-

Posts

824 -

Joined

-

Last visited

-

Days Won

44

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by timkingsbury

-

From the album: 1949 Plymouth Business Coupe

-

Anyone making the trek to Spring Carlisle this year ? http://www.carlisleevents.com/carlisle-events/carlisle-spring-swap-meet-corral-auction/default.aspx Tim

-

Flat Head 6 Engine Swap 218 to 228

timkingsbury replied to Fargone's topic in Mopar Flathead Truck Forum

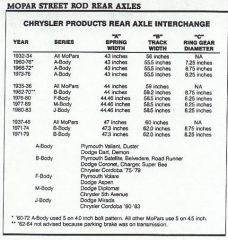

The 228 came in all kinds of things, including my 1949 Plymouth business coupe. That engine, the 238, 250, 265 will all go into your truck with no issues what so ever. If the 228 came from a car, you change the bell housing to the truck one. You can also slide on dual or triple carb intakes and split exhaust. I will attach some pictures out of the manual. The 228 goes back until 1939 I think. I would have to go looking through manuals. It was in trucks, cars, and started to be dropped out of some car lines as the 238 motor with 3 7/16" bore arrived, and then of course they just changed the crank and rods and that engine became the 250 (or 251) and then 265. Externally, other that looking at serial number, casting date and head codes.. pretty tough to tell. But its more in the generation of the American 201 than the 230. The 230 is more the generation of the 238-265. Tim -

-

Free for all thread - issues, problems, want advice ?

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

HI Scott - Remember at this point we are chasing what is the expensive side of increasing performance with a flathead as custom forged pistons have gotten expensive. But let me try and address your points and answer your questions. The term "pop up" piston really is anything that rises above the top of the block deck at top dead center and of course we often raise compression by shaving the head which lowers the space for the pistons to rise up. We have seen and have done the technique of taking 3 9/16" forged Pistons that the Chevy world would use, and have the pins placed so that they work with a flathead application. Keep in mind that is 125 thou over bore, which we have often done, but your at the end of the limits for the flathead and you need a 1948 and newer block. The 1952 and older Canadian big blocks, also have the side of the block carved to handle the 4 3/4" stroke of a 265. That is whether it is a 265 block or a 250 or 238. They are all the same. In the Chevy pistons you need to cut off 90 thou off the top of the piston so it doesn't hit the head. But back to your original question and point, yes raising the roof of the head would be extremely helpful. This isn't a slam at some of the recent aluminum head creations, as I am always super happy to support any one in the performance flathead mopar world. However having said that I wished they had changed the chamber of the head, and in one case, put in more water jackets towards the front of the head, like Edmunds did because it tends to heat up a the front. We have carved the roof of some of the 1954 and newer big block truck heads which have a little more meat in them to change the roof. Numerous guys have done that for relief of the valve, when the head is shaved to the point the valve hit the head. But we do know what is needed if someone was to create an aluminum or cast head. We have 2 experimental heads which actually raise the roof of the head, they are almost 3/4" thicker and the head is in fact a hemi or hemispherical chamber. I have also seen and tried to get for years, a 3rd head exactly like the two we have, although the head has 2 plugs per chamber. Back to custom pistons here is a picture of 1 design beside a stock piston You are correct in this design and the one we have recently gotten from Venolia you place the rod pins at the place you want depending on how far you want the piston to rise and what rods you are using. Remember the 265 is 4 3/4" stroke, the 250 (some call 251) is 4 1/2" stroke and the 238 is 4 1/4" stroke all with a stock bore of 3 7/16" To accomplish the stroke it is just the crank and rods. The longer the stroke actually the shorter the stoke. So in the pistons above, the much longer 238 rods were used. Now that is not without challenges. If you look at 265 rods they bolts are recessed and the rods have factory "carving" so it clears the cam. The reason you would want to use the longer 250 or 238 rods is a) they are much easier to find and the longer rods are much more straight up on the power stroke. First thing was the rod pins are place way further up the piston sides. Second more grinding or carving was required on the block side so that there was enough clearance, and a little bit of carving/grinding was required on the cam side to increase the clearance beyond what it started with of 1 thou (cold). It is a bit of a reversal in thinking I realize but it is definitely cheaper to use longer rods or change the rod pin placement on pistons than it is, to buy custom rods to mirror the shorter 265 rods to have block and cam clearance. Believe me I have a custom set of rods and what was supposed to be fairly cost effective turned into a very very expensive project. The custom piston side and/or custom pistons with longer 250 or 238 rods are a more cost effective route to go. A final comment on custom pistons. The pistons I show above, the strategy was smaller, lighter forged pistons to utilize 238 rods. It is a super idea and definitely has huge gains and advantages over stock. The rev quicker no question. We have gone the super light route and we have also gone the route of getting Top fuel grade coated forged pistons and plasma moly rings from Venolia . They are definitely heavier than the light weigh versions. We had blower and fuel beyond gasoline in mind when we went that route. We went a much more radical cam route which didn't need the instant rev. If we were building a short track stock car engine, that would have been a different story and the super light weight pistons would have been the preferred route. In the end, these days, the custom forged pistons route is expensive. at 8-15 x the cost of a stock set of cast pistons, there are lots of more cost effective ways to pull power and torque from the flathead. Its still in this order, 1) dual exhaust 2) dual or triple carbs to provide better fuel distribution 3) shaved head 4) performance cam as the most cost effective route to get horsepower for the overwhelming majority. But if you want to chase the limits of the flathead mopar, well that is a different movie! Hope that helps Scott. Tim -

From the album: 0123 - Flathead Intake & head pictures

-

From the album: Das Boot

-

From the album: Das Boot

-

From the album: Das Boot

-

From the album: Das Boot

-

The all Mighty Cam - Flathead Style

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Hi Fred - yes that is correct. I don't have those off the top of my head. Its a cam that almost every performance place has so I never bothered checking it with a degree wheel. I can do it if you want it. In terms of wild enough, well, that was what you wanted so that is what is in it.. lol.. Its all personal preference. We have cars with 40 -50,000 miles using the .435 cam which is what is in my car. Its got more HP in it and I prefer it out on the highway where I am definitely keeping up with traffic. I don't do much racing, but then I also don't take too much **** at the lights from 350 chevy's and any of the vintage lead-sleds that figure they will blow me off the road across the lights. I think you will be very happy with your setup I really will. Now if you happen to find yourself in our neck of the woods as they say, and come for a ride in something with a 435 cam in it, you may get the itch for a little more.. lol.. In which case, your engine is build for it. as is any nice fresh built mopar flathead. -

The all Mighty Cam - Flathead Style

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Ok Danny - I covered the 380 and 435 lift cams Next the ½ mile “1023”- this was a stock car cam or the modified .375 increasing duration instead of lift which will give you a little more rev, so the 5000 rpm range. It was for quick bursts coming out of the corners at stock car tracks. Barely idles at 1000rpm tech specs - intake opens at 20 degrees and closes at 50 degrees, and exhaust opens at 57 degrees and closes at 13 degrees, Duration .250 and lift is .375 Next one - Modified Scholler full race cam. Higher lift and increased duration cam which was use for drag racing in the later 50s and early 60s. your starting to get a little lumpy at idle, it will idle down but you need a fresh rebuild as this is the point where your starting to test the limits of a flathead. This is a modified version of the famous Scholler full race cam - stock car racing and drag racing - Higher lift and increased duration (Intake - open at 18 degrees, closes at 54 degree. Exhaust opens at 54 degrees and closes at 18 degrees - duration is 252 and lift is 400 Next one - 430 - Briggs and Stratton – Tractor Pull Grind was born out of looking at cams from different manufactures and believe it or not Briggs and Statton made a high lift higher torque cam. This was born from using other performance mopar cams and the briggs and Stratton cam. Its an extreme lift cam, with big torque pattern at slightly higher rev than a stock mopar truck cam. It is here where the engine modification has an effect on engine vacuum, Its 430 lift and 247 degrees of duration , And the last one being the the AoK Velociraptor Grind cam.. Its 446 lift and 280 degrees of duration and there is a little more to the cam than that but there is the main attractions. This cam, we have a licence agreement that needs to be signed and notarized before we will sell you one, and it covers exactly who is using it, for what and has a non-disclosure agreement to it. There would be very few that would ever want this cam, and those that do, well usually we wont sell them one.. lol Hope that helps. Tim -

From the album: 0123 - stuff related to intakes

-

From the album: 0123 - stuff related to intakes

-

From the album: 0123 - stuff related to intakes

-

From the album: 0123 - stuff related to intakes

-

The all Mighty Cam - Flathead Style

timkingsbury commented on timkingsbury's blog entry in Keeping Up with the AoK boys

Hi Danny - I would be happy to do that and to be honest, if guys can get the cams ground themselves I am ok with that. Prices of cams is something that is in a little bit of a flux at the moment. Guys want new cams but don't send back their old cams and the cost of getting cams, especially big block cams has risen a great deal. I can tell you a few guys we wholesale cams to are about to crank their prices because we just cant do them for what we could. So right now, your talking $300 + shipping for any cam we do, and we will take $50 off if you send us your old cam. That is the price right now, and really is dependant upon what everything costs us. Now small hub cams are 1" and that is the size of the hubs one every small block or big block from 1936 (and likely prior on small blocks) up until 1951 for the big blocks. The small blocks I am told it is around that time. They changed to a 1 1/8" hub on the cam and the reason was you actually could break a cam. They saw it will bigger trucks used for dump trucks or plow trucks. Unless you really hard on the engine, and by that I mean rev-ing it hard, changing gears and dumping the clutch your likely never ever going to have an issue. If it is straight rev, you can rev the engine to any level and the cam will be find, its the changing gears and dumping the clutch at high rev, that sees the torque do damage. I don't know of anyone that has ever broke a big hub cam, nor has my partner in crime George. Hope that helps and I will put something together on cam profiles beyond what I did above .. soon ! -

Lol, I can not confirm or deny the existence of any Chrysler Motorcycle project! Now the super lightweight auburn pressure plate, 6 lb flywheel (yes 6 pounds), lightweight Aluminum bell housing that there were only ever 3 cast in Windsor Engine facility, a specially lightened transmission that George built, a "dual fire" magneto and an ultra rare 12 spark plug head for a 25 1/2" Chrysler 6 cylinder flathead, that may be in my possession are purely coincidental tee hee.. Now if I was building such a project did you know that Honda made an shaft drive rear end capable of handling 450 hp ? They call it 210 hp I believe but its been tested well above 2 x that amount. With the Plymouth Motorcycle tipping the scales at over 1500 pounds I would say its possible to get a Chrysler Motorcycle at under 900 pounds. Gee I wonder what 30" tires and 7500 rpms would actually propel such a project ? But sorry Danny, I don't know much about that project.. lol

-

I just realized that I did not update this thread, just the original thread - "Solving the Modern Overdrive with a Floor Shift using Mopar Parts" which you can go directly to on this link http://p15-d24.com/blog/17/entry-91-solving-the-modern-overdrive-with-a-floor-shift-using-mopar-parts/ in any case in terms of the truck bell housings mission accomplished. We now have an adapter plate for the both heavy 3 speed floor shift and light 4 speed bell housings and heavier 4 speed bell housings. Bellow is the truck adapter which works for both, then a picture of it with the car and light 3 speed column shift for tucks, and then a picture of the two truck bell housings that the new adapter plate works with. Price is going to be $135 & shipping for the kit. The kit will be the adapter plate and 4 bolts required to mount the adapter plate to the truck bell housing. Here is a picture of the car and truck adapter plate and just the truck adapter plate which will work with either of the above bell housings. . Bottom line: In the continental United States car adapter plates with recessed bolts/screws for mouning are $140 shipped and truck adapter plates are $150 shipped. Outside of that area cars are $125 + shipping and trucks are $135 + shipping.

-

The all Mighty Cam - Flathead Style

timkingsbury posted a blog entry in Keeping Up with the AoK boys

As suggested by Captain Fred in his blog entry on his 1940 Plymouth build, he wanted something done on cams. Well, that can be quite a topic, and while you can find all kinds of article on the "inter-web" on how cams work in an engine, my goal is to put a Flathead Mopar slant on the topic. Of course as my Grandfather used to say, an engine is nothing more and a large vacuum pump. Your cam turns lifting up intake valves, as pistons are being turned by a crank and that creates a vacuum. The vacuum sucks in whatever is near by into the engine. The cam turns a little further, closing the intake valve, we "light a candle" to whatever is in then in the cylinder and after what we hope is a controlled explosion, the cam turns a little further lifting exhaust valves and those pistons coming up push out whatever is left out of the engine.. In the V8 world a great deal of people used to think that making power, aside from the "no replacement for displacement" concept was putting in a wild cam. As time went by in the racing world, while the cam was important, we know it is the heads that are a much bigger factor to the V8 world. Sure superchargers or turbo chargers, trying to jam more stuff into the cylinder and the type of fuel you use for your controlled explosion also became a big factor, but in the world of cam vs heads it is the heads that lead that world. In the flathead Mopar world, fuel isn't entering via the heads, and so it is definitely a cam that leads this world over the heads. Next lets talk about stock lift and duration and even there, Chrysler Corporation made a huge number of cam profiles so the second I toss this out here, its easy for someone to say - "my stock cam is different" and yes I know that. But in high level terms, a cam has two major factors and a few lesser factors. Lift and most of the p15-d24s were a 375 lift and then duration. Lift is how high the cam lifts the valve from its closed position, and duration is the degrees of the 360 degree circle that it keeps those valves open. In other terms how high we lift the valves and for how long we keep them open, whether intake or exhaust valves. Again high level - you are limited by how high you can lift the valves in a flathead by the head. Lift the valve too high and it hits the head. On the duration side, there becomes a point where you have kept the valves open too long and it starts to effect the actual vacuum level in your engine. Remember again, a big vacuum pump. as we open and keep open valves we loose the seal on the vacuum. Of course we do that because we want to get and fuel and air mixture into the engine. The change in duration also does things to the torque curve on your engine, but that is a whole different level of the discussion and I am trying to keep this more on the basic side. Again in general if we keep the intake valves open longer and lift the intake valves higher, we get the opportunity to get more fuel/air into the engine. More fuel and air, and yes, clearly effected by the compression ratio, the more "bang" when we ignite the mixture with the spark plug firing. Now, in the cause and effect department, generally as we raise up the valves higher (aka the lift) and hold those valves open longer (increased duration) we tend to change the rpm idle and things become what most of us call "lumpy". In the good old mopar v8 days of the 1970s I am sure lots remember pulling up to the lights with a guy running a "cammed up" motor and it was idling rough, shaking, coughing an weezing and yes that was also how the timing was set, but it was the duration of the cam that was causing that. When the light turned green and they hammered it, assuming the timing was set correctly, the goal was for that high lift cam to allow for a lot more fuel to get into the engine dramatically raising the RPM and turning the lumpy idling engine into a smooth running race engine. Yes I am isolating and slanting this entire discussion towards cams, when timing can also be a huge factor. No better example being when Big Daddy Don Garlitz was forced to use a 426 hemi after they actually ran out of 392 hemis. He couldn't get the 426 to run as well, and out of frustration he advanced the timing way way beyond what anyone would have thought would work. In fact Don often tells the story that he intended to blow the "blanking" thing up. But as the engine rev'd up that advanced timing suddenly brought out the inner Monster of the 426 Hemi and all of a sudden the 392 Hemi was obsolete in Don's mind! Back to our cams and remembering that the generation of car cams we are talking about were 375 lift. There are two school of thoughts on creating high performance cams. 1st is to raise the lift gradually and some pretty famous high performance cams raise the lift to 380 an and then increase the duration to 242 degrees. The 2nd is to raise the lift up as extreme as we can and also increase the duration. in the 1950s a pretty famous performance cam used a 400 lift. and 250 degrees of duration. The other factor without diving into the details to much, is what I call the split. A great deal of cams have the intakes open and the exhaust close at exact same time, but some use a split. So for example an Esky 3/4 miles cam the intake opens intake valves at 20 degrees and closes them at 50 degrees and the exhaust opens at 57 degrees and closes at 13 degrees. The Schroller full race cam - again a stock car racing - Higher lift and increased duration the Intake - has the intake valves open at 18 degrees and closes at 54 degree. The exhaust opens at 54 degrees and closes at 18 degrees. If you are using a turbo or a blower, you often want a period of time (number of degrees) in which the intake is close and the exhaust hasn't yet opened, or visaversa. The age old question is of course - so how much lift can I have before the engine sounds like it is misfiring. Almost always visions of those 1970 v8 engines coughing and wheezing are the reason for thing that. In reality the flathead just doesn't really act like a great deal of those badly timed, over cammed engines.. lol The reality is in the flathead world it is more a case of the rpm rises at idle than it is about it sounding like the 1970;s v8. Of course most want a cam that sounds like it is rock stock, idles like the engine isn't running, but then they want a Top Fuel Monster to come alive when they hit the throttle. That becomes a delicate balance and is always a compromise. So lets talk extreme. Maybe there is a wilder cam out there, but if there is we have never seen it. Ill keep the origins of this cam a little bit of a mystery, but the cam we use in the Velociraptor is the most extreme cam we know of. I chuckle these days as this phrase that seems to be in vogue again, but decades ago my Grandfather used to refer to a car that had this cam as "The Hot Mess Express". Today we call if the AoK Velociraptor Grind . It is tough to get it to idle below 2000 rpm and we have with a ton of work have actually gotten our dragster to idle around 1800 rpm. It will wind up to North of 7200 rpm. You can run an engine on alcohol and will need 3 carbs and need to shift to 6 exhaust pipes for at least 42", to get it to run properly. Its lift is are you ready, 446 and its duration is 280 degrees. At this point we definitely have issues with vacuum and it would be extremely rough at idle, thus increasing the RPM just to get it to idle. For those that figure that isn't possible, by reply is gather up and bring all the cash you can find, because I am happy to say - "How much would you like to bet!". Here us a link to 3 videos of the Worlds Fastest Dinasour Now from the extreme, to lets say a mid-50s truck cam which topped out around 3600 rpm, becomes the topic where many recipe's for performance have been made. Some by Chrysler Corporation for everything from cars, to boats, to combines and even Massey Harris 101 Super tractors powered by Chrysler Flatheads. The later were built for high torque and low rpm, which is great for plowing a field, but achieving a high way speed, not so much! Today I think we have a catalogue of around 25 cam profiles. Of those we have cam patterns that we use , made for about 6 or 7 cams and of those, the number drops down to 3 or 4 for most engine builds. I think right now among the Kingsbury motorized items we have 14 different cams in use. In the Asche fleet of motorized items I am going to say they have 7 different cam profiles. The major difference, lol, yes I have more junk... I have a marine version, several truck versions, a combine, a water pump, a welder, a compressor which actually uses 4 cylinders to run the engine and 2 cylinders to make air, and an engine that used to be in a certain motorcycle.. lol.. Oh and I have an actual cam from a tank engine, but it isn't in an engine. I could make a pattern if someone ever needed one ! For Fred's engine, we used what many call an Esky 3/4 race cam. The 3/4 stands for stock car racing on a 3/4 mile long track. This is what I today call, a fairly mild cam and we likely sell the most of these. I suspect part of that reason is as I talked about earlier, that people think back to those lumpy, poorly idling v8 engines with wild cams.. The .380 lift cam is going to give Fred 4500 rpm quickly. Its been around a long time and has a quicker rev over stock and was used historically for stock car racing. As you can likely figure out by reading this thread so far, we likely sell the most of these because most guys think they want power..... but..... they want to start it and not hear the engine running or running like a sewing machine. Tons of guys call this cam a race cam.. For me, its far from that. The tech side = 242 degrees of duration and .380 lift Finally I will end the cam conversation for now, with the cam I am using in my 1949 Plymouth. It is what I call a little lumpy but still very much streetable and no, it is nothing like a 1970s over cammed v8 with bad or good timing.. lol but it is definitely aggressive, with a .435 lift and 258 degrees of duration. This cam was developed from tweeking a full race cam through the 1950s and 1960s and was what Harry Hein #90 (NASCAR hall of fame) used at the end of his career. Harry who is still alive would be the uncle of one George Asche Jr. The intake valves open at 20 degrees and close at 58 degrees, while the exhaust opens at 58 degrees and close at 20 degrees. Here it is in my 1949, when it was started for the very first time, so its not tuned and its running 47" straight pipes out of the headers. It is a bored our 265 ci 25 1/2" Canadian big block flathead And here is the same cam in a 230 ci USA 23 1/2" small block I hope that helps a little Fred, without confusing things too much! Now what is in that Engine of yours, I can not confirm or deny what was originally put in the engine is what is in it now.. Who knows what happens in the middle of the night in George's shop... Only the shadow, or in this case the 1929 Desoto knows for sure.. lol -

From the album: Das Boot

-

From the album: Das Boot

-

George And Eddy discussing The Desoto Roadsters 6 And 12 Vo

timkingsbury posted a gallery image in Individual Member Photo Albums

From the album: Das Boot

-

From the album: Das Boot

-

From the album: Das Boot