-

Posts

824 -

Joined

-

Last visited

-

Days Won

44

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by timkingsbury

-

Hi Guys - The key to your car Lloyd is that the 1939 is the last year of the top loader transmission. They came in two configurations. A floor shift like the 1939 and a column shift as yours is. To accomplish that they used the cable connecting to the top of the transmission. In 1940 the transmission moved to a side lever connection and there were subtle differences which gave you a little more room. So if it was a 1940 and newer, absolutely no problem putting in an r7, r10 overdrive as the connection points were exactly the same in terms of the connection to the shifter rods etc. In terms of the steering column plyroadking is correct a steering column from a 1940-1948 will work, just as long as you have the column shifting rods and levers to connect to the side mount of your r7. Your question still remains unanswered in my mind though.. You are looking for someone who has a 1939 and possibly a 1938 Plymouth, that moved from the floor shift or better worded top loader transmission to a transmission with the side connections. I know its tight in there and I think it will work with two rods verses a rod and a cable, but it would be sure nice to hear from someone who has actually done it recent enough that they can tell you how the conversion went and provide any tips. Here is a 1938, but same concept in that it is a top loader transmission here is the1939 overdrive then here is the1952-56 r10 and attached is a better picture in terms of showing the shift lever connections

-

The thickness of the head is a red-herring. There were lots of different head thickness's with the same compression ratio and some heads with the same thickness with different compression ratio. Big Block Dodge trucks are a classic example. But the cc of the chambers is the relevant item. Your range of close to 8.4 cc difference across chambers is unusual. Not saying your not accurate but I have never seen that much range across chambers and I have done a lot of heads personally.

-

my apologies for misunderstanding what you were meaning. I know the carter webers I have seen that were for the slant six, are into the 2nd barrel way way before 3/4 throttle.

-

I can not speak to your ford, but for a flathead mopar you definitely do not want progressive linkage. Here is a high level view of why, some of which I see someone already touching on. With a flathead 6 cylinder mopar of the 23 1/2" USA small block or the 25 1/2" Canadian big block variety, both have 3 intake ports entering the block that feed the 6 cylinders, commonly known as Siamese ports. if you put 1 carb in the middle of the intake, and assuming all 6 cylinders are of equal compression, you will be feeding more fuel to the middle Siamese port than the outside two. I wont go into the details, but actually as you accelerate the balance changes slightly. When you put a 3 carb intake on a flathead mopar and if all three are exactly the same, you provide a better fuel and air mixture with a better balance into each of the 3 Siamese ports. The concept of progressive linkage, say on a v8 which has a balanced plane going into the 8 cylinders, is that the more your press on the throttle the more fuel you will want, and you can introduce more carbs. But with the 3 intake port system, you will actually get better fuel economy at say 55 mph with 3 carbs than 1, and you actually require less throttle to achieve it. So while progressive carbs work well on many engines, and most v8s are good examples, for a flathead mopar progressive carbs are not a good idea, in terms of adding more carbs to the mix. The progressive carburation for a 3 carb flathead mopar is called the throttle pedal. Push it and you progressively put more fuel into the engine, but each carb needs to be putting in the exact same amount of fuel. Now back to the ford.. that I cant tell you. On a side note, the carter weber that was designed and introduced for the 170 ci slant six, was feeding more less cubic inches of motor, but also had the advantage of a reworked intake port situation that saw long runners all equally feeding each of the 6 cylinders. They work well on the slant 6, but are definitely a compromise for a flathead 6 over a carter ball and ball, in my opinion. Tim

-

Solving the Modern Overdrive with a Floor Shift using Mopar Parts

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

** Dec 22 2015 - Just to be clear, the A833 adapter plate is for Mopar 833 Aluminum 4 speeds for use in Mopar cars, and was not designed for use with the - 1981 -1986 Chevy/GM Truck Overdrive which I believe is a 833/RPO MY6. We were contacted in May by a customer and in the conversation it became apparent he was considering using a GM version of the transmission and he was told there appears to be a great deal of difference between it and the Mopar version of the A833. It appears he has been able to make modifications and get it to work and we will attempt to get a report from him, but up until now we have had zero experience trying to use A833 chevy truck transmissions with this adapter -

** Dec 22 2015 - Just to be clear, the A833 adapter plate is for Mopar 833 Aluminum 4 speeds for use in Mopar cars, and was not designed for use with the - 1981 -1986 Chevy/GM Truck Overdrive which I believe is a 833/RPO MY6. We were contacted in May by a customer and in the conversation it became apparent he was considering using a GM version of the transmission and he was told there appears to be a great deal of difference between it and the Mopar version of the A833. It appears he has been able to make modifications and get it to work and we will attempt to get a report from him, but up until now we have had zero experience trying to use A833 chevy truck transmissions with this adapter

-

Different truck bell housings

timkingsbury replied to timkingsbury's topic in Mopar Flathead Truck Forum

Hi John - Up until recently when we have been asked by customers about using an a833 overdrive its been for car applications and we have quite a few customers who have made the conversion. You can get some more information on my blog entry, including a picture of the adapter plate, the transmission etc. Yes the transmission shaft is a different spline, but you can for the cars use the same pilot bearing, flywheel and just change the clutch. You then need to decide what your doing for an emergency brake because with the removal of your original transmission your removing the emergency brake that is not in a modern transmission. On the pickup side, I have a 1955 fargo half ton which came with the car bell housing and originally a column shift. My Dad put in an a833 transmission out of a pickup in the late 70's but up until fairly recent, we were never asked about the a833 in trucks. That is why I started this thread, because despite having quite a collection of trucks, I didn't have many bell housings loose and out of trucks. This week we got digging further into the parts we have and through Dodge/Fargo factory manuals and got a bit more information. I am only tonight seeing your an Merle's notes which both are helpful and I honestly wished I had seen them earlier in the week, but hey it is what it is. Check out my blog entry on the topic with pictures etc, and then if you need more info or want to chat drop me a note: fargopickupking@yahoo.com http://p15-d24.com/blog/17/entry-91-solving-the-modern-overdrive-with-a-floor-shift-using-mopar-parts/ -

Different truck bell housings

timkingsbury replied to timkingsbury's topic in Mopar Flathead Truck Forum

thanks Merle - This week we had a chance to start digging out bell housings, and we have come up with 13 different ones in 2wd trucks, but if we remove the 5 speeds from the heavier trucks out of the mix we find 3 patterns. There is a light 3 speed out of pickups which are using the car pattern in which case our current adapter plate works just like it does in cars. Then there is the heavier 3 speed and lighter 4 speed (for want of better wording) and it has the 4 bolt pattern equally spaced on the right and left side, and the heavier 4 speed which is with the narrower pattern on the right side. So mirroring what you have shown. I have attached a picture of the two bell housing patterns. You can actually take our adapter plate and use it on the heavier 4 speed bell housing but it requires you to drive and tap 4 holes. That is not an ideal conversion, but it is possible. For the other bell housing of the heavier 3 speed and light 4 speed which is what we think is the other common one from the pickups, its likely easier for us to make a new adapter plate for that application. Tim -

Different truck bell housings

timkingsbury replied to timkingsbury's topic in Mopar Flathead Truck Forum

They do have a different bell housing but from what I can see in my Dodge/Fargo engineering manual the tranny looks the same in terms of bolt pattern. It definitely has a longer shaft. Here are the trannys.. Obviously the 5 speeds isn't anything we would be looking to do adapter plates for. I have the part numbers for all of the bell housings for all the 2wd but not even pictures of them. Lol.. well actually not from the tranny side, -

Howdy Folks - I know there are several different truck bell housings and I know this is not the definitive list. A link I can put up on the forum, here is one from Vintage Power Wagon with the early 40s and up powerwagons http://www.vintagepowerwagons.com/featured-parts.html He lists 4 different bell housings http://www.vintagepowerwagons.com/pdf/parts/02clutch.pdf Vehicle Type: A Part #CC592386 Vehicle Type: B,C,(D up to early 1956) Part #CC921197 Vehicle Type: D-late (1956 & up with NP420 Synchro Trans only.) Part #CC1786131 Vehicle Type: E,F Part #CC1269428 I also know there were different bell housing configuration in pickups, with some having car transmissions, and then truck transmissions. The a833 isn't going to be an alternative for the 4wd's with transfer cases. I am just putting them up as an illustration of the various bell housings. There are also heavier truck bellhousings, with trucks with 5 speeds and 5 speed with overdrives. Again not likely an application for a modern a833 4 speed with overdrive. What I am up to is trying to put together adapter plates for the various bell housings so that people can bolt up the A833 over drive 4 speeds. While I am pretty sure I have a truck with every combination ever made their in trucks. Ideally I would like not to have take out bell housings to measure everything up. So my question is, ..... any chance there is another truck nut like yours truly that might have the various bell housings out of trucks, and that might be able to help with my pursuit to make patterns ? I am thinking of 2 wd pickups with 3 speeds or 4 speeds in them. I would say 1 tons and below, but I realize I have a "pickup" that is a 2 ton configured truck with a 10 foot box from the factory with a 265 ci motor in it and it was definitely a candidate for an A833. In fact it has one in it. I just don't want to have to pull the tranny to look at that adapter plate that was done about 25 years ago. Tim Kingsbury fargopickupking@yahoo.com

-

Dear Don - since it is clear you cant take a hint I could do what so many do and just leave the forum as your know it all attitude gets so annoying, but when you post comments in an attempt to be a smart ass, and comment about leaving finger prints on my car while it was being worked on, you have crossed the line and if you and your gange are not bright enough to realize its far more than leaving finger prints, well, I cant fix stupid. You have failed to fully read my post, you clearly need to be hit between the eyes to get a hint, so hey, as pointed out by an administer, I could just put you on ignore. So thankfully my world on the forum just became a lot more pleasant (see the attached picture), As for potential future visits, you may just find the friendly receptions may be a little less so, but then I expect you wont get why that is happening either.

-

Don - I realize with 19 1/2 thousand posts on your "Don Coatney" account, you tend to try and deflect when you have been caught red handed.. and there are tons of examples where it seems you just like to hear yourself talk or think that people owe you and explanation or something. Well perhaps you best read my notes on this thread a little closer. Then have a real close to my next post !

-

I am not sure how many of your 3 total visits you have made to Fertigs my 1949 plymouth was there, but thanks Don, for your public admission to your "finger prints" on the fenders. You may not realize that living in the country side tends to build light coatings of dust, and running your fingers in the dust, isn't exactly a smart thing to do. So yes, I believe this may be a pair of pictures taken right after your last visit, when both George, his Son Rob and I wondered who decided to put their finger prints on several parts of the car. George, his boys and I will make sure we increase security to make sure tourists are not scratching cars in the future. In terms of your other questions Don, forgive me but when I stop seeing red from finding out who decided to run their finger in the dust on my car, maybe I will be able to better answer... Then again maybe not. So Don, please don't go away mad, just go away. If you haven't figured it out yet, you may have worn out your welcome.

-

Well its been an interesting thread and without trying to start a fight attempting to debate reliability vs long lasting is an easy debate. How many of the cars, if any will be around 50 or 70 years from now and make it 250,000 or more miles? We can debate reliability and what should be done to improve a vehicles braking or whether you need electronic vs points. Here is what I know. Walter Chrysler and the Dodge brothers had engines with full oil pressure, and modern crank bearing inserts decades before ford and gm, who had dippy oil systems or babbet bearings. Chryslers braking system was light years ahead of others and was both reliable and capable of stopping a vehicle at speeds well in excess of the speed limits. I own a 1936 Chrysler which has a documented 538,000 miles on it. Yes, the brakes have been gone over, yes it is on its 3rd engine rebuild. The reality is that it likely now only goes 500-1000 miles a year now. It is basically the same car that came off the line in 1936. It has an overdrive, its capable of driving over 100 mph and it will stop in a pretty short distance. I believe the key to its reliability was maintenance and good oil. Many older cars died prematurely because of bad oil, lack of oil or lack of maintenance. Yes, parts can fail. I can tell you in terms of stranded on the road, over its lifetime the 36 Chrysler's worst stranding was because of tires more than mechanical. On its current rebuild it has now over 140,000 miles and for the last couple of decades has run full synthetic oil. After its last brake job, where a line was leaking and I decided to go over the brakes front to back, we replaced all the lines and put full synthetic brake fluid in it. We also had my friend sleeve the master cylinder which provides the "poor man power brakes". I think that may be the biggest modification to the car from an engineering factor. I can point to dozens of mopars with well over 250,000 miles on them. Some like George Asche's 1929 had the working engine removed in the early 50s for a high performance flathead Chrysler engine. That engine has been replaced with another similar engine and it is still today, driven like it was stolen. How many miles it has is more a guess than documented. But I would bet it far exceeds 99.9% of cars that will come off an assembly line this past year. I can also show a 1952 truck, it is a 4 ton truck with a factory 265 factory dual carbs and exhaust. It was purchased brand new by the township of muskoka, in Ontario Canada and its log books last entry was at 240,380 miles. At that point the truck which was a township plow truck in the winter and a dump truck in the summer had just had its 70th oil change and was sent to auction. The person who bought it, regularly serviced it and used it year round in a logging operation. It plowed sometimes 8-12 hours a day in the winter and in the spring was shifted to road building. Unfortunately how many times the speedometer rolled over, wasn't really kept track of. Its owner figured he put another 100 or 200 thousand on the truck. When my Dad and I purchased the truck for $1 it hadn't been run in 10 years. We spend about 3 hours, got it running loaded on to a tilt and load and brought it home. It didn't take long to realize the engine had been rebuilt, but it was only 10 thou over stock. The exhaust manifolds are wafer thin but still appear original. That truck cleaned up at 20 thou, and the crank and rods are 10 and 20 bearings now. We put a new oil pump in it, not because the old one failed but because when your rebuilding one, there are some things you may as well replace. But the point being I would say that engine was definitely reliable and most modern engines in similar applications couldn't hope to last as long. That doesn't mean we would only drive something out of the 50s. My Dad;s last truck was a 1998 dodge with a Cummins diesel - interestingly still an inline 6. It is in KM not miles, but roughly translated has 370,000 miles on it. Like the Dodge, Chrysler and Plymouths of the 30s and 50s Dad;s 98 outlasts the ford and gm pickups of its generation by miles. For that I can point to documented Dodge's with Cummins Diesels with more than well north of 1/2 a million miles. So one could use that as evidence that the modern engines last longer.. lol.. yah I guess you could. But then I wonder if we put a brand new 265 ci motor from 1952 in a 1998 dodge, exactly how many miles it would have run ? I suspect it might just surprise you on how reliable it would be. In the end, it all depends on what you want. I recently owned a VW Passat with a v10 diesel in it.. Yes I am that guy, and yes I could prove it. It has massive hp and technology coming out its backside. I could get into it at my place and drive from my place in Ontario Canada to Carlisle PA, picking up my buddy George on the way and never put a drop of fuel in it. I certainly couldn't do that with Dad;s 1998 or my 1936. But I can tell you, I wouldn't be afraid to jump in either of those and make the same drive. All three are super reliable, and I do drive all three of them. But in the middle of the summer, if I am going to drive a 1000 miles or so, I must confess.. Heated and cooled seats, satellite radio and a car that can pretty much outrun anything on the road, likely has a bit more appeal for me. Now if I was going to haul a race car, or a trailer with several tons on it, well the 1998 Dodge clearly has the edge and if I want to take 6 people out at the same time on a summer Sunday afternoon, well the 1936 Chrysler like make a lot more sense. Yes I could put 3 in the front and 3 in the box of the truck, or 5 in the VW and 1 in the trunk but some how the 1936 has the edge and is a little cooler. But back to the topic at hand.. reliability is a question of what your doing and like ice-cream what flavour you like. I think my 1949 Plymouth is reliable and clearly it is a barely streetable flathead. I think our rear engine dragster which is a flathead is reliable, but clearly if it didn't get you into trouble out on the road, its fuel capacity and consumption likely deem it by many as unreliable... lol.. and my 1936 has proven to my family that is as reliable today as it was when it rolled off the line. There is my two cents.. Tim

-

The Rough Field Spotters Guide for Mopar Overdrives

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

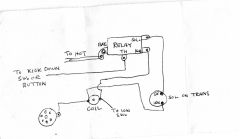

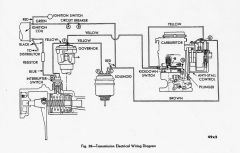

We have all that stuff in stock. I will drop you a pm and for the r10 for your application, here is the wiring diagram ! -

-

-

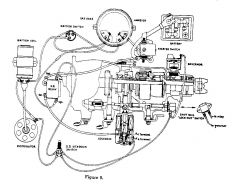

M6 gyromatic Or Tip Toe transmission

timkingsbury posted a gallery image in Individual Member Photo Albums

-

52 56 borg warner R10 Plymouth Overdrive wiring schematic

timkingsbury posted a gallery image in Individual Member Photo Albums

-

Nostalgic Chrysler Flathead Racing Blog

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Well lets get the party started.. and kick it off with a team that we are big fans of. "The Montana Dodge Boys" Few know this and I will later on upload the “well buried” story of the boys.. which short Version is Pete “Pedro” Hendrickson who was challenged by a $100 bet by Earl "Edgy" Edgerton aka the owner of Edgy Speed Shop that there was no way they could make a competitive car to run on the salt flats in well 364 days. Earl, a great guy, had no idea just how motivated to win a $100 Pedro was, and this started the team known as “The Montana Dodge Boys” Now we will start off by disclosing that the real secret of this car is that is runs on “Montana Ale Works” product…. That is our story and were sticking to it.. lol Keep in mind they used what was called a Dodge “Fast 4” which had full oil pressure And 5 main bearings. This compared to Henry Ford was light years ahead of its time. It was a super short run of around 8 or 9 months, and was just before Walter Chrysler would purchase the company and soon after move from 4 to 6 cylinders, even though Less total cubic inches. So here we were speed week, 2008 as the Montana Dodge boys hit the salt! <iframe width="640" height="360" src="https://www.youtube.com/embed/Cncmru1IsG8?feature=player_detailpage" frameborder="0" allowfullscreen></iframe> The result.. not only did Earl have to fork over the $100, but Pedro had 3 world records Topping at 116.378 miles per hour. Trust me this was a very expensive $100 to win, but it was only the start ! Now a little look back.. hidden on the Dark Web, lol.. The Story behind the story ! <iframe width="640" height="360" src="https://www.youtube.com/embed/1JvV-BYNgt8?feature=player_detailpage" frameborder="0" allowfullscreen></iframe> Now you might think with that “C note” in hand, Pete “Pedro” would say, mission accomplished, we have done what we came for.. lol.. you must be kidding.. It was just starting.. So back to tuning, or modifications, and all kinds of secrets from various flathead mopars, and just not 4 cylinder Dodges came together and in august of 2009 it his the chassis dyno. The results – 124.73 hp <iframe width="640" height="360" src="https://www.youtube.com/embed/b28K9HthU1Y?feature=player_detailpage" frameborder="0" allowfullscreen></iframe> Its back to the salt flats and the results.. 127 mph.. Not to shabby… <iframe width="640" height="360" src="https://www.youtube.com/embed/Nm_SiFs4vtU?feature=player_detailpage" frameborder="0" allowfullscreen></iframe> Now yes they had hit the salt flats the year prior, and they did after.. But there would be more changes, including the big one, which in my mind wasn’t the head that they thought was the “bees knees” but the cam. List closely when in 2013 for their 10th world record, the “fast four” which was then 215 cubic inches dusted across the salt at just over 143 mph. <iframe width="640" height="360" src="https://www.youtube.com/embed/iCgMxIf6wwU?feature=player_detailpage" frameborder="0" allowfullscreen></iframe> Now 4 cylinder, 215 ci, more that 1 hp per cubic inch and we have the approval of the M.D.B to post that. https://www.facebook.com/MontanaDodgeBoys/videos/10152647914468707 Now here is a little sneak peak into the “Montana Dodge Boys” as they figure they should graduate to the 6 cylinder class.. Introducing “Clyde” which is a 1931 Supercharged F head DeSoto SA coupe. Yes F head, and not L head hot rod and definitely not a Model A Ford! <iframe width="640" height="360" src="https://www.youtube.com/embed/8GwiWNYdDLU?feature=player_detailpage" frameborder="0" allowfullscreen></iframe> For those interested the Desoto does not run a Desoto big block but a Dodge 230" inline flathead six so they could use the EDGY F-head conversion (1 of 4 cast). Its running a 1954 Kaiser supercharger blowing through three new heavily-modified Strombergs 97s on a homebuilt log intake and a vintage Paxton boost-regulated fuel regulator. It uses Fenton headers and runs on the stock 19" wires with Excelsior radials. What we know is that it definitely has more than the 40 hp of Henry Fords 1931 roadster and definitely exceeds the 2200 rpm of Fords engine.. It will also definitely beat your average “Echo”.. Now can it out run an AoK 1949 Plymouth... interesting question I think... lol.. -

lol... shhhhhhhhh those are the top secret ingredient for high performance ....... mopar operators ! lol now the truth is that George's son Rob snacks on them, and they make good conversation pieces, and storage of nuts, bolts, bits and pieces. But well done, clearly you do have good "eagle eyes" there Greg. Maybe instead of where is Waldo we could do a - "what can you spot in George Asche's garage" lol.. let the games begin !

-

Since you asked and there is nothing wrong with Autolite 306 or NGK or Champion plugs, but if you want the best plugs, then in our engines we use Bosch Platinum 4214 plugs. With most heads you will need to put extra washers but if you want the best in my opinion, then this is what we use. I will attach the latest engine George Asche put together for a member of the forum, and you can see that is what is in it. Since this will no question spark some to jump up and down.. And for oil, once the engine is broken in, and by that I would define that as a fresh rebuild, once it stops using oil, it is broken in... then we change over to full synthetic oil. George uses Amsoil, with the heavier weight racing oil in the heat of summer. I use the exact same grades but north of the 49th Amsoil isn't a common oil, and we use Castrol full synthetic. I have at least 2 flathead mopars with more than 100,000 miles on them using full synthetic oil and I think George has more than that with 80-150,000+ miles on them with full synthetic. Back to plugs, what we have noticed is that with gasoline with ethanol in it, as the % of ethanol rises so does the operation of the engine and the heat range of the plugs (not the outside weather temperature) can effect the operation of the engine. Don't laugh but our advise is avoid ethanol fuel additives if at all possible ! Tim

-

Hi guys - As covered on the earlier blog entry, we have an adapter kit that allows you to bolt up a modern A833 floor shift overdrive on to your stock bell housing. Please read this blog as it covers a lot more details. We recently got a new supplier, and have kept the aircraft grade aluminum. The have drilled and bevelled holes for the flush mount and come with the appropriate bevelled bolts, and have threaded holes were required. The truth is we could have done these at a fraction of the price if we had done them in steel, but from weight to corrosion, we decided just to do these like the originals we made a number of years ago. As George Asche says, if we cant make Grade A stuff, I don't want our name (AoK) associated with it! Lol.. They are in stock right now and they are $140 USD each (adapter plate and bolts) shipped anywhere in the Continental United States. A 2nd, 3rd or 4th adapter plate would be $125 USD each and all go in the same box, so you save the shipping on the additional plates by a combined shipment. And watch folks.. there are different length snots on the a833. and different shifter positions. We have heard the 1979-80 car is long and shifter near at the back on the tranny. That is going to be like the t5, really too far back for a lot of applications. So measure from your bell housing to your stock floor shift (if you are floor shift) We got them in this week and have already started shipping adapter plate to those who were on a waiting list. Thanks to those who have been patiently waiting. ** We have recently been asked if the adapter plate will work on trucks. The 1st response being what truck and what transmission is in it now. We know of conversions that have been made, but they were all in late 50s pickups that had light 3 speeds with car style bell housings. *** Nov 21 - In addition to the car bell housing there are several bell housing in trucks. We will take 4wd and heavier trucks with 5 speeds out of the mix here. We believe that believes us with 3 bell housing patterns from the late 30s to the late 50s. The one with the car style bell housing , 3 speed column shift our current adapter plate should work. For the heavier 3 speed or light 4 speed both floor shift, the bell housing is the one at the top of the attached picture, which has 2 holes equally spaced on the right and left of the bell housing. For this one we are going to develop adapter plates for. The other bell housing pattern is the ones at the bottom of the attached picture. It has the 2 bolt holes on the right closer together than on the left side. This is for the heavier 4 speeds in heavier trucks. While it looks like you can use our existing adapter plate, by drilling 4 holes, tap them and use our adapter plate, we have not actually tried it. At this point unless there turned out to be a demand for them, we don't intend to make new adapter plates for this bell housing / the heavier trucks at this point. The reason being, we really need to make a minimum of 10 pieces, and to make the price reasonable 25, so unless there is a demand we don't anticipate it doesn't make much sense to make them for the heavier trucks. * Update: The adapter plate is completed for the trucks now. Pricing is for the car version, in the continental United States the adapter kit (plate and bolts) are $140 shipped and truck adapter kits are $150 shipped. Outside of that area cars are $125 + shipping and trucks are $135 + shipping. If you want 2-4 plates they can be shipped in the same box so you save the shipping on those additional plates. As usual happy to accept emails or give you a call to discuss.. Let us know if you are interested in either truck version. Tim fargopickupking@yahoo.com .

-

Solving the Modern Overdrive with a Floor Shift using Mopar Parts

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

November 26th - Update Happy Thanksgiving.... and we have gotten a new source to make out adapter plates. The issue was our past supplier wanted to more than triple the price of the adapters. We sought out other suppliers, and the issue was the material, and specifically the grade of aluminum that we were using. We could have changed to a steel adapter plate, but it would of course be a lot heavier and susceptible to rust, so we just were not willing to go down that path. In the end, we sourced out the aluminum. and then using our pattern a new supplier. The end result, is they are a little more expensive, but we think at $125 for the kit (plate and screws) it is still very good value, and really is something that we are doing as more a public service to provide a mopar alternative than anything. Here is the picture of the 1st pile that just arrived, and we will have a bunch more coming next week. Bottom line is they are $125 USD plus shipping for the car adapter kit or inside the Continental United States it would be $140.