-

Posts

812 -

Joined

-

Last visited

-

Days Won

16

Everything posted by Loren

-

If you need or want a chunk of frame, I have a 50 Windsor frame I am going to scrap and I’d be happy to donate a section to help your repair.

-

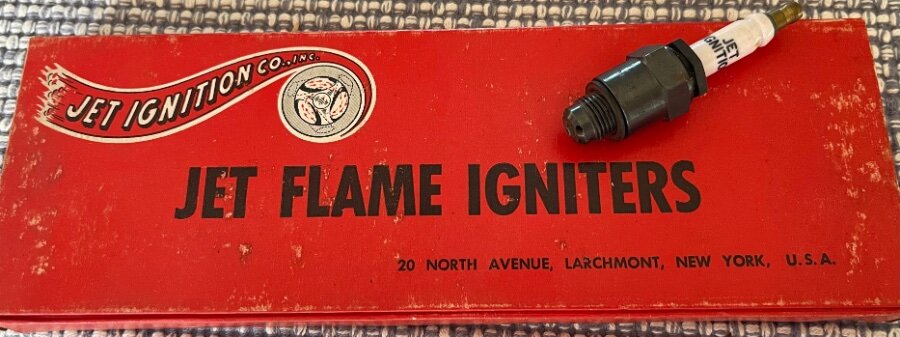

I’ve checked out the Mahle system it is interesting. Not something you can screw in like a spark plug, it’s much more complex. I can’t even say for sure if the pre-chamber spark plugs such as the Jet Ignition plugs could have any value in higher compression OHV engines. I really doubt that they would work with multi spark ignitions. They remain a curiosity from a by gone era.

-

On the topic of old spark plugs, old being the key word as opposed to worn out spark plugs, I offer a plug that hasn't been made since 1965. I became aware of these via a friend of my Dad's, EJ Brown who was one of Briggs Cunningham's mechanics. Back in the 1950s EJ thought these were the secret weapon. My Dad put a set in our 49 Mercury and he ran the wheels off that thing. My experience with them was with my Quarter Midget when I was a kid. It normally had a Champion plug and it was hard to start with so so power. You put the Jet Ignition plug in and Hang On! I maybe biased but I was impressed! It's a "pre-chamber" type plug in that it has a chamber in its tip like the pre-chamber of some diesel engines. One thing that bothered me was the numerous types that were made. It seemed like every engine had its own part number and design. With so many types it's no wonder the company finally closed down. The inventory must have been massive. Unlike regular spark plugs which have very minor differences the pre-chamber plugs had those plus the tip designs for each engine. There is a company in the UK which makes a pre-chamber unit for a regular plug that is supposed to preform the same. But they only make 14mm 3/4 inch long units and they are pricey. I've chatted with several "Spark Plug Collectors" and nobody ever heard of them. So... For your entertainment I offer this photo of some I have gathered.

-

WWW.speedwaymotors.com #91011025 Looks close.

-

I just googled Hellings & Stellings, they made lots of air cleaners but I couldn’t find the ones in your photo. I recall see them in a magazine ad when they were still in business. The ones you will find now are reproductions. The Early Ford Store of San Dimas has the “Bell shaped” ones which are kind of cool and would work ( cheap at $35 ).

-

I believe those are “Hellings & Stellings” air cleaners. They are pretty close to period correct. If you check out some magazines from the later 1950s you’ll see ads for them.

-

Thanks to you both! I gave it another “look see” and it’s serial number starts with P26 which would indicate a 1955 Plymouth. The crank has a forging number 952068. I’ve decided my 52 block is in good shape and it’s the original and the title has the engine number as the VIN ( which I intend to correct ) so it seems like the right thing to do to overhaul it and replace the crank and rods for a power boost. I have a new old stock Bendix-Stromberg WW carburetor and the Power-Pack manifold for it as well. Very exciting!

-

Actually it’s a Plymouth engine the serial number starts with a P Believe it’s in the 55-56 era. It also has a harmonic damper.

-

I have a 230 engine with some serious cracks in the block and a 52 218 engine. I’d like to double check to make sure I can put the 230 crank and rods in the 218 block. Any thoughts?

-

I am used to salvaging the brakes from self serve wrecking yards. In that case you take as little apart as you can. Thus my procedure is to break loose the tie rod end first. It’s a taper of course so I take the nut off and smack the end of the arm with the aforementioned BFH. Remove the brake line by unfastening or cutting. Then look for the long end of the King Pin locking pin and tap it with your pin punch. The pin is straight with a tapered cut on the side and is held in place with a couple of dings in the short end. The King Pin only comes out the top because the steering arm is bolted across the bottom so you take your pin punch and punch through the tin plug on the bottom ( there’s a space to do this over the steering arm ) and it pushes the top plug out with the King Pin. Once you pull the King Pin the complete spindle and brake assembly is free as a unit. In a self serve wrecking yard you want to present as few pieces as possible on check out. They have this nasty habit of wanting to charge you for each piece. I’ve even put the wheel back on to discourage this. lol

-

You gotta use a BFH! lol If you tap on the wrong end it gets tighter. A pin punch the right size ( and be careful if you slip off you'll peen the thing over and you'll have to grind it down ) I use 3 1/2 Engineer's hammer ( aka BFH ). Done right and you can reuse the pin. As you can tell I've done a few of these. When you get the hang of it there's nothing to dread, the job is fun.

-

High Quality H4 Headlights for 12v Cars (Cheap!!)

Loren replied to Sam Buchanan's topic in P15-D24 Forum

FYI There are 6volt H4 bulbs available and there are 6 volt Bosch type relays available too. From the photos I can see the Toyota relays are different from the Bosch but I expect they will work on 6 volt. Like most online purchases BUYER BEWARE! I got all set up to purchase from two sites and when you get to the shipping calculation the cost is way out of line, even within the same dealer organization I finally ordered some from an AutoNation site that had shipping cost by half what another AutoNation site quoted. I don't have any Toyota dealers near me but the next time I am in Reno, NV I will try them for more. Years ago the SAAB dealer I worked for used to buy NGK BP6ES plugs from the Datsun dealer in town ( yes it was that long ago ) for a ridiculous price because somehow somebody made an error and ordered a monstrous number of plugs and NGK delivered! I think that dealer ( or was it Datsun? ) was on the NGK Christmas card list for years! -

Hi Bob, The 50 Windsor chassis I saved from the scrap heap has a bar ( Sway Eliminator ) that is 0.744 inches in diameter and is a direct fit for a Plymouth ( at least on my 49 ). It seems the Imperial was a wider car and had to have a wider bar. A consultation with a spring shop would be in order. They routinely reverse the eyes on hot rod springs. Actually they don't reverse the eyes they re-arch the springs so the eyes are on the top instead of the bottom. It's more of a Blacksmith job than a metallurgy thing. ( That is they heat it up and bend it without any heat treat involved )

-

The quick and dirty way to remove the Windsor spindle is to take a long pin punch from the bottom and punch through the plug in the bottom and remove the king pin from the top. Try not to damage the needle bearing in the top as they are no long made. BUT FIRST: You have to remove the pin that holds the king pin in place. In your photo #2 you will see a pin about mid-way on the "Support" ( which some folks call the Upright ) Take your pin punch and tap on the end that sticks out. Once you get that pin out the king Pin is free and will come out the top. If you are using a disc brake kit made for a Plymouth...the spindles are different. Your Windsor brakes and spindles have value don't toss them.

-

The heat shield on my P17 has a hole for a stud or stand off on a dual chamber fuel pump. Not all dual chamber pumps came with the stud/stand off which replaced one of the upper chamber screws. The quick and dirty way to make a substitute would be a piece of “all-thread” rod, 3 nuts and 2 washers. The stud/stand off braces the heat shield over the pump so that it is level. On a single chamber pump the heat shield is allowed to hang however it wants to because there’s chance of contact with the pump.

-

Good ignition and carburetors have been issues since the beginning of the automobile. Charles Kettering gave us the point type ignition back in the 2nd decade of the 20th century. Back in the 1960s we started to get something new the Capacitor Discharge ignition. I had a friend who was tired of his buddies coming around and idly picking things up only to drop them or put them out of the order he had them in. So he get some old electronic capacitors and charged them up then sprinkled his shop with them. Soon it became well known that you shouldn't touch anything in his shop because you could get BIT. The way the Kettering system works is when the points close current builds a magnetic field in the coil and when they open the field collapses and a spark is sent out the secondary winding of the coil. The way the capacitive discharge system works is the circuitry charges a capacitor and the points give the circuitry a signal to discharge the capacitor which sends its charge to the coil which now acts as a step up transformer. The points only act as a signal generator and do not carry the load of the magnetic field, thus they last much longer. So the CD Ignition is really the answer to poor ignition performance. If you have a car converted to 12 volts you could build yourself an HEI set up ( it's not that hard ). But what if you don't want to convert? Well you can try a Pertronix which many have and they are not that happy with them. Or you could go on a treasure hunt and find the best CDI from way back which was the Delta Mark Ten. I went that route because I like treasure hunts and having stuff nobody else has. I even found a guy who can repair them! One of the advances of the "B" model was a switch on the end of the box which switches the unit back to Kettering ignition, but they never made them in 6 volt. So when mine crapped out on me ( corrosion - I live on the coast ) and I didn't have any tools to move the wires back. I determined to find something with a switch. Turns out the son of the inventor has a cottage industry making an advanced 6 volt CDI. He hand builds them to order and they have a three position switch on the top. CDI-OFF-Points. He also makes a 12 volt version. Not cheap but about what Langdon got for his HEI distributor. Fred Winterburn is his name and he's in Canada. If you google Capacitive Discharge Ignition he comes up with a lot of material. So if you have a friend with a syncrograph ( aka distributor tester ) you can get your distributor set super accurate then reinstall it, time it and install Fred Winterburn's ignition box and you are good to good for as long as the rubbing block on the points last. Anyway that's what I have done. And if you really want something unusual go on your treasure hunt for a set of Jet Ignition Spark Plugs. ( aka Jet Flame Injectors ) Really hard to find but worth it. Last made in 1965.

-

These are fun cars! I have one too. The overdrive sure does nothing to hurt the charm of the car. Instead of disc brakes I put Chrysler Windsor 12 inch drums and I am going to add a booster. I am looking for a Special Deluxe club coupe front seat as the P17 doesn’t agree with my back side. The car is so much lighter than the P18s I am seriously thinking of changing the axle ratio to a 3.54 that I have.

-

I have used them and I have recommended them. They have an incredible amount of carburetor data sheets too.

-

Two items worth a question. 1) Does your car have vacuum Wipers? If so get the dual chamber fuel pump and you'll thank me for asking the next time you use the wipers. 2) Does your car have the heat shield over the fuel pump? If so good. You'll find a hole for the stand off in it and the stand off should be on your new fuel pump. If not find one. You'll thank me when your car starts every time when hot.

-

Well all this talk about engine stands is infectious. I got a coupon from Harbor Freight and I had to use it yesterday. So I looked at what they had. They are now using the old Sears "Good, Better, Best" tactic. Years ago I worked for a dealer that had been a Lincoln/Mercury store and in one of their storage areas I found a really nice heavy duty engine stand with a gear crank on it to rotate the engine. I made a couple of adaptors for the stuff I worked on and I was hooked. Years later I had my Snap-On guy order me an OTC version. It was very pricey of course but I still thought it was a labor saver. If you intend on leaving an engine on the stand it's not worth it. If you intend to use it for assembly then it is really worth it. Harbor Freight's "Best" is a copy of the OTC engine stand and I think it is actually better. It has more features and seems to be a little heavier duty. With my coupon it was lots cheaper too. They call it a 1,500 lbs stand but the gear drive is really very nice. When you see three grease fittings on the head and you pull the cover off and see the gears, you know you got a good piece. Next I am going to put together a dedicated mounting plate to mount the engine on the distributor side cross ways. I have worked on inline engines lengthwise and I didn't care for that. A little unstable.

-

A spark? One of the problems I have seen on other cars is the ground wire between the breaker plates is missing. The points have to be grounded ( or is it “positived” on a positive ground vehicle? lol ). The car will run because the current will find a ground if it will start but not always. What usually happens is a progressive decline in ignition performance. Each time the points open there’s a spark. The points are made to last a long time with these sparks but the breaker plate is mild steel and it erodes a little each time a spark is made. I have seen breaker plates so eroded that when the car reaches cruise speed the vacuum advance pulls on the breaker plate and the ground is broken causing a miss until the vacuum advance returns to it’s former position. So I’d pop the distributor cap and look for the ground wire for starters.

-

I can tell you with 100% certainty that old tires can explode. Michelin says tires need to be replaced after 6 years whether they are worn out or not, everybody else says 7 to 10 years. Since the ones I have had explode have all been Michelins, I can verify they know their product! The others just leak or never fill. If you have a car sitting on a flat, try jacking it up before you put air in the tire. Some times they will take air and you can move the car. In a recent move I ended up scrapping over 120 tires that would not hold air, so I think I can speak with some authority. A Bubble on the side of a tire is from damage, like hitting a curb. One of the most injury producing Michelin explosions I had was a tire I took off a car and put on my tire machine. Locked on to the machine I started putting air into it. It got up to 27 psi ( going for 30 ) and 3 inch long gash in the sidewall opened up with a BANG! I was wearing a floppy hat with a chin strap, the blast hit me in the face, blew the hat inside out and strangled me with the chin strap. Luckily I was wearing eye protection and I got a nice bruise where it fit on my face! I felt like I had been hit in the face with a shovel and it took three days for my jaw to get back to normal. Needless to say my ears were not happy at all! After that when I encounter an old flat Michelin, I jack the car up attach an air chuck ( one that stays on ) and apply air from a safe distance. They still blow up but I don't put myself in the line of fire.

-

Years ago when I got out of college my first job was with the Black & Decker Industrial and Construction division. ( 1974 ) They were the world's largest portable electric tool company. After considerable mismanagement they merged with Stanley. I have to tell you the outfit that's selling the stuff I buy these days is Milwaukee. They used to be the tools plumbers used. They make some really outstanding cordless tools that impress me. I have their 1/2 inch M18 cordless impact wrench and it works! A guy I know says Home Depot's Rigid Brand ( another plumber's tool company in the old days ) are warranted for life. When the battery craps out you call them and they send you a new one. They don't even want the old one back. Not sure about all that but that's what he said. Milwaukee even makes hand tools now. A recent purchase was a really nice 1/4 drive set. The sockets have 4 wrench flats! The case has a removable tray so you can put the set in your tool box. The sockets have the size written on two sides in a way you can actually see. Very thoughtful stuff.

-

In an earlier post on this I mentioned that the amount of blow by past the piston rings can exceed how much the vacuum can draw out of the crankcase. It has to go somewhere and that somewhere is either the breather cap on the oil filler or in the second type it goes to the air cleaner and gets sent into the intake stream. Thus while the vacuum side is all one way, the breather side can be two way. That is why the closed system is the only type now allowed under emissions regulations.

-

There are two types of PVC systems and they relate to whether the breather is open to the atmosphere or it is a closed system. The regular filler cap has a mesh screen to keep the bugs out of your crankcase, but it will allow vapor to pass both directions in or out. A closed system uses a sealed cap which has a hose to the air cleaner. Any vapor going into the crankcase passes thru the air cleaner first. Any vapor which comes out of the crankcase will be captured in the air flow going into the intake and thus burned. Whenever you place a vacuum on something it pulls the water vapor out. Water vapor ( along with acid ) is a product of combustion and the source of sludge in the crankcase, so a PVC system is a real good thing. It’s not just emissions, it makes engines last longer. PVC valves serve to prevent intake backfires from causing oil leaks. There are systems which do not use them. They depend on long small diameter rubber hoses and a fixed orifice to prevent excess pressure in the crankcase. I have also repaired blown seals and pan gaskets on these engines. Not many but it happens.