-

Posts

475 -

Joined

-

Last visited

-

Days Won

1

FarmerJon last won the day on February 29 2024

FarmerJon had the most liked content!

Reputation

220 ExcellentProfile Information

-

Gender

Male

-

Location

Virginia

-

My Project Cars

1948 Plymouth Special Deluxe Club Coupe

Converted

-

Location

Central Virgina

-

Interests

America

Contact Methods

-

Occupation

Quality Control

Recent Profile Visitors

2,079 profile views

-

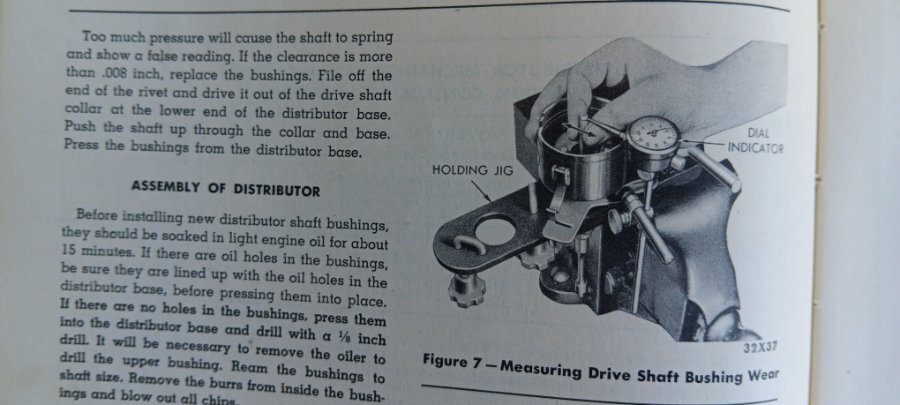

Autolite 295 Sparkplugs at Walmart equal to Champion J8

FarmerJon replied to desoto1939's topic in P15-D24 Forum

Despite the factory warning, I had good luck running the "power tip" type plugs in my Plymouth. Autolite AR73 can be had for less than $4 ea from Rock auto and added a little power to the top end, and seemed to have a little more push down low as well, tested by take-offs in 2nd gear. I did not take the time to track down a resistor version, in theory it might give a slight advantage as well. Autolite 74 plugs are the standard performance version. The "racing" plugs are side gapped, so have a shorter service life, but in 2.5 years of running them, I did not put enough miles on them to notice much wear. I put around 5000 on the first set. I replaced them due to a cracked insulator on 1. They also had no problems with fowling. I will dig around on my computer to find the pictures I took of one in a stock combustion chamber. Even with a milled head, there is no chance of valve to plug interference. -

1948 Plymouth Club Coupe. Great driver with Overdrive

FarmerJon replied to FarmerJon's topic in For Sale Classified Ads

Price droped to $15,000, available for inspection and test drive in Appomattox Va. -

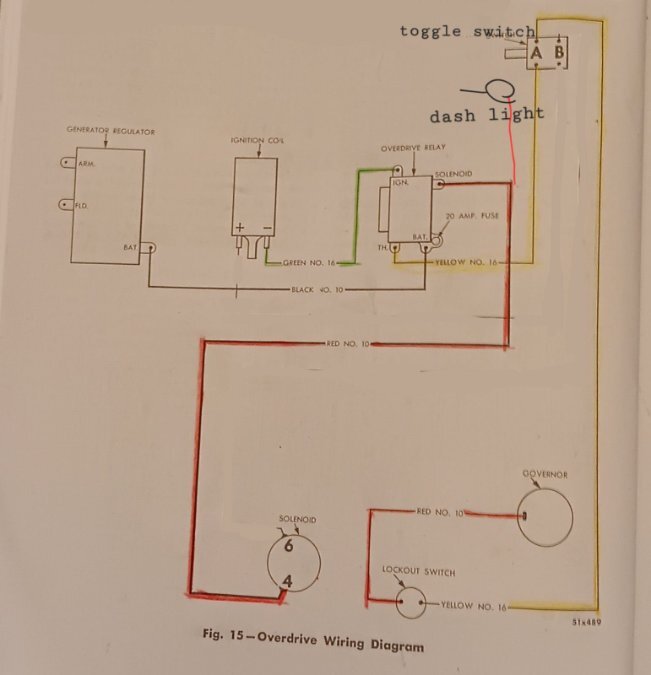

Don't do it. OD is one of the biggest upgrades you can do to these cars. The 6v->12v is pretty straight forward, and I believe that you could overcome the electronic ignition issue with some minor adjustments to the wiring. I have my OD wired to a toggle switch instead of the factory kickdown, so there is no ignition interuption. I believe that would work for you as well, but I cant be sure, as my car always started fine with 6V and points.

-

It is time for me to part ways with my Plymouth. For sale: 1948 Plymouth Special Deluxe Club Coupe. Strong 217 CI Flathead Straight 6 Engine. Freshly rebuilt overdrive transmission,3 on the tree. New Napa 6V battery. Well maintained and previously restored car. An excellent driver both in town and on highway. Car will happily cruise at 70+MPH. I have spent the last few years making into a reliable daily driver. Only selling due to moving. I would like ̶$̶1̶8̶0̶0̶0̶, $15,000 OBO. Car is located in central VA, and is available for inspection or test drives by appointment. Cash is of course King, but I am willing to take most reasonable secure payment methods. I am not looking for any trades, but would consider payment in precious metals. I have made a number of improvements to further enhance an already nice car such as: Sound deadening and heat insulation added to floors,doors and roof. New carpet and custom matching floor mats. Added interior visors. Swapped standard 3 speed transmission for a 1955 Plymouth 3 speed overdrive. Borgwarner R10G1. Trans was meticulously rebuilt with many new old stock parts and all USA made bearings. New clutch throughout bearing and pilot bushing installed. Flywheel resurfaced and balanced with the pressure plate. New ARP pressure plate bolts were used. White post restoration rebuilt master cylinder with bronze bore. Added oil filter. Dual exhaust with Brockman mellowtone steel pack mufflers and chrome pencil tips. Heat shield added under freshly rebuilt Carter WA-1 carburetor,with K&N filter. Mallory "Best" performance coil. Vintage dual points conversion in rebuilt distributor with Terril machine rebuilt vacuum advance unit. Custom made "00" sized battery cables and starter to solenoid cable. NOS starter solenoid. 6 month old Napa battery 6V. New side mirrors. New thermostat and water pump and belt. Rebuilt fuel pump. Vacuum canister and check valve for wipers. New "Aerostar" coil springs in front for 3" drop. 1.5" lowering blocks added to rear. Rear lights rewired with 14 gauge wire and extra bright bulbs installed. New shocks all around. Rubber replaced on the steering box mount.

-

You can find them on ebay, they are out of production. Torrington NB-15OH (oil hole) should be the right size.

-

Coolant leaking out of the clutch housing?

FarmerJon replied to temecularevev's topic in P15-D24 Forum

I was able to sneak my flywheel out of the bell by knocking the bolts halfway out (torwards engine) This gave JUST enough room to get the wheel off. YMMV, but worth a shot. Edit to clarify: my transmission was removed before pulling flywheel -

-

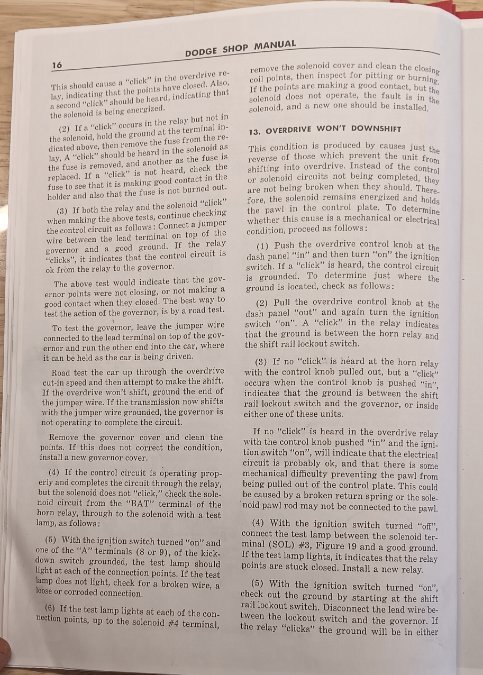

My OD didn't want to engage when I first wired it. Turned out to be a bad interrupter switch AND an internally shorted kick down switch. The interupter switch can be bypassed, or is available NOS on ebay (PN 1370462, or NS-60) The Kickdown switch I didnt have a good way to mount anyway, so I used a toggle switch in-cabin instead. The factory OD manual has some good trouble shooting tips, I will dig it out and take some pictures, but I have the text of part of it. Service Manual reads: "If both the relay and solinoid click when making the above tests, continue checking the control circuit as follows: connect a jumper wire between the lead terminal on top of the governor and a good ground. If then relay clicks, it indicates that the control circuit is ok from the relay to the governor. The above would indicate that the governor points were not closing, or not making a good contact when they closed. The best way to test the action of the governor is by a road test. To test the governor, leave the jumper wire connected and run the other end into the car, where it can be held as the car is being driven. Road test car up through the OD cut in speed and then attempt to make the shift. If the OD won't shift, ground end of jumper wire. If the transmission now shifts, the governor is not operating to complete the circuit" I hope that helps. The OD really is a great improvement, so it will be worth all the trouble in the end.

-

Sure, but he didn't mention doing that when putting it to bed, and I am of the mindset that it is better late than never. The oil that spashes up on cylinder walls is mostly scraped off by the rings, so the remaining film is (relatively) quick to evaporate off. The only downside is that it can be a little messy, smokey and, in theory, an etra cost ( but who here doesnt have an odd quart or two of sacrificial oil, you know, that 0w20 you have nothing to run in?)

-

If you wanted to be extra diligent, you could pull the spark plugs and put a couple drops of oil in each cylinder before spinning it over. That will give the rings and upper cylinders a little lube. It will smoke a little for the first couple miles, and you may want to spin it over before you put in the plugs back so that they dont foul.

-

As much as I like engine cleaners and Italian tuneups, I dont think they will get any of the soot out of the tailpipe(s). Some soot is natural, but if the weber is giving a better air/fuel ratio, it should be much slower to build up. I would fashion something that you can swab out the tailpipe with. Think gun brush, but broomstick based. You may be able to find a bottle brush of the correct size at a hardware store or on Amazon, but a rag stapled to a broomstick would also work. I would get the exhaust nice and hot, then stick the wet swab up the pipe a few times. Of course this will only get it clean for the foot or two before it loops over the axle, and you may find that black water from deeper in the system still runs out. Maybe a few cleanings will remove enough of it that it isnt splattering your bumper and garage floor. Good luck!

-

FarmerJon started following Accelerator pedal mystery..

-

Sorry if you have already said, but have you put a fresh set of spark plugs in, since it started running rough? Last fall my car picked up a light miss that would clear up at rpm, but power was down. I blamed the carb for loading it up. So I put a rebuilt WA-1 carb on it. Same problem. Pulled a couple spark plugs, they were around a year old, but clean and gap was fine. Problem continued. In frustration, i pulled out ALL the spark plugs, and inspected them with an eye loupe. #5 had a hairline crack in the inner insulator, allowing the plug to ground out. Fresh set of plugs and all better. Have you done a compression test on the engine?

-

I think the part that I highlighted is crucial. It isn't poor workmanship to use sealants on in-spec surfaces. I will often stone a surface flat, then use an appropriate sealant on the (actual gasket material) gasket, especially if it is an assembly that I hope to never open again or is below an oil/fuel/coolant level. Oil pans, transmissions, rear ends. Anaerobic sealant is nice for installing lip seals, to insure oil cannot seep past the outer seal case. I do occasionally wonder how "tight" the original tolerances were on some of these parts. These carb lids probably started out only but so flat, and after being installed and the first few heat cycles, they can get out of hand. There is a reason that many hot rodders (and a few manufacturers) back in the day preferred to build on "seasoned" engine blocks. Foundry technology has greatly improved in the last 100 years, even though the workforce of tradesmen has drastically declined.

-

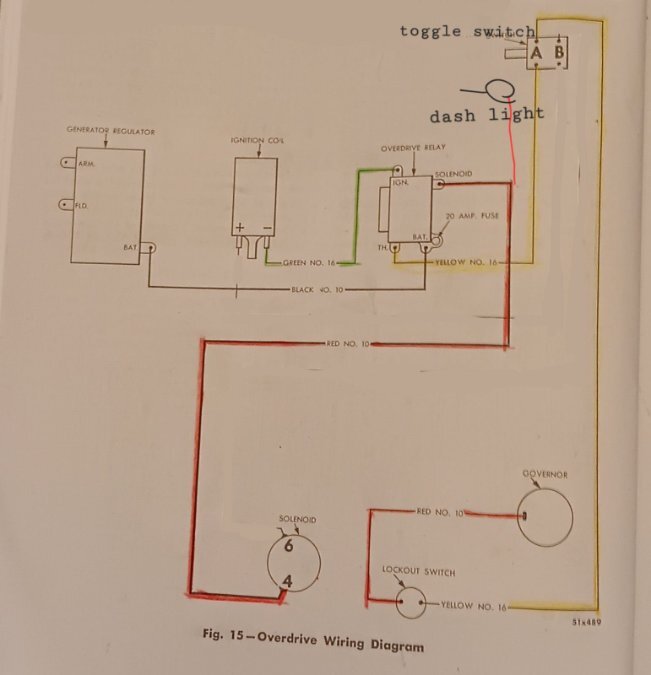

Whooo boy, that thing is crusty. Does that advance plate move freely? An ultrasonic cleaner does great getting all the crust out of the ball bearing pivot. Hopefully, fresh wire inside, with everything clean and lubed will fix the issues you are having. If not, at least you will know that the distributor is OK. Manual calls for .008" max play. If you can feel much slop at all, it may be worth setting up an indicator on it to see if you are in spec.

-

The problem with using sealant is that it makes it difficult to remove the top after applying. Seems like no big deal, but if you ever need to make a float adjustment, prime a dry carb after winter storage, unstick the vacuum piston, or for the hot rodders among us, change jets, It really sucks to replace a lid gasket every time you have it open. It is also possible to bend the lid when prying it off of a sealed surface. Just make the flat parts, that are supposed to be flat, flat. Its no big deal.

.jpg.ed646ace1e86eb82565874a416e6113d.jpg)

.jpg.b03060358b1050d47df1079a249d6f43.jpg)

.jpg.d3eec9bd6aaf90425aefdb6c2714c837.jpg)

.jpg.ffff77635104aa70b507d9d931a68ccc.jpg)