-

Posts

824 -

Joined

-

Last visited

-

Days Won

44

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by timkingsbury

-

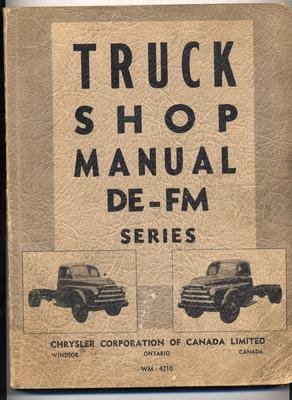

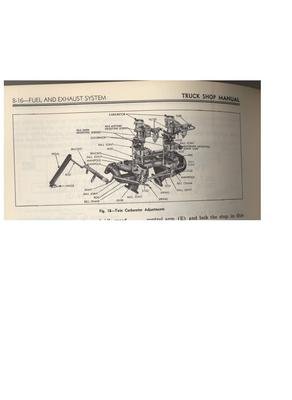

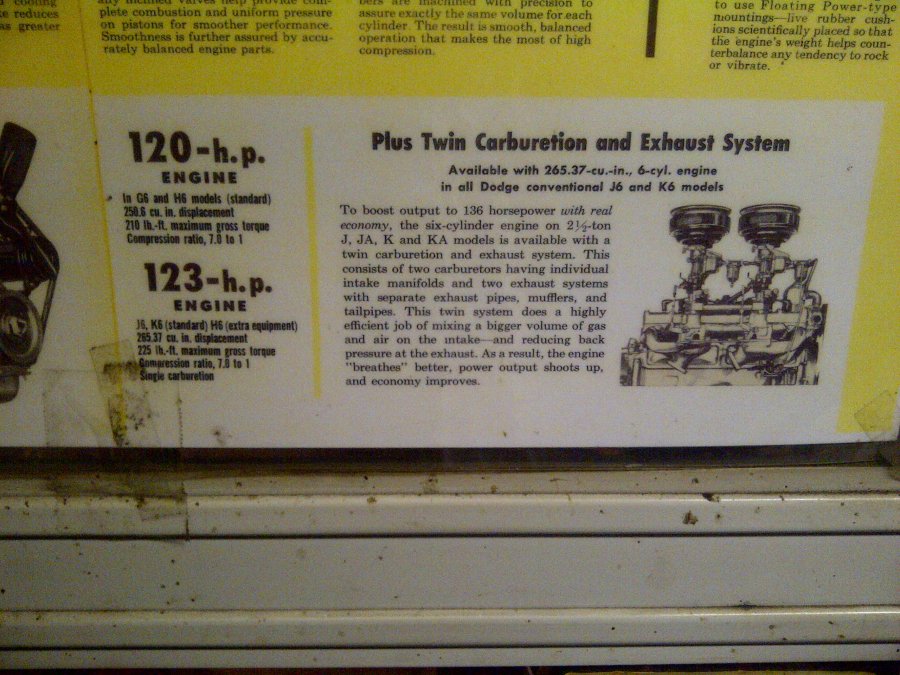

I apologize as I thought I had directly posted an answer to you original post and I don't see it posted so I must have done something on the multiple response. I also see you have a plan to balance the linkage. That certainly wont hurt, but if I doubt it will solve your problem. Moving to two barrel carbs, will cost more and be less effective that rebuilding your current carbs, making sure they are exact twins for all of the components. While there are some things like plug gap I would change, you seem to have racked you brain and tried almost everything else. If you wish drop me a PM and I would be happy to try and help. I do not have an Edmunds dual intake on a 230. I do on two other motors, and have multiple vehicles with dual carbs, some from the factory and some added later, and 2 with triple carb setups. Ive encountered what you are describing many times. Once everything else was checked, including making sure there is no leaky gasket situation, if unresolved it was always time to get into carbs and get them built or rebuilt. I use the term built because even a pair of carbs with for example mis-matched centers are by their very nature unbalanced. Well the dual carbs is not just for higher rpm. Chrysler put dual carbs on lower reving, higher torque engines from the factory. Drop over to my blog "Keeping up with the AoK boys" and you can see pictures of that and all kinds of intakes. You are correct that 3 single carbs with dual exhaust is the ideal street setup. It provides the best fuel distribution into the flathead 6 engine, and ironically I was asked to do a blog entry on the topic. The key for multiple carbs is to have the correct sized carbs. If you have a factory 201 ci 25 1/2" engine, rebuilt completely stock and put 3 smaller cfm carbs on it. you will get better fuel mileage, better throttle response and better performance and that is not just theory. We have a customer with one of our AoK triple intakes who has this exact situation on a 201 engine. Perhaps he will feel comfortable enough to chime in here. Now you did tweek my interest, you have a 3 x 1 Tattersfield ? I would love to see a picture. We have a 2 x1 which is the coolest intake ever. Wish it performed as good as it looked but still cool. Would love to see a triple as that I have never seen. It actually doesn't work as well as you might think. It worked slightly better with the modification of the block to provide individual access to each cylinder and then providing a balance tube where multiple carbs were mounted. My father and grandfather worked on the concept on multiple engines and I believe at some point I can come up with one of the later experimental blocks. In any case they could never get it to perform as well as a similarly built engine with an Edmunds triple carb intake. I do admire your spunk and despite how it may come across this isn't intent to start a fight. Open throttle is not how it actually works and attached at the bottom, documentation and a picture of an actual dual carb and dual exhaust manifold, right from the Chrysler Engine Plant in Windsor Ontario for the 1952 Model year trucks. Somewhere I am sure I can come up with the HP and Torque curve, but for sure its advantage was definitely not only a wide open throttle. Far from it actually and it had zero to do with racing. As for a 30 mpg goal, that is a lofty goal although, not impossible. Quite a deviation from this thread, but one I would be happy to chat about or point you in the direction of a few who have built lighter weight cars, with mopar overdrives, better rear end gear sets and have been in the upper 20s for miles per gallon. I don't know if any have hit 30 mpg or better. For me - Your the best answer on the thread! Yes perhaps a biased point on my part, but I still think in the end you have the correct answer. With that, I realize everytime I post, it has the potential to continue on and on, so I think MarkAubuchon and others have given the original poster information to solve his problem so for me, time to move on from the thread. Thanks folks, if you want me pm me, drop me an email or visit me on the "keeping up with the AoK blog"! Tim Kingsbury fargopickupking@yahoo.com

-

Why would you need your flame suit on ? It appears to be pretty much directly plagiarised section from a well know carb manufacturer. From a pure engineering and scientific standpoint their statement is correct. In fact in pure carb functioning making 6 barrels would be better, and on and on until you get to the point that you get to the fact that a carb is obsolete technology. That being said your piece, well it wasn't written for an engine with 3 Siamese intake ports feeding a 6 cylinder engine where its clear that the separation of fuel distribution trumps a single multiple barrel device!

-

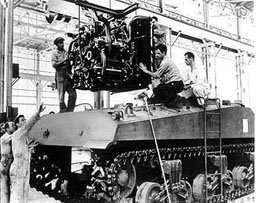

· · For Decades I have listened to people talk about Flathead Mopar 6 Cylinder Engines in terms of intakes, what is the best carb configuration for their particular situation. Discussions on putting two carbs and those who claim to be sure that is too much carburation or that it will use to much fuel. Then every once in a while the discussion of 3 carbs comes up, and that almost always sparks the debate on how it would take a race motor to need it, or how the engine will bog, or run poorly. In the last 20 years with a good friend of the AoK boys coming across a huge stash of 2 barrel carter weber carbs which were designed for slant six engines, the discussion on utilizing a 2 barrel instead of two singles comes up. I just smile, but then I know that when the stash of 2 barrel carter webers were found, its finder put them on his website as a carb for a flathead mopar. Its amazing how a market can be created and how quickly – “this is the way to go” spreads like rapid fire, without as much as any background check into something. But 1st, let me go back to the 1st time I heard the discussion on multiple carbs vs a single multi-barrel carb, or put another way, comparing that “old technology carter ball and ball vs a modern 4 barrel carb”.. It was about 45 Years ago, when I 1st heard someone in a conversation with my Grandfather and my Dad, suggesting they knew a lot about Flathead Mopars and were sporting a 4 barrel carb on a homemade intake. This gentleman had played with flathead Ford v8s and had came across a Dodge 2 door sedan from the mid-50s. He was suggesting he had built the ultimate flathead Chrysler Engine and he was one of those guys that whatever he had at the moment was just the best and the only way to go. Well after my Dad explained he had far from the ultimate flathead Chrysler, and that his wife’s daily driver (my Mom) was good enough to kick his ass, Dad pulled out my Mom's pickup. It was sporting a bored out 265, with a cam, a factory dual intake and exhaust with a pair of carter ball and balls, and an a833 4 speed tranny. After a little bit of fun that really wasn't much of a contest, licking his wounds sort of speak, Mr "Ultimate Flathead Chrysler" started down the road of excuses when Grandfather shook his head and cut him off at the pass. Grandfather like my Dad were automotive Engineers, and Grandfather literally knew more about Chrysler Flatheads than any person alive. Given he saw the very 1st flathead roll of the line in Windsor, Ontario Canada in 1935 and saw the last block cast in 1959, he had some pretty good credentials to give a lecture. What is explained in a few minutes was not only how the flathead engine worked, but why the engine this gentleman had came with only 1 carb failed to perform. Most think that 1 carb was put on the engine and that it has sufficient carburation for the engine, and if it needed more, Chrysler Engineers would have put more on. On a basic level that is true, but what engineering was building was an engine to a specific HP, torque and fuel consumption target and not to get the most out of the engine, make it as efficient as possible or even have it run to anything close to 100% optimum performance. By Optimum performance I am not talking maximum hp or maximum rpm or optimum fuel mileage on a vehicle. Grandfather then explained that in fact when Chrysler was faced with the need to meet a 5 ton truck specification for dump/plow trucks asked for by Canadian Municipalities during the winter of 1950, that the requirement had filtered to engineering in late 1950. They developed the 265 ci motor which was 3 7/16" bore and 4 3/4" stroke and have dual carbs and dual exhaust on them, which was what was in Mom’s pickup. Few realize that that engine actually had more hp than any other engine on the market. I will attach the picture of the poster that was on Grandfathers office at the time. I gave it to George Asche Jr years ago. In any case you can see the hot v8 mopar had in 1952 was 133 hp and the flathead 6 had more hp. As an aside Grandfather with the cam grind out of the 1952 Chrysler that engine exceeded 150 hp at the time, but given the time, energy and money that have been invested in the new Hemi v8 that was never going to see the light of day on any marketing information. That engine and the fact it had a factory intake, immediately became a stock car favorite in the 1952 season, when Mopar dominated stock car racing everywhere it landed. In any case Chrysler didn't just put on a second carb on it because they needed more carburation. By then Chrysler already had Carter building Ball and Ball carbs from 85cfm - 425 cfm each and we now know they had a 625 cfm carter ball and ball single barrel carb if they needed it. The reason for two was the basic issue, some would call flaw, but Grandfather would call basic restriction to taking the engine to the next level. I say that folding back to the earlier point that Chrysler was building engine to a spec of "x" hp, "y" torque and "z" fuel consumption. The flathead 6 build by Chrysler has 3 Siamese intake ports, each of which feed two cylinders. Setting aside the exhaust for a second, and keeping in mind that an engine is really just a giant vacuum pump, putting 1 carb in the middle of the block, basically over the middle intake port feeding cylinders 3 and 4, means that if all cylinders are the same in compression ratio and ability to create vacuum and suck in a fuel mixture coming from the carb, then cylinder 3 and 4 are going to get more fuel than the intake ports feeding cylinders 1 and 2 or 5 and 6. Yes Chrysler made intake modifications to help that, but they again were not trying to make the perfect engine, just have it meet specs required. As a little aside if your look at intakes from the 1930s through to the 50s you will notice Chrysler Engineers raised the level of the carb. With the Dual Carb truck intake it also was raised further with governors placed under the carbs. The height of the carb mounting above the intake posts can easily be seen to rise from the 1930s to the 1950s. Its also why if your look at some of the aftermarket dual intakes made in the 30s and compare them to say the 3rd generation Edmunds in the 50s you will notice a huge difference in height. The raising of the carbs and providing a smoother run from carb to the intake ports saw huge benefits in performance. Of course maybe buried in the story is the fact that early intake was designed for a marine application where quick rev was far more the desired trait than was torque. When the intake was moved to an automotive application you would find a quick rev with the clutch engaged, but disengaged there is a significant loss in torque and it will actually burn more fuel than a single carb. But back to my story, if we now add the exhaust component into your stock Mopar flathead (or L-head) which depending on what year engine and what vehicle, has the single exhaust exiting at one of a few different locations. For this discussion lets say it exits at the back as does the post ww2 cars. What you find is as the cylinders push out exhaust there is almost no restriction or back pressure at cylinders 5 and 6, but there is a great deal of back pressure at cylinders 1 and 2. So here we have the most back pressure making it tough to push away the exhaust and actually the front intake port receiving the least amount of fuel. While the engine meets specs with no problem, its clear that if you can balance the exhaust, by having 3 exhaust cylinders exit through 1 exhaust pipe and the other three through a 2nd pipe, you can better balance the exhaust back pressure. We sort of glossed over the fact that while there are only 3 intake ports, each cylinder does have its own exhaust port. Something that changed with the introduction of the slant 6, which had 6 equal intake runners each feeding a cylinder. Back to the flathead, if we can better distribute fuel to balance the opportunity for each of the 3 Siamese ports to get fuel, then the engine will run more efficiently. So if you were to take a big block 25 1/2" engine, and anyone of them, not just the 265 and put the factory dual carb and dual exhaust setup on it and then put on the appropriate carter ball and ball carb on it, it will gain hp, torque and improved fuel mileage. The reason is it runs more efficient. The same takes place with the 23 1/2" USA small block which has the same intake and exhaust configuration, although slightly smaller ports. If you take it one step further, putting 1 carb on top of each intake port, you can provide the optimum amount of fuel efficiency for the engine. Back to our 4 barrel friend, putting on a large carb just provides a further opportunity to over fuel the center siamese intake port. When he hammered the throttle it was actually not able to burn all of the fuel in the middle two cylinders and was “bogging” ,until it could gain enough RPM to use some of the fuel. When he was running against Mom’s pickup which had more balanced back pressure, and a better distribution of fuel he had no chance even if the engines were internally the same. Of course they weren't but that is another story. Years later when we created the AoK triple intake, we placed the first intake on an almost rock stock 201 ci motor. It had been rebuilt stock, although required to be bored out 10 thou to clean up cylinders. Beyond that it was a stock cam, intakes etc. With 3 of the smallest CFM carter ball and ball carbs on board and headers made from a stock exhaust systems, the car ran smoother, had better acceleration and got 6 miles per gallon better highway mileage over the single carb and single exhaust. In the end, it is just a myth that you need some bored out, cammed up engine for 2 carbs and a full race motor for 3 carbs. The reason why Chrysler didn't run 3 carbs was simple. 1) The cost of 3 carbs was no inconsequential 2) They could meet the HP, Torque and Fuel useage targets with 1 carb. The exception was when there was a time window where the dual carb, dual exhaust 265 ci motor was released, but with overhead valve v8s and Hemi's coming shortly after the multiple carb flathead life-cycle was short lived. There is a bit more it than that. I have glossed over a bunch of the engineering parts of why you don't just put a carb directly to each intake port with no equalization tube, but I am sure you get the drift. Unlike a v8 where you might try and make carbs progressive because your feeding a intake plenum that equally or close to equally feeding all 8 cylinders, the flathead engine has 3 intake ports each feeding 2 cylinders so progressive carbs just are not effective. On the flathead Mopar, with either 2 or 3 carbs you want them to produce the exact same fuel to feed each of the Siamese ports exactly the same. Its not progressive in terms of additional barrels or carbs, its progressive by pushing on the gas peddle. The key is making sure both or all three carbs are identical and that you have linkage that operates all of them exactly the same. Its a common misconception that they must be hard to keep synced. We have engines with tens of thousands of miles on them with multiple carbs and are never adjusted. George Asche's 1929 Desoto that he has owned since 1950 likely has an unbelievable amount of miles on it and likely the carbs were only touched when George has redone the engine. I own vehicles with 100,000 + miles on them and the linkage for the dual carbs has never touched. That has a lot to do with just how good Carter Ball and Ball carbs are.. We also get asked quite often about modifying the block to provide 6 intake ports, or using webers or other carbs, or running fuel injection. Dad and Grandfather with too much time on their hands, as my Mother would say, did modify a couple of engines to provide 6 intake ports. There were several intakes made including one with an 18" runner set on it, one with 6 side draft webers and one with modified hilborn fuel injection. At the end of the day, with various levels of success, nothing seems to outperform an Edmunds triple carb intake with riser blocks and 3 matched 1952-56 Truck carbs on them and maybe with some jetting changes. Of course, since then we have developed a couple of new cam profiles and of course the AoK triple which utilizes better and modern casting technology, as well as better flow bench testing and computer modelling that neither Chrysler or Eddy Edmunds had. Have we thought about digging out the 6 intake port block that is still in Dad's shop, well yah we have, but that is another project and a blog entry for another time.

- 22 comments

-

- 11

-

-

-

There are dozens and dozen of cam specs coming right for Chrysler Corporation, depending on what the engine was built for. Not sure is would help the vast majority and for me would fall into the nice to have, but not sure for what category. I know I could look up every Canadian build flathead engine from 1935 (for the 1936 model year) until the last one was cast in 1959 (and used up until the late 60s etc). but the project just for that would be significant. If there was a true benefit for a wide amount of member of the site, it might be something I would consider. The USA side I don't have that details, but this entire topic has been discussed prior on the p15-d24 site and some lift and duration specs posted for factory engines. Sorry, I am sure that your hoping someone will just post a chart of all the cams.

-

That is ok we can agree to disagree. The performance of an engine can clearly be effected by the piston weight and compression ratio, but you often see engines with wide range in compression ratio using the same cam profile. Now picking 7:1 and 10:1 are clearly wide spreads in compression ratio, so while both could use the exact same cam profile, it is very likely that an engine build with a 7:1 compression ratio is purpose built for one thing and the usage of the engine will suggest a different cam profile than would someone who is building a 10:1 compression ratio engine or greater, which is clearly an engine build for a different purpose. I will stand by my post.

-

Hi Bones44 - You are correct and I actually did a series on my blog on "Rough Spotters Guide for Intakes, Heads, Headers" and did note at the time Earl was making both big and small block heads. My note should have said the edgy head and fenton intake tells me he is dealing with a small block. But good catch and I half expected the original poster to come back with a comment on what he had and likely a picture of the extensive collection of stuff he has gathered up.

-

Hi Presride - With all due respect there are too many variables and too many unknowns to recommend a cam grind for you. From a t5 which can range so widely in gear splits, with a gear set that is reasonably high requiring torque. The mustang suspension or HEI have zero to do with anything related to the cam. The edgy head tells me you have a small block engine and the low carb mount of a fenton means you are already going to be starved for torque and escalated RPM if you used a stock cam.The fenton headers will definitely let it breath better. What cfm and what carbs you use are a factor and hopefully you didn't go for the carter weber trap, although like what bore you have and whether your using heavy 4 ring pistons or lighter weight 3 ring forged pistons wont factor what cam grind you should use. In terms of where to get the cam, as much as I could help, reading through your plan I would wonder why your not getting your cam from Earl "Edgy" Edgerton who made your head? That is where I would likely suggest you going. But to your original question, I now have enough information to be very confident to say that cam is not what you will want for your project. Best of luck. Tim

-

Its too wild for the street and has an issue with creating vacuum. That pattern was modified by Iskenderian to make his #1023 cam for the 1/2 mile an long tracks dropping the duration to 250 degrees and its pretty wild for the street. tech specs - intake opens at 20 degrees and closes at 50 degrees, and exhaust opens at 57 degrees and closes at 13 degrees, Duration .250 and he reduced the lift. I run a modified version of the pattern you have, in my 1949 Plymouth running the 25 1/2" big block- Tech info - intake open 20 degrees closes at 58, exhaust opens at 58 and closes at 20 degrees. 258 duration .435 lift. Its a bit lumpy but will spin north of 6000 rpm. Of course it depends on what you are planning and going to be doing, but one thing is sure, that cam you need to have a well built engine because it is going to really test the upper limits of the engine. Back in its day, that cam came for both the USA small block with offset rods/crank and the Canadian Big Block. Both engines had a pretty short fuse using it, but the small blocks more so. Its definitely a great and cool find, just short of making a vintage long track stock car, I am not sure it has a lot of viability. Tim

-

I assume your referring to me. lol.. you certainly don't upset me. I was just trying to figure out what you were referring to. I definitely missed your 41 Dodge car and Truck build. Id love to see that build documentation, but alias that is stuff for another topic.

-

You do not need the damper. I am not sure if those two pulleys have the same pattern although easy enough to check. If your stuck I can dig you up a pulley from a Canadian install and send it to you. No charge!

-

Happy to have a chat with you and currently my families truck collection sits at over 85 trucks, the vast majority are Canadian Big blocks. The USA small blog has offset rods and so does require a damper. The 250 ci as is every Canadian 25 1/2" big block, does not have the offset rods/crank combination and does not need the external damper pulley. USA 23 1/2" small blocks are not 25 1/2" big blocks and while lots of big blocks have damper pulleys for various reasons, every 250 ever made can run just fine without one and in fact I own many trucks with factory 250s in them that have no damper pulleys. In your case, looking at only a limited number of pictures there are a few things that come to mind. If you want to chat about potential solutions send me a PM and I can try and make sure I am following thing and give you an opinion from someone who owns a collection of trucks with various configurations and a big number of which are from the 238/250/265 series of engines. Tim fargopickupking@yahoo.com

-

The Desoto /Chrysler / Dodge Truck engine your referring to is 238 ci, 250ci and 265. They all weigh within 2 pounds of each other. They are all 3 7/16" bore and use different rods and cranks to get to 238 ci - 4 1/4" stroke, 250 - 4 1/2" stroke and 265 - 4 3/4" stroke. While the Desoto never had a 265 ci motor stateside, after Chrysler and Dodge Trucks have them in 1952, you could but the 265 in the 1953 model year in Canada, just like Plymouth could be bought with a 250 ci motor later. Yes I realize people often refer the 250 as a 251 or 252, but I am just going by what Chrysler called them. In any case those engines are 422 pounds. That is the engine.. Not bell housing, not intake, exhaust and carbs, pulleys, starter etc, but does include the distributor. I haven't scaled one with all the accessories on it, but someone's estimate of 450 lbs is likely pretty darn close. Our 265 engine in our race car, including the intake/exhaust, carbs, ready to hook up to the bell housing weights 410 pounds. There is actually a lot of weight you can take out of the engine if you really want to Tim

-

-

Merry Christmas & Happy New Years from the AoK boys

timkingsbury posted a blog entry in Keeping Up with the AoK boys

Well folks as 2016 starts to wind down we reflect on the year and what a different year it has been. It seems like just yesterday the new year started and here we are in December! What a magical month December is. The countdown to Christmas is well under way. Santa Claus parades throughout the world. Cities and towns lit up every night with fabulous Christmas light displays. School kids and churches putting on Christmas plays and pageants. Hopefully hearing the sounds of coins and bills dropping in to the bottom of the Salvation Army red kettle drums and other charities receiving support for all the great work they do. The elves at the North Pole working furiously to satisfy the wishes from the tons of letters arriving at the North Pole. Hockey fans counting down the days until the IIHF U20 World Junior Hockey Championship tournament begins (Had to throw in some Canadian Hockey influence here) and visions of getting your Mopar out next spring dancing in many automotive enthusiasts head. I am sure every Mopar fan has made their list of parts they hope to find under the tree Christmas day, and I am sure a lot of good Girls and Boys will find a few Mopar related items boxed up for them. I definitely know the AoK boys shipped a lot of stuff to the North Pole recently as, well we subcontract to Santa for some of those harder Mopar items that his elves have a difficult time to make! lol We often get Christmas cards and Christmas wishes, many come in different forms as technology evolves. Here is one of our favourites containing a lot of our favourite things - a Fargo pickup (great for hauling presents), a little Mopar Period Performances additions, and of course that it has Santa ! On behalf of the Asche family; George Jr and his sons George III & Rob, the Kingsbury family; Tim and his son Dan, collectively known as the AoK boys, we wish one and all a Very Merry Christmas and a Happy and Prosperous New Years! -

Free for all thread - issues, problems, want advice ?

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Well I agree, and while this is a little tongue in cheek, it is laced with a good dose of reality. What your refer to as the forum has become over-run with a subculture that has grown and grown over the years. Its clear that no matter what the topic, whether some have any real experience, or even own, ever own or plan to own certain vehicles they have to weigh in with comments. There is no greater example than lately in the truck forum. Unfortunately where it should be a community of like minded wrench heads a few have spoiled that, and I don't know about you, but I know of dozens of users who left the forums never to return. In those members were some of the truly smarted p15-d24 people going. So I understand Rockwood's frustration. I really do, but I also share Ptaming's mixed emotions, although perhaps a different mix. What I can say is on this blog the subculture is a Chrysler, Plymouth, Dodge, Desoto, Fargo or other Mopar products. I don't allow swearing, so unless your kidding mentioning putting in a Small Block Chevy being a great way to improve a p15-d24 is swearing in my books, and truly verging on stupidity. Its a subculture were using Chevy, Ford and parts designed for them like T5 transmissions as viable better solutions to Mopar parts, best be in jest, because its not part of the subculture on this blog. While I suspect it was out of frustration, I actually thought the recent idea of a forum for the culture of "lets put a v6 or v8 in a p15-d24. or that ultimate, mustang front end, Chevy transmission, ford 9" rear end and debating a v6 Buick or a 350 chevy crate motor idea can go hang out was a great idea. I can tell you it would be a forum I would never enter. Beyond that, I think a subculture exists over in the other forums that you may not realize exists and over here, if there is a sub culture, its one that I think Walter Chrysler would be happy to see. Mopar 1st. Period performance concepts where you can, improving those concepts where you can or where you need to. Flathead's Forever! That's the culture, and if that is seen as a subculture, so be it! Its not for everyone! -

Freds 55 Fargo Goes Dual Carb and Exhaust Build

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Following Fast Fred.. starting in "The start of winter tour" subtitled - "So you say dual carbs don't work well in the cold ?" How about - 25 F wind chill! -

Hi Billy - Its very possible I am not seeing all of the posts as I have people blocked, but I would say to you that there is a big difference between your 1949 dodge and lets say a 1948 Plymouth that I had in the past seen people hacking frames and oil pans and other builds. It sounds like your going to need to pull your engine to address its using oil and likely just time for a rebuild, so if you have the Canadian big block, why not see if it fits ? Id suggest starting with the super easy stuff. Look to see if the frame is pre-drilled for the rad push forward . If it isn't that doesn't mean its tough to do, but if they are then its a clue of how easy it could be. As well through the serial number of the car where it was assembled would be an easy but important piece of the puzzle. If it was Detroit, then that frame is the same frame and cross member as used in Windsor Ontario Canada where every Dodge (non-convertible) had a 25 1/2" big block. At the end of the day there is nothing wrong with rebuilding what you have and using that, but if you want to upgrade to the 25 1/2" big block its very possible its easier than you may be lead to believe. The big key here being its a 1949 Dodge, not a pre-1949 Plymouth !

-

Hi BillyBoySmith - Depending on where your car was built, its quite possible in 1949 the frame was made in Hespler Ontario and shipped to the assembly plant in Detroit, in which case the holes are already drilled in the frame to turn the bracket and move the rad ahead. Some of the Dodge Wayfarer's I saw in England were Plymouths with Dodge badging. In any case had your car been made in Windsor like by 1949 Plymouth, whether the Plymouth or the Dodge it would have the 25 1/2" big block in it and the cross member is the exact same part number in the Canadian and the USA car. I can certainly put you in touch with people who have made the change and depending where you are in England maybe even someone close to you. Tim fargopickupking@yahoo.com ps: The use of Spitfire was far more a tribute than it was a marketing ploy, but that is another discussion

-

Anyone put a dry sump on their Lhead Mopar

timkingsbury replied to timkingsbury's topic in P15-D24 Forum

Andy - since both of the deceased are directly related to me if there was enough knowledge I wouldn't have needed to ask. Not trying to be difficult here but my intent was to see if anyone who frequents the site has actually done dry sump on a flathead mopar. After that I am not interested in getting into a public discussion of who were are doing it for, where they are racing etc as its not ours to disclose. Again not trying to be difficult but its like many innovations and projects we have or are doing for people, we have been burnt too many times getting into the discussions. You are correct there has been lots tried before this customer came to us for help. As an update, we have not found anyone who has done a dry sump system on any mopar flathead but now have the information required to set it up on a flathead mopar. The cost would be prohibitive to anyone building anything short of a specialized engine so really its relevance has pretty much ended so if the moderator wants to lock or delete it that is fine. -

AoK George Asche Jr Ltd Edition Intake - now available!

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Dec 3rd - The casting of intakes were completed yesterday. They will go out for heat treating Monday, then will be boxed up and shipped to us. At that point we need to machine them, tap and thread them and they will be ready to ship. Obviously for those wanting linkage that will be made on a custom basis to meet specific customers needs! At this moment there of this production run, there are 2 of the AoK triples coming that are not spoken for, and there are 6 of the new AoK dual intakes not spoken for. Triples are $495 and Duals are $425 plus shipping Tim & George -

Anyone put a dry sump on their Lhead Mopar

timkingsbury replied to timkingsbury's topic in P15-D24 Forum

Your correct on all counts. I put the picture of the 4 as I half expected someone to mention it, and it is not dry sump. I have talked to Rich personally about this and many of his projects. Yes both people I know who have used dry sump systems on flathead 6 cylinder engines, have gotten the checkered flag and are no longer with us. Beyond that as a general comment, dry sump really is something that 99.999 % of builds would never need. That doesn't mean someone hasn't built and engine with it and that is what I was looking for. It is also something if I did know exactly what the ultimate configuration was, it wouldn't help many people. If its just a general knowledge of how dry sump systems work, that I am happy to point people in the right direction to learn about. But for this specific project a little more than the high level knowledge of how it works is needed. Tim -

Anyone put a dry sump on their Lhead Mopar

timkingsbury replied to timkingsbury's topic in P15-D24 Forum

I am looking for information about dry sump in a flathead 6 cylinder, although as I mentioned Rich's flathead 4 is not a dry sump system, just an external pressure pump. Our customer is into vintage road racing. -

Anyone put a dry sump on their Lhead Mopar

timkingsbury replied to timkingsbury's topic in P15-D24 Forum

Not a bad suggestion. It draws oil from a lower engine pan and pressurizes the system using the side oil passages. The lower plan holds 25 quarts of oil and it drains down to the lower oil tank/reserve. The challenge we have is more the twice the rpm, with the normal circle track racing already naturally tossing the oil to the one side of the pan at higher rpm, and then in essence, tossing the engine on its side and the oil balls up and doesn't drop until its too late for the engine. So more capacity and a pump capable for more pressure and way more volume is a good start and might even do it, but we would like the scavenger side of a dry sump concept and of course we have lots of questions about the pressure side as well. Tim -

Anyone put a dry sump on their Lhead Mopar

timkingsbury replied to timkingsbury's topic in P15-D24 Forum

Well we know it has been done. Unfortunately the two people we know that have been involved are no longer with us. In terms of need, we have a customer who had his race car come unglued when it was starved for oil while racing on a high banked race track. In terms of the pressure side, yes its been done on a few applications. I will attach Rich Fox's salt flat 1932 Plymouth 4 cylinder engine. It uses a pressure pump, and does exactly that. But it pulls oil from the stock pan. The big key for a dry sump for us is to use a scavenger system to pull oil into a reservoir. In terms of asking on Hamb, yes I have but haven't found a flathead mopar application actually done. Just speculation and suggestions. That well great isn't what we are looking for. Attached what I call the Prezel rod, and my case for the need.. and a picture of the flathead 4 cylinder Plymouth with its external pressure pump.