bkahler

Members-

Posts

1,951 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

On my B3B the rivets are on the doors only and yes, they are rivets. The top hinge on the A pillar has a nut plate welded on the inside of the cab and the hinge arm bolts to the nut plate. The bottom hinge actually uses the hinge itself as a nut plate and is captured between two sections of sheet metal on the A-pillar.

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I've got a question about the gasket between the transmission and the floor cover plate. I bought the gasket from Roberts and it's advertised as going between the transmission and the floor cover. The gasket itself is somewhat pliable but it's going to take some pressure and possibly some carving of the inner diameter to get it to fit. Anyone used this gasket before and made it work? -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The only container I could find big enough to hold the pumpkin required two plus gallons to even get close to the top of the housing. While it was soaking I decided to take advantage of the fluid and added a bunch small parts to the bath. Amazon is delivering a 3rd gallon tomorrow at which time I'll remove the small parts and lay the pumpkin on its side. -

Did that set the tone for what was to come?! Do you have a parts manual for your truck? I don't think I've ever worked on or restored a vehicle that I didn't have the parts manual for. It's possible the parts manual might give an indication as to whether it's screwed in or pressed in. My vote is it's pressed in. I don't recall anything like that on my truck. There's just a lot of slots to make things adjustable. Looking at the pictures you posted the hinges on your truck look just like my B3B. If you look at my attached pictures you'll see that the top hinge pin has splines where it contacts the upper section of the hinge. The rest of the pin is smooth and is a slip fit in the bore. There are no nuts that can fall down and get lost. Just unbolt your hinges from the A pillar and take the doors off. You'll notice I never removed the bottom hinge pin on my doors. That might be something I have to deal with in the near future but then again, maybe not

-

I thought you might get a kick out of this on ebay

-

Well, it's been 24 hours since it popped.....any updates ?

-

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I believe that is correct. It's currently soaking in Evapo-rust. I'll give it a day or so and then take a look at the progress..... -

Some places I've lived I couldn't find a welder or fab shop within 50 miles. Other places, like here in Richmond, I've got an old time machinist 4 miles up the road, a fab/welding shop 7 miles away and mirid of other handy outfits within 20 miles. Oddly I can't find a starter/generator repair shop anywhere! In bambabmshere's situation I'd try to find a local shop. Even if he spends $200 on mounts he's money ahead and can use the other $800 on parts for his truck. As much as I like to fabricate things sometimes it's just easier to have a professional do the work and move on, I do that from time to time. Don't get me wrong, I've got a mill, lathe, 3 or 4 welders and heaven knows how many other tools and know how to use them. Each situation is unique. Only bambabmshere knows what's best for his situation. Brad

-

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

You're getting into areas that I currently know nothing about. I'm really hoping to keep this diff, it's original and it's a 3:73. First I'm going to try what Ken suggested which is soaking it in Evapo-rust and then washing it off. Until I've got the junk out of their I'm leery of just blowing air through it. I'm hoping to pick up some Evapo-rust this morning along with a bucket. It's going to be raining all day but the temps will be in the 50s so running a garden hose won't be to intolerable Thanks! Brad -

-

? ? California is a long way to go just for a dust cap!

-

Do you suppose this is the right Spicer dust cap ?! I'll know in a few days, I just ordered one JB's going to be disappointed because I won't have to blacksmith anything ? Brad

-

Thanks! Great picture. Not to figure out what beverage can best approximates that profile ?

-

Bend over tabs makes sense. Did you use see the cap in the parts manual? If so I guess I didn't look hard enough. I'm sure I can get creative enough to make a cap although I think beverage cans are probably a little to large in diameter! The splines themselves are 1-1/4" so figure another 1/2" to match the diameter of the yoke, 1-3/4". Dang, now I'm going to spend the rest of the weekend looking at old cans ? Thanks! Brad

-

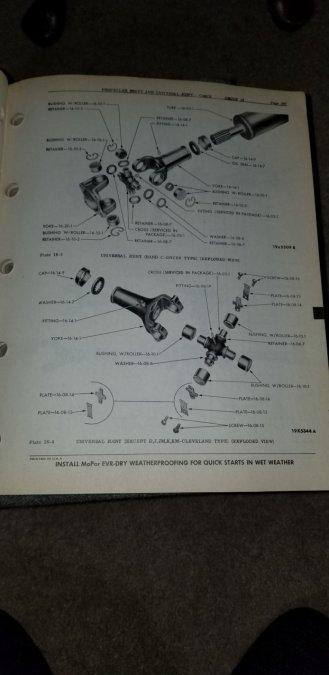

I think you might be referring to the u-joint end. I'm referring to the splined end. I'm used to seeing a felt seal and some sort of threaded metal retainer to keep the grease in and dirt out. This yoke isn't threaded so I'm a little confused.

-

I'm trying to find out if this particular Spicer yoke had a grease seal & cap on the tail end to keep the grease captured. So far I've not found any pictures showing a seal & cap. I would find it odd if there wasn't one there originally. Anyone have Spicer yoke like this one they can check? Thanks! Brad

-

512 cid C series on Dakota chassis- build thread

bkahler replied to Radarsonwheels's topic in Mopar Flathead Truck Forum

Very impressive -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Needless to say I really hope you're right! Time permitting I'm going to look a little closer at things and move forward from there. Thanks! Brad -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Last night I was browsing through an old Chilton's that I have and found a pretty decent one page write-up for working on the differential. -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Removing the dust/rust/ect has been my first thought as well. How long should it be soaked before flipping over? What is odd is back when I installed the pumpkin in the diff housing I don't remember it being this hard to turn. The point at which it seemed hard to turn was after I re-installed the axles and the backing plates. At that point I figured I needed to possibly add backing plate shims. So when I pulled the axles yesterday and found the pinion still difficult to turn I was somewhat surprised. I know what 20 years has done to me so I can only imagine how the truck must feel ? I'm not holding my breath but I am hopeful -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's good news about the crush washer, or lack thereof. I feel more comfortable working on it knowing that doesn't exist. I've got all of the tools you describe, except for the crayon Testing pre-load dry would explain why the unit is dry now. The only thing that worries me about using compressed air at this point is all of the powered dust/rust whatever it is that is coating various area. Thinking back to when I picked it up from the shop I don't remember it being as hard to turn as it is now. 20 years of sitting wasn't kind to it. Currently it's a two handed effort to turn the pinion. -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I do have the factory service manual and it assumes you've been trained. Unfortunately I haven't! I wondering if it's not something as simple as the opinion nut being to tight. I'll spend some time tomorrow evening to see if I can see where the tightness is. -

B3B differential rebuild - not as expected

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I can check the backlash but will first have to figure out how to do that! I've never worked on a diff before. However, looking closer there is a powdery dusty type substance on some of the castings and parts. My guess is it's the result of condensation buildup over the last 20 years. Aso there doesn't appear to be a lot of lubricant inside at all which concerns me. I'm thinking the best option is likely going to be to tear it down and just put it back together again, by the book. At least that way I will know what shape it's in. With that in mind I guess I'll dig through the service manual to see if it can educate me. Does this diff use a crush collar on the pinion or is the pinion nut torqued to a set value? Thanks, Brad -

Something just came to mind. Is any part of the pin extending below the bottom of the hinge? If so if this is even slightly mushroomed or bent it's not going to willingly be pushed up through the hinge. If it does extend past I would consider cutting the bottom off flush with the bottom of the hinge and then using a small section of 1/4" rod (1/2" long maybe) and us that to press up on the bottom of the hinge using your C-clamp method. I believe the hinge pin diameter is about .3125 or 5/16". Anyway, just a thought.

-

Probably a dumb question but what are you using as a penetrant? Some are definitely better than others. Kroil and PB Blaster are two of the better ones. After spraying you can tray smacking the side of the hinge with a hammer a couple of times, sometimes that little bit of vibration can help the fluid work it's way down inside. It's a slow process but don't give up just yet!