-

Posts

943 -

Joined

-

Last visited

-

Days Won

10

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Jim Shepard

-

Thanks!

-

I picked up a couple of B&B’s at the swap meet the other day and I can’t identify the vehicle(s) they came on. Hoping someone out there can. The numbers are: E6K4 and C6F5. Any ideas?

-

I’m doing the same thing except a triple carb setup. I’m going to have the flanges CNC’d locally and weld ‘em to steel pipe. Haven’t decided if I’ll do a “log” design like your illustration or something where each intake port has its own curved pipe and a smaller pipe connects the three intakes, making a balance tube.

-

I think these gears are extremely hard to locate now. I looked for several years. I ended up going with a 1997 Ford Ranger (same lug pattern) 3.73 axle. Other than re-positioning the spring perches it was pretty straight forward.

-

Has anyone here installed a dual chamber MC with remote reservoirs on a Pilothouse?

-

I was just re-reading a very old thread where George Asche and Tim Kingsbury were going to start casting dual and triple carb manifolds for the 25” and 23” flatheads. I don’t think they ever produced any of the triples for the smaller engine but they apparently did make some for the 25” engine. At one point in the development I understand they were considering the pros and cons of casting the bosses to accommodate the linkage for both a car and truck application. Don’t know if they actually did this but, if so, did anyone on the Forum actually ever put one of these on a Pilothouse truck?

-

I understand throat size figures into this but, generally speaking, does anyone know the cfm rating of the Carter B&B carburetor?

-

Great truck!

-

-

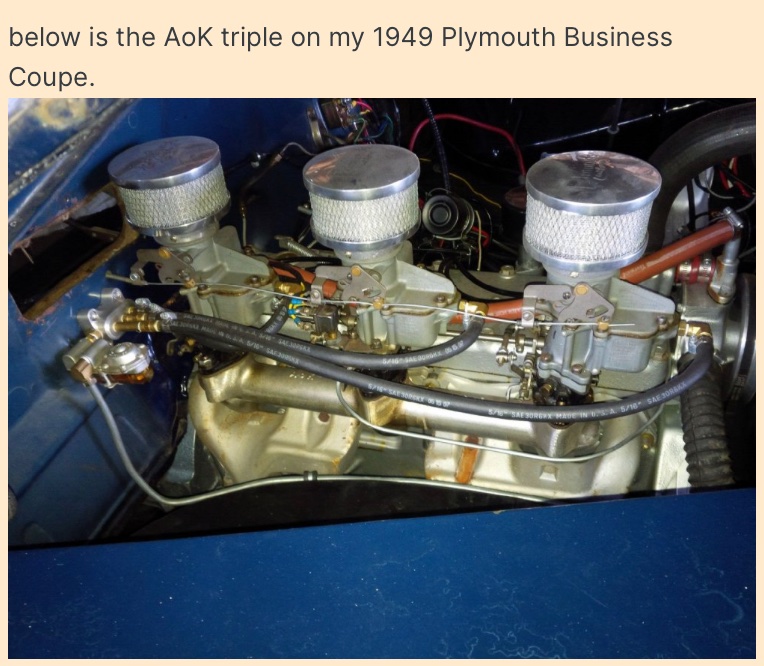

A number of years ago there was some discussion about the production of double and triple carb manifolds for the MOPAR flatheads. I think George Asche and Tim Kingsbury were involved. I’ve seen photos of both versions. One guy even posted this photo on this site of a AoK triple carb setup on his 1949 Plymouth Business Coupe. I haven’t been able to find anything more recent than about 2017 on this venture. Does anyone know what happened here? Did they go into production? Are they still in business? What’s the latest?

-

If you happen to find a set still on the truck, be very careful removing them. The nuts are almost always rusted to the studs and if you don't use a lot of penetrating oil and take your time (it took me about 3-4 weeks) you'll break them off. I did that my first time...

-

Don't know what kind of horse power your looking for and I did consider (even purchased) a "baby hemi" from a 1954 Dodge Coronet. These are 241 ci and the one I picked up had been previously bored 60 over. Never got around to mating it to a transmission but my choice would have been some version of the Torqueflite. Eventually, after a friend gave me a 230 flathead out of a 1956 1 ton, I went with that. I bored it 60 over, put in a mild cam with factory 2bb Stromberg and Fenton headers. Additionally, I swapped out the transmission for a Borg-Warner S10 five speed with overdrive and a 3.73 axle from a Ford Ranger. Eventually, I'll install front disc brakes. While not exactly a speed demon, it's plenty fast for my needs, which are mainly to stay out of everyone's way.

-

I did check with Scarebird and they said it “should work.” Not very reassuring…

-

Thanks. Clearance issues is what I was getting at. I knew the bolt pattern was correct.

-

Brent However, I did stay there…

- 99 replies

-

- 3

-

-

-

- bbq april 2nd 2022

- bbq april

-

(and 5 more)

Tagged with:

-

For anyone out there who’s using the Scarebird disc brake conversion: does it work with the stock MOPAR 15” 4.5” wide wheel?

-

Took the truck out for an extended spin. No obvious pinion angle issues so I think I'm good-to-go on the rear end conversion. I still have some vibration in the front when I get up to 55mph or so. That will be dealt with when I convert to a Mustang II kit.

-

My truck is a B2B so the pull handle is under the dash. No, the instructions did not say to wrap the cable first. In hindsight, that might have worked better...

-

Thought I'd update everyone on my rearend conversion. Got the new axle back on and the brakes are bled. Took it for a very short drive yesterday and everything seemed ok; however, I didn't get out of third gear (Remember I said "short"). Next I'll go out some of the back roads where I can get into the overdrive. I'm looking at any issues with the brakes or the pinion angle. The other thing I need to deal with is the e-brake setup. I purchased a Lokar universal e-brake kit and everything went fine until I cut the inner cables. The instructions say to use a certain type of Klein pliers, available at Home Depot. I purchased said pliers and the'y would not cut the cables. I then went to a cut-off wheel and it worked fine on the first cut. However, the second cable completely unraveled on me. I still need to pull these cables out of the sheathing so I can shorten the spring between the backing plate and the e-brake lever, located inside the drums. I'm hoping I can purchase just a replacement cable from Lokar and not have to buy a whole kit. We'll see... Check out the photos. The first two show the routing of the new cables. The last one the frayed cable after I cut it.

-

The other thing I discovered was that I can use all the brake lines from the Dodge on the Ranger axle. At first I thought I’d have to use some type of adapter fitting because the Ranger lines are smaller. What I discovered is that the Ranger fittings that go into the backing plate (and then into the wheel cylinders) are the same size as the Dodge. So, I can use the hard lines, the distribution/breather block, and the flex line from the Dodge with no modifications or adapter. Sometimes things just fall in place…

-

-

What Jeep M/C did you use?