grea235

Members-

Posts

75 -

Joined

-

Last visited

-

Days Won

1

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by grea235

-

Ford Borg Warner Overdrive Parts Prices (vanpeltsales.com) has them. A9AZ-7A651A. I believe the Ford and Studebaker used the same switch. https://www.fifthaveinternetgarage.com/ has them too. #05415KDS

-

#3 is a front valance/stone guard isn't it? The front lip goes into the back of the bumper.

-

I appreciate this info. I'm planning on doing this soon.

-

If you are talking about a D6H2 with a Sisson, I have one and took a picture of the choke lever side. The choke moves in the same direction, but it looks like the choke rod from the Sisson would need to be able to adapt to the UN2. Maye graft the Sisson rod to the UN2 rod? The stock air cleaner wouldn't fit.

-

That's good. I'm glad it's working for you. Been driving mine with the duals and it's been running great.

-

I pondered how they preset it and to what flow. They are running fine so far. It's not loading up on gas or starving or hesitating, starts fine when it's hot. I'm going to pull the plugs, clean them off, then recheck them after it's been run for awhile to see if it's lean or rich. If either, I'll adjust the mains.

-

Update - I put the UN2 carbs on and got the linkage sorted. I left the adjustable main jets alone; the instructions said they were preset. Tweaked the air mixtures with a vacuum gauge and synched them up with a Unisyn. It runs very well, idles nice and part throttle is great. Way more driveable. Starts up easily. I do have a return spring on the linkage. I'm adjusting it to get the least pressure on the pedal and ensure the carbs return. I don't know how functioning dual ball on balls run; mine were cobbled together from 6 different carbs and I got tired of fiddling wirh them. I am very happy with the new UN2's.

-

If it helps anyone, here's pics of the UN2 throttle lever. Closed and open in two different dimple positions. I had to use the 2nd dimple position otherwise it hit my dual throttle linkage bar when it goes full open. Between the two holes would have been perfect. 1st position closed 1st position open 2nd position closed 2nd position open

-

I used a square to measure my old D6A2 and then the UN2. I tried to keep it on the same plane as the center of the barrel. The pictures don't quite show it well, but I have the differences. This is the D6A2, obviously. This is the UN2 Relative to the base, the location of the choke holder on the UN2 is 3/4 inches shorter and 3/8 inches inboard, so your cable will need to be 3/8 inches longer. The throw of the choke lever itself is about 1/8 farther inboard and has a lot shorter throw. The whole carburetor is 3/4 inch shorter. The base flange is about 1/8 inch thicker. My car came with a rusted up Sisson choke and a D6H2, so when I replaced it with the D6A2, I had to get an aftermarket choke cable, which by the way, fit too loose in the holder, so I had to put a copper tube sleeve on it to make it fit tight. I don't know the diameter of an original choke cable, so I don't know if you will run into that issue. I can get pictures of the throttle lever positions if you want.

-

I live about 30 minutes north of Mike's Carburetor. I went down yesterday and bought two. I have a dual offenhauser manifold. They fit ok, same fuel line fitting, same air filter input size as a D6A2, which is what I am replacing. Throttles spring closed, not open. Biggest thing so far is the clockable throttle lever is either straight up and you don't get enough throw, or leaned back toward the fender. I need to extend my throttle linkage. I'll post a new thread when I get them sorted out and fired up.

-

I don't know if this would help, but I recently had an issue with one of my D6A2's. The throttle was intermitently sticking. I have it on the long throw setting and the lower flat part of the accelerator pump was rubbing against the hole in the bottom of the body. When it is set at the short throw hole it was fine because the angle is narrower. I looked at a couple of my old bodies and I could see rubbing as well. I think the slot for the accelerator pump wears out. I dremmeled the place where it hit the body and it's better. Been contemplating the UN2's myself, but I need two.

-

Mounting a lockout cable for the r10g overdrive

grea235 replied to comedtech63's topic in P15-D24 Forum

No problem! -

Mounting a lockout cable for the r10g overdrive

grea235 replied to comedtech63's topic in P15-D24 Forum

You are very welcome. -

Mounting a lockout cable for the r10g overdrive

grea235 replied to comedtech63's topic in P15-D24 Forum

Unfortunately, I didn't install a kickdown switch yet. I have one wired in, but it is not on the throttle linkage, so I can't help with that piece. -

Mounting a lockout cable for the r10g overdrive

grea235 replied to comedtech63's topic in P15-D24 Forum

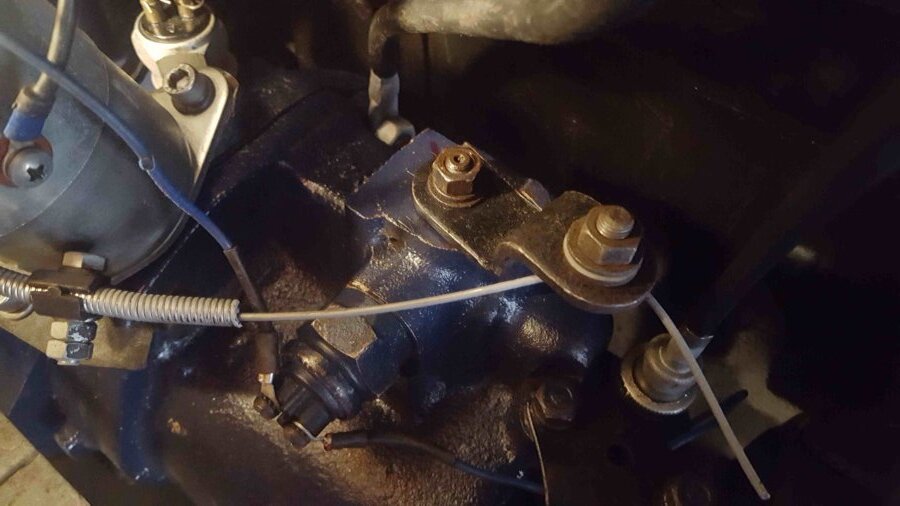

Sorry for the delay. If no one has gotten back to you, I took pictures of mine. It's an R10. The first picture is the bracket that bolts under the solenoid. Sorry for the upside down picture. The second shows the lever locked in, the third shows it locked out. I hope this helps. -

Flywheel runout was fine. Had my neighbor come over and look at the discs. He a contractor/mechanic fir the military. Has worked on more vehicles that I can list. He didn't like the disc wobble. We looked at the original disc and it has life left in it and we decided to put it in and see what happens. I'll return the new one. It will be awhile before I get the OD part to test it. I appreciate everyone's help!

-

True. I checked when it was in the car and it was ok. I'll check it again. It's easier now that it's out. Thank you.

-

Thank you for posting. It's in first and second. It's a moderate shudder. The clutch and pressure plate have been in for at least 200 miles and hasn't gotten any better or worse. Way more pronounced when starting up a hill than downhill.

-

It feels like uneven engagement for sure. The flywheel was resurfaced after the clutch change and it has a could spots on it. I've been trying to make incremental changes when I have the transmission out to troubleshoot overdrive issues. You are correct in how much play can you have. I will do more research on that. The original clutch has some wear left. I could put it back in along with the bell housing shim and see what happens. But I have the overdrive out to replace a part so I may just send it in to get rebuilt just like sniper suggested. I'll also double check the pressure plate. I'll report back, but it will be awile. Thank you for your advice. I appreciate it.

-

It only occurs when letting off the clutch. Once it's engaged it's fine. No vibration when driving. If I keep the rpms down and dump the clutch there's no shudder. The more I rev the motor and slip the clutch the more shudder, especially going up hill. No vibration in neutral and reving the motor. As far as I know clutch discs should slide on without play. The original disc has no play.

-

Thank you! I appreciate it!

-

Thank you for responding. Yes, I've seen their address in posts. I'll try to find a place around here, then Tennessee.

-

While the motor was out on my 1952 Plymouth Concord, I saw that the clutch disc was worn, so I replaced it. It was a 9 1/8 disc with a Borg and Beck 9 1/4 pressure plate and the disc fit onto the transmission splines with no wobble. I replaced it with a 9 1/8 disc, but it had a about an 1/8 wobble side to side. Not knowing any different, I installed it and then had some clutch shudder. The faster you rev, the more chatter you get. There was a lot wrong on the car before so I can't say for certain that it had clutch shudder originally because of bad motor mounts, bad shackles, etc. Motor was changed out and does not have a rear main seal leak and has new motor mounts, not hard ones, new leaf springs and shackles, new u-joint driveshaft, etc, pilot bearing is ok, flywheel has been resurfaced and it still has clutch shudder. I pulled the transmission and motor to do some other work and to check the bellhousing face. I found that the bellhousing needed to be shimmed at the top right about .008 of an inch. I checked the pressure plate with a press and didn't find any variance. Thinking the 1/8 wobble is contributing to the clutch shudder, I ordered a 9 1/4 inch disc from a vendor and received a 9 1/8 inch disc and it has the same wobble. It's not the transmission input shaft because the original disc fits with no wobble. I'll be calling on Monday and returning it, but I would like to know if anyone has gotten a 9 1/4 from any vendor and if it fit ok. Also, is a 9 1/8 disc appropriate for a 9 1/4 pressure plate? If I can't get a good fitting pressure plate I will have to get the old one rebuilt. Any information or advice would be appreciated.

-

I used bobclassicauto for my 52 glass. It matched the old glass just fine. It was 400 something for all but the back window. The local shop wanted 235 just for one door window. I don't recall how long it took for them to get it to me.

-

For gears in the front, I used ebay. For OD parts, I used vanpeltsales.com for a 12v solenoid and the big 4inch snap ring. They list parts as Ford, but some fit the plymouths. A couple days ago I called and ordered a balk ring/gear. They are used, but he said they are cleaned, inspected and tightened. I'm pulling my R10 soon to replace the balk ring so we'll see. For $45, I'll take the risk on condition and fit.