-

Posts

1,646 -

Joined

-

Last visited

-

Days Won

8

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by falconvan

-

Not a lot of car stuff done today; I had a big list of honey-dos since we're doing a family BBQ tomorrow plus it was really hot out. I did do a trial fit on the intake. A few things you have to do to turn the intake to face the front is to grind the EGR passage off the intake, cut the top lip off of the timing belt cover, and put some 1/2" spacer plates under it. I've got a water jet guy cutting the spacers, the other two items are done. Looks like it's going to fit in the firewall just right.

-

Possible Drivetrain Swap 48 Plymouth 4-Door

falconvan replied to jrodenbucher's topic in P15-D24 Forum

Id have to agree with Arthur on the front end. I've seen a 47 with a Camaro subframe and it wasn't pretty. The frontends on these are good, just relocate your upper shock mount from the A-arm to the frame and rebuild what needs it. As far as using an SBC; should be easy as long as you can weld, fabricate some mounts, and possibly handle a little firewall surgery. I've seen several of these old Mopars with Chevy motors.- 14 replies

-

- Drivetrain

- P15

- (and 5 more)

-

Good looking old beast, I'll bet it has some stories to tell. Enjoy!

-

Thanks, Paul; but Im no better of a builder than any of you other guys. Everyone on here does some fine work. As far as completing; just stay organized and tackle one task at a time.

-

I got the firewall roughed in yesterday using 18 gauge sheetmetal. I ended up cutting a couple inches higher for more clearance. For now it's just tacked together; I'll make it neat and paint the firewall when the engine comes out for cleanup.

-

Pretty righteous deal for only four bills. I wonder what freaks him out about CL? People who buy from there aren't any crazier than anyone else.

-

Still not sure; I'll have to build a raised section but haven't decided whether to bolt or weld it in.

-

Crazy, I thought a Vette would really be light! Got the tank finished and mounted today. Im not real happy with the way the filler came out; it's sticking out too far but I'll address that later. I cut a section out of the trunk floor and will raise that section a few inches to give me clearance for the sending unit, fuel lines and wiring. I also bought a Wilwood MC for the clutch with a remote mount resevior. I built a bracket for it and have it mounted to original clutch pedal after putting a longer pin in the pedal arm and reversing the direction that the pin went in. Looks like it'll work; I threaded the pushrod, cut it in half, and put it back together with a coupling nut to give me about 1 1/2" adjustment on the rod.

-

That's a really nice color; fits well with the year of your car.

-

I finished up the welding on the tank and as a precaution I put a coat of All-Metal body filler over the welded areas. Also here is the Taurus fuel pump/level control assembly; I fitted it with a new Carter pump and replaced the stock level control with the one for the aftermarket gauges that are in the car.

-

Makes sense to me, plus a shorter wheelbase and lack of all the power window and seat motors probably account for some of it.

-

Found this interesting; I was checking the specs on both cars today: 1949 Plymouth P18 Business Coupe--GVW 2983lbs 1994 Taurus SHO Sedan with auto trans--GVW 3503lbs Who would have thought the old 49 would be 500lbs lighter?

-

I hope so, too. I dont want this to be an all winter project; I'd like to have it back on the road in a few months. Funds are the big thing; seems like parts for this little six are pricy. There's a recommended 60k mile tuneup for it; I'd like to take care of all that stuff before it gets bolted in place permanantly. Plus I need a new clutch set, radiator, exhaust system, driveshaft, computer mods, a few custom parts I had to farm out......it starts to add up pretty quick.

-

Thanks! Usually when I weld a tank I mix up some All-Metal body filler and go over the welds on the outside and then a coat of paint. I've done a few that way and haven't had and issues.

-

I got everything together and welded up today; just need to add the overflow tube and it's ready for a coat of paint.

-

While Im waiting to get my header flanges back from the water jet guy I decided to address the fuel supply. Both the SHO tank and the Plymouth tank are the same depth so to simplify things Im just going to transplant the fuel pump from the SHO tank and fit it with the Plymouth sending unit. I'll also put this baffle from the SHO tank in the bottom. Today I took the SHO fuel filler with the overflow line and shorted it up so it will fit the Plymouth tank location; and I'll change the tank inlet to match the size.

-

This was much easier than I thought; one wedge cut and the steering clears fine. No internal interference as far as oil pump pickup or dipstick; all I have to do is find someone that welds aluminum to patch in the notch for me. On another + note; it's really clean inside and looks like it was well taken care of.

-

Looks good! What color are you going with?

-

Bummer! Is it in a place you can reach it to put it back in?

-

We've certainly had our share of rain, Tim. It's been a weird summer; unseasonably cool, too. I've just been really lucky with time lately. Work has been smooth so I haven't had to spend a ton of extra time there and my wife does a lot of things with our church women's group so I've had the time to work on it.

-

Thanks! Finished the crossmember and got it back on its feet tonight. Now I have to notch the oil pan for tie rod clearance, build some headers, and figure out how to mount the clutch cylinder.

-

Got motor mounts built today; not the prettiest things but it's solid and level. Once I grind a few crappy welds and throw some paint on them, they should be fine. For insulators I used the rubber biscuits that were the trans mounts for the flathead; worked out great. Tomorrow I'll build a crossmember for the trans and then the drivetrain will be self supporting.

-

I'd go with the Explorer setup. Easy to do and all parts either boneyard or regular auto parts store.All you need is someone to cut out the brackets out of 1/2" steel plate for you.

-

Will do; I hope to be building motor/trans mounts within the next few days. I got a set of 3.8 Mustang headers last night; the flanges are different but with some modification I should be able to make them work. That's the three biggies for now; mount the drivetrain, make the exhaust work, and alter the oil pan to fit around the steering link. Once those are done the motor/trans can come back out for some final prep.

-

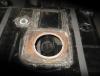

It's looking better; I cut out part of the firewall to move the motor back. I'll box it in once everytning is where is going to stay. I took the oil cooler off and I could just screw a filter there and be ok, but I think Im going to use a remote mount so as not to have the oil filter right above the starter. Drivers side wiill definitely need some fabrication on the header. This is right where I want it to sit so now it's time to build motor and trans mounts and figure out how the oil pan will have to be cut for tie rod clearance.