bkahler

Members-

Posts

1,947 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Yes, the pipe does stick up into the manifold, by about 1/4" to 5/16" or so. I'll check the local parts houses to see if they have in stock. If it's a better fit around the pipe itself it might worth trying. Thanks for the part number. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I think therein lies the problem. It looks like the new down turn was built to handle up to 2-1/2" pipe so the opening is straight (parallel?) to the tube and not tapered. So the donut likely won't do the job either. Yours's sounds like an interesting arrangement. Finding a gasket for the original rear dump was easy, finding something appropriate for the front is a different story. The gasket I'm using at the moment is 2.16" ID which leaves 1/16" gap between the tube and the gasket. The biggest problem I see is the thin width of the flanges themselves. I think they are about 1/4" which is not a lot of material when you're dealing with hot exhaust gasses. I guess the good news is the pipe does stub up into the down turn which should help the situation. I guess we'll know once I start the engine. -

Nice! Know anyone that is reproducing in steel the 51-52 rounded rear fenders?

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I was doing a little more digging into exhaust gaskets and I'm wondering if maybe a gasket like this is what I should be using on the front down pipe? -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I can see where side to side flex could take place and with an engine that rocks slightly in it's mount, that makes sense. I doubt engines move much front to back, at least they shouldn't anyway ? I don't think the fixed mount would work well with one of the Power Wagon twist frames! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

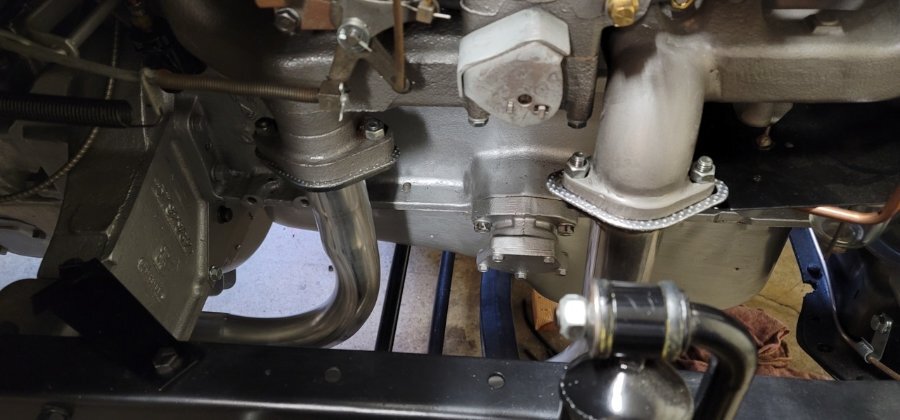

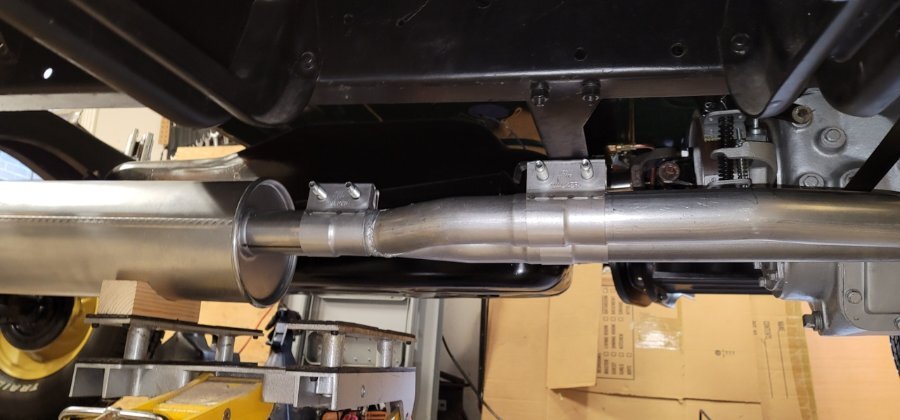

I spent a little bit of time yesterday tinkering with the exhaust system install. The front manifold down turn fitting is really kicking my butt. It's a really odd size and I've not been able to find any gaskets that fit properly between the pipe and the manifold. Here's a picture of the opening on the manifold. I'm a little concerned about how little metal there is for a gasket to be sandwiched in. The down tube flange is considerably wider as shown in the pictures. I'll keep looking but for the time being I've installed what I have and I'm moving forward with the rest of the install. I'm basically done with the down pipes, and the muffler portion and am currently working on fitting the tail pipe and adding hangers. DCM sent along three flexible hangers so I'm working the best places to install them. As I was researching exhaust system installs I looked at Mark's installation and it appears his rear mount is a fixed bracket and not flexible. Was the original exhaust system hard mounted throughout or were there any flexible hangers? If it was all hard mounted how does that work with an engine that was soft mounted? In my stash of parts I have a hanger similar to the ones shown above although it has been mangled pretty badly. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Painting is more or less at a stand still due to cold weather but I'm making some progress in other areas. I did get a couple of new exhaust flange gaskets but I will still need to elongate the mounting holes for the front down pipe but at least it fits over the tube. I'll tackle that issue tomorrow. In the mean time I started the process of replacing the two angled bed rails that are spot welded to the bed sides. Some of the holes were burned out with a torch or torn at some point by previous owners. Having found correct replacements I wanted to replace them. So I finally got a chance to use the spot weld cutter I bought probably 25 years ago! It took me about 1/2 to get this far. The other thing that I will need to do is figure out how to straighten the side walls. This one is pretty decent along the top tube but down where the angle gets fastened to the bed wall it's out by about 1" or so. I'm not sure about the other one but I thought one of them was fairly straight and the other had a curve to it. I should have the bed wood in my hands in a week or two so hopefully I'll be busy milling and cutting it to size in the near future. -

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Well, the gaskets arrived and.......they don't fit The description said 2" but they measure 1.9 inches and don't fit over the pipes. The pipes measure about .002 under 2". I don't know why manufacturers/sellers can't get their information right. It's frustrating as all get out. With luck I'll track down some tomorrow. So much for plan B, now it's plan C time. -

Wow! That was way to subtle for me to have been able to figure out ?

- 717 replies

-

Well, that's about the only thing these old eyes see as being different. You've seamed things slightly different between the two doors but the end result comes out the same. That's it, I've shot my wad......

- 717 replies

-

- 1

-

-

In my own words I would describe the above arrangement as somewhat of a cocoon where the seat is a self contained device with seat and seatbelt built into sort of a pod. At one time I had seats from a Mazda Miata for another project where the seat rails contained the mounting points for the seat belts and the shoulder portion was part of the upper seat back. If I remember correctly the mounting bolts for the seat tracks to the floor were in the 3/8" (10mm) range. If you are concerned about mounting bolt sizes being to small couldn't you just increase the size to 7/16" which seems to be the standard for aftermarket seatbelts? I think (but not totally sure) that the mounting bolts for the seat tracks on the trucks are two 5/16 bolts on the front bracket and two on the rear bracket for a total of 8 bolts holding the seat tracks to the cab. The tracks themselves are held to the brackets with two 5/16 bolts each. I think after having this discussion I'm going to fasten the seat belts to the cab floor with reinforcing washers. This seems to be the accepted practice and keeps me from having to modify the seat frame in anyway. I guess sometimes simple is the best approach Thanks! Brad

-

The cutout on the blue panel is slightly different than the cutout on the red panel. Do I win the prize?

- 717 replies

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The exhaust flange gaskets are supposed to arrive today so I believe the exhaust system will be complete sometime this weekend. Stay tuned..... -

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Thanks! I'm hoping the final install will have the tail pipe closer to the frame rail which would uncover both holes but at least I know which one I can't block. My truck didn't have the hanger when I bought it, I had to scrounge through several junk yards and talk to Larry Frank to get all of the parts I needed.\ -

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Quick question. I'm really close to finishing the muffler and tail pipe installation and I noticed that there are two holes for the spare tire hanger bolt. For 1/2 ton trucks which hole is used? The last thing I want to do is block the hole with the tail pipe! Thanks -

While I'm pondering whether to mount to floor or seat frame I'm curious how many of you use retractable lap belts vs non-retractable lap belts. At the moment I'm thinking non-retractable. All of the retractable lap belts that I've seen require the use of plastic sleeves to keep the ends of the belt up high enough for the driver/passenger to reach them. That just doesn't seem like it would be to convenient to me. The reason I haven't made up my mind on whether to mount to the floor or the seat frame is due to the anchor point required. The anchor point might be to far behind where the seat tube is located. There are things I can do to overcome that but in the end is it worth the effort when all I really need to do is drill four holes in the floor board?! ? As you can plainly see, I have WAY to much time on my hands at the moment

-

? About the only air bags you could fit to a Pilothouse would be some bags for the cab to ride on.....?

-

The addition of a fore-aft support makes sense and probably wouldn't be that difficult to add. I will need to make my mind up soon as to whether or not I want to go this approach because I'm scheduled to take the seat frame to the painter Friday! I'm not sure about the 2 additional mounting points to the cab. The seat frame has to be adjustable fore and aft. Yes, this would only be for lap belts. I think if an accident occurs that is violent enough to rip the seat frame from the cab will likely be violent enough that I won't need to worry about much after the fact. Having been in a high speed roll over (2-1/2 flips) and walked away from it I'm pretty sure if an accident like that happened with this old truck the results would be considerably different. There's a lot to be said for the safety features in modern vehicles.

-

If I remember right the stock GM mechanical pump puts out around 6 psi. The surprising thing is on a 31 foot motorhome it's pulling from the tank which is about 20 feet away. That's a long stretch for a mechanical pump to suck fuel from the tank, through an electric pump no less when the pump is off. The real reason for the addition of the electric pusher pump is for grades. The engine requires so much fuel the mechanical just can't keep up.

-

I should add I think the return line concept is an interesting one. I have a 1994 Cushman Truckster that has a little 22 hp motor using a Walbro carburetor. It came with an electric pump and a return line setup from the factory. The fuel filter itself had the return line port which makes for a very simple arrangement.

-

I'm curious as to how you would implement a return line? My assumption is a return line needs to be directly fed into the tank which means you would have to add another port to the tank. Is there another way to run a return line?

-

This is not true. I know of many motorhome owners who have the Carter P4070 pump on their motorhomes and they only turn the pump on when they approach a grade or when first starting the vehicle. Normally they just rely on the mechanical pump for operation. I don't run my pump that way but it does indicate that you can pull fuel through the Carter pump when it is turned off.

-

Recently I've been prepping the seat frame and seat tracks for installation in the cab. While looking at the seat frame it occurred to me that a possible location to fasten the lap belts would be the rear lower horizontal cross tube. The reason I bring this up is I was recently working on my motorhome and it came to me the seat belts on the dodge truck could be mounted similar to how RV seat belts are installed. With the RV seat pedestal the belt is attached to the the horizontal bar. If the seat assembly is separated from the vehicle the seatbelt stays with the seat. I guess in my mind I see the horizontal tube on the dodge seat frame being equivalent to how the seat belts are fastened on the RV seats.

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Just got a text from the upholstery shop. Seat cushions are ready to be picked up! If weather holds I hope to pick them up Friday or Saturday -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I finally managed to weld the two flanges to the down tubes yesterday. For some reason my camera didn't focus very well on this shot. Probably because the welds aren't some of my best I suppose the good news is that you can't really see the welds once they are installed ? I went to install the pipes and found the gasket that was sent with the kit was not correct for the front pipe. The front down turn on the manifold is kind of an odd size so I ended up spending a bunch of time searching for one that will work. I think I found one and it's on order but I don't know when it will arrive. Hopefully by the end of the week.... In the meantime I'll go ahead and assemble the exhaust system so I can figure out the muffler orientation and hanger locations.