Search the Community

Showing results for tags '218'.

-

Hi everyone, I am new to this board. I have purchased a 51 Plymouth Cranbrook Belvedere with stock 218 flathead 6 that I will be trailoring home next month. I've been scouring the internet looking for ideas on a dual carb, dual exhaust setup for this engine. I have seen people using everything from weber 32's, to strombergs, to holley 94's, to 9 super 7's for twin carb setups. I would prefer to stick with a pair of carter ball and balls to stay true to period. I see the offenhauser dual carb manifold available on summit racing with two hole flanges which appears to made for original carter carbs. I am looking for the right pair of carter ball and balls to pair with this engine. My homework tells me I need two single barrel carbs which are approx 125 cfm's apiece based on the amount of air the 218 is capable of sucking. I didn't a picture of the stampings on the existing carb, but it looks like this car would have rolled out of the factory with either the Carter BB D6H1, or D6H2. Just looking for advice on a pair of Carters for this setup, I don't want to be running rich, want to be right in the sweet spot. I cannot find any technical specs on any of the old Carters on the web anywhere, if someone has a pdf file or link on this can you please share, or just let me know what has worked/hasn't worked from personal experience. Not looking to get performance crazy, just looking for a modest step up in performance. I may add an aftermarket head for a modest increase in compression at some point down the road. I'm at 7100' above sea level which means I'm already losing HP, and will need to run smaller jets than most of you. I want to stay stock but will need every ounce of HP this engine can make, without spending thousands of dollars on boring cylinders, performance cam, etc. Thanks in advance, Greg for SW CO.

- 37 replies

-

- carter

- ball and ball

-

(and 5 more)

Tagged with:

-

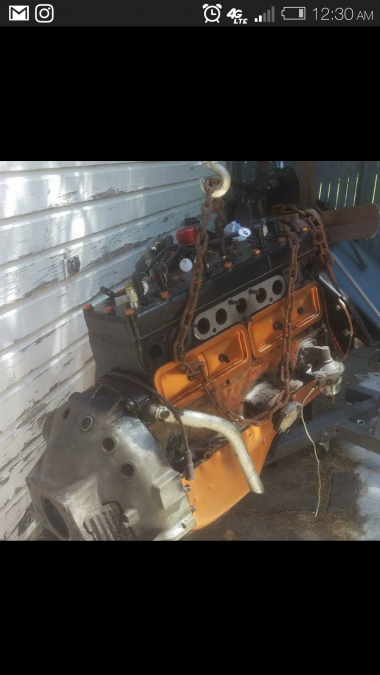

So I've started working on my next project - a '52 Plymouth Suburban. It's in remarkable shape except for some small rust-through spots under the accelerator pedal. My plan is to use a working P20 218 I recently purchased for $300 (local Craigslist), mated to a TH200-4R automatic overdrive transmission (also Craigslist). The guy I bought the motor from had it set up that way on a '50 Plymouth wagon, using a Wilcap Adapter, which came with the engine, and said it ran great. He felt that he wanted more power, so he pulled it and replaced it with a SBC. The 200-4R is an overdrive tranny and from my measurements, I don't think I'll need to modify the firewall. I will need to add a support for the rear of the tranny, however. In order to get the most hp/torque out of the 218, I plan to run the 2bbl carb NiftyFifty recently posted about, with spilt exhaust and electronic ignition. I also plan to shave the head, and I've been told I could boost the compression ratio even more by using a thinner head gasket. In looking on ePay, and the usual vendors, thickness is rarely if ever listed. I haven't found a gasket reference chart to compare. How can I find a thinner gasket, and is it really worth the trouble?

- 10 replies

-

- compression ratio

- wilcap

-

(and 6 more)

Tagged with:

-

Checking my brakes and with the front wheel off I find a couple bolts partially unscrewed. They don't appear to be holding anything, so why are they there?

-

Hello all. My name is André, and i live in Switzerland. The original 218 engine of my 1947 Plymouth special deluxe is broken. My plan is to install a 230 engine out of a 1950 Dodge with fluid drive, and keep the bellhouse and standart 3-speed transmission of my Plymouth. I 've heard there are problems with flywheel and crankshaft. Does someone knows if this is possible? Thanks in advance

- 35 replies

-

My 51 dodge two door originally came with a 230..thinking it was bad I replaced with a 49 Plymouth 218...now piecing it back together I find the bellhousing doesn't reach the cross member!! Do I need a 230 bellhousing ??? ..are they different??

- 20 replies

-

- 1949plymouth

- flatheadsix

-

(and 1 more)

Tagged with:

-

Hi everyone - looking for feedback on my recently acquired '51 B3B pickup. Not sure the last time that it had run - but on compression test the #2 cylinder I'm getting nothing from (absolutely 0). the others are all around 85 to 110 PSI. Looking down the spark plug hole I do not see anything moving when I crank over the engine (which I presume I'm looking at the cylinder? v's a valve) Depending on costs to repair I'd be tempted to switch out to another frame / engine combo - but checking in to see if I missed something easy / cheap to fix thanks, Jason.

-

Hello there, I come here seeking wisdom on a possible starter issue. I would like to apologize in advance for my lack of technical terms, but I will try to explain myself the best I can. I took apart my Plymouth's Starter this week, I noticed the pinion gear had flywheel marks all along the side on the gear on it's housing. I feel as if the pinion gear bottom housing is hitting the flywheel when it engages, but this might just be normal. One thing I noticed is the "worm gear" the pinion rides in has a "lock" that prevents the pinion from retracting once it rides out past a certain point, as if locking the gear in an engaged position. When I bench tested the starter the pinion got stuck in the engaged position, I had to take the pinion assembly apart in order to retract it. What was the purpose of that design? I took the starter out after my car was not turning over consistently when trying to start but with the starter removed the engine turned by hand, I had the battery charged but was not satisfied. The brass bearings are very worn out and are being replaced and one of the field coils has a rip on its cloth tape, may have been caused by the worn bearings. I am thinking that those markings mentioned earlier may have been caused by the worn bearings as well. any knowledge on the subject is greatly appreciated.

-

I took the flywheel that came off our 1946 P15 Plymouth Club Coupe project, over to a highly recommended differential clutch and gear machine shop that repairs the majority of older flywheels here in the Dallas Ft Worth Tx metroplex area. Super nice bunch of folks, incredible busy bunch - my gut impression was really good and my understanding is they've been there for over 25 years, anyway - Reason for getting with them is to have the flywheel re-surfaced and to replace the ring gear. Immediately upon looking at the flywheel - he asked how many miles were on the car. (the odometer reads 44,000 and some change),....he said I need to know if that's supposed to be a flat or a step flywheel, as he pointed to the round depression area (exactly where the clutch rides) on the flywheel surface. (I measured this lower surface area where the clutch rode in relation to the flat outer surface of the flywheel, with the slide rule end of a set of dial calipers, and I get a depth measurement of 24 thousands lower then the outer flat surface area of the flywheel. Their machine shop books did not go back as far as 46-48 so he wasn't able to look it up in his documents. But in looking at the lower circular area he stated that it would seem like an abnormal amount of wear for a car with 45K miles, so his guess was that this flywheel was a two step flywheel and not a flat flywheel that could possible have that much wear. Obviously I'm not much good here - except to show what details I have been able to put together, which are as follows: ###note### just an fyi - This car came from a car collection in Louisiana. So far in dis-assembling the car (and I've got it completely taken apart except for the frame and suspension), it has been a 100% original oem part car...course that still doesn't mean that this flywheel couldn't be a step child - but I would have to think the odds are in my favor, (initially, I had thought the rear motor mounts might be something odd but the more I've studied them I think they were just so badly deteriorated and squashed that they looked wrong at 1st eyeing them, the more I've studied them I believe they were also original). 1: 1946 Chrysler Corporation, Parts Division, Parts List Book, shows oem starter to be pp# 1113 119, (this is a match for the starter on the car) 2: " " " " " " " flywheel to be a PP# 1119 716, (the only numbers I can find on this flywheel . are a (2) and a (13) as shown in the casting, see the following 2 pics... . , 3: This car does have the standard 9 1/4 " clutch, however you can see in the pictures that the flywheel is drill and tapped for the 9 1/4 clutch basket, as well as what looks like the larger 11 " clutch basket. , . 4: The lower, round surface area of the flywheel - where the clutch rode in relation to the flat outer surface of the flywheel, when measured with the slide rule end of a dial caliper, shows a depth measurement of 24 thousands lower then the outer flat surface area of the flywheel. I'm trying to rule out the possibility that someone has done something (C R E A T I V E) here , regarding this flywheel - but obviously my knowledge isn't sufficient to know or see what might be going on. Any of you 1946 - 48 P15 guys out there who can shed some light on this,....your help is needed and greatly appreciated. QUESTION: Did the 46-48 Plymouth's have a two step flywheel ? Could they have a two step flywheel ? etc.. Thank you all so very much. If I never received any further help from this forum, I would still consider it in nothing but a positive light. The help sent my way to date has been second to none. I've certainly gotten more than my share of help and I will definitely try my best to hold up the standard set by the folks here on the forum, and try to help others in the future as my knowledge grows, again with and thanks to the help of YOU ALL. Steve Gentry

-

hey guys i decided to start a new subject my old one is kinda dead now. so as you all know i have a 1950 b2c with the 218 l 6. i finally got it to run rebuilt the carb today and it wont stay running for more than 5 minutes but still ik it will run once its really hooked up. but now that i have an exhaust system installed on it somewhat. its more quiet at the engine and i have noticed two things. crankshaft pully wobbles a lot. and theres a ticking coming from inside the valve train. so i started the engine and ran it and the weird thing is none of the lifters are stuck they all move freely with the engine running i was actually able to spin the lifters with my fingers they seemed to spin pretty freely is that what the should do and i dont know if the engine is supposed to do that i mean its a 1950 im sure the lifters werent dead silent but any help would be greatly appreciated. all valves open and close i dont have the tools to adjust them and not exactly able to run it long enough to get the engine to temperature. so if they are supposed to spin freely like that when the engine is running what could be making the ticking? i used an oil gun and sprayed thick oil on the lifters and it didnt silence the ticking at all they look like they are getting lubricated. ive been having oil passage problems so im scared to run the engine to long i dont want to break it. basically my oil gauge reads 40-50 and when i unplug that line it spurts oil but when i unhook the line to my oil filter the return and the supply nthing comes out of those two lines so i dont know if just that passage is clogged or something else is. you see if this was an earlier engine the info would be available but like my dad said it being a 1950 and a chrysler we just dont know too much about it. so if you could give me info and tips on how to chase the tick and adjust my valves and just any info you can really. i need every ounce of knowledge i can get!!! thank you all so much ill try and get a video of it maybe and post it or post it on my youtube so you can watch and listen also my enghine has some pretty bad sludge whats a good additive to remove all that??

-

Hello all, I am new to this forum and new to flathead engines. I have just purchased a 1939 Plymouth P8 Deluxe and getting started on what will no doubt be a learning project. The car is all original and in good shape for its age. I have done some research and found the engine is a 201, 'P8 369589'. I have not heard the engine run but the seller told me it did however he heard what sounded like a rod bearing tapping. I thought I would swap it out for a 230 but am having a very difficult time finding one, so I tried a 218, those are hard to find as well. Just the engine anyway, I have even started looking at other project cars to buy just to get the engine. So - I have been thinking about rebuilding the 201 that is in there. I understand that it can be made a 218 by using a 218 crank and rods. Plus I would bore the cyl out 40 over. I have come across a few websites that I can get these parts from so it seems to get a little more power and since it needs rebuilt this would be about the best way to go. I am not looking at smoking the tires or high speeds, just cruising at about 60-70mph on the weekends down to Galveston. Putt around town here. However this is Texas and it would be great if I could get some AC going on inside. I have researched a place in Houston that advertises they do that sort of stuff. So I am concerned about running a compressor on it as well. Anyway I'm kinda stuck wondering which direction to go, I would like to get a 218 or 230 but if I can get by just doing an overhaul on this engine then it seems the best route. If anyone could offer some advice, will the 201 work for what I need? Is there any 218 or 230 out there? Thank you. Lloyd

- 99 replies

-

I am getting ready to build a 218. My intent is to boost, using a turbo. I am considering using the stock exhaust manifold and stock intake, but the plan is to port and polish to open it up some. I can force feed the Stromberg, with some jetting adjustments, or I could pull through a Holley 2 barrel. I have seen TurboStude, and am pretty inspired to something a little different from the same ole upgrades to a Mopar flat six. I will run 5-8 psi, but would like some input/thoughts on which turbo would be the best size/fit. I am aware that diesel turbos are very different from gasoline turbos. My first thought was to use the classic KKK K26 from a Mercedes Benz 5 cylinder 3.0L TD because they are cheap and easy to find at a P-n-P salvage yard , but do not know if it will boost/spool the same as a gas burner. Perhaps a Volvo turbo would be a better match? Let me know your thoughts Mark in NC

-

After a busy couple of weeks, I'm back to Special D. Despite my earlier panic and confusion about the engine, you guys hit it on the head with stuck valves. I've finally got my intake and exhaust headers off and am trying to get the valves freed up. I was lucky with almost all of the bolts. One bolt had threads screwed up with the nut coming off (galled?) and I'm going to have to replace that. Most had 'dry rust' on the threads and squeaked coming out, but nothing totally frozen. Bolt on the tail end of the exhaust header was apparently broken in the past and there was just one bolt in place. Interesting. There were also only three bolts in the heat riser, as apparently one was broken off in there. I'll have to see if I can Easy Out those. Several questions . . . The valve access panel inside the right fender well . . . Is this thing supposed to slide out relatively easily? It seems to have a hole in the upper/forward corner of the panel, that a bolt goes through. The back side of the bolt WOULD be accessible, in a car without a heater. Without a slot there, I have not been able to get it out. So it's 'rolled' forward, toward the bumper. The stuck valves . . . Is it common/expected that it's the INTAKE valves that are the ones that are stuck? Here's #6, #5, & #4 And here's #3, #2 & #1 I'm spraying "PB Penetrating Catalyst" on the the upper end of the valves/guides in hope of freeing them. Is there any tapping or prying I can do on the lower end of the valve stems? I squirted Marvel Mystery Oil in the plug holes last Saturday and ran it through several revolutions; most of that seems to have ended up in the intake header. Header bolts . . . How do you back one of those out of the block to replace it? Vice grips and crank on it? Heat riser is frozen and I'm trying to work on that while I'm at it. More penetrating oil. I've been alternating PB, Marvel and some scraping and tapping. Spring is good. Little 'bell shaped' washer that keeps it from rotating on the shaft is a goner. Have to see what I can fabricate. Thanks again for the help. Cheers! John

- 14 replies

-

- 218

- heat riser

-

(and 2 more)

Tagged with:

-

so first of all, i have a 52 dodge truck b3b, with the original 218 and 3 on the tree. resently i did the conversion from 6v to 12v. i changed the battery to neg. ground, the ignition coil with an exsternal resister, a delco 10 si alternator and got new voltage gauge cause i blew the old one. after doing everything truck starts right up. it started maybe 10 times after the switch. but know when i turn the key the voltage gauge says 12v, when i push the button to turn the engine the volage drops to almost nothing. wft? could i have alread y blown the 6v starter? or maybe the distibitor? i dont know. all help would be greatfully apperiated. man i wish this thing had spell check.

- 7 replies

-

- 218

- conversion

-

(and 3 more)

Tagged with: