-

Posts

249 -

Joined

-

Last visited

-

Days Won

5

Go Fleiter last won the day on December 10 2022

Go Fleiter had the most liked content!

Reputation

118 ExcellentAbout Go Fleiter

- Birthday 05/03/1951

Profile Information

-

Gender

Male

-

Location

Düsseldorf, Germany

-

Interests

My Plymouth 1951

Modelrailroads -

My Project Cars

1951 P 23 Cranbrook Convertible Club Coupe

Contact Methods

-

Biography

born in Münster, grown up in Milan / Italy, Studies in Göttingen, Köln, Buenos Aires -Argentina

-

Occupation

Dentist, retired

Converted

-

Location

Düsseldorf, Germany

-

Interests

My 51Cranbrook P23 conv., Model railroads,

Recent Profile Visitors

3,758 profile views

-

I agree: if beeing in the miniature car business, I wouldn´t consider to offer a 1951 or 52 Plymouth model. For my 1:87 model, it was the front which gave me some headache!

-

Thanks all for reading and answers! It seems that I have to stay with my 1/87 bastard model! Greetings from Düsseldorf! Go

-

"good" means: not a stamped sheet metal one or a soap box gift style. Friends of mine could scan this within 1:24 or 1:18 scales and scale it down to 1:87 and 3-D- print it for my model Railraod. That would undoubtedly produce a better model than my attempt below. I had posted this helpless model before, but can't find the post again. I made a 1:87 scale "VEREM Chevy 4dr" to look close to my 51 Plymouth convertible. The VEREM model: a Dodge (much worse quality compared to the Opel left), not used for the Plymouth transformation: my 1:87 sculptured result, well I would like to have a closer copy of the original! Only the Coke coolbox (passive, for ice cubes to do cooling) looks near its prototype. Greetings from Düsseldorf! Go

-

Thank You! Very helpful! - I really did not find the volume data! - I follow the procedure with the rear wheel bearings since 1995, but I didn´t know that a zerk fitting would allow too much pressure. I´m glad I never had put a zerk there! Thanks again! Greetings from Düsseldorf! Go

-

Hy all, as finally the weather gets nicer here, the Plymouth needs to be driven! I checked it over the last week, changing the oils etc. For my records, I would like to find information on the oil volume for differential and rear axle. I checked the "Service Manual", several other Mopar books ... Even the P15 D24 Database does not specify these either. Does somebody know?? Thanks for answers! Greetings from Düsseldorf! Go

-

if I remember well, the "cold" procedure is adressed in my service manual (not on hand here, I' in Rome). Don't know if any difference between my 217 cui cranbrook and Your bigger Wayfarer. Greeting! Go

-

Ist jemand aus Deutschland in diesem Forum?

Go Fleiter replied to Pearsebln's topic in P15-D24 Forum

yes, I'm not very active. Winter is my model railroad time. As regarding the weather in Düsseldorf it is still winter... I had my 51 Ply out only 2 times this year. Greetings! Go, currently in Rome -

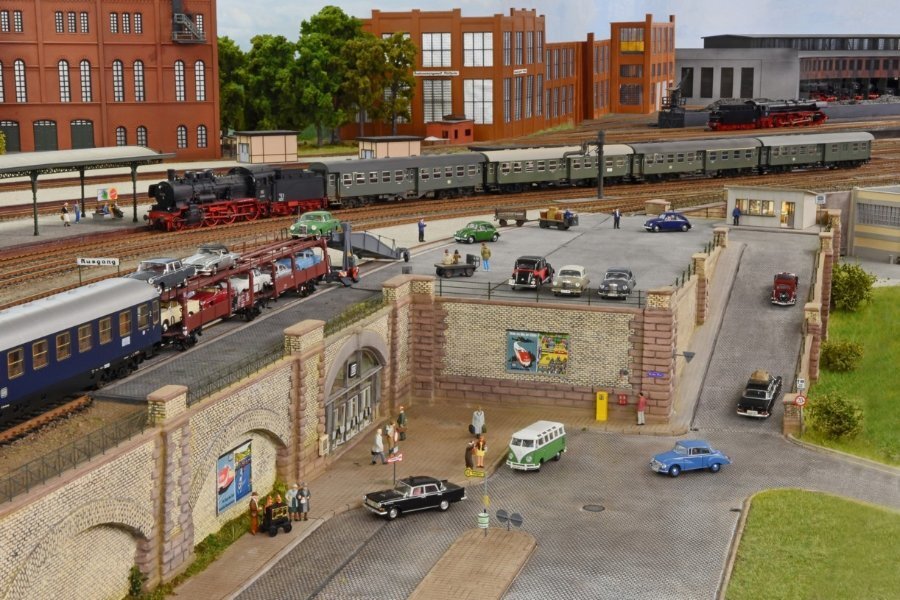

both are perfect plans to retire! I can´t move since 1982, because of a stationary model railroad. So, I must make do with 3 Garage places 3 mintutes in bicicle from my house plus this summer awning in my yard as shop and for the cats. If interested in my friends Egon and mine model-RR, here is the index of my postings: https://www.drehscheibe-online.de/foren/read.php?10,6607746,6607803#msg-6607803 Here is a choice: I love 50ie´s cars! Greetings from Düsseldorf! Go

-

beautiful posting! Enjoy!!

-

Hallo For now I presented Your worthy hints to my mechanic. I will see. Thank You all !! Greetings from Düsseldorf! Go

-

While repairing a flat tire, my mechanic found remnants of a disintegrated rubber (?) part, of which I know neither the name nor the appearance. It is different from this Valve Stem Cover (see foto) made of metal. I guess it was supposed to be put over the valve of the tire tube and pushed through the rim with it. It should probably prevent migration of the tube. My other wheels don´t have this part but the metal variety only. Any hints?? Greetings from Düsseldorf! Go

-

The breaker contacts I had bought before ~2007 failed each after ca. 1000 km. I helped me buying original Bosch breakers for Citroen (nothing other available) and transplanted the very contacts to the Plymouth points. It worked well, but I didn´t trust my work on the long term and didn´t want to repeat the transplant again. I have a pertronix unit since than: no more problems with ignition. They made me two 6V neg GND units, and sure, one is in the trunk!

-

maybe You should test the starter directly: 1. connect the clamp of a heavy jump cable to the starter's terminal. 2. Be sure to have the transmission in idle! 3. Touch the active battery pole ( "minus" IF POS. GROUNDED!) with the other clamp of the same cable and see wether it spins or not. 4. if not: disconnect that clamp from the batt. 5. use the second cable/ clamp combo to give direct ground from batt passive GND pole to starter (Connect to a cleaned nut or bolt) 6. touch the active batt pole again. Batt voltage may fall under 5,5 V and when released rise again to 6,4 So You know if starter is ok or not. 7. Starter SOL must click when activated. if not: try direct connection from active batt pole to SOL activating terminal (can't search for its correct name here with holiday equipment) Beware: even if reading 6V at the SOL outlet to the starter when unloaded, its contacts (or old Cable connections to starter or batt) may not let pass 40-60 Amps when loaded. Next would be the switch and its cable connections... Good luck! Greetings from Portofino! Go

-

?? lower Generator mounting: plain rod or threaded one??

Go Fleiter replied to Go Fleiter's topic in P15-D24 Forum

Thanks all, so it seems, that the GEN must be fixed thightly at the bottom too!