-

Posts

668 -

Joined

-

Last visited

-

Days Won

2

The Oil Soup last won the day on August 21 2014

The Oil Soup had the most liked content!

Reputation

229 ExcellentProfile Information

-

Location

Tucson,AZ

-

Interests

Wall covering, painting, family, friends and working on my pick up

-

My Project Cars

1953 B4B short side

Converted

-

Location

Tucson, AZ

-

Interests

Paint and glue

-

The rear fender is not a ‘53.

-

This might help, I think on mine the channel was glued on. https://www.vintagepowerwagons.com/products/new-reproduction-window-glass-channel-run-clip-cc1561798

-

I would look on eBay for the hood ornament.

-

high exhaust header temps on 230 engine

The Oil Soup replied to wiboater's topic in Mopar Flathead Truck Forum

I had the same problem of fuel boiling in the carb once up to operating temp and difficulty starting after sitting for a few minutes. Have the shield over the fuel pump, tried running without a hood and that solved it so i put the hood back on after having it louvered. -

I also had an off brand heater in my truck with a bad core and searched a list on oreilly auto parts website, found a replacement and made it work. https://www.oreillyauto.com/shop/b/air-conditioning---heating/heater-core/b8e4def0b5a5?q=heater+cores Also sourced a new fan motor for it.

-

Nice YOM plates!

-

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

You could position the pieces together with a few sheet metal screws and take it to someone that would weld it, got to be easier than bending the brackets. I’m not much of a welder either but my grinding skills are improving. Good luck! -

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

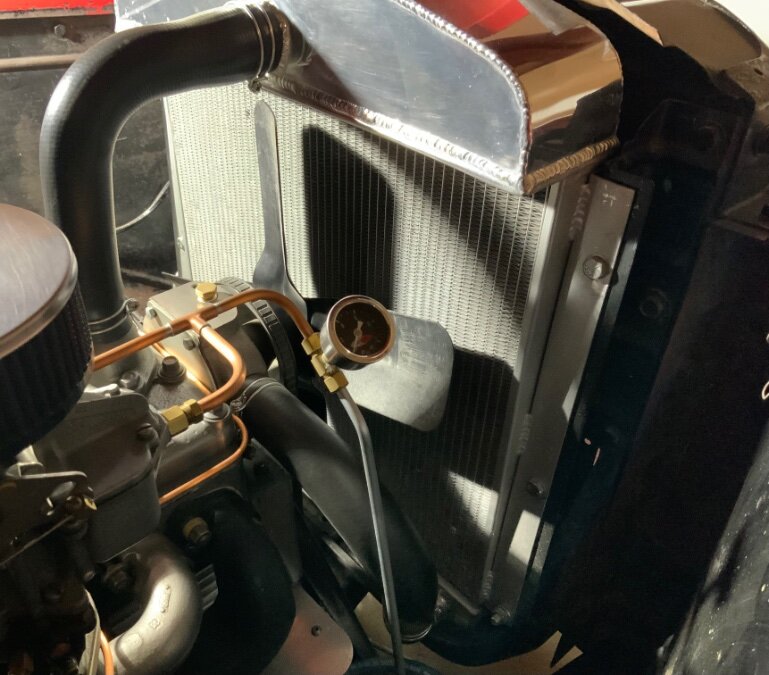

I did use the mounting brackets (4 pieces) from the original radiator and after positioning the new radiator in relation to the fan, I welded those together and bolted the Champion to them (6 bolts). The front of the radiator is painted black so it looks stock through the grill. You can also still access the hand crank if need be. -

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

The upper hose is Gates 20573 and the lower hose Dayco 70480, iirc I trimmed the length on both hoses to fit correctly and I cut off the angled portion on the upper tank inlet. The fan has about 3/4’’ clearance from the radiator core and from the underside of the top tank. -

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

-

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

-

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

-

You can also “clock” the lower part of the pump to accommodate a better fit.

-

Aftermarket radiator options ('51 B3B)

The Oil Soup replied to ktb's topic in Mopar Flathead Truck Forum

I used the Champion cc4749 with the side brackets from my stock radiator and cut that downward part off the upper tube, the fan is just slightly under the overhang of the top tank and the radiator works fine in the Arizona heat. I may have numbers for replacement hoses. -

A833 transmission for my flathead

The Oil Soup replied to Tony_Urwin's topic in Mopar Flathead Truck Forum

I have a T5 in my B4B 230ci with a Cherokee rear end (3.55), I also am running 17” rear wheels 31”h and with a mustang gear set 1st 3.35, 2nd 1.94, I can take off in 2nd, not ideal but 2.47 would be better. The stock 3 speed was 1st 3.3, 2nd 1.78, 3rd 1.1. I followed John-T-53 T5 build thread and it was a great help. YRMV