-

Posts

2,487 -

Joined

-

Last visited

-

Days Won

12

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Ulu

-

I have been back to work on the Volkswagen chassis every day, and I have been stripping off all the dirt, grease, and old paint that’s on top of all the grease and dirt. There is more than I hoped for. I am trying hard to get the weird chassis and suspension ready for paint, but I am only 3/4 there. I took a couple breaks from this to do welding on my security doors and other household things. Also temperatures have been above 100° every afternoon so I am only outdoors until about 1 PM. Which is what it is now. See you soon.

-

I was just looking at my old books and I found the Andy Bernbaum catalog from 1990. Or thereabouts. It’s catalogue number 21 and it has the 1991 price supplement stapled in the front cover. It’s in a really nice shape and destined to become a collector’s item.

-

I did this myself because I have the same goggles Plymouthy shows in the foreground of his photo. I did not have quick access to surgical tubing (Our pharmacy is over half a mile away) but what I did have is silicone rubber airline that I bought for my aquariums.

-

Somehow I missed reading this thread, but it was of interest to me because I had a few transmissions with this balky shifting out of first gear. One was a ‘66 Ford custom 500 and its problem was a sloppy cheap aftermarket shifter. If you tried to shift it fast, it would go into second gear, but the shifter would go back into the neutral “gate”. You could not change gears without climbing under the car to manually put the shifter into second gear. One was a 1974 Dodge D100, and it’s problem was that the rubber engine and transmission mounts had sagged, causing the shifter to be out of line. One wrench adjustment under the hood and the owner was smiling. He didn’t want to change the rubber mounts but now that his truck would shift, that was all he needed. One was my ‘59 Edsel and the other was my ‘47 Plymouth, and both had the same problem: Balky shifting from first into second. In both cases the problem turned out to be worn out fingers on the shift forks. I had them welded up and dressed them down with a file, and the transmissions worked perfectly after that. Well, except that the Plymouth transmission was a rock, and you could beat the snot out of it and it did not care. The Ford transmission had a glass jaw, in that the first gear was very weak, and you could rip them up quite reliably even with the small 223 six cylinder engine. This is why I sold the Edsel. It had a great engine, I loved the outrageous styling, but the transmissions were poop.

-

These are the rear frame rails after welding and painting. I made these little standoffs so they could be securely clamped to the rear suspension torsion tube. Previously these just bolted right to the sheet metal floor pan with no brackets to attach them to the actual frame of the car.

-

I did a test fit of the engine and found out that it didn’t quite clear my new struts in the back frame. I ended up re-designing them a little bit and now there’s plenty of clearance and the car will NOT try to unsnap its own valve covers.

-

-

The frame did spring back quite a bit eventually, but I chopped out the bottom of the fore tunnel with an angle head grinder. Then I flushed out the whole frame with a garden hose, and an air hose, and the high-volume air hose from my shop vac, until it was all dry again. It didn’t happen as easy as it sounds. There were a lot of different cuts with the grinder to get all the internal reinforcements and welded on patches. So I got to do a lot of forensic investigation. When this was originally repaired the entire bottom of the tunnel was all rusted out for about the 1st foot from the front axle back, and they had completely replaced that with a patch that covered way too much and welded to the wrong spots. The whole business was 3rd rate. In the process of all the cutting, I uncovered a considerable amount of mouse nest and debris. By uncovered, I mean I sent it up in smoke. I removed the pedal set so I could figure out how far the rust damage went, and it goes another foot on the driver side. Just to the end of that lumpy weld to the right of the right bolt hole. It is hard to tell from the photograph just how much trouble they had with this, but you can see they had to hit that patch with a torch, and beat it down (until they actually ripped the floor) in an effort to get the pedal assembly to fit back in the hole.

-

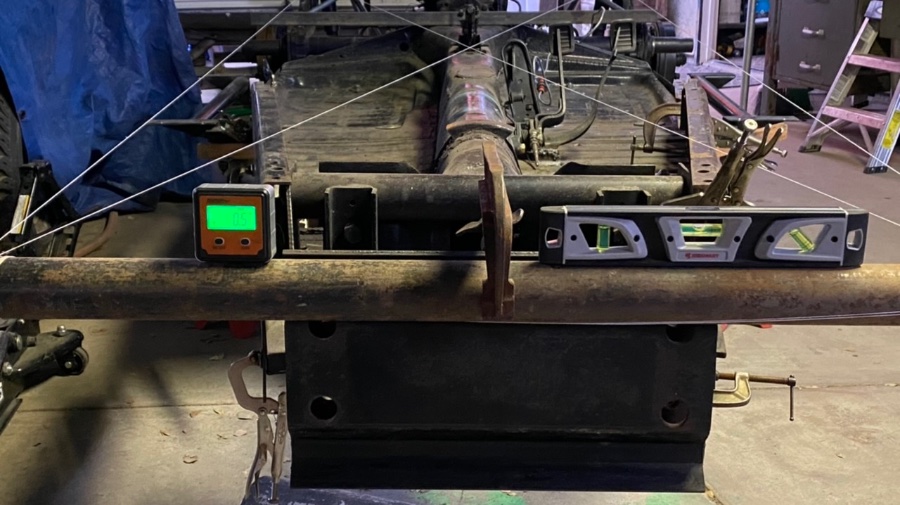

When I look at my photographs it appears that the new struts might be a little bit close to the rocker covers, so I will need to do a test fitting of the engine soon. I decided that I needed to check out the front beam axle for straightness and other damage, and I hoisted the whole assembly off the front frame adapter. Checking for warp and twist at the adaptor. She’s down about a half a degree at the driver side and it’s pushed back at the driver side slightly less. Basically the car is twisted a half an inch at the front wheels and it’s pushed back a half an inch at the left front wheel. After I do my test fitting of the engine, I will put some indicators on this frame and start making relief cuts to see how much it springs back. There appears to be a lot of weld draw and once I cut out that bit of metal I expect the frame to spring back almost 100%. But if it doesn’t I will set it up with big hoist and draw the frame out straight hydraulically.

-

I have recreated the tail frame braces from scratch. This is stronger and now the axles wont strike the braces. This will reduce frame wrap (twist) as the engine moves. Basically the engine and transmission are mounted in a fork, and it winds up a little bit as the car accelerates and decelerate, to cushion the actions. They had extra reinforcement in the vans, to control the frame twist with the bigger loads. Commonly, people run those braces to a thin tubular crossmember at the shock absorber bolts Since my body does not sit on the Volkswagen body mounts, I was able to add a square tube crossmember there, and run all my braces to the crossmember. This will be just enough.

-

I have smaller ones for the detail work. But that monster strips it down fast! I have half an acre of used steel to clean up before I start welding it. It’s gonna get a work out.

-

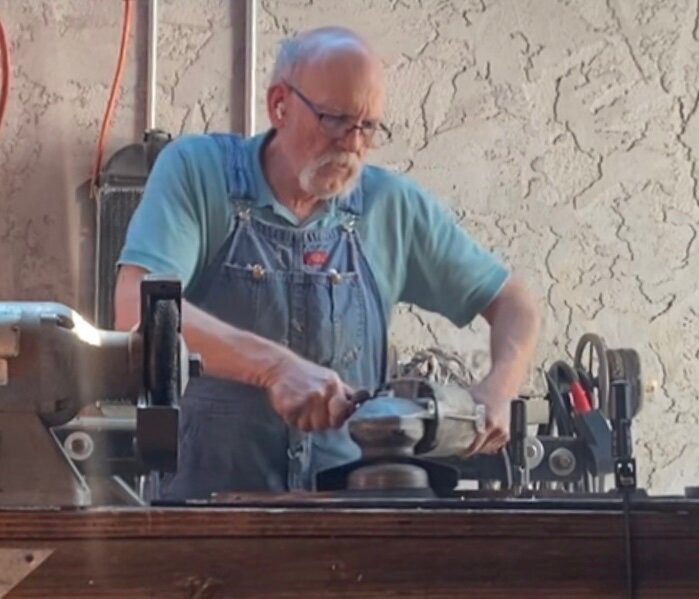

Well it seems like I get back to this about every six months. I’ve been attempting to adjust the rear suspension and I’ve been cleaning things up so I have room to work on the car in my welding area. Just a lot of nasty layers of paint and dirt in some places. Particularly the end of this torsion arm housing. This must get really clean before the rubber bushings will slide off over it. That Milwaukee knocks it right off but it is a beast to work with all day.

-

When I was a Cub Scout, Dad and I built a replica of a fenderless car called The T Bug that we saw in Hot Rod magazine. The front of it looked like a Ford model-T & the back of it looked like a boat tail Bugatti. I searched the Internet in years past for a photograph of this car, but I never could find one. It was probably someone short-lived project car and it became, in time, something else.

-

a news story on the Rapid Transit Mopars of the 70's

Ulu replied to DJ194950's topic in Off Topic (OT)

It is an awful shame at the quality of reporting about everything, partly because there’s just so much more reporting compared to yesteryear. Reporters in California can’t pronounce the name of well-known towns and cities here. I was watching an automotive reporter who did not realize that Edsel was not just a car, but also a person. I’d sure like to quiz him about Studebaker Hawk. LOL -

I considered this. I think modern engines all have bypass oil filtration so the filter doesn’t fill until the rest of the engine has pressure. But yeah the weak spring in the bypass valve could possibly do this. I would imagine it has an Autolite filter because he has it serviced at the Ford dealer. I didn’t look to see. I’ll probably get the chance, because it sounds like his starter solenoid is going out.

-

I just remembered after reading this that I also owned two Ford pick up trucks: ‘57 and ‘59. I also owned a ‘59 Edsel. I actually bought the rusty ‘57 for the engine, And I bought the ‘59 to put it in. When I bought the Edsel I put the engine in there and sold both of the pick ups. The truth is, I wasn’t very impressed with the pickup frames. I thought the frame needed one more rivet on each side of the front crossmember because they all crack out right there. The door sill design was of course a rust trap. Regarding V-8 engines, they all sound broken to me. It’s the “bent” firing order. I think all the V-shaped engines sound weird. Of all I have owned, I like this one the best.

-

I don’t ever remember anybody turning down a free hemi engine. For a Ford or their Chevy or whatever they owned. But like some of the cars I own and have owned, They are delightful to look at but not terrific cars to own. It is getting to the point that if you want a shiny car in California you better buy one that’s already been painted or take it out of state.

-

Crickets huh? I get the same reaction if I post a picture of a mopar over on the jalopy journal. I’m almost at the point where I have to delete old images in order to post a new image, So these will go bye-bye soon enough.

-

Sorry guys…. It’s the cam phasers. Based on what information the dealer gave my neighbor, I expected this to be a far more exotic problem. It turns out that it is VERY well-known and all over Google if I had taken a minute to look. It appears that the parts to fix his truck are going to cost about $800 plus the gaskets if we do it. I think that he may be under some kind of warranty. Otherwise I expect the dealer to want $3000. It would be interesting if you could put a pre-luber on this engine, that would bump the oil pressure up electricity before you started. it looks like those phasers are supposed to have a lockout pin that engages when no pressure exists, but it appears to be a flimsy arrangement compared to the mass of the rotating cam assembly, chains and phaser assembly etc. All that stuff has lots of inertia and it looks like it slams that little spring pin around until it wallows out. At that point it gets stuck and the cam phasers can slam back-and-forth under start up, until enough oil pressure builds to cushion them.

-

My neighbor has a lovely 2017 F150, with a 3.5L gas engine. It has about 60,000 miles on it. When he starts that thing cold it makes a racket just like a diesel engine. I swear to God it sounds like an old Detroit diesel 6 starting up. The sound goes away after a minute or two, And it sounds like any normal gas engine. Very smooth. The dealer told him this was caused by some solenoid, and related to the fact that the truck was a four-wheel-drive. They also told him that he would have to bring the truck in and leave it for a few days to get it fixed. This noise doesn’t sound like it’s coming from inside the transmission or someplace inaccessible. It sounds like it’s coming right from the top of the engine, but it is very loud. It sounds louder than any 3.5 L engine which is dieseling during shut off. I told him I would ask around and see if any of you folks have heard this before.

-

I saw these on the way home from the dentist in Fresno the other day, and both were for sale. I was tempted to go clean out my Ira account but I can’t live on air & gasoline fumes, which is what I’d be left with.

-

I could certainly see it as some sort of signage.

-

On top it says U.S.A. and the original paint was gone over sloppily at least once. It does not appear to be a liquid container. It has 4 obvious screws up from below, but no bung or spout or anything. Sounds like 18 or 19 ga steel when you tap it. Like an old car fender from 1949. Nobody at the auction house knew anything about it or its origin. It had not sold when they closed the auction house during covid. Probably still there. When I moved here in 1975 there was a chain of USA gas stations, but I don't recall this.

-

Seen in a local auction house. Any ideas? I think it was from a display rack in a tire shop or similar.