-

Posts

197 -

Joined

-

Last visited

-

Days Won

8

Everything posted by Semmerling

-

Good morning... So lets answer these questions...."So if Langdon's headers are $366 with shipping and yours are ??? and they improve HP marginally... Plus are they chrome plated steel or stainless?" By Langdon's I take it you are referring to the FENTON copies? First my thoughts about the copies I have seen . From above.. "Fentons? Better, as the exit has much better outflow than the original and smooth pipes are better than any of the boxed variants. But, and its a real big but, the Fentons were never designed properly as they come way too close to the stock fuel pump. How close? Close enough that anyone would have know if and when the Fenton design was to be copied, that should be immediately fixed by simply moving the forward three inches ...away ...from ...the ...fuel ...pump. Wait...it was copied. Sorry. At least that copy, unlike the original comes with verbiage that goes something like this “now that you mentioned it, you need to run an electric fuel pump as these header...(wait for it)...run way too close to the original fuel pump.” With an electric fuel pump, the original and copied Fentons will work. I am not running an electric fuel pump and I wont be using Fentons or their copy. So what comes next? Folks, the answer is real headers. Simply put, good exhaust flow on the straight 6 is the vast majority of a performance build in the absence of a hot crank. Re-read that last sentence please." On the difference between flow headers and the Fenton originals and the copies, From above.. "What good headers do is allow the exhaust to travel as far away from the block as possible directly out from the block and then the bend route begins along its final path. None of the lateral boxes do this as well as a smooth direct exit should. Fentons? Better, as the exit has much better outflow than the original and smooth pipes are better than any of the boxed variants. " As to the comment about "they improve HP marginally." I'll cover boxed lateral manifolds, Fentons or their copies, modern well designed headers. Manifold cut and weld end and flange, from above.."marginally" "Flow is not satisfied by cutting the original cast iron Dodge exhaust header in two, boxing both ends while adding a flange to the forward threesome. It attends to the over pressure issue of the front 3 exhaust ports, but laterally cross flowing exhaust in a box that sits right on the block and exits stage rear is a nominal improvement. Will it help? Of course. It also commits you to running dual exhaust pipes and mufflers that would most likely need to be crossed closer, not farther, down the run." Fentons and their copy..From above.."much better" ""Fentons? Better, as the exit has much better outflow than the original and smooth pipes are better than any of the boxed variants. " Real modern header design..Best flow possible. "Exactly the right room for a mechanical fuel pump and clockable filter. No lateral cross cylinder flow, just a clean, long exit. If one was running injection, plenty of places for a bung/os." As to the issue of price... As I am using the stock fuel pump, the Fentons could be free, I'm not using them. We add to that that I am also going to be using the stock engine guard plate....Fentons don't allow that. A set of headers that are like the ones I posted are $100 more expensive then the Fenton copy. Now as to the materials used in the headers I showed you and a whole lot more Here is a binary choices laid out..... By not having a manifold exhaust and using a header, one leaves vintage and moves closer to hot rod Having said that..... - By not having a manifold and using a header, one would be resolving everything that can be resolved in exhaust flow - By using this header will have a true straight, long exit, lateral crossflow out of the block, it does not get better. - By using this header one CAN use the stock mechanical fuel filter with a clockable old style filter as well - By using this header the radius' are so tight that stainless cannot be used, it would only be possible with mild steel - By using this header in mild steel it should be coated with a product like JET HOT for longevity. - By not having a manifold exhaust and using a header, one would be increasing engine area noise because of leaving cast iron for thinner steel. - If one was going to use Slant Six fuel injection, here is a perfect platform for a bung/OS for post reading to map - By using this header one is committing to dual exhaust, dual mufflers and a cross over. Jet Coat as an example... https://www.jet-hot.com/ Let me know if I answered your question.

-

Thanks for the kind comments. I won't be dynoing it as the projected gains are all at the margin. What does that mean? The gains just are not going to be important enough past stop watch/seat of the pants observation. When one is working with one atmosphere of air and is not going to supercharge or turbo charge, its all about what is going on inside the block. These early 30s engines cannot support all the important changes that a modern block might be able to. A little more bore, slightly more compression, slightly better head flow, slightly better spark, slightly better lift and duration, slightly better induction, slightly better exhaust, slightly better performance. The big changes in top end might come with lightening up the body (its not like this is a 6 on a rail), swapping out transmissions and gearing, etc. I'm looking at this though "its 100 years old for God's sake" glasses. Flow AND stock fuel pump

-

Two important points, one is a killer. First, it may be stronger than steel but that means that if you have an 1/8th inch steel plate and an 1/8th inch glob of resin they are ready to be compared. Smearing paste wafer thin and hoping for surface radial torque strength is, is, well not going to happen. Second, Why do you think the VW "Thing" was taken off the roads? Because its slanted front trunk hood took the lower impact energy and immediately transferred that to that very same hood design, forcing the hood back back and literally cutting off the heads of the front passengers. Crappy as The Thing was it at least had flimsy side pillars. This body takes that principle and makes it much more dangerous. Love your grandchild? Keep your head before you "Louisette."

-

Some may remember awhile back I started a thread to ask the general readership here about sourcing, setting up and the what the observed performance gains of Speed Equipment on an early Dodge straight 6 might actually be. I asked these questions after leaning into the search abilities of this site for all the information I could wean out. I very much appreciated the responses of those that had thoughts on the subject and, perhaps like others, was surprised that the articles posted (all vintage) during the day stated performance on the Speed Parts mentioned are “not known.” As much as one would want to think otherwise, the available vintage products are either very expensive, if in reasonable shape, but much of the vintage material is pretty rough shape and modified. Modified parts tell an experience eye something, there is not much to suggest it worked well back in the day. Bright exceptions exist for newly produced Speed Parts and that is what I am going to touch on in this thread. Folks, it doesn’t take an Elon to tell us that available speed parts are in freefall for anything other than Ford. Enter my own project and a discussion on Speed Parts. Speed Parts for Dodge (et al.) Straight 6’s is poor. While understandable; with close to a 100 years since new, what can one really expect to find for Speed Parts for the early MOPAR models? Well, with the exception of George Asche and Son the supply is close to zilch and if you are thinking about the Montana Boys actually coming back and being a force in the next number of years and concentrating on Speed Parts as opposed to bling, after holding my breath, I have fully exhaled and gotten on with it. Want broadly supported early Speed Parts? Do what most people do and buy an early Ford and have reasonable/typical access, even new and sometimes improved new blocks. If you are a Dodge owner and want to begin the process read on. Most likely you will end up talking to George Asche. I would also suggest you know or be a machinist with good mechanic skills and performance builds under your belt. Swapping out the Straight 6 and dropping in a V8 is what most do and the lack of Speed Parts is partly why. No news there either. I have a Dodge and I am keeping the 6. Some background, I have been working on a Dodge heavy horsepower beast for decades. I wrote technical pieces for years on mechanically supercharging the V10 and was “mapping” in a car when most thought that meant going from point A to B. Injection, atmospheres, compression, ignition, flow and lambda all day long for years. Having said that, the majority of that work has absolutely nothing to do with actually deriving any significant improvements in performance in an early 1930 Dodge straight 6. With one exception, knowing that these engines are air breathing flow machines. Knowing what a proper breathing engine actually means and how to get there and having worked towards lambda for longer than many have been alive is an advantage. To the extent that a 1930 engine can be improved, it is to a very large part going to be all about flow and, to a much larger extent, keeping the engine in one piece. Have reasonable expectations for a 30’s modified stock straight 6 engine that is going to be registered for the road and still look and sound “reasonably” like a stock car as opposed to a hot rod. The actual improvements that would be felt in the seat of your pants are going to require a very broad combination of applied work and parts to achieve anything truly measurable and noticeably faster. Here let me sum this up for you, in the case of 1934 straight 6, improve the restriction in the exhaust manifold, tuning your carb, increase the compression safely, improve the pistons (overbore), use the highest test gas you can, consider a performance crank and you are close to done. Take note; with the exception of the exhaust manifold all of those changes cannot be seen when finished. Louder is not what I am talking about here, nor is fuel efficiency, I am talking about flow that creates horsepower that makes a measurable speed difference. I am confident that, with a stock transmission, the whole of that performance upgrade will best be felt when you are able to accelerate up a steep incline to a noticeable extent faster. As a result of being able to build rpms faster, you can move through the stock gears faster or swap out gears and actually achieve higher speeds. Also, never discount the remarkable effect of fresh, balanced tires. That is what many want and that is what they will most likely achieve if they are realistic. And so.....we begin with the following.... The engine has been completely rebuilt again (third time) and is currently running like a top. Everything mentioned has been done with the exception of a new grind on the crank. Why? Well because I might cross that bridge when I come across a resource for one. Exhale. What you see here is single Stromberg, and it is true that I did not list out dual carbs on my short list of things mentioned above, right? Right. So why is George's dually here? The answer is because George Asche represents exactly what a healthy Speed build hobby should have, a deeply experienced, knowledgeable and committed Speed Parts contributor. This gentleman is a pleasure to deal with, so I did. George has provided dual and triples for 6s, depending on the block, and he provided the superior intake you see here. I would have bought his intake and put it on a shelf just to thank people like him. What I am getting is better intake flow because of the raised nature of the manifold, its superior internal surfaces and the opportunity for better fuel efficiency. Swapping out to the duals is where a good amount of thoughtful work begins. There are some major changes that will occur if we actually change out the intake manifold, among them are; - We will be separating the intake from the exhaust manifold as it relates to the warm-up heat exchanger that Dodge provided. This allows for the heat from the exhaust manifold to warm up the air/gas mixture in the intake initially. Once warmed enough, a spring loaded thermal coil spring will close a gate separating the two. It works perfectly as long as the spring is in good shape and the gate is free. It should also be noted that the intake will warm up perfectly without it in about 4 minutes longer. When you unbolt the stock manifold, you are left with a gapping hole in the top of the exhaust manifold. More on that later. - That hole means no heat to the intake. Now it get down right weird. The Hatfields and McCoys had nothing on those that engage in the notorious “icing” issue that has somehow come about around "unheated" intake manifolds. Perhaps you have heard that, in the absence of the aforementioned heat exchanger, that the intake acts as a “natural refrigerator” and will ice up your intake? And the solution? Pumping hot radiator fluid through a sealed galley in the intake to insure that your intake won’t turn into an icicle. Let me help, no it won’t. If it did this Ford Model B made by George Riley for Henry Ford himself, which ran alcohol under hand pump pressure and was no where near the exhaust manifold, would be an ice cube. It didn't, wasn’t and won't. Maybe at the arctic in the winter, but the track there is seasonal. In fact, the issue is not cold but rather over heating the intake manifolds as the vast majority of Dodge 6’s did not really have functioning thermal gates and the intakes ran hot to the point of vaporizing gas in the float bowl and other forms of fuel heat saturation . The vast majority of electric pump installations are for heat soak, not the “Ice Box” physics. When someone tells you the “science is settled,” smile and remember alcohol in dual Winfields. - The whole linkage issue surfaces immediately. Buckle up, here we go. As most of us know, these early Dodge break down into essentially three major categories, those carbs that are actuated by the stock throttle and choke assembly crossing over the head from the driver side, those that travel along the fire wall to the passenger side and then attach to the intake side of the engine, and lastly those Dodges that have the “special feature” throttle/choke/cruise control capabilities. In the case of the 1934 Dodge DR convertible coupe, we are confronted with all three; there is a full firewall pass to the passenger side and a single marvel of an actuator that incorporates in a single design; the throttle and a speed adjustable feature. The choke is a typical separate run, more on this below. It does all this while working with the stock carb by moving the carb mounted accelerator UP, not down. I am going to use the whole stock shooting match, so that means that I will need to reverse the original actuator to operate. I will do that by keeping George’s linkage work on the head side and building an intake side assembly that engages with his dual accelerators. Now remember that George’s intake importantly adds height to the primitive original stock intakes, so that my work will need to potentially address the rod that is attached to the firewall transit bar and run to the newly placed original actuator. That work I am modeling and, if there is interest, I will post the final design in regard to location, attachment, reversal of motion etc. If yu are wondering what and where those air filters came from, they are from a great East Coast resource "O'Brians Truckers" https://www.obrientruckers.com/ and are a recreation of the early oil bath customs except with a high flow cleanable air filter element. They are mounted on the carbs with an adapter ring made out of aluminum as I have had no luck with the plastic ones. - Low pressure gas runs will have to be made and run to the duals. Low pressure hard lines have many advantages around not needing to do flair work. Why is that important? Because we can avoid the impactful extended lengths required to make flairs that interrupt tight radius bends. Flair tools need to be set behind the work and with the exception of those that have a Canter flair tool(1940s) and that required length is too long. Equally true, when flared, that flare requires the lead-in into a tight radius bender tool to be too long. If you think that using the wonderful copper/nickel hard line (seen here) is going to make that all better with flares, it won’t. What does work, is using low pressure compression fittings that utilize the bead/pit. Just be sure to tighten them gently as you can always make them tighter. Yes you can barb and run flex tubing but the barb itself is too long for a compact flex bend and, well, it’s a Dodge not a Tecumseh. Why the gauge? Four cases, first is that these carbs are sensitive to over pressure. Over pressure will flood the bowel. Second is that the mechanical fuel pumps are known to quit and you can instantly see the deterioration if that is the case (carry a spare). Thirdly, there are any number of available fuel logs that make running one easy. Fourth, fuel gauges, especially the rarer low pressure type send an important message that the builder is fully susceptible to using any excuse to mount yet another gauge, if only to draw the eye to the well set out hard line runs. In short (pun intended), if you want to really run a single clean line from a Dodge original mechanical pump to a dually set and want to onboard both a fuel log and gauge, you can. And the runs are so well supported that the whole rig is a marvel of anti vibration. But you are going to need an onboard backing plate. I came with and tested a ton of designs, both on the duals and/or the head or the firewall. Every possible hold down nut was tried and I ended up with what you see here, a simple one access point that is firm as can be especially with the hard line. My son in law made it up in stainless but one of the exact test plates can be seen in raw steel on the top right near the wood. The pic below all the test plates shows how it wraps around and attached to the right hand carb's main mounting bolt. - Two carbs, two chokes. You only will ever really need to choke one to make a well tuned car run so what about the 2nd carb's choke. While many just wire or short pipe them statically closed, one can always just make a tiny manual choke linkage. - Remember the part about separating the intake from the exhaust manifold and therefor opening up a center hole where the heat transfer took place. Lets talk about flow and exhaust manifold. This subject can create friction, but nowhere near the “refrigerator conundrum.” Flow is not satisfied by cutting the original cast iron Dodge exhaust header in two, boxing both ends while adding a flange to the forward threesome. It attends to the over pressure issue of the front 3 exhaust ports, but laterally cross flowing exhaust in a box that sits right on the block and exits stage rear is a nominal improvement. Will it help? Of course. It also commits you to running dual exhaust pipes and mufflers that would most likely need to be crossed closer, not farther, down the run. What good headers do is allow the exhaust to travel as far away from the block as possible directly out from the block and then the bend route begins along its final path. None of the lateral boxes do this as well as a smooth direct exit should. Fentons? Better, as the exit has much better outflow than the original and smooth pipes are better than any of the boxed variants. But, and its a real big but, the Fentons were never designed properly as they come way too close to the stock fuel pump. How close? Close enough that anyone would have know if and when the Fenton design was to be copied, that should be immediately fixed by simply moving the forward three inches ...away ...from ...the ...fuel ...pump. Wait...it was copied. Sorry. At least that copy, unlike the original comes with verbiage that goes something like this “now that you mentioned it, you need to run an electric fuel pump as these header...(wait for it)...run way too close to the original fuel pump.” With an electric fuel pump, the original and copied Fentons will work. I am not running an electric fuel pump and I wont be using Fentons or their copy. So what comes next? Folks, the answer is real headers. Simply put, good exhaust flow on the straight 6 is the vast majority of a performance build in the absence of a hot crank. Re-read that last sentence please. I am exploring properly made steel headers that properly allow for flow and are away from the fuel pump. Are they made? Yes, but unfortunately not out of stainless and would therefor need Jet Hot or some coating to actually last long enough to be worth the money. And, as we all know cast iron is much quieter that any steel build so I will lament the day somebody decided to redo the Fentons and not attend to the obvious flaws. If you read this far, thanks. Let me know if you want to see this all unfold. The assembly will be done this winter.

-

I'm in the process of working through a new dual carb set-up and, since I am planning out the whole fuel path past the mechanical pump, I am asking myself if there is any real need to consider including a "no return line" low pressure fuel regulator. On one hand I am thinking "the single never had a problem handling the fuel pressure provided by this pump, why would 2 Carters?" I just thought that if I am going to complete this path, do it all now. Thanks for any thoughts you all might have.

-

After working with 6volt for 2 generations, the 3rd switched over to 12v a while ago. We used a "5th Avenue" 12v kit. I think Sniper's response above properly describes the process and the general feelings about this conversion. It's a personal choice. All the original 6v related parts have been rebuilt/restored and set aside for anyone who would choose to place them back on the car...which just quietly mumbled "what?!?"

-

Dodge DR Convertible Coupe comes out of winter hiberation....

Semmerling replied to Semmerling's topic in P15-D24 Forum

Thanks for that will find it. Again, I appreciate all the kind comments. -

Dodge DR Convertible Coupe comes out of winter hiberation....

Semmerling replied to Semmerling's topic in P15-D24 Forum

Dan, NY State for most of its life . Southern Maine where we had very little snow all winter and 54 right now. -

Dodge DR Convertible Coupe comes out of winter hiberation....

Semmerling replied to Semmerling's topic in P15-D24 Forum

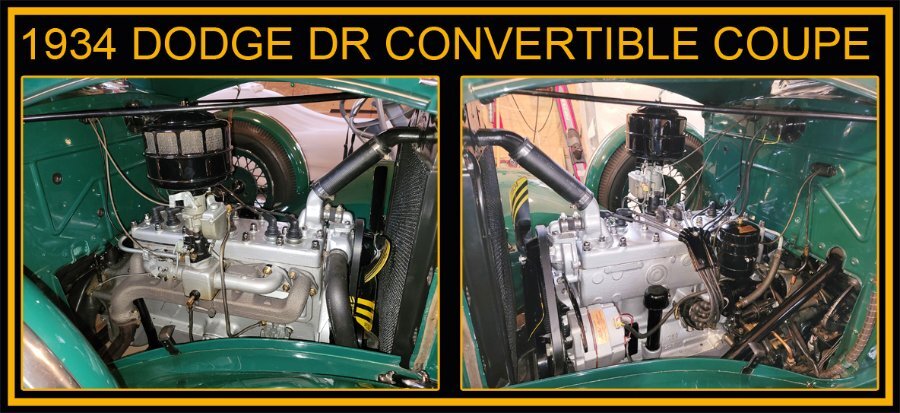

Keith 216 CID inline 6 cylinder L-Head Power: 82 bhp / 3.600 rpm Production: 1,239 Curb weight: 1380 kg Just bought the car new.....1934. That is my father sitting on the fender. -

Dodge DR Convertible Coupe comes out of winter hiberation....

Semmerling replied to Semmerling's topic in P15-D24 Forum

Thank you for the kind words, as we all know, this is a great deal of work for all involved. As to the questions, the car was originally black. The blue green you see here is a standard color for the 40's Dodge trucks. My father always liked that color and so many years ago the car was repainted. There is indeed the Free Wheeling vacuum assisted clutch and it is activated or suspended by a central dash pull. The whole affair works as designed but is really quite dangerous and was not offered for long. The clutch is drawn in when one's foot comes off the accelerator...not what one would want when driving down hill and want anything that ever comes close to engine breaking. This is the only year of the body type with IFS, 1935 came and it was gone again. It also has the ability to crank all the window frames into the doors and, along with folding forward the windshield, the waistline of the car is the top of the dash. He are some more pics over the years. -

Dodge DR Convertible Coupe comes out of winter hiberation....

Semmerling replied to Semmerling's topic in P15-D24 Forum

This car was bought by my Grandfather in 1934. Four generations have now worked on the car. It has had the good fortune to have just about everything that it needed throughout that period. The engine has been rebuilt three times, I'll put up some pics. It gets driven regularly as in multiple times a week while the weather is good and is the focus of a long winter's worth of maintenance. It has been driven from New York to Mexico city (1935) and back again and some may remember that during the Bicentennial year it appeared on the cover of Dodge's celebratory annual issue. I would be happy to answer any questions. -

Dodge DR Convertible Coupe comes out of winter hiberation....

Semmerling replied to Semmerling's topic in P15-D24 Forum

-

1934 Dodge rumble seats, where did the water go?

Semmerling replied to Semmerling's topic in P15-D24 Forum

As I didn't get an answer on this forum, but did on another one, well here it is for those that may be interest. When the rumble seat is folded forward to the lock position, the back and lower metal forming on the rumble seat door itself provides a run off channel that dump the water outside and above the rear body panel. -

Quick Question..... With the proper weather seal running in the body channel for the top 2/3 of the rumble seat hole, I can see that that might keep the water from entering into the whole top length and down about 2/3 of either wide of the seating well. Then, the seal ends...the channel ends and I don't see a natural appropriate pathway for all that diverted flow. What was the original concept for the water when it runs down past that body seal? Did it just dump into the interior space and find its way out? Thanks.....

.jpg.cc7f0c0a1d673689f149c2a9b30c6bd1.jpg)