wagoneer

Members-

Posts

411 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by wagoneer

-

Mobil one DTE light recirculating fluid From @MarcDeSoto I'm one of the guys who had a big thread on this subject. You're right, you can't look up past threads very well here. James did a long study and research on this question and came up with this product. Mobil Light Circulating Oil ISO 32. This product is difficult to look up. I tried searching for it on Amazon and it gave many look alike Mobil oils, but NOT the right one. I had to look up my order from Grainger's and use the product number to look it up on Amazon. I saved a few bucks by driving 30 miles to the my local Grainger's, but even they had to order it. You might well say that this is just 10W oil so why not put 10W motor oil in the fluid drive like you do in the semi auto transmission. Well, because it won't work well. This oil has anti-foaming agents to prevent cativation in the fluid drive, which will cause the car to have poor acceleration and slipping. It's because this oil is made for turbines that it works well in the fluid drive coupling. It does not come in one gallon sizes, so you have to buy more than you really need, which is just under two gallons. https://www.amazon.com/Mobil-DTE-Light-ISO-gal/dp/B07CSLKT1J/ref=pd_rhf_se_p_img_2?_encoding=UTF8&psc=1&refRID=HMVQFANK8D7F8CYKVMYX#descriptionAndDetails

-

to summarize —— a) high rpm + accelerator = noise b) highish rpms and no accelerator != noise c) noise is definitely coming from engine bay d) clattering noise like metal on metal clashing Key component is acceleration (wide open throttle). When let off throttle, noise abates. this tells me the engine is not the issue because it is spinning at high rpms doing its thing with and without the noise. This leaves carburetor Couple things: 1. take a short 15 second video of the Noise occurring and abating and then occurring again when you accelerate. 2. Clattering noise might be from an accessory, carb linkage, throttle cable, wire, chain or something connected to the engine and vibrating heavily (and loudly) under the combination of high rpm. 3. Check the carb for loose or wet areas at the gaskets. I have a whine noise that I can hear through my carburetor that I suspect to be a vacuum leak. a rebuild is part of its future. Really the info you provide does limit and refine areas to investigate as you have said: . 1)Start with your carburetor . Consider vacuum leaks even possibly your vacuum a advance. 2) maybe engine mount bolt loose allowing engine to move ever so slightly during load

-

1. Welch plug There is a curious statement in the Chrysler manual - “On car models C30…C40…, the water distribution tube is located behind the Welch plug near water water pump. Remove Welch plug, after which the tube can be removed. A heavy rod with a hook forged on one end will facilitate removal.” Which Welch plug specifically? The large hole to the side of the WDT an uncapped repurposed Welch plug ? Should it be capped b/c there is no slot for it on the pump? The other one that might help is the rear plug you indicate but that’s not exactly convenient most of the time to access. The only other one could be on the side next to the pump, but doesn’t seem helpful for rip and replace? 2. Fill the inlet / Flared tube? Second , Is the tube supposed to fit snuggly to fit in the whole half moon inlet space? Is the tube supposed to match exactly the half moon space that is on the pump to prevent back pressure and direct flow around the pistons? The service manual says, ”care must be exercised when installing a new distributor tube to see that the front end of the tube is flared in a manner similar to the original installation” I ask because I just put in a new water distribution tube but it certainly doesn’t fill the whole space. Would I need to use something to force it to fill the space? seems to me it “should” fill the space so water from pump goes directly into tube without spilling around the sides. Thoughts on potentially using a mallet to tap the sides to have form more closely into the shape while it's in the block? Below is from the truck with the new wdt This is the existing one from the Chrysle; It seems to fit more closely.

-

I’m doing valve adjustment cold at the moment, and I find the front 3 sets to be easy but under the exhaust manifold is awkward at best even with proper 10 inch tappet wrenches. All the videos show the front three sets being adjusted, but none show the back three sets (cylinders 4-6). Probably because there would be too much cursing . I’d like to see how others are doing the back valves hot. #5 valves are right behind the downward pipe.

-

Last few bits, clips, and pieces needed for a completed restoration...

wagoneer replied to meezy's topic in P15-D24 Forum

Showing off the goods is required on this site. We are all voyeurs, and live vicariously through the success of those succeeding. What a sharp looking nose on that vehicle! I think the 50' Plymouth is nicer looking than the 50' Chrysler redesign. I'm not a fan of post-48 DCPD re-designs, in general, but your 2-door looks real nice especially after they lengthened the back seat and shortened the rear-end. A lot like the 2-door coupes of later years. Did you do away with most of the badging? It looks super clean; Well done! Based on the reflection in the bumper (polishing giving you away), you seem to have a warehouse of cars behind you. -

Last few bits, clips, and pieces needed for a completed restoration...

wagoneer replied to meezy's topic in P15-D24 Forum

Don’t tease! Post some pictures of the finished vehicle . Nothing more exciting than to see the end result of lots of hard work , and where many of us are aiming for . -

Tonight I punched out the bottom two large welch plugs, and flushed out the block! Some silt but very little at the bottom, just some gross coolant water. The old welch plugs look solid and steel, pointing again to recent rebuild. Thanks @keithb7 for the great video on the topic. I also took out the petcock and cleaned it out. I know so much more now that I've gone this far into the engine, and now reading the manual makes so much more sense! Project Elise is my learning project to prepare my Chrysler, and it's the best $400 (cost before expenses of courses).. I've spent. Tomorrow onto the oil pump and oil pressure relief valve!

-

http://www.jholst.net/interchange/ 1949-1965 There is a whole section on engines covering 49 and up. There are 'interchange' books out there that cover older. https://www.ply33.com/Parts/numeric from our very own @TodFitch - Lots of older stuff https://www.dodgepowerwagon.com/pw/pw_pif.pdf - Trucks

-

Reads to me more as convention rather than rule, but regardless I need to check the oil pump and pressure relief valve for rust and replace the springs, and for good hygiene put it at 7 o’clock. ive gone through every external part of the engine , and touching the inside top, I have a new master cylinder on its way , and the timing will be set properly and easily with the head off. for parts that are relatively internal or just bare metal generally, what do people regarding rust proofing once you get rid of the surface rust … say inside the intake manifold, or on the carb after a good but plating corrosive soaking? anybody done any home zinc plating (seen some good kits online)?

-

Thanks for the clarification @Plymouthy Adams I figured it was a typo. It's on my to do list for this weekend. I found some other threads on this forum that cover it too.

-

One of my near term goals was to reindex my distributor so tdc points to 7 o’clock instead of 9 o’clock . In principle, this shouldn’t matter though right, it’s just me being OCD?! We’ll, back in 2011 in the engine rebuild tips thread, @Plymouthy Adams stated the timing pump (timing chain?) needs proper alignment to get proper distributor position. fiest, did you really mean oil pump here or is it the timing chain that controls it? If the latter, I have a lot more work than I hoped so I’m hoping it’s the former . my understanding was I could change the index by adjusting the oil pump (remove and rotate so it’s at 7 pm instead of 9 in my case. Plymouthy Adams 4,989 Posted December 22, 2011 I have come behind a couple folks and found that you should properly index the timing pump to the cam at TDC for correct position of the distributor rotor. AND it is also a good time to install the distributor as more than not you will end up rotating the engine crank somewhere between this point and engine firing..Pay attention to the oil lines and see they are connected and tightened. Lastly..test you fuel system prior to start to ensure the float is not sticking as it has been laid aside for the rebuild period.

-

@Crazyred Your compression numbers are pretty good, so probably some carbon build up on the cylinders heads or valves, or valve seats. You may just want to leave her be, but if you want to go a little deeper, then taking the head off is the next logical step. Have you checked the plugs, if they are fouled, or whether the wires are still good? If you can isolate which cylinder is misfiring, then when you want to go deeper, you can focus on that one. As I have discovered recently, It's simpler and easier than you would think to take the head off, and clean the carbon off , and loosen up any valves, plus it's a whole lot of interesting fun to go one level deeper. I used a combination of brake fluid and PBBlaster soaking in the valves to loosen them up (with a light mallet tapping the sticking ones as I hand-rotated the engine). I keep the cylinders and head sprayed down in wd-40 to keep the rust at bay. A new head gasket wouldn't hurt either.

-

This special is exactly what many of us do now and would be quite desirable even today ! I doubt there is a commercial mechanic shop out there whose time it would be worth to do this in this day and age for a price we could stand.

-

I still recommend that you bench test your dizzy and coil before ordering anything. A 15 min test will tell you what you need to replace.

-

Oh so pretty! A little elbow grease, water displacement #40, sponge and a hard bristle attachment made my heads go from ugly to oh so pretty! I even put some of the children to work I did notice the cylinder head combustion chamber is very bumpy (not smooth as I would have thought). Is that normal? I also flushed my block and head with not too much stuff coming out before water was so clear. a productive weekend ; next up oil pump. To boot, I got to show up a 57 Chevy Belair!

-

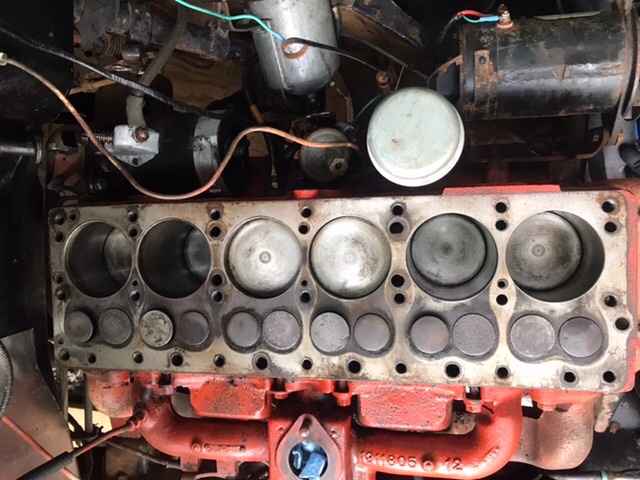

Today I have done exactly this @Plymouthy Adams and it answered a lot of questions, as well as created some more work . I pulled the head off today to reveal: 1. Engine was rebuilt with .040 oversized pistons 2. honing marks were still very clear in the cylinder 3. I was able to free the sticking exhaust valve quite easily with a careful combination of brake fluid (thanks @JBNeal), PBrust, and plastic dead blow mallet so now I have all working valves! 4. there was quite a bit of carbon deposit on the piston heads, combustion chamber tops, and on the valve heads. this was amazing ! I found a video showing how to bring it back to shiny aluminum using wd40 and a green scotch beige scouring pad! it worked so well and was so quick. No amount of soaking would have done it so well. You can see a couple of pistons have been cleaned and others not in the pictures . I’m amazed; blown away. I’m mid clean but I’m expecting my pistons, valves and head will be nice and shiny once done! I’m being careful to only clean while piston at TDC and avoid piston walls. 4. I’m going to take this opportunity to inspect my oil pump, oil pressure relief valve, replace gaskets and springs, and reindex to the proper 7 o’clock position on my distributor . question: manual says set distributor to firing for #1, does that mean I should bring it to 2 degrees BTDC as the manual specifies or exactly TDC when indexing, and should 7 o’clock then really be 2 BTDC? 5. when rebuilt the engine builder *forgot or didn’t know* to put in the water distribution tube ! No water distribution tube must have led to a hot engine and probably why so much carbon deposit! 6. Cooling passages are full of crud and my water pump is rusted out; replacing that with new one. decided to punch my Welch plugs and flush out the engine as best as possible . So much crud it’s hard to believe even just in the head! 7. Will likely pull manifolds while I’m at it. 8. take the opportunity to set all the valve lashes properly with my fancy new tapper wrenches 9. set my timing properly ! 10. put it all together, cross my fingers, and hope the compression is back and it fires!

-

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

Since police and insurance are involved, you will need to take possession and stock somewhere away from where it is now before any company or person will take it off your hands. I don’t think anybody will wade into the middle of this now legally. Those body parts at a minimum are very desirable as they are in excellent shape. Parted out they could sell for $2k-$3k alone. Gauges go for $500 to $1000. Fenders for $800+. @Plymouthy Adams has a point. Has to be done soon. Maybe police/insurance action provides breathing room. -

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

As a postscript , after those few months of time pass with the truck sitting and in your possession, you may consider the mental transition away from rational roi to hobby/passion where the costs up to now are sunk costs and become fuzzier like fish stories become greater, and you look at it as a hobby whose costs invariably are irrelevant, and complete has lots of positive and fond memories of your sister and boyfriend, and one day those will be important and this debacle will be a footnote. To boot, it will also have some nominal pretty decent resale value, and you will enjoy it thoroughly. The fact is you have a very solid and complete (in terms of pieces) truck and it’s on its way to being a very nice daily driver. If you can afford it, plow forward with rose colored glasses, and join us in this forum, start a build thread, and the peanut gallery will join you on your journey, and maybe meet you at the annual picnic in California. -

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

I thought about this Next step. Somehow it just galls me the state you’ve been put in for a moving vehicle to come out in parts and it just costs and costs. As a consumer there must be some recourse for such a travesty, and as a minimum contact Wisconsin consumer protection bureau (at the link I sent earlier), but also a lawyer over the phone can give you advice. ———- selling procedure: 1. rent a 20x30 storage space for a couple of months (~$500) in the area (or target area) 2. rent a uhaul truck (for the parts) with a car towing trailer (for the truck or alternately a tow truck) and hire a couple of people (like those college guys and a truck people) to help move everything. (~$500) 3. You should travel there yourself and at least one or two friends to supervise (this is where the posse would really help) to collect all (absolutely everything including original pieces like the gauges and interior, nuts and bolts) Anything thrown away should be carefully documented as disposed of by the shop. a checklist of areas of stuff like earlier would help. you can use the factory parts manual and a factory shop manual as a source of truth and list of components with pictures. Your truck was complete so complete parts should come back. You should come bearing pictures of what your truck was inside and out (the video is good too) 4. place everything in the storage unit carefully documented with pictures. 5. place an ad in auto trader and eBay. Hopefully you still have a clear title. When sold , it will be responsibility of buyer to collect and move everything and you close it down and move on . ———— You could drive it all the way back to California and keep your options open (uhaul plus trailer). Maybe in a few months and distance of time and space, the perspective won’t be so bad, and you can have someone or yourself work one system at a time. It can be your next house renovation . -

Generator gave up the ghost, alternator suggestions?

wagoneer replied to Sean Jackson's topic in P15-D24 Forum

Look at powermaster powergen alternators as one option, or one I'm looking at that doesn't have the issue @chrysler1941 describes of parasitic use is from gener-nator. He'll take your current generator, gut it, and basically build an alternator inside of it. It's externally regulated and uses existing wiring and external regulator, so it looks completely stock and compatible. 2x price of others, but worth it avoiding hassle of fitting ones that aren't made for our cars/trucks. Outputs 50 amps. -

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

Your truck in 2017 was amazing, and a stage that many on this forum (including me) aspire their own trucks to be already. It's a really solid truck, and has all the parts, but suffered from the usual deficiencies that require a little bit of updating including: A/C, highway drivability, engine maintenance, brakes, and maybe a nice wax. The solutions this mechanic chose are the "easy" way out - rip and replace , instead of refine and hone, and unfortunately those nuances are not readily there unless you are steeped in the options available and a strong vision being followed. To be fair, the engine/drive train restomod will achieve the goals above, and get you a very very nice daily driver truck. A really experienced mechanic could at this point really give you an accurate estimate of parts and labor because there is no mystery any more to the mechanicals, and (presumably) the rest of the body is still there. As a truck, it's quite a simple vehicle with not a lot of parts or detail work, so to speak, unlike the sedans. I refer you to this page on Wisconsin consumer protection laws: Be careful now in what you say to him, and do not ignore the bills, as they are protected under Wisconsin Law. IANAL (I am not a lawyer), but basically your rights are protected for authorized repairs, and your best task is to carefully document *everything* from the beginning. The trick is distinguishing authorized from *unauthorized*, and any estimates provided or not provided along the way along with itemized invoices (including part prices and labor). He is required by law to keep parts for your inspection/retrieval, and my mechanic always keeps them for me until *after* I pick up the vehicle in case I want them. Any kind of expert tends to wash over the details for the customer by necessity, but that is normalized through the estimates and approval process. I have been in your position before too, surprised by a bill by a mechanic on my vintage Chrysler, and it's not a good spot because you know work is done, and you wonder why it wasn't communicated or did you ask for more, or you just don't want to create conflict. It sucks. I'm not sure this was ever really a "trust" relationship, it's a business one with ill-defined parameters. It frequently comes about from being too palsy and loose with the mechanic: "Oh could you just do this, or 'how about this one little other thing'". It's easy to become "pseudo-friends" when the work is long and drawn out, but really you want the work to be more like when you take the car to the reputable factory dealer for repairs - very mechanical and procedural. It happened to me especially in the beginning when I was more nostalgic and less informed about what is required to do the work and I needed to trust the mechanic to do the job for the goal I was asking. This unfortunately needed a proper oversight and project management like your house restorations which really is the mechanic shop's responsibility. It especially becomes problematic when you have something so open-ended as "safety and pretty", because that is open to interpretation, and really the onus on the repair shop owner is to really nail down what it is you would like done at the detail level. This is similar to any type of project whether automotive, residential, or building software. As one example: Would it have been sufficient to just check all the drum brakes, replace master cylinder, and move forward, or was it necessary replace front drums with disc brake kits (ala scarecrow kit), or a third option is to replace the whole front end (which they did here) giving you stopping power, easy steering, modern radial tires. Slippery slope especially when customer is uncertain at the technical level and depends on the service person to make the technical judgment call. Your check-and-balance is the estimate plus progressive invoices and milestones. That decision point should have been made with your consultation and appropriate cost estimation, and if it looks like it's going to run over the estimate, advisement well in advance Basic project management and part of the accounting the shop should have been doing regardless. You see this happen on those TV Show builds quite a bit -- person drops off their car with shop, and 6 months or years later, the car comes back bling bling with an equally bling bill. They almost never show the billing conversation, but I have seen that they do keep the owner apprised and send periodic bills. What has happened is NOT water under the bridge, but now must be dealt moving forward. Sentimentally, this would be amazing to finish, but is it a $55,000 truck? No, and you will never get $55k out of it. For that additional $28k, you could get a completely restored most anything you want kind of vehicle with fresh paint, and the reality is that the money you put into these vehicles almost never pays out in market value (see labor estimates as an example). Frankly the next owner will get a steal-of-a-deal from your truck because it's mostly there, but takes some skill and knowledge to finish it off. If they have it themselves, then for another $5 to $10k in parts, they will have a sweet truck. This is why you see some/most builds go on for years here on the forum. We are doing it on the side, when we can, bit-by-bit. If you really are keen to finish it, call up custom shops in your area, and explain the situation and show the pictures (or rather go to the shop). You basically want to get it back to original running order from 2017 but with this new power train. Maybe for another $15k it would be worth it considering in the market a fully restored restomod goes for about $35k. They will tell you they can't give you an estimate without looking it over, but still they should have an idea. Heck, I have only seen low res pictures, but they should have some clue. $20k is probably not unfair for the work done so far, it's just not the $20k worth you were expecting (or maybe even agreed to). This current shop could do you a solid by telling you what has and hasn't been done from the list plus anything else. I hope this info helps you forward making a decision and action. -

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

A couple of interesting things here from these photos from April (3 months ago). This has turned into a complete restomod rather than just enhancement. The owner should have appropriately informed you, or rather given you appropriate estimates and expectations. It's looks to be only about 1/3 complete (that's I guess the 20k out of my estimated 60k full restomod), unfortunately, though possibly the fitting of the engine and trans was majority of the work, there is quite a bit of work to be done but not impossible, and you would have a very nice truck afterwards, except @Frank Elder may never talk to you though he might join the posse forming (he gets a bit annoyed at putting "cheby" engines in Mopars). This mechanic definitely is not the only one who could do the work, but it would take someone who has done complete end to end builds before to do it efficiently. You don't have to take them to court, but you have to sound convincing and assertive so he takes it seriously. In the end, the work looks quality-ish so far*, but the expectations on what you want vs what he thinks you want or knows how to do are totally off. He's way down the road of restomod, and going back now is pretty much gone. There are folks on this forum who have done similar and could give better estimates. My original numbers above presumed back to original with few mods. This is like an episode of Texas Metal; just be careful it doesn't come out lowered 12 inches. On the positive side, now that the running gear is "modern", then most any mechanic would know how to work on it, and hook everything up, so your options are greater. Instead of looking for a restoration shop (though they are still good), you can tell them you have a truck that half-way through a Chevy 350 restomod, but needs to be "finished". Summary: Given the state of the truck, you are likely $20k away from a good daily driver truck. a) You could sell this one for probably $7k in its current state (parts alone), and let someone else finish it. You could buy something (or nothing) else. b) You could Finish it yourself in your spare time c) Have this guy bring it to some state like running d) have another shop do the work that you trust and can supervise. A good shop that focuses on it could knock it out in a couple of weeks, but rest assured you are in the middle of a complete restoration. If that's not what you bargained for, or negotiated, then you may seriously consider suing, but lots of other custom shops can finish this truck for you. You can also take your pick of personalities on Motor trend network; I'd go with Stacey David though I think Garage Squad would be more appropriate here. ? Observations: 1. He's got a 1950 or so Chevy truck behind this one; I think He's turning your Dodge into that one. more interesting and relevant: 2. The engine is in place and mounted, and presumably so is the transmission. It looks like this GM 350 just by looks but they all kind of look the same *Is my imagination, or is that engine and cab sitting too far back? That front cross member should be underneath the engine 3. Front suspension and steering changed completely -- rack-and-pinion now. No steering wheel shaft so steering not yet connected. 4. Not clear from these pictures what's going on with the drive shaft or the rear end, but the rear wheel hubs are the same as the front wheel hubs, so I think the rear axle was also changed out. Did he mention 4-wheel disc brakes? 5. Not seeing a lot of wiring - so on the todo list 6. whole front end fascia needs to be put back together and wired up. 7. rear truck bed and wiring needs to be put back together 8. Not seeing any brake lines - need master cylinder probably too 9. not seeing any fuel lines - probably never fired up 10. Need exhaust, cat, muffler 11. A/C needs to be connected as well as heat 12. Linkage for transmission 13. Interior - totally needs doing - that's quite a bit of work (what happened to the old one?) 14. Did I mention wiring, lights, etc? 15. Giving away/getting rid of a complete engine/trans/steering/diffs for the truck is a shame. That alone would be worth at least $1000 sold to many of us on this forum. 16. No Carburetor - need to buy one 17. No radiator/cooling system Questions to get current status on and expected work in regards to: For each, what has been done, what remains aa) What's the minimal work required for the vehicle to move/stop under its own power a) Wiring: sub-a) 6v to 12v conversion b) Fuel system c) Brakes d) Front suspension e) Rear Suspension f) Rear Differential/Axle g) Engine sub-g) Engine management, fuel injection 2) Is the engine placed appropriately to keep proportions? h) Transmission, Transmission linkage I) Drive shaft J) Front Fascia K) Interior seats, dash L) Steering M) Fuel system N) A/C O) Heating P) Bed/Running Boards Q) Doors/Windows/Windshield wipers R) Cooling system S) Overall Look - The truck should look original with original proportions bb) What the heck took 3 years? Would love a timeline of this work. It's like anything, can you come to amicable terms with this person, or is it better to break up, because you are in a broken relationship with this mechanic. I listed about 20 items (incomplete list), consider (generously) if each item took 1 day for one skilled mechanic, then a build would take approximately one month in total, and each day costs $560 labor/day + ~$500 in parts (that's a generous underestimate), then remaining build is approximately $21k. Yeah... that's why they call it a "passion". -

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

Hi Julie, This explains some of the complexity that others on the forum can detail better than I can for sure, as there are certainly those who have done a chevy conversion. Changing the engine to an unspecified Jegs engine ($4k might be an LS Swap) with associated tranny would necessitate changes to the mounts, drive shaft, tranny tunnel mods, steering, possibly axle, and other assorted bits and pieces. Wondering why this even necessitated an engine Swap? A good rebuild would have been $2500 and dropped right back in. A/C Could have been added ($1500), even a 12v conversion could have been easily done - $1500. Power steering - $1200, Front Disc brakes $2000 -- (parts only) plus labor. Frankly this sounds like a lot of messy technical issues potentially, including the need to do further fabrication. The original estimate described adding air conditioning... which I don't see in the one picture you indicated and would be attached to the engine. The cab is bare so all interior work would need to be done. This sounds like the mechanic bit off too much or could be his "chevy hammer" and every car his chevy nail. You will need a clear picture of what has and has not been done, and what state it's in right now when talking to other mechanics. We are now all in your superficially invested in your tragedy, so any description of the state or work done would be helpful for perspective on work . Also knowledge about whether the original engine/transmission are still around, as that could be a possible route forward. -

Help! Where to Stop? 1951 Dodge P/U Restoration

wagoneer replied to Julie's topic in Mopar Flathead Truck Forum

Situations like this end up in court usually, and maybe even small claims court. Recommend documenting everything (all communication, pictures, timeline of events). Seems to me that trust with this mechanic is gone, and depending on him to put it together back again in good working order with warranty is unlikely to end well. 1. Find an alternate shop that you can trust and will put your build together. Call up every place in town or nearby towns and get some quotes, or even close to your home. You need shops that specialize in restoration so they know how to work on older cars. 2. Expect at least $10k if not more from other shops, though I think the total should be no more than $5k. 3. Settle on an amount (not the one billed) with this shop, and I would say 1/2 to max 2/3 the bill, and settle it, or threaten to take him to small claims court for any number of reasons (see below) the least of which is defrauding you based on false estimates. Learn All About the Law for Suing a Car Repair Shop [Pro Tips] (donotpay.com) Erroneous estimates is a reason to sue, and you may need to do some more internet digging for what Wisconsin provides. He may choose to make an alternate offer that includes putting it back together on a hard timeline. Not sure I would take that. A good mechanic (assuming nothing really mechanically needs fixing since you got new motor, etc), should be able to put together everything in 30 hours max. ~40 hours (1 week) * $100/hour should be no more than $5,000 given some minor things that invariably crop up and taxes. That is an upper estimate, in my mind. At their rate ($70/hour) shouldn't be more than $2-$3k max, and I would start with $1,200 for pure labor and put it together. 4. The reality is the vehicle itself is not worth more than $15k (max), and in parts, it's worth about $3k-$5k (sentimental reasons aside that do give it much more meaning and personal value). $20k should have kept it in one piece at least. Transporting the vehicle costs too - ~$2,000 cross country by transport. 5. Expect to wait. You've unfortunately waited 3 years, and that is a hell of a long time indicating your build was low priority, as well as they were figuring it out as they go. 6. Consider fixing it yourself - pack it up and bring it home to your own garage. You can join us here on the forum, pick up some tools, and one piece at a time put it all together, while farming some of the work out to local mechanics. Net: He has the the vehicle and (unfortunately) it is in parts (though it's not clear how many). This shop in question is certainly NOT the only mechanic to be able to put the truck back together as a forum of amateur mechanics is doing it in their spare time , but it will cost you money. Find a new shop and shop around, but if you can negotiate a close to this situation for a fixed rate and fixed timeline with the alternative being court. Put reviews in Google/Yelp/BBB once this whole thing is settled. Frankly, not a good situation, altogether, but salvageable. You may consider buying a working truck and using yours as a parts truck... One thing that caught my eye in the early pictures was the engine laying on the floor - a v8. Did the mechanic swap the flathead for a v8 of some sort with a new tranny? -

Too bad, I thought the flowers on the dash were a nice touch. ? I am installing fog lights on my car, and I find it interesting how this detail of installation -- drilling holes into the bumper or interior was left to the dealer to install without nominal provision for placement. That is trust and does takes skill to not mess it up. A little too high, or too low seems like it won't look bad...