-

Posts

2,489 -

Joined

-

Last visited

-

Days Won

12

Everything posted by Ulu

-

I bought a gallon of phosphoric acid solution at the local swimming pool supply store. Our hot tank had an electric heating element in the bottom of it, and it also had bubble pipes for agitation with an air compressor. When I worked at the Kawneer company, we had giant tanks to etch 20 foot long aluminum extrusions. They would collect the aluminum hydroxide sludge from the bottoms & haul it off in railroad cars. That’s how much we were making. Most of it went to the cosmetics companies. (Check the ingredients on common types of under arm deodorant.)

-

50 years ago I worked in a shop where we had a big hot tank with caustic soda in it. It was nasty and stinky but it worked well. Probably completely illegal in California now. Amazingly one of the senior mechanics thought he could put an aluminum porthole frame from his boat in there, and it completely disappeared overnight. LOL I’m telling you, a little chemical knowledge can go a long way in this life.

-

I finally stripped the paint off of those bumper brackets today. I would normally buy Jasco paint & epoxy remover or Zip Strip brand paint stripper, but this time I decided to try caustic soda in the form of generic barbecue spray cleaner. I have never tried this before. I got the brackets as hot as I could in the sink with scalding water, but I think it would work better if I heated them up to about 400° in the oven first. It ended up taking me three applications and some scrubbing with scotchbrite, but they’re looking just about ready to paint. I do like the finish better than when using the zip strip.

-

Welcome to the age of bluetooth. The only thing I find myself listening to in the truck nowadays is YouTube. Unless I want local news on AM radio.

-

Very little was accomplished on the car over the past two weeks. I did lots of household improvements that had come due. I got back to my brackets, and finished welding up the unneeded holes. There was lots of shaping and filing, but it’s nearly ready to sand, strip and paint.

-

It’s almost brochure ready now. When did you start working on this one, Plymouthy?

-

My neighbor has the gasoline powered version of that truck but he bought the TwinTurbo V6 gasoline engine. Ford is rebuilding all of those things under warranty because they were failures. Some people reported that the rebuilds are only lasting for 30,000 miles. They keep changing the parts that are failing so maybe they finally made some that last? The newest ones have a redesigned bearing cap for the front of the cams. So be happy you got the Diesel engine. Do not get water in the tail lamps. There have been horror stories reported where rusty tail lamp sockets caused all the same tier computer modules to start failing one by one, as bulb power back fed into the communications bus. Remember when a bad ground on a tail light was a simple thing to identify and repair? The basic tail lights are reportedly $1200 each without the circuit modules that go in them. One guy that had the late model with all the departure lane warnings and electronic sensing systems paid $5600 as I recall to help both tail lights and all the modules replaced, and it took a long time to do the diagnosis because of the “zipper failure” action of the electronic modules. When the first one burned out it took out the next one and that one took out the next one etc. When the cam phasers blew out on my neighbors truck he had to fight with Ford and wait months, but in the end, even though it was technically out of warranty, he got it all fixed by Ford. I don’t know if that means they replaced the heads with the newer model heads (which evidently solved the cam phaser problem.) My question to you, is do any of these modern diesel engines have variable valve timing on the cam? I am only used to working on Detroit diesel’s from the 1960s. I could rebuild one of those In my dreams, but don’t ask me to look at a Caterpillar!

-

I got that cross frame all finished up and painted and put it away to cure while I work on the bumper brackets. I figured out why I could never get the front bumper to look really straight with the fenders. One of the front bumper brackets was put in the brake crooked, and it doesn’t match the other one at all. These things are 1/8” steel plate, and I am not going to bend them easily nor will I be able to heat up the bend and hammer it into the correct orientation, so I cut the offending flange nearly loose and bent it into the correct orientation so I could weld it.

-

This is the frame which under-girdles the floorboards and connects them to the running boards, fender tips, seatbelts, and seat frame risers. I decided I should weld up all the unnecessary holes in this thing before I weld it up under the chassis. At least a dozen holes got relocated and there were about 30 holes in this that needed welding. There are a lot of corresponding holes in the floor boards that need to be welded up as well. I did this, again, by first clamping an aluminum chiller block underneath the work and then flipping it over to weld the backside. I find it if I leave the aluminum chiller on until the weld cools considerably, I don’t have any corrosion problem on the back of the weld, and they come out clean. I got about 3/4 through before I ran out of Argon and had to head for the welding shop. I will finish this up tomorrow and sand it and put some paint on it. Then I will put it away until it’s time to fit it on the chassis.

-

After many side projects and other delays I finally did finish cleaning up the suspension on the back of the Volkswagen. I degreased it and acid etched it and flipped it over so I could paint both sides. I painted everything that I had stripped to bare metal but I did not paint anything that I need to weld on yet. When this is dry I will cover it all up so the welding can continue.

-

I have been spending some time on little projects for my wife, but I did get the rest of the burnishing done on that suspension. At least that which I can get to with power tools. I am down to the little corners that you can only get with a little scraper. There’s a few more hours of that before I can degrease and paint, but it’s looking pretty good.

-

This is going to be at least its third assembly. ? Maybe more, because there’s 30 years of its history I don’t know about. Anyhow, it’s like any other custom car. Once you get it all together and running, you will decide you need to change something. In this case half the frame, LOL Who knows, maybe the whole frame. I’m not close to done yet.

-

I’m slowly cleaning all the corners in the rear suspension. This flame-cut block is the outer spindle bearing block. It’s MIG welded to the stamped suspension arm and there’s about 30 dingleberries remaining, even after stiff mechanized burnishing. I have been knocking dozens of these dingles off the chassis wherever I find them, because they prevent me from doing a good cleaning job, and just look messy. After knocking off most of the dingles with a small hammer and a nailset, it looks cleaner. I started out with a cold chisel, but that leaves marks, and isn’t necessary 99% of the time. It’s nearly ready, but I still need more solvent to degrease it all.

-

Videos; YouTubers, etc and so on... looking for content

Ulu replied to Curt Lee's topic in Off Topic (OT)

Curt, I feel sorry for some of those guys struggling with the unknown. I was lucky because when I was little my dad gave me his 1957 Motor’s manual which covered all the ‘40s cars. It was a big deal when I bought the P 15. -

The gauge in my 47 Plymouth always worked OK, when I was getting a good charge from the generator. When I was not, it would seem like I was low on gas. If I looked at my gas gauge while I was sitting at a traffic light idling it was likely to read low after a minute and then after driving for a few minutes it would be normal again. The bottom line is I never trusted it, and I always carried an extra gallon of gas in the trunk.

-

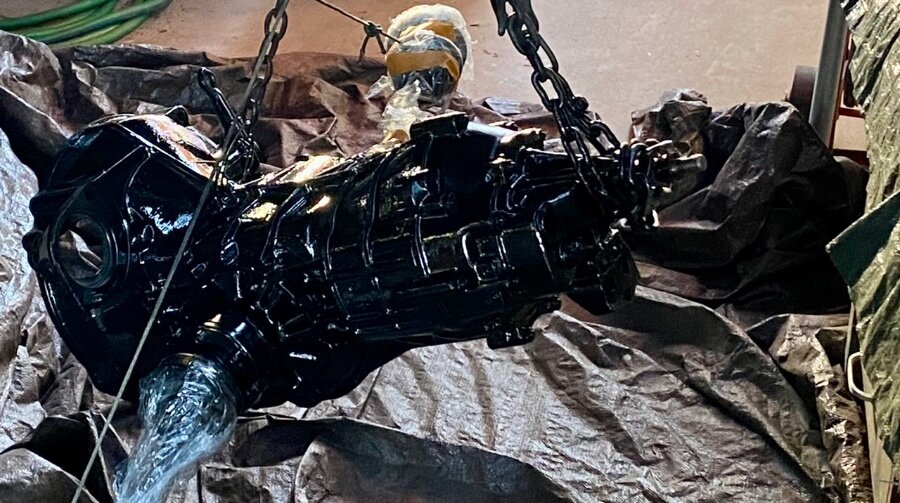

After two days with too much wind and humidity, it finally dried up and calmed down today, and I got my transmission painted. I had to do the last little bit of cleanup on the bench and then I put it on the hoist. I washed the whole thing down with acetone, and blew it off. There it is with several coats of self etching black paint.

-

Plymouthy, the most wonderful thing about this project is that I don’t have a deadline for it to be finished. I have other projects waiting, but if this one takes the rest of my life it’s not a problem. I have run out of photo space again, so until I delete some old photos all you get is the fuzzy little stuff.

-

Still no paint except for a few small parts involved in the transmission mounts. I’ve been scrubbing on the transaxle itself for about three days. It’s starting to look pretty good.

-

Thank God it’s not as ugly as the Bedford or the Powell. Does this have the engine crank that also runs the Jack up and down?

-

With these sturdy shock absorber supports, each suspension arm is practically its own jackstand. I also made a steel “horse” to support the nose. I did not want it just hanging from a chain. Essentially it’s standing on nine legs, plus I still have the chain on for safety.

-

We got swatted by hurricane Hillary four times in three days but everything is dry now and I am back on the case. I’m glad I fogged down all that shiny metal with oil, because the spots that I missed started to develop surface rust. Any rusty spots that I did not fog are now slightly rustier. Maybe I will be able to get some paint on this by next week.

-

Hurricane Hillary has hit Clovis, shutting down all progress for the immediate future. Normally in mid to late August we expect day after day of 100° temperatures. but the rain started with a cloud burst yesterday afternoon, continued on and off during the night, and started pouring about 5 AM. Fortunately I had not bothered to degrease anything as I wire brushed the chassis, and so nothing rusted from the humidity. But when this started up I went out there and covered every bit of shiny steel with a fog of anticorrosion oil. I have a jug of swimming pool cleaner, which is a heavy detergent mixed with water and phosphoric acid. When I decide it’s time to paint, I will hit it with that first, degreasing and converting all the rust. Right before I paint it I will degrease with gumout, then acetone. Finally I’m going to use a rust converting black paint on the bottom. I expect to do quite a bit of welding before any of that happens. Although it may currently be too wet to paint, I’m pretty sure I can TIG weld in this humidity without electrocuting myself. But I actually have quite a bit of grinding to do before that can start, plus I have to buy some more metal. I am not satisfied with my current collection.

-

I owned a 1961 International Harvester pick up truck, and it warms my heart to know that there was an uglier pick up truck built on this planet. Sorry but I wasn’t into photography back then, so no pictures of my Rusty pick up truck.

-

I got the transmission cleaned up pretty good so it was time to take it out of the chassis To finish cleaning and repaint. I built this rollover trunnion for the back end of the car. This was just built from random junk including an old trailer hitch & a piece of a tractor clutch. The front end I just suspended with a chain from the engine hoist as I rolled it. This is going to save me a lot of work not having to work overhead. Here it is inverted. It seems like this day has been a long time coming!