-

Posts

2,404 -

Joined

-

Last visited

-

Days Won

11

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Ulu

-

That sounds like a awful fracture and I wouldn’t want to be in your [s]shoes[/s] shoe right now. I remember just a few years ago that Darlene was on a knee scooter with a bad leg. I hope this doesn’t run in the family. I sure wish you had sold that silly buggy, and went back to work on your Plymouth, buddy. This is no joke.

-

Paul that looks very painful, and I hope it’s not as bad as it looks! (… here I was complaining about a stupid colonoscopy!) Yikes! I have been so busy the past week that I just missed all the excitement here. I just showed my wife the gruesome photograph of your injury, and she was pretty startled. I remember breaking my shoulder, not realizing it was actually broken (In spite of the pain) until I went and had an x-ray. I’d like to think that this **** is easier at my age, but it’s not easy at my age, and you are 17 years my senior. I would bring you a tie rod but my only one is bent severely. The long ones I found were always bent. I’m amazed you found a straight one. I am going to cut mine and sleeve it. The ends are still good, but this tie rod has been bent and straightened before, at least once. Maybe twice. I want it to wind up stronger than a stock tie rod. If it looks like a dog’s leg it’s going to be slightly flexy.

-

-

Well that stuff is all on the opposite coast for me. I picked up this English bicycle last week, and it’s about 60 years old. In this photograph I have already changed the wheels and tires and the seat. Some of it was a challenge to get apart without messing it up. Particularly the crank cotters and the crank bearing cups. I had to press the cottters out, and I used this English ball joint press, which has authentic whitworth threads. I made this special tool to get the cups to unscrew. That chunk of steel came from a 64 Mustang trailer hitch my dad cut up in the 70s.

-

It would be tempting except that that would change the frame number and I’d have to get it back to the highway patrol for re-registration. They will want to see a title for that frame of yours, which you do not have. That makes it a salvage vehicle under the law, so I have to have full equipment & smog inspections, and get a blue tag riveted on by the highway patrol. What an incredible can of worms that would be! Anyhow, my plan is to eliminate a lot of the Volkswagen frame where it is bolted to the Frame extension, which is the weak point in the whole business. I’m going to cut away the Volkswagen tube frame and replace it with frame rails welded to the extension directly.

-

7 months later…. I have the bicycle pretty much wrapped up and done working on my motorcycle so now I’m working on the Volkswagen again. After I repair this, I will rebuild the engine in the Scout, and once it is running, I will probably go back to work on the P-15. Anyhow I got the VW chassis uncovered for the first time in seven months and cleaned all the leaves and dirt up a bit and started looking it over really well. This has been hit and repaired sometime in the past, and you can really tell when you look down from the top in a certain direction. There is only about 1/4 by 1/2 inch piece of rusty 1.5 mm steel holding the front head frame from ripping loose at the pan. It was bad before, and after driving the car and doing some general hooliganism, it is much worse. I was wise to take it off the road when I did, because if this popped while I was driving it, it could send me off the side of the road into a tree. I wasn’t looking forward to being impaled by the steering column. Anyhow I have to get this thing apart and cut off the cancer and then build a real frame under it. This is my first major custom frame job. Thank God the Scout don’t need framework. The Plymouth has got some frame damage, which is one of the reasons that I put it aside until it got more valuable.

-

I don’t know if you can tell from the photograph that I lowered the seat. It rode much better and I actually did 20 miles on the bike in this configuration. But then I went home and decided the seat needed to go back a little more, so I redrilled my seat bracket. That allowed me to push the seat back another 3/4 of an inch which should be just perfect. We will find out today.

-

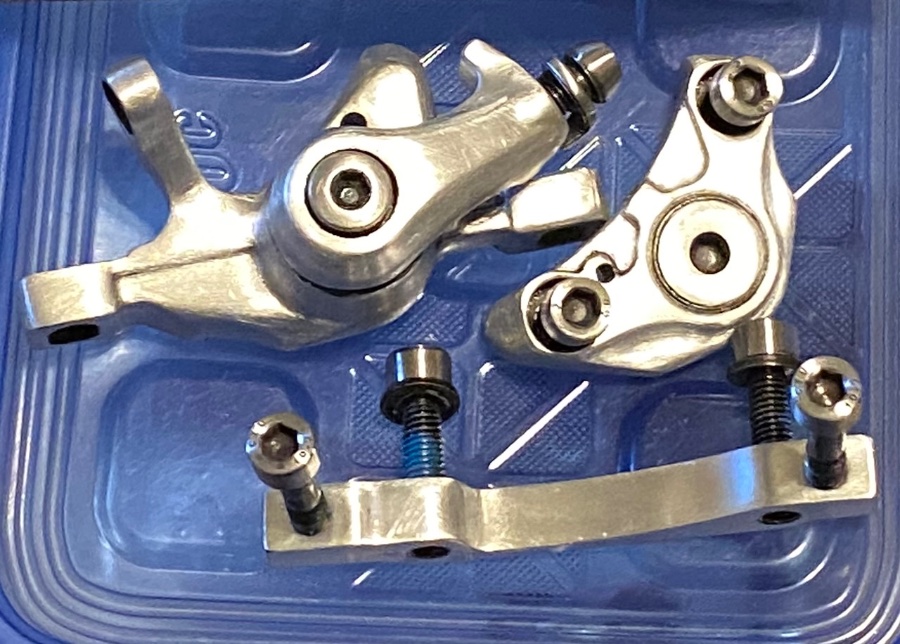

More late night polishing here, as I cleaned up the brake caliper With sandpaper and buffed it out. Also I’ve been feeling the bike was a little too tall in the saddle, so I drilled out the pop rivets and cut my sissy bar off 1.5” I had to use the right angle drill. There you can see the cut offs, which are not exactly the same length, due to irregularities of the sissy bar I never considered when I first cut it. I’ll take pictures of the whole bike when the sun comes up, and I go out to ride it. It was too late when I finished last night.

-

@cheesy ” A friend in Savannah…” Are you aware of the ratrod bike forum guys local to Savannah? Kingfish, Tankenstein, Jakesensi? This bike by Kingfish took a prize in our latest contest.

-

I bought a lightly used longbed, 4dr 2012 Tacoma pickup in 2016. 32k on it & I paid $33k cash. With tax and 13 mos license. So far I have changed battery, brake pads, rotors and tires, oil and filters. I put my used bed cover on it from the old truck which got smashed. I put airbags and an anti-sway bar on the back axle, and premium shock absorbers all the way around. Those were also from the smashed truck. I also put better front springs on it and shimmed up the rear springs. I changed all the ball joints and tie rod ends myself, because I can. Also the wheelbearings which were expensive. I think the bearing design on these trucks could be better. Anyhow I have good spares now for most of those parts, because only two of the tie rod ends were getting worn. and one ball joint was loose. Everything else is serviceable. Except for the tires and genuine Toyota brake parts, None of those things were desperately needed. I just wanted the truck to be Tip-Top, and I had the money and time to do it. I might’ve spent $100 on new tools. It now has 52,000 miles on it. I’m going for my third smog inspection next month. That’s about $50 each time. I changed the differential oil one time. I’ve had it in for alignment three times. I keep changing the shocks, springs, etc looking for better handling. (It was the sway bar and the spring shims that made all the difference.) Nothing has gone wrong otherwise. So I’ve spent about $38,000 including tax, lic, insurance and gasoline. And my labor. That means if it disintegrated today my total cost of ownership would be $6166/year. My labor not included. But on the basis of mileage, it would be a horrific $1.90+ per mile. This truck is still so nice, and prices have gone up so high, that I think I could sell it for $30,000 today. That brings it down to a more reasonable $.40 per mile or $1334/yr. (plus my labor)

-

The shifter really works well now. I buffed out the ugly black chain tensioner. I Reforged my kickstand and straightened it all out. Now it is the right length for the lowered bike.

-

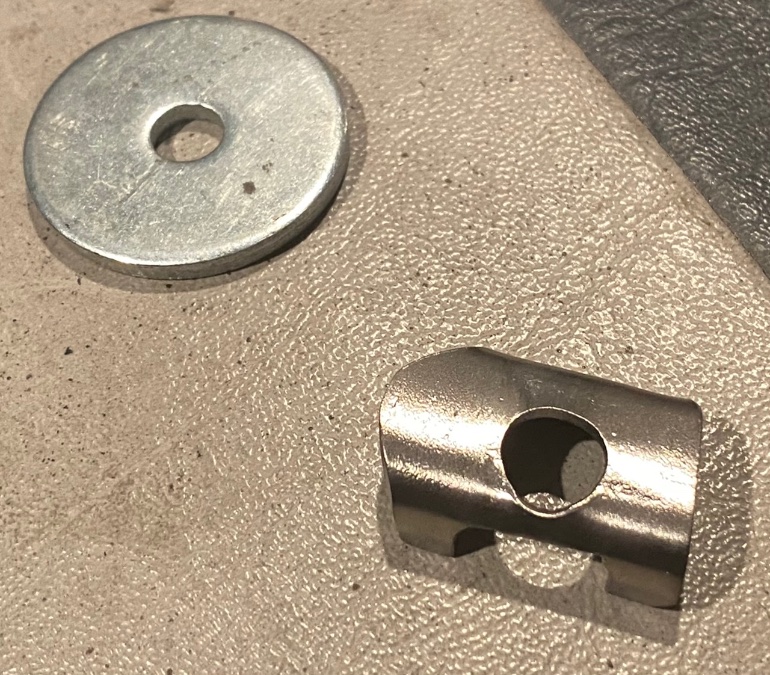

I needed to tighten u the shifter spring a little more, so I made this cover plate that sucks the spring together tighter. It started life as an ordinary flat washer. It needs to be a little longer to cover that spring completely, just for looks. I may make another one that is more attractive.

-

I changed the week steering neck for one that was shorter and much stouter. I had to do a little trimming to make it fit, but it was worth the effort. I did have to trim off my stem with a pipe cutter. I decided to polish those black rings since they were aluminum.

-

Well my shifter spring was a bust. I finally created this new double leaf, and it works much better. It also doesn’t put any side load on the spindle. This one was putting a lot of sideload on and causing a lot of friction. This is the new double spring. It took me about four hours to develop this little booger.

-

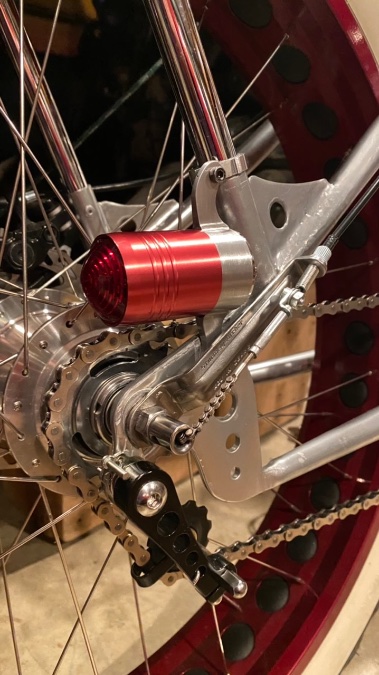

I’ve been working on this tail light for the bike. It’s built from a automotive vacuum test pump that could not hold vacuum. Most of the shaping was done with hand files & sandpaper. The rough form was done on the bench grinder. That little clamp at the top came from a Shimano twist grip shifter. There’s no wiring yet. Also I haven’t buffed it or clearcoated.

-

The voting is almost over, and it looks like I only took 8th place. I feel I would have done better if I had time for an elaborate paint job. Personally, I like this more than any bike I have ever ridden. I improved the shifter spring, removing the extra clamp on the handlebar. Also I raised the headlights one inch, and mounted the Tokyo bell. Except for a tail light, I think it’s finished for now.

-

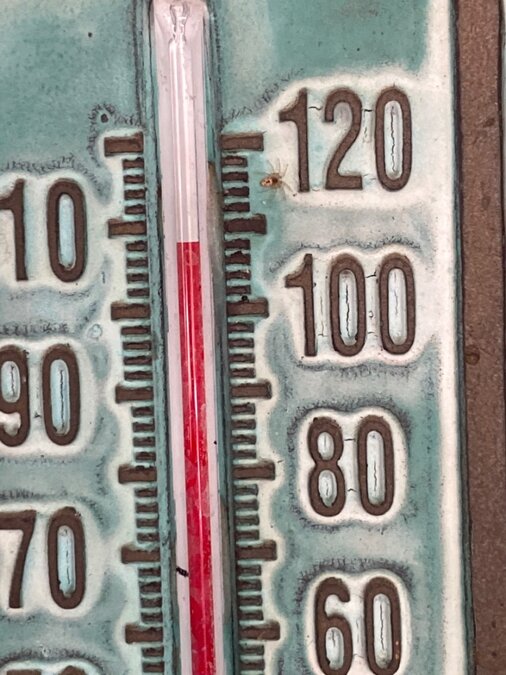

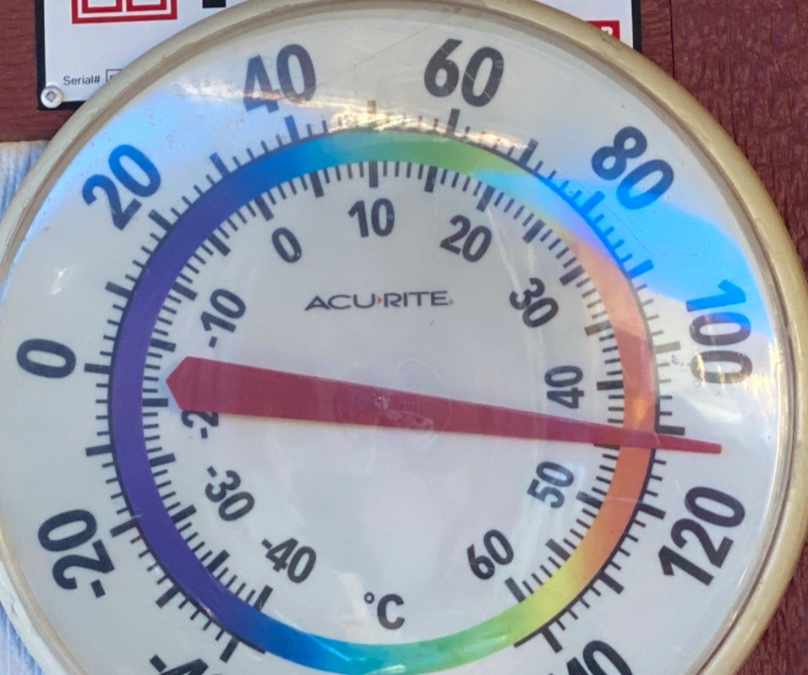

That was my back porch today at 2:30. That was my back porch today at 2:30. This is at the welding shed, same time. Outdoor aquariums holding about 88, Because the water circulates to the indoor aquarium which is in the air conditioned house.

-

IT LIVES! But I painted it without any filler over the welds, and it needs it. I’ve been putting in ridiculous hours working on this bike and it has been well over 100° every day. Fortunately I’m used to living in the desert after all of these years. Not that it’s enjoyable, Working in such heat, but for me it is possible. I am 100% glad that the contest is over and I’m not worried about the deadline. I never wanna have another job with a deadline and my entire life. LOL Anyhow I went for a ride and did some wheelies and bopped over some curbs and this bike rides pretty well with little danger of pedal strikes because I didn’t lower it too much. Steering stability improved because it has 3° more rake, and some actual positive trail!

-

Well, you finally got the shop cleaned up. Did you ever get everything lined up to put that engine in?

-

It’s 6 AM on the West Coast. I had a good nights sleep but I am still sore from yesterday. It took me eight hours to grind and sand and sculpt the new welding. I spent four hours just with the Dremel Moto tool sculpting the welds. To make it go faster I did a lot of hogging with the 5 1/2 inch grinder and that is a white knuckle experience: Trying to shave hundredths of an inch away in tight locations. Today I’m going to get this thing painted and I will assemble it tomorrow morning before 10 AM, and take photographs for the contest, as that is the deadline. There are still a lot of scratches but I buffed it down with the flapper just after I took this photo. It’s almost ready to paint. I need to do a little hand sanding and mask off.

-

More tacking up. Squaring up the sissy bar. Prelim assembly after tacking up the sissy bar sockets. Everything clears. Setting up to finish weld. There was a bit of porosity but everything’s welded from both sides, and I think it’s going to be plenty strong.

-

I got sick Thursday night and my work went on hold, but I did get back on the bicycle yesterday. These are the handlebars from the Huffy Sea Star 12” French princess bicycle (found in someone’s junk pile.) It’s Grinder Time. Tubing cutter keeps it square. These should “handle” the sissy bar. But more gussetry is needed before welding! A bit of metal from a broken wood lathe and a cardboard pattern. It’s gonna look very laid-back. I don’t know how it will ride yet.

-

I got the filler plates shaped and drilled and I should be welding them in this morning. It was 110 Fahrenheit in the boat yard yesterday, and I couldn’t finish the welding. I didn’t like the black stem, so I started sanding it down to shiny aluminum.

-

-

I have the later AWC 36h which has the coaster brake inside.