-

Posts

6,965 -

Joined

-

Last visited

-

Days Won

72

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by JBNeal

-

HOLLYWOOD random TV show screen capture

-

kinda looks like something that could be found at Western Auto back in the day...

-

Got any pictures to show which filter canister you are working on? The hex head should be removable, but if it's binding up during removal, there might be another problem that needs to be looked at a little closer. As with any banjo-type fitting, gaskets are required to avoid any metal-to-metal contact.

-

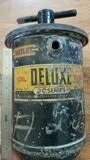

A big thank you to Brad aka bkahler for helping me get the ball rolling on getting reproduction vinyl decals made for the DeLuxe oil filter canisters. I'd also like to thank Rob aka Dodgeb4ya for helping me with some of the background information clarified with his parts books and expertise. Without their help, I would have only had some tracings, some part numbers, and just a general idea on how to get things done. THANKS GUYS !! ? Worth mentioning is billrigsby who made me look up the definitions of "honesty" and "integrity"

-

- 5

-

-

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

additional information - DeLuxe Products Corporation -- LaPorte, Indiana

-

CHALLENGE ACCEPTED

-

JC SERIES – DELUXE PRODUCTS CORPORATION – LA PORTE, INDIANA

JBNeal replied to JBNeal's topic in Mopar Flathead Truck Forum

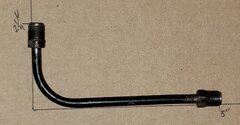

Of note is the inlet tube that sets the height of the canister in the clamp. In cleaning up the ’48, ’49, ’51 and ‘53 tubes, they appear to have the original black paint on them and were all very close in dimensions. The outlet tubes have all been replaced as they were rusty and did not survive removal intact. This inlet tube is installed at about 45° from the block to complement the fitting on the bottom of the canister. This should locate the outlet port perpendicular to the flathead block on the 45JC canister, or parallel to the flathead block on the 48JC and 53JC canisters. -

JC SERIES – DELUXE PRODUCTS CORPORATION – LA PORTE, INDIANA

JBNeal replied to JBNeal's topic in Mopar Flathead Truck Forum

Spiffing up these canisters is fairly straightforward, but it’s important to be patient, clean thoroughly, and pay attention to the details. The cosmetic restoration would be meaningless if the filtering functionality is lacking. The T-handle for the lids houses the bypass check valve, and I have found that a #1 Phillips-head screwdriver can be used to clean out the passage and move the check valve for cleaning. This handle also holds the perforated dome in place with either a hex nut or a speed nut. This perforated dome has two sizes, depending upon whether the lid has a raised handle opening or a recessed handle opening. Both require an appropriately sized soft copper gasket. Note the original orientation of the brass fittings before removing. Removing the brass fittings can be done carefully by using a spare flare nut to keep the brass from deforming. Hold onto that canister like an uppity teenager in a headlock, and the fittings should unthread. With that bottom fitting removed, the inlet flow restrictor can be seen. On two of my canisters, I could see a glob of goo in the flow tube, so I used my long shaft #2 Phillips-head screwdriver and rotated while working it back and forth, scraping the tube walls of crud, and was able to dislodge and remove that goo and rinse it thoroughly with aerosol brake cleaner. I wiped down the canisters with parts cleaner, and sure enough, on the 45JC and a 49JC canister, I found specks of yellow flakes in the area where I expected the DELUXE decal to be. But the paint was in such bad shape, I was not able to save any sizable remnants. I removed the tool rest from the bench wire wheel buffer and was able to clean up the surfaces well. After cleaning with Dawn like them parts were a slicked up duck, I could see OUTLET stamped in the 49JC canisters but not the 53JC canister; the 45JC canister, not so much. That’s when I started to notice some differences in the lids. Apparently, my 45JC lid did not get the corporate info stamped into it that day. And the lid that came off of the ’49 was unlike any of the others I have as it calls out a different gasket. Lids either have a raised center hole, or a recessed center hole. I painted with Rustoleum rusty metal primer and gloss black, as I have had good results over the years with these coatings being durable and not fading too badly from heat. Original decals for the 48JC and 53JC cansiters line up relative to the center of the outlet port and the center of where the clamp bolts in place. On canister 1504092, the clamp and decal switch places. On the 45JC canisters, the faint stamping of OUTLET appears to be so that the decal will place closer to the port so as not to be blocked by the clamp. -

DELUXE PRODUCTS CORPORATION can be seen stamped into the lids of oil filter canisters that originated from a long-gone parts supplier whose origins and demise are not readily verified. But DeLuxe had the forethought to also stamp the filter element required into the canister lid for service needs, so that information endures. Questions about these filter canisters and elements in 2009, 2015, and 2020 got me motivated to do some research to see if I could find anything dispersed across the internets and in my travels about this orphan company and, more specifically, how that affects Dodge Trucks. What I was able to find has clarified my knowledge of these oil filters but I cannot say for certain if these findings are definitive as the source material for these things may be buried in boxes in a warehouse somewhere in Indiana for all I know. But to summarize, the DeLuxe JC filter elements used on Dodge Trucks were available in basically four different filter canisters that were adorned with five decals depending on the year and engine configuration. Early Chrysler flatheads had pressurized crankcase oil lubrication, but apparently no filtration, so companies like Purolator, Fram, and DeLuxe made aftermarket kits that relied on colorful product finishes and informative advertising to sell their products as a cost effective solution to extending engine life. I reckon DeLuxe first sold the CU series around 1937, before developing the JC series around 1939. This 39JC canister is notable in that it has an offset hemispherical sump to accommodate the drain port that is adjacent to the inlet port. These 39JC canisters appeared to have been painted red with two mounting clamps, and have the DeLuxe Clear Oil decal, available from Jim Osborn Reproductions [DZ0054]. A very rare service poster from 1945 changed hands to a private collector around 2010, and this was shared online, showing the evolution of the JC series from the bottom drain port on an offset hemispherical sump to an angled drain port on a hemispherical sump. This 45JC canister appears to have the outlet and drain ports in the same vertical plane. Pressurized oil filtration was an option on Chrysler flatheads, as seen in these two screen captures from the 1951 Dodge Truck Sales Training Film: Early B-series build cards may have listed this filter option, as seen in this ’48 1-ton build card: The B-series factory parts manual lists two part numbers for the oil filter canisters (1265706, 1503494) using the same replaceable oil filter element (676575), with the second canister p/n applicable to the B-4s. There is no diagram for this shown, but looking at the Power Wagon and Route Van parts listings, they use the same p/ns and show a diagram for each. The Route Van differs from the Power Wagon in that it has that bracket that mounts the filter canister to the rear of the flathead engine. The 1265706 canister shown appears similar to the 45JC canister, with the outlet and drain ports in the same vertical plane. These two screen captures from the Route Van Servicing Master Tech video show the installed RTVan DeLuxe filter. These also appear to have the 45JC canister. A September 1948 magazine advertisement found online describes the new DeLuxe-Baldwin cartridge, apparently showing the JC405 sock filter element, as well as a perforated metal cased element, but no part numbers are listed. The 45JC canister shown has a new decal on it that predominantly displays DELUXE, possibly a new branding of this filter product. Could a Baldwin buyout have been the demise of the DeLuxe Products Corporation? The best factory picture of an installed DeLuxe JC series filter that I could find was in several of Bunn’s books for a ’51 with a column-shift. Notice that it uses the old DeLuxe decal, and that the outlet and drain ports could possibly be in perpendicular planes. This appears similar to what I have seen in a ’50 Spring Special and my ’51 flatbed. I could not find any pictures of the B-4 1503494 canister, so for years, I assumed that it was some minor difference in the canisters done as a cost savings. Then I spied a ’54 stripped of its powertrain at auction, and discovered a barely legible part number: 1504092 [image pending] Looking at the C-series factory parts manual, 1504092 is not listed, just 1503494, same as the B-4. Looking up oil filter interchange numbers, and 676575, 1265706, 1503494, and 1504092 all refer to the Baldwin JC405, which I thought was odd since 3 of those 4 numbers are for the filter canister, not the filter element. Since the 1503494 was used on the B-4 and C-series, it dawned on me that the C-series parts manual might be incomplete, lacking the listing for the 1504092. Then I found a C-1 with a very similar looking filter canister as the one on my B-4 and it finally hit me: 1503494 was used on the flathead 6, while 1504092 was used on the V8…the differences appears to be the port fittings, lid and the use of a bolt or a T-handle. I found two factory pictures of V8 engine compartments in Bunn’s books, but the filter canisters were mostly obscured by the engines, though looked similar to what I found at that auction. Canister 1265706 appears to have two configurations of the same 5 parts. Both configurations use a smooth hemispherical sump that has a continuous resistance weld joint (similar to what is used on B-series fuel tank perimeter welds) with the housing. Inlet, outlet, and drain ports are brazed couplings. The 45JC configuration has the outlet and drain ports in the same plane, similar to what I removed from my ’48 B-1-B-108. The 49JC configuration has the outlet and drain ports perpendicular, similar to what I removed from my ’49 B-1-D-126. Canisters 1503494 and 1504092 use a 4-piece assembly (53JC) with a ribbed hemispherical sump that has an almost seamless joint with the housing. Inlet and outlet ports are brazed couplings, and there is no drain port. Decals differ by part number and location as engine mounting and firewall mounting differ. On the 1503494 canister, the T-handle appears to have been replaced with a simple hex head bolt that has a machined shoulder to seat in the recessed area on the lid. The perforated dome is spot-welded to the lid, with a lower profile than previous domes. I was not able to remove the T-handle on the 1504092 that I found at that auction, so could not confirm if that had a similar lid construction. The lack of a check valve as with the T-handle made me take a second look at the spot-welded dome, and sure enough there are perforations located closer to the lid than on the previous version. My guess is that if the sock filter element becomes clogged, the oil pressure is great enough that it breaks the upper element seal to the center flow tube and allows fluid to bypass the element and escape through those upper perforations to the outlet. And that is a guess that I am unwilling to verify (continued for restoration tips...)

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA

-

From the album: DELUXE PRODUCTS CORPORATION - LA PORTE INDIANA