-

Posts

1,232 -

Joined

-

Last visited

-

Days Won

17

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Radarsonwheels

-

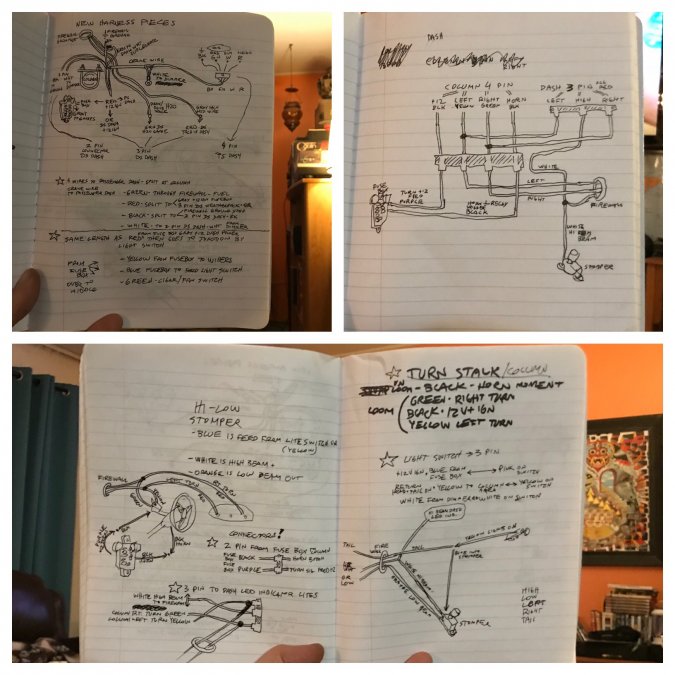

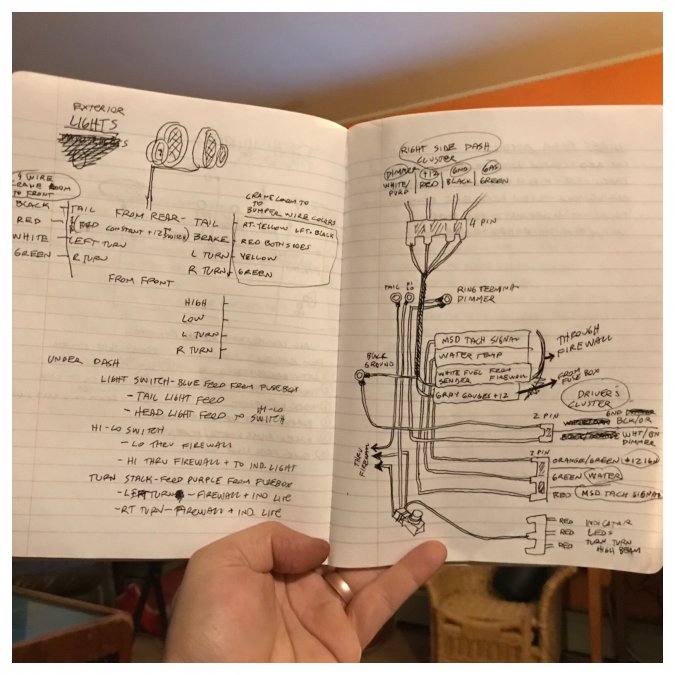

The cab wiring is almost done. I have a few unused circuits to tuck away in case I ever get a cabin light or line lock or whatever. I still have to make a ground lug to the firewall and put ring terminals on the ground wires. The wideband gauge needs a mounting plate made that will cover the old radio holes and I have to weld a bung into the exhaust for it. For the heater box I have a circuit running to the hole in the dash but I need to get a high amp three position switch to run the heater fan at two different speeds. Then I’ll run one output through a resistor and one straight 12v. All the wires are run through a fresh grommet in the firewall. Once it’s all done and loomed I want to make a taper/cone of electrical tape covered in heat shrink so the whole harness can seal more air/water tight through the grommet.

-

'47' rear bench, storage drawer done

Radarsonwheels replied to kendall's topic in Mopar Flathead Truck Forum

The fat radial spokes are fancy! -

The instrument clusters, keyswitch, light switch, and high-low beam stomper switch are mounted and wired up. The tail and brake lights are already wired up to the engine bay from the bumper. The horn button and turn signal harness is made but needs a connector under the dash. I’m trying to finish the cabin wiring as a break from all the sheetmetal work. The ‘plan’ is to just leave a loop that will go through the firewall once the front inner fenders are done. I was able to sneak under the car cover and sit in the truck to do a bunch of work which was nice and peaceful and a lot was done on the bench inside too but working in the snow sucks.

-

I looked up that link to the loom- I got some that looks similar but isn’t split. You have to thread it and unless you cut it with a hot knife the ends fray. quickly. It’s nice though because when you bunch it up its diameter increases dramatically and when stretched it tightens up around the wires- the chinese handcuff thing. I think I will be able to stick wires out the side too through the weave like when a long run has a couple wires that stop early or make a detour from the group. I don’t give it a chance to fray I have been taping the ends tight then shrink wrapping over the tape for clean permanant installation. Or sometimes a couple baby zip ties if I don’t have that size shrinkwrap like in the pic. edit: just took the slack out of the parking brake adjustment. Feels good.

-

Like this? I have been working on the harness here and there at night since before christmas. I have a bunch more to use finishing this all up- high temp plastic (pet?) braided loom that expands or shrinks like chinese handcuffs. It’s gonna be pro-fesh-uh-nall! At least as good as I can get it. I’m 40 this year- trying to learn and improve from years of doing it wrong, not knowing any better, and being too broke to buy the good tools and materials. Nothing worse to deal with or better to learn from than working on something after it was all screwed up by a hack. Usually I try to leave things better than I found them if possible and do stuff right -once-. Right now I’m trying to get a final count on wires through the firewall so the bundle can be made, loomed, and measured before I drill for a grommet, then cut to length and pinned into weatherpack connectors on the engine compartment side after the whole snake is pulled through. I’m still not sure where the voltage regulator and ignition box are going to live. Gotta make those inner fenders. Had to work today though. It’s supposed to snow gangbusters here tomorrow- my kid’s school already called a snow day. In honor of the ground probably being horrible to lay on for the next week or so I went ahead and assembled, indexed, tightened, and cotter pinned the transmission side of the cable shift linkage from my B&M ratchet to my 727. It’s one less thing to do that requires rolling around on the ground. The other fun one is tightening the adjuster on the parking brake. The splitter that goes from the front cable to the rears is attached to a threaded rod that needs a nut tightened to take out the slack. It goes easy with a ratcheting wrench but the lever doesn’t actually pull the cable very far so the adjustment needs to be just right if you don’t want the truck to still be able to roll with the parking brake on. It’s all matching stuff off a 90’s jeep ZJ grand cherokee.

-

'47' rear bench, storage drawer done

Radarsonwheels replied to kendall's topic in Mopar Flathead Truck Forum

You are having too much fun with that thing I love it. Is that an evo softail springer or heritage dressed like a knuckle parked next to it? -

I kinda like that idea- it would solve the problem of the extra holes where the stock choke and throttle etc knobs used to live and also allow me to weld up and smooth over the 1960s volkswagon radio holes. I love the 1954 paint that’s on there though- such a shame about all the holes. I also gotta add the wideband O2 sensor and wiring into my plans. It would be nice to put the gauge down in the radio hole area or maybe even hidden inside the glovebox door so I can put away the lightshow when I’m not tuning. I’m trying to think of everything while doing this wiring before I get too far in the weeds. I feel like on a lot of projects my wiring starts out all loom solder and shrinkwrap then ends up getting a bunch of crappy electrical tape add ons later...

-

It’s always kind of amazing and a little sad when a bunch of brand new parts come together. It will never be this clean again. Lotta work left but not too much clutter to add. The mechanical speedo and oil pressure gauges are hooked up and all the other gauge wires are already pinned into weatherpack connectors and diagrammed so I can finish my wiring runs without dash disassembly. I picked out the holes I wanna use for the keyswitch and the light switch. I’m getting a little fancy with turn and high beam indicators and a dimmer for the dash bulbs, but mostly keeping it as simple as possible.

-

'47' rear bench, storage drawer done

Radarsonwheels replied to kendall's topic in Mopar Flathead Truck Forum

Haha Kendall you’re crazy as hell but if you have the space to park that thing inside to keep it nice and the patience to wait for a nice day to cruise it then it looks like you can stop anywhere and relax in the coolest tiki surf shack around! I really like the red striped wood and the glass floor. -

Ha! Yeah I decided early on the polygon route would look businesslike and not require a month of hammering and bending. Thanks! I’m so stoked that the cabin is a closed box again. It’s raining here and I snuck in the garage while my kid was getting showered and pajama’d. I ‘repaired’ my left upright on the seat back spring frame with some round stock to connect the broken pieces and the bendy horizontal rod. The break had been repaired with a torch twice before- once ‘welded’ then ‘brazed’. Neither oldschool ‘farmer repair’ stayed fixed and even after die grinding as much brass off as I could I wanted to weld away from the contaminated weak spot. I also extended the upright tabs on the seat frame- my seat bottom ended up overstuffed when I had it reupholstered and the seatback sits 3” higher than stock. I can’t be mad- I dropped it off broken and ripped with mouse house horse hair stuffing and without the frame and they did a great job!

-

Yup I’m in the salt belt but I only drive the 4wd ramcharger until we get some good rains after a salt-down. I am not scared of rain but this is a fair weather driver. It’ll probably drive like crap on a wet day. A rubber skirt that flaps over the control arm relief area is a good idea. I also could use the real estate to neatly bolt up some items- ignition, regulator, fan relay, insulated remote battery +12 terminal. I shouldn’t be scared of these little filler panels after doing that geometry puzzle firewall.

-

The snorkel is awesome. Now I only have to take breaks in laying beads to let things cool down or if my hand gets fatigued. I got smart and ended up welding the vertical up corner over the gas pedal from the engine side of the firewall. The inside just shows a tiny little bead of penetration in the corner which is perfect because it leaves room to screw in the throttle cable fitting. There was some stock firewall left as an unneeded flange inside the motor side of the pockets so I torched that off before painting it to keep the rust monster away. I kissed the welds with a flap disc, painted all of it black and called it a good day!

-

Yup I already did a full rainex treatment on it. It was better but just couldn’t deal with 90° breath into a 30° day. My cheap snorkel came in the mail yesterday. It had a one way exhale valve near the mouthpiece which I hotglued shut and it came with fancy headgear because apparently I ordered one that is supposed to go up the middle of your face instead of out the side. Doesn’t matter- I’m just gonna let it hang down from my my mouth. I’m pretty excited to be able to see what I’m welding

-

Thanks Farmer! My buddy said it looks like hvac ducting- he said “is that for heat or AC?” Heat. Ha! It’s definitely going to be nice and toasty but there is still a nice amount of room for airflow, maintainance, and shifter throttle and kickdown linkages. I still might spend the money and do dynamat all under the seat & rubber floor but the console and firewall might give more benifit. The problem then would be how to make those areas look finished. I guess I could contact cement more black rubber sheeting but I don’t think I could mold a nice one piece like an oem and I don’t want carpet that could end up soggy and smell. The inner fenders have me a little unsure. I feel like maybe they should tab onto the frame top with self tappers and possible into the cab on the inner fender side of the outside firewall corners. I also need to relocate my heater box about 1/2” outboard. I think I might make a plate to weld in so I can just cut out the old swiss cheese mounting area. Dunno if I’ll have to shorten or modify the ducting outlet that sticks off the right side of the box?

-

Cut it out, put it back in with only one 1/8 gap that I tacked a piece of tig rod into and migged right over. I still gotta take the column loose and weld up the left corner but that joint is nice and tight so it should go well. My welding helmet fogs up like crazy in the cold!! I’m about to buy a snorkel so I can stop holding my breath in there.

-

Is that a nine foot long v10 crank? What does that go in? Boat? Agricultural equipment or earthmover? It looks impressive!

-

Replacement new or rebuilt carburetor (Carter B&B)

Radarsonwheels replied to RedHot71's topic in Mopar Flathead Truck Forum

I put a repop weber on from the stovebolt site 32/36 model. Night and day but my ball and ball was pretty tired