Matt Wilson

Members-

Posts

641 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Matt Wilson

-

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Yes, I do believe it's a viable option, and one I'll probably pursue if I can't make the factory housing work. But I just think the factory piece is cool, so I'd really like to try to make it work. I'll probably poke around to see if I can find out if a shorter starter will work on my truck, but I'll also look into mocking up a spacer between the block and the filter, as you suggested. That might be the easier and cheaper option, but it doesn't hurt to check into both options. It'll probably be a few weeks before I get to the mock-up, as I work during the week, and I'll be going on a family trip a week from now. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

I think you're right. I wonder if the shorter starter will interchange. The lever looks pretty similar to mine, though not exactly the same. Alternatively, I could still try the spacer between the block and the filter, that Sniper suggested. Thanks so much for looking into this. You obviously have some significant resources, in terms of vehicles and books covering these vehicles. Your willingness to spend time looking at them for our benefit and to share what you learn is appreciated. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

One other piece of info: The starter body diameter is 4.5" on mine. I don't know if they're all the same diameter or not, but maybe that could change the potential for interference in some instances. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Good image. Definitely shows a high-mounted starter, like mine. Just a question of whether it is as long a starter as mine. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

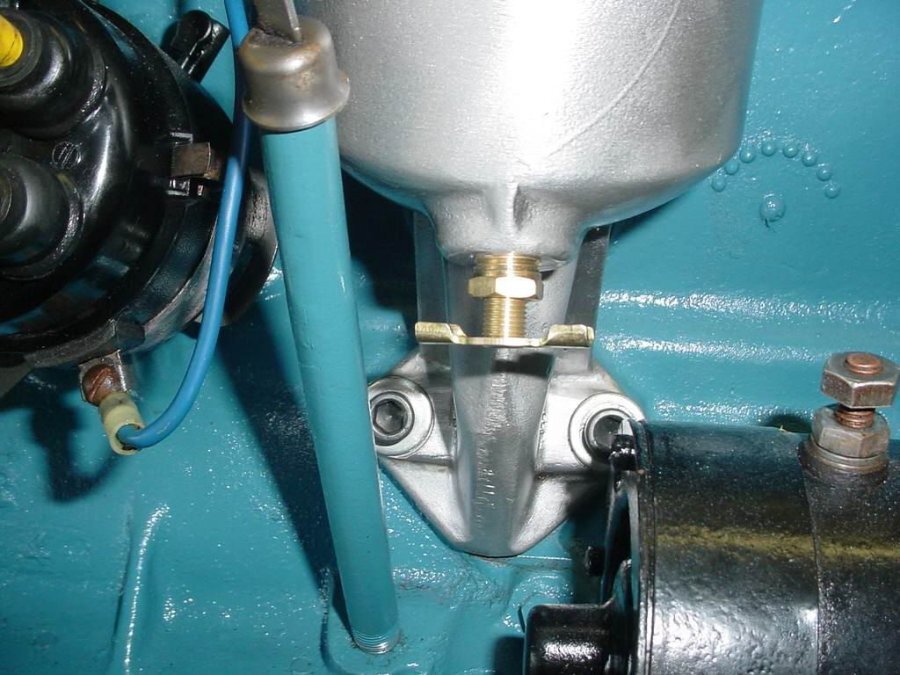

Thanks so much! One thing that may vary across some engines is the height of the starter. Here's a pic of my bellhousing, and you can see that the starter sits pretty high, whereas the pic of Don Coatney's engine (my original post that began this thread) seems to show the starter sitting lower. That could be the difference in having these difficulties or not. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

I hope I have the same luck that you had. I'm not terribly optimistic, though. My starter doesn't quite go to the center of the diamond, the way Wallytoo was talking, but it's close. As I said before, I probably won't know for sure until I bolt the engine and starter onto the bellhousing, and try to fit the filter too. Or I might be able to do a more accurate mock-up with the engine still on the stand. Here are a couple of photos of the starter. It may not look like it, but the tape measure starts at the rear face of the mounting flange, and the distance to the forward tip or nub is about 9-1/2". -

Once again, thanks! I really value your comments. And I will especially take your comments regarding tuning to heart. In fact, as I re-read your thread the other day, I made a mental note that I should probably buy a device to measure the air-fuel ratio, and set up my engine like yours, so I can read that data in all driving regimes. I can read the plugs, but using a meter seems to be the way to really make sure that things are as they should be. It's worth it to keep from tanking my engine. Plus, I'm a geek who likes data, so it will satisfy that part of my personality.

-

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Hmmm....that's an interesting idea. It would have to be a pretty thick spacer. Maybe 2 to 2-1/2" thick, but might work. I'll mock up a wooden block as a spacer in the near future. Thanks for the idea! -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Thanks, but I just bought one...and unfortunately, it doesn't fit, unless I can figure out a way to make it fit. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Well, I bolted the filter housing to the engine, as it sits on the stand, and then held the starter up next to the engine, roughly where it would be if it was installed....and sadly, it clearly interferes with the filter....bummer. It's hard to say exactly how much shorter the starter needs to be, but I'm confident it's somewhere between 5/8" and 1-5/8", depending on whether the starter sits high enough for the nub protruding from the front of the starter to interfere or not. It's very close and hard to tell without bolting the engine and the starter to the bellhousing, which won't happen anytime soon. The starter is a foot pedal starter (as a reminder, the vehicle is a '49 Power Wagon), and it's part of the truck's character, so I don't want to lose that aspect. I wonder if there's a foot-operated starter that is shorter, perhaps from a different model, which could be substituted without (much) modification. If I can't make the full-flow filter work, it's not a huge deal, but I was really looking forward to having it on the engine, like icing on the cake. I can always install a remote spin-on full-flow filter, but having this cool factory part sure would be nice. -

Great info, Jim! I think I had read too many racing-oriented articles on piston and ring selection (cuz those are about the only articles out there) and I felt like I was in over my head, but it sounds like it doesn't have to be that big a deal, and that most of that stuff is not very relevant for our engines. I agree that much has changed since these engines were common on the road, such as oil, so they have a much better fighting chance of long life today than back then. I also agree that engine tune plays a significant role. Having said that, I see folks who rebuilt their flatheads in the last 20 years or so, so they are almost certainly using good-quality oil, but they're still often getting something like 60,000 - 80,000 miles before seeing definite signs of needing an overhaul, with piston, ring and cylinder wear being a very common reason. I'm hoping to pick/spec modern rings and improved pistons to give me a leg up in that regard. I know many folks will ask if I really plan to put that many miles on this engine, telling me to be realistic The answer is, I don't know, but I have had this truck for over 30 years, and I plan to keep it another 30, or however long I live, so while I have it apart, if like to do a few things to improve the odds of longevity. Couple more questions: You mentioned you wouldn't use JE Pistons. Do you mind elaborating on this? Also, I saw that your piston-to-bore clearance was 0.0035, which seems somewhat large for a modern, street hypereutectic piston, so I'm guessing your pistons are not hypereutectic alloy (I don't think forgings are available in that kind of alloy, anyway, but I'm not sure). With that clearance, do you ever hear any piston slap when the engine is cold? Thanks again!

-

Hi Jim, I've been doing searches to find out more about custom pistons and modern rings, and I came across this thread again (I read it a few years ago too) Still a great thread! I see that you ordered custom pistons from JE Pistons and used modern thinner rings. I'm interested in doing the same thing for my engine (a 265). I'm interested in doing this for durability and longevity reasons. It seems that our flatheads often suffer ring and cylinder wear prematurely compared to modern engines, sometimes accompanied by ring and ring land breakage (usually after 75,000 - 100,000 miles, I realize, but still, if I can do something to fend that off, I'd like to). So I'm wondering...how has your engine held up? How many miles have you put on it? Are you satisfied with the performance of the pistons and the rings? Any oddities or deficiencies with the compression or power output? Any oil burning beyond what you'd normally expect in an engine like this? How do the spark plugs look? Any signs of blow-by or premature dirtying of the oil? If you had to do it again, would you take this route, or other custom pistons, or just use original-style pistons? Are there any other things you would caution me about? I see that JE has a custom piston order form. I don't know what some of the terms mean (like spin boss, accumulator grooves, contact reduction, etc.), but if their technical rep will walk me through it, I'm sure I can get what I need. I've never ordered custom pistons or tried to substitute different rings in an engine before. Looking at articles on thin/low-tension rings, it seems that there are a LOT of considerations and questions, most of which I don't have answers for, and the articles make it sound like you really need to know what you're doing and be prepared to experiment a lot, but I have a feeling those articles are geared toward racing applications, where folks are really tricking out their engines and trying to squeeze every last drop of power out them. There are considerations about gas ports, compression heights, ring coatings and many other details, but again, maybe these are not such an issue for a mildly hopped up street engine. How did you decide on these aspects? Of course, in talking with others, I've come to realize that modern production engine rings are not necessarily low-tension rings. I had just figured they were, since they are lower tension than the ones originally used in our engines. I'm a bit nervous when it comes to ordering something that will work well, but maybe it's not a big deal, and just a matter of buying rings for a modern reliable engine from a reliable ring supplier and let the piston supplier figure out some of the details. Any advice you can offer would be appreciated. I'd really like to do this, but if there is anything risky about it, I might avoid it.

-

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Well, that's a good point you guys are raising. Never thought about that starter interference. The engine is going into a '49 Power Wagon with the original pedal starter. I guess I'll find out at some point. I have a full-flow filter housing on its way (hope it's the right one - it looks right based on photos from the seller). It'll be some time before I have the engine assembled and mounted to the bellhousing, so I'll find out then. Although maybe I can take some measurements of starter length, filter size/placement before then and see if it looks promising. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Thanks again, folks! This is very helpful. I'm passing along all this info to someone I'm talking to about one of these units. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Thanks so much for the info! -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Hmmm...ok, it sounds like, based on Dodgeb4ya's post, that this p/n might not have been used on the six cylinder, but it might still be useable, if it bolts up to the flathead six block. Do you mind looking at your casting number(s) and posting them, or maybe posting the pics showing the casting numbers? -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Thanks. Do you have the part number for the housing itself (that the element fits into)? The housing was different between the flathead six and the V-8 (2-bolt mounting flange on the six and 4-bolt flange on the V-8)? -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Yes, they were available for certain blocks - the blocks with the diamond-shaped raised pad on the left side of the engine, just aft of the distributor. -

Full Flow Oil Filter Part Number and Applications

Matt Wilson replied to Matt Wilson's topic in P15-D24 Forum

Yep, my 265 is what I'm trying to fit with this filter too. Thanks for the filter element number and other info. Still looking for the housing part number. -

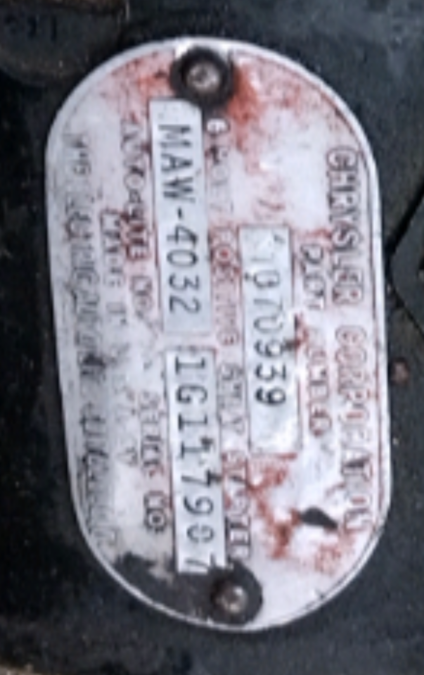

Does anyone have a p/n for the full flow oil filter housing that was used on the early 50s Chryslers, and a more complete list of vehicles it was used on? Was it used on any trucks? I'm talking about the type with two mounting bolts (not four), which mounts to the diamond-shaped pad on the left side of the block. See images of one example owned by the late Don Coatney.

-

Yes, absolutely, you don't want those sprockets to be misaligned... very bad way to run. I'll be sure to check what I've got first, before changing anything. Where did you get the shim stock? I suppose it can be found on Amazon, but maybe there are better sources.

-

James, I wonder if you have a later camshaft hub on your camshaft, paired with an earlier crankshaft or crankshaft sprocket. It was recently pointed out to me in a separate thread in the truck forum that there was a change of part numbers at a certain point in time. I have what I believe to be an earlier camshaft and sprocket hub and a later camshaft and sprocket hub in my possession, and they are nearly identical (and certainly appear that way visually), but the later hub is a little thicker in the bolt flange than the earlier one, and this seems to result in a greater distance from the back of the thrust plate to the front of the hub flange, by about 0.010 -0.012". This would place the sprocket forward by that amount. Is this about the amount you had to use when shimming, in order to get the two sprockets to line up? I'm putting together a later block and cam with what I think may be an earlier crankshaft, so I'm wondering if I'll need to swap hubs from the earlier cam to the later cam to get the sprocket spacing correct. Of course, I'll do a test of the parts as they are currently before making such a swap, but I'm trying to get a heads-up to be a little more informed. Thanks.

-

As Merle said, I doubt it matters whether the sprocket has square or round valleys, as long as the chain and sprockets are matched to each other. I have sprockets that are square bottomed and others that are round bottomed (different engines, but both flatheads and they worked fine). I have pics of a double row crank sprocket with square bottoms and another with round bottoms. Í just got a new phone and am having trouble posting them, but let me know if you want to see them and I'll get them posted. Oh, and I'm the guy Merle was talking about who was having trouble with the mismatched timing set, so I've gained some familiarity with these parts. Still working on that, but I'm sure we'll get it worked out.

-

Uh-oh, good thing you mentioned that. I didn't order a different cam hub when I ordered my timing set a few years ago. I'd better check to see if my old one that was boltwd to the original single-row timing set will fit the new (NOS) double-row cam sprocket. Thanks for pointing this out!

-

Yeah, that's a good idea. I've already contacted the vendor who sold me the parts I have, but meanwhile, I'll look up Melling to see what I can find.