is the key but, all of those engines that came equipped with the setup and purpose built cams. So you only need to take a cam from a 1952-1953 chrysler and put it into the truck engine to raise the rpm, keeping the torque curve. It actually will develop 8 more hp with nothing more than that cam swap. Again, I am not talking putting in a custom cam or making any other changes, beyond putting in the period car cam into the truck engine. The dual carb/dual exhaust intakes were all produced in Windsor Ontario Canada, and were available at dealers as parts starting in march 1952. I clearly cant speak to all dealerships but can say the Wellington Motors in Guelph Ontario Canada could still get you the dual carb setup in june of 1974. I have a receipt for a complete setup purchased that way.

-

Single Carb Intake, Dual Carb Intake, Triple Carb Intake, why not more ?

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

George Asche can make you one out of your stock intake, You can do it integrated with your exhaust and split them internally and added a second pipe, or do it with headers. In terms of an aftermarket intake, Eddie Edmunds made a decent on and I do see them up for sale from time to time, although they tend to be pricy. The factory dual carb and dual exhaust manifolds that came on the 1952-1956 trucks are also available from time to time, but big time pricy. I know a guy who has a fully restored setup, from carbs to linkage to cross over pipe and dual exhaust but your looking at $3500. The fentons or offy or other low profile intakes I wouldnt touch with a ten foot pole. They loose too much torque. In terms of our AoK plans, we wont be making a dual carb intake. Our triple works so well on everything from a 201, though to the later 238/250/265 series it just doesnt make financial sense for us to develop a dual. Finally sorry for the late reply. I have not been on the forum much this year. -

You can use any 23 spline (fine spline clutch) from the 1960s and newer. The current one you have is a course spline that was from the 1950s and older. I would use the biggest clutch your pressure plate will take. The last one we put in was for a 1966 dodge cornet rt clutch (10 ½”) and it came with a pressure plate as the one that was in the car was in rough condition. It came from napa and was listed as a clutch pack although there are lots of great and inexpensive options available. If your current pressure plate is in decent shape then likely a 10 1/2" clutch will work fine and they are readily available from all the major part suppliers. I really dont know the width of a jeep cherokee. Here is a handy chart for a lot of the cars which gives you the widths and that is the key for you is making sure you have the track width close. Having the spring widths the same is also a nice thing as it saves more work. In terms of drive shaft its just a case of having the yoke with the finer spline for the transmission and the rear end. So measure your spring widths and your track width and compare them to the jeep. Personally I prefer going to a car version and depending on what your doing engine wise, likely around the 3:55 or 3:73 ratio. One of the mistakes guys do is going to something 3:23 or 2:73 and you suddenly have a dog at lower speeds. So unless your really building a performance engine 3:55 would be as low a number as I would suggest. Hope that helps get you rolling. Tim

-

George update, and AoK Intake updates

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Just thought I would share a picture of fellow Canadian Joe Flynn's cool ride, now running an AoK dual carb intake, linkage and air cleaner setup that I just got. -

Howdy Shull - The fact that there is no stamped number of the block likely means at some point in time the block was cracked or could not be bored out any further and someone bought a replacement block. The casting number on the block and the head actually do not really provide you the information one might hope it does. For the year of the block, on the oil filter side of the block, right close to the oil pan and close to the oil filler there will be the date of casting. It was used for internal purposes as blocks became generational items that often were used over several years and several engine sizes. The last generational change for the 25 1/2" Canadian engine was october 1951.At that point the block was carved internally to allow for the 4 3/4" stroke motor for the 265 ci motor, however that block was also used for the 238 and 250 ci motors. Same block same bore for those 3 just different stroke. After 1955 the year was actually dropped as there was no further block generation. So if your block has a month and day but no year code is was cast after Jan 1955. So your back to the strokes using the method BobK outlined will tell you if it happened to be a 238 (4 1/4" stroke) 250 ( 4 1/2" stroke) and 265 ( 4 3/4" stroke) although you could also have a 228 ci motor or several other cubic inches with a spitfire head on it. As well while the 238, 250 and 265 are 3 7/16" bore stock you would have to remove the head to know for sure the cubic inch. I would however do as BobK suggested as a start. Pull the brass plug and measure the stroke. That really narrows things down quickly. Tim