bkahler

Members-

Posts

1,948 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I'm fairly certain the adjusting bracket is correct. I've got at least two dozen pictures of various trucks all with the same bracket. I've attached a couple of those pictures and they all seem to show the same bracket. I do have the same size v-belt as you're using so apparently Dodge just like to space t he generator away from the engine block. Possibly for heat purposes? I might get a slightly smaller v-belt just so there is a little more adjustment room available. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

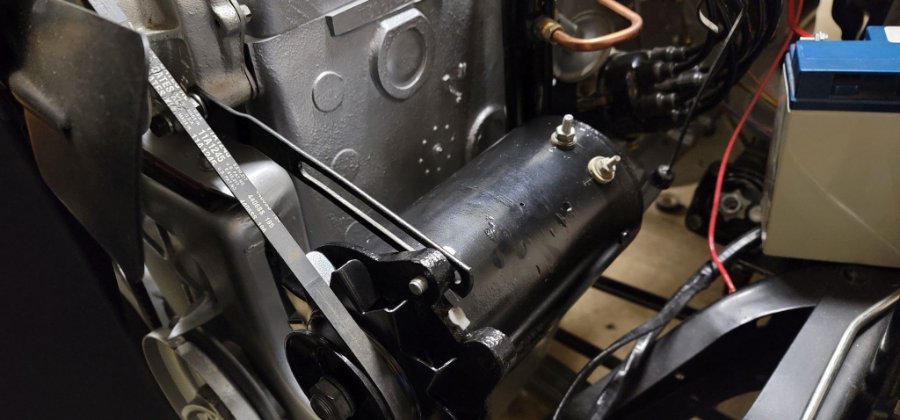

More progress on the truck the past week or so. Today I finished rebuilding the generator and it's sitting in place on the engine although I still need to find the correct mounting hardware to finish it off. I'm a little surprised how far it tilts away from the engine block with the current v-belt. I've been looking at various pictures that I have of other trucks and it seems that many trucks are set up this way although there were a few with shorter belts. I might try buying a slightly shorter belt to see how it looks. Also a friend of mine is working on cleaning and polishing all of the sheet metal. All of the body parts were painted back in 2000 and were subsequently moved from Lincoln to Dallas to Little Rock and finally to Richmond. Needless to say over they years the parts have collected a lot of dust and grunge and unfortunately some nicks and scrapes. A couple of pictures show some of what he is dealing with while trying to make them look presentable. The grille panel managed to come out looking fairly decent all things considered. It still has some scratches that he is going to try and either buff out or possibly dab a little paint on and try to blend it in. It will be interesting to see how well that process works. I'm definitely getting close to trying for the first engine start. My goal is to at least have the engine running by the end of the year. We'll see..... -

The one on the trailer of course!

-

Nice looking truck

-

No burnouts or wheelies allowed during the trip......

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The new switch arrived a few days ago and it's identical to the original from the truck. I started to check the connections between the various switch contacts at which point my multimeter died so I had to order another one which arrived today. So this evening or this weekend I hope to compare the new switch to the old switch to see if there are any differences between the two switches. When I had the motor apart last year everything inside looked good. I did a quick test back at that time using a 12 volt battery and the motor seemed to run fine. I don't believe I ran it long enough (seconds?) to do any damage to the motor. I have a spare motor I need to dig out of whatever crevice it's hiding in and compare it to my original motor. Maybe that will give me some insight as well. I stayed away from this option but will consider it if all else fails. Bottom line is I should have something to report this weekend. Thanks! Brad -

Ah, I miss understood the original question. Thanks for clarifying.

-

That all sounds correct. The fittings are always smaller in diameter than the tubing. Think of the tubing as a reservoir or buffer for the carburetor.

-

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

bkahler replied to billrigsby's topic in Mopar Flathead Truck Forum

Who knows how many years the 1498-770 kit was available. I do know the one I got has a 6-volt bulb in it so it was likely for the earlier years. The 51 sales literature shows the following cigar lighter. I've never seen one like it before. What I will likely do is take one of my spare knobs and fill in the letters and just make it a smooth face like the glove box door. At least the knob will look like the rest of them. -

5/16" fuel line is correct. You'll starve the motor of fuel if you use 3/16".

-

Aw...Nuts and Bolts and Toothed Periphery Washers!

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The word BUSTED comes to mind..... ? -

Aw...Nuts and Bolts and Toothed Periphery Washers!

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

WCL was the first link I ran across searching the forum earlier yesterday. I never knew the name of the washers until that point! From what I read you have to order a minimum of 100 but as you mentioned no prices listed. I'm going to do my bolt/washer sorting this week so that will give me an idea on just how many I might need and what sizes. This could turn into an expensive little endeavor! -

Aw...Nuts and Bolts and Toothed Periphery Washers!

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

David, thanks for the tip. There is a Fastenal store about 10 miles from me. If I don't have to work I'll stop by there Friday and see if they still offer them. Thanks! Brad -

Aw...Nuts and Bolts and Toothed Periphery Washers!

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I was thinking about doing exactly what you suggested, only using them where they show. I could always use the black cad plated parts in the hidden areas assuming I hae enough good ones. Later this week I'll be digging out all of the plastic bags with the all of the mounting hardware. Years ago I sorted through and individually bagged hardware for each fender, door, etc. Now I need to sift through it all again so I have a better idea as to what I may need to replace. Thanks for the links, at first glance AMK Products look promising . I'll reference them as I sort through the plastic bags No need to worry about your floor mat.....I have a NOS mat laying on the spare bedroom floor waiting it's turn to be installed. ? -

Aw...Nuts and Bolts and Toothed Periphery Washers!

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

They only list them in packs of 5. What's odd is the 3/8" are only $10 for a pack of 5. I guess I need to do a washer count this week to see just what the price tag might look like. Any tips on bolt sources? -

I'm within weeks to a month or so of being ready to install the front fenders, doors, etc. Years ago I took all of the bolts, nuts and washers that I had saved, scavenged and stolen over the years to a plating outfit in Texas and had them black cadmium plated. Fast forward to today and I'm now rethinking just how I want to bolt all of this together. As I've been assembling things over the last few years I've been using these bolts that I had cad plated and many times I've had to deal with rough and dinged threads. Some of them I was able to chase the threads with a die but a few weren't salvageable. Now I'm not so sure this is the best approach for attaching all of this sheet metal. Does anyone have sources for correct looking bolts and the toothed periphery washers that were used on these trucks? I found the washers at McMaster Carr but they are $13 for 5 of the 5/16 size ? It's going to get expensive real fast if that's what washers are going to cost. Any tips or suggestions on where to find appropriate hardware? Thanks! Brad

-

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

bkahler replied to billrigsby's topic in Mopar Flathead Truck Forum

I would bet it's the black version My 51 came with a cigarette lighter from the factory but no ash tray and the heating element was long gone. I scrounged a bunch of different lighters out of various trucks in the junkyards and then found this one on ebay a number of years ago. Most that I found were rusty chrome although a couple of them might clean up reasonably well. -

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

bkahler replied to billrigsby's topic in Mopar Flathead Truck Forum

Interesting. I have the same NOS lighter with the same part number but it has a different lighter insert. -

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

bkahler replied to billrigsby's topic in Mopar Flathead Truck Forum

Nice! Only problem is it's only going to be about 78% efficient -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

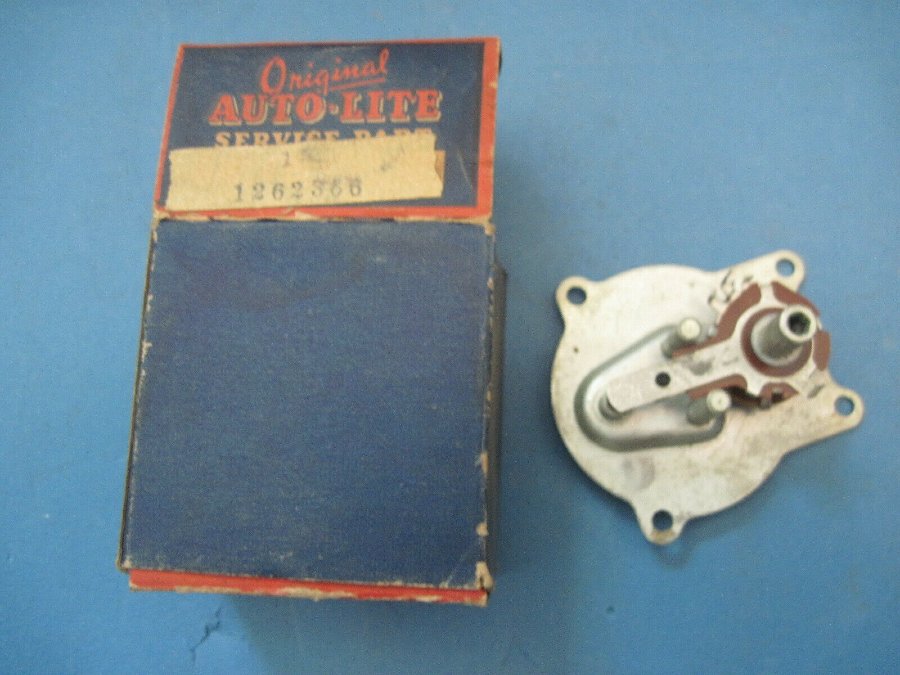

Last night I started doing some parts research to find the part numbers for the wiper switch on the dash and the wiper motor. The motor is an Auto-lite EWJ-4006 (mopar 1272-340) and the dash switch is a Cole Hersee 7508 2-speed wiper switch (mopar 898-571). There is also a switch on the motor itself, Mopar 1262-366. I couldn't find anyone selling a NOS motor but I did manage to find a NOS dash switch and NOS motor switch. I should receive them sometime next week. I'll use the instructions in the service manual to test the motor and my existing switch but it's always nice to have NOS parts on hand -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

At least up until now I've only been installing small parts so there is still no extra room in the shop! Hopefully once the fenders, doors, etc. start getting installed then I might see an increase in floor space You need to start paying less attention to those blondes and brunettes and more attention to your hobby.....? I only glanced at the switch when I was cleaning and painting the motor but from what I remember it seemed to be an interesting looking switch. I'll be removing the motor and switch sometime this weekend to take look see. Know of any sources for replacement switches? Over the years I've found that yelling at something generally has no affect on the overall outcome other than relieving a little bit of stress in me -

I believe that is the remains of a radio, not a fuse panel.

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

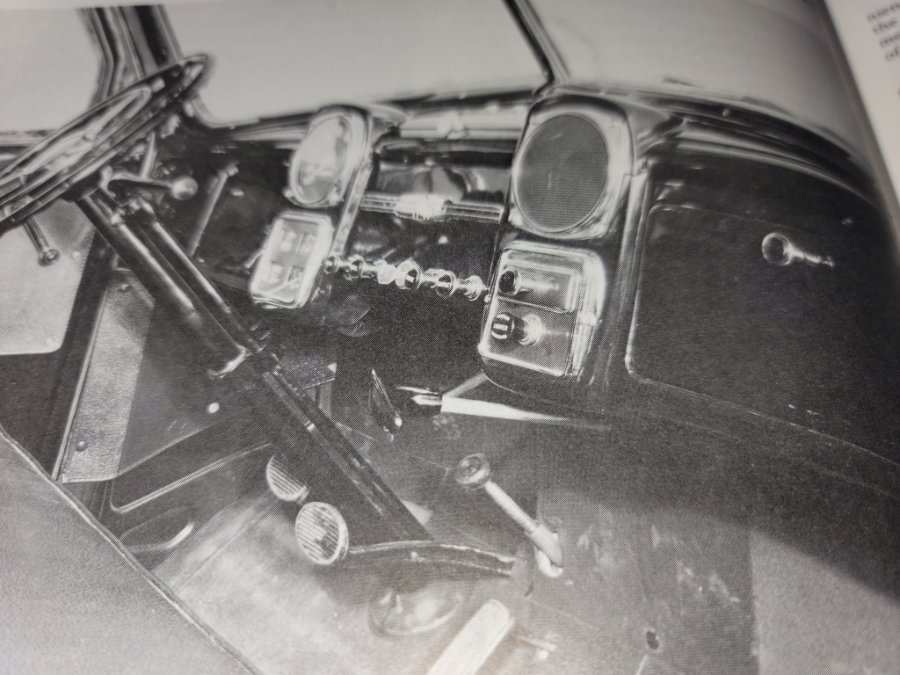

The dash wiring is now complete with one glaring exception. The wiper motor which I had cleaned and tested now seems to be acting up. I removed it once this weekend and fixed a connection on the switch and reinstalled it. After that it worked for a few minutes and now won't run at all. So I need to pull it again to see if I can figure out what's wrong. Other than that the rest of the dash is complete and all the dash components function properly although I haven't tested the fuel gauge and probably won't be able to until I fill the tank. I did relocate the ignition resistor and also installed the voltage reducer for the wiper motor. Both are tucked up out of the way on an aluminum bracket. Hopefully the aluminum will help dissipate some of the heat those two devices generate. On a separate issue, has anyone assembled the bed on the truck or is it better to assemble it as a separate entity and then set it on the chassis? I think I already know the answer but figure it can't hurt to ask Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Now that you mention it I think I've seen similar pictures. I wonder if the doors were completely assembled before they were hung on the cab. I bet they were. Due to the overwhelming amount of crap that I own it would take me weeks of reorganizing to make room to assemble the front sheet metal separately! One of my first tasks when I retire is to start getting rid of all the excess crap...that should keep me occupied for years I took a glance at the cab this weekend to see which method would be better and from what I could tell it might be easier to hang the fenders if the doors were not installed. With the doors present it would likely take two people to handle a fender. Without the doors it might be possible for one person and and engine hoist. Definitely something I need to look closer at. No matter what, I like the idea of hanging the doors before they have been assembled. Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Now that the dash work is mostly complete the next thing will be prepping the engine for it's first start and hopefully that will happen sometime yet this year. So...at this point it's time for me to start planning the front sheet metal installation along with the running boards and doors. All of this brings up a few questions that I have as to the best order of execution 1) What is the best way to install the front sheet metal? One piece at a time on the truck or assemble the pieces as a separate assembly and then install the completed assembly on the truck? Based on my limited work area assembling the pieces as a separate unit that could be a challenge but if necessary I can work something out. 2) Should or could the running boards be installed before the bed and rear fenders are installed? 3) Is it better to assemble the doors on the work bench or to hang the door shells and then start assembling the innards? 4) Should the doors be installed before the front sheet metal or vise versa? Thanks! Brad