-

Posts

197 -

Joined

-

Last visited

-

Days Won

8

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Semmerling

-

I tried to track down as much as possible to see what has been offered up on the subject of adjusting the valves on the flathead 6. Setting aside all the suggestions for solo numbers, hot or cold, stopped or running, gloves or salve, I came up with the following, FOR THOSE READING THIS THREAD, USE THE RECOMMENDED GAP FOR YOUR CAR'S YEAR THE PROCESS IS CORRECT AND ACCURATE THIS IS A NEW IMPROVED IMAGE

- 42 replies

-

- 2

-

-

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Very helpful, I was wondering if it had to do with being really high. Duly noted, thanks for clearing the air.

- 17 replies

-

- dual carbs

- hot rod

-

(and 3 more)

Tagged with:

-

Very interesting and generous response, all very much appreciated. You are doing a super nice job and I look forward to seeing where it all ends up. I worked with SUs when, as a younger man, I set them up in pairs on Pahheads and Shovelheads. Many pairs SUs and Dellortos from Coast-2-Coast to as far away as Hawaii. If you add the air cleaner....do you have enough room to the hood? As you can see in the pictures of my Asche, the linkage was done by George and is on the block side. I am going to keep it there as it is out of the way and is, like the intake, a very high quality job. When he realized that it should have been on the hood side for my model year he immediately offered to swap it to the hood side. I thanked him and left it as it is the pics. Why? I gets all that linkage out of the way and makes for a much cleaner presentation on the hood side. The reason I took so much time to fashion and test out a dozen potential locations "on board" this intake for a fuel log/and pressure gauge and do all the tight bends was to make the whole presentation look as clean as possible. Also, as we all know, the stock fuel pump can put out enough pressure for 2 or 3 carbs because they are such low pressure affairs. The gauge is there to insure that it is low and provide an additional "JyNormous" horsepower increase in all Static Racing discussions for the whole intake. As my wife reminds me, I have more torque in the wheel lugs in the other Dodges, Having said all that, here is the thing, the original throttle actuator pushed UP on that single stock carb and the linkage that George put on pushed DOWN. That means I was confronted with two choices....use the original actuator and deal with a clean reverse bridge, either by "lever and arm" or "wheel and wire" or reverse the whole assembly, I did the CAD work for that already. Regardless...there are a couple of important observations using the Asche, 1- The whole intake is much higher than the original position 2. The Original actuator was set on the intake nearer the center (single carb), we are actually moving it closer to the firewall on the Ashce and, you are right, a new rod from the firewall lever to the throttle actuator is going to be made. 3. In the original location and set up the intake joined the exhaust manifold so there was no space between the two, 4. We do have the Asche plate and that is a good thing, Now with the Asche, the intake is quite high. Aside from having much more space, that is an important improvement over the stock single and many of the other "flat" dually intakes in regard to post charge mix velocity into the head. Add to that real headers that gives us much more space and allows all six cylinders to travel straight out before slamming into a high pressure single horizontal channel that literally chokes out the first two cylinders. There is much more room to set up a very clean and reliable throttle linkage system. I don't see any issues on mounting the original actuator on a plate-to-plate AND tapping the required vacuum. Like you, I would like to see the wings go if possible even though that would make it pretty much a '34 intake solution. Winters are loooong up here in the North Country, I get to go real slow and take the time to make this really look good. hang on, its coming, I am just getting the tranny done and then its full concentration on everything flow. Up here....over time....rust and ruin can become something incredible....enjoy the following about 5 years of winter work and do post your work when done. Some of these are 6 feet tall, endless numbers hanging overhead and nobody even looks at the rides.

-

You are most likely right on both accounts, not enough vacuum and will disrupt air mix. Having said that....here are some of the very real problems with the Asche intake. 1934 DRs and the placement of the throttle actuator assembly. Unlike the majority of later models, the 1934 Dodge and Asche intake runs headlong into the following: - Actuator of the 1934 does not cross over the top of the head to articulate the carb(s) and therefor the factory intake has a place that one mounts the actuator on the intake itself. On the Asche intake there is, as you pointed out, a mounting area. It is small and so conflicted by the "side wing mount" (shown in your photo above) that the original actuator cannot be mounted. That is, by design, most likely the same place that will be needed for the placement high vacuum line. The answer for all of this is that that very same provided area in the Asche intake is used only to mount a separate plate that addresses its location and having that area make room for a vacuum mount. Plates upon plates...... - The Asche solution as seen in various photos (few and fewer of completed and functional systems) do not provide for the dashboard mounted idle/throttle control. What we see from George and others does allow the car to be driven, but all of those I've seen thus far looses what this author uses allot....the hand throttle. Given everything else unique about the 1933/1934 we just deal with it as best as we can. - The Ache intake has no feature (boss/stud) that allows for the simple mounting of a throttle linkage return spring, a must for safety. This is less of a problem for later years where the actuator cross over the head, as the linkage can (and Asche does provide) a lever to accept a spring running back to some point on the head. but that is not the case if one assembles that linkage on the wings provided facing the hood. There there is no place for the spring mount. Interestingly, George set my linkage up for the later years by accident, but I have opted to I run that linkage there and may very well end up milling off the hood side "ears" to make room for proper solution for all of this on the '34. Why do I mention it in your question/observations on vacuum? Because the manner that I use to tap for vacuum and the throttle actuator will most likely have the means to attach a spring as well or, perhaps, on a milled remanent of those hood wings might as applicable. Not sure yet, I am still taking the time that should have been taken prior to casting to work it all out. One either loves this kind of puzzle or one doesn't. Other possible considerations surrounding vacuum Run an electric vacuum pump (noisy) Turn the vacuum mount windshield washer into an electric affair. My advance in mechanical. Best

-

Sorry for the delay, big storm up here. I will start by try to see if the vacuum port on the base of either carb is strong enough to do the job. That port is behind the large brass plug you see on the left hand lower section of the carb. That position my be enough for the windshield wipers. My advance is mechanical on the '34. In truth, to drop the windshield on the '34 one has to take off the exterior windshield wiper arm/blades and store them away. We shall see. If that doesn't work I will have to drill and tap a hew vacuum location farther on down the line to the head.

-

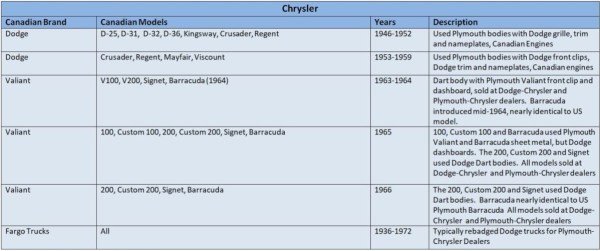

Very interesting read and some wonderful pics. My grandfather used to say "You'll know the Canadian parts by their suffix, all of the Canadian part numbers are followed by an Eh?" I can offer up the following. https://www.hemmings.com/stories/article/canadian-combine-1934-canadian-dodge-dr https://www.curbsideclassic.com/automotive-histories/automotive-history-the-cars-of-canada-part-1-an-overview-of-canadian-brands-and-models/

-

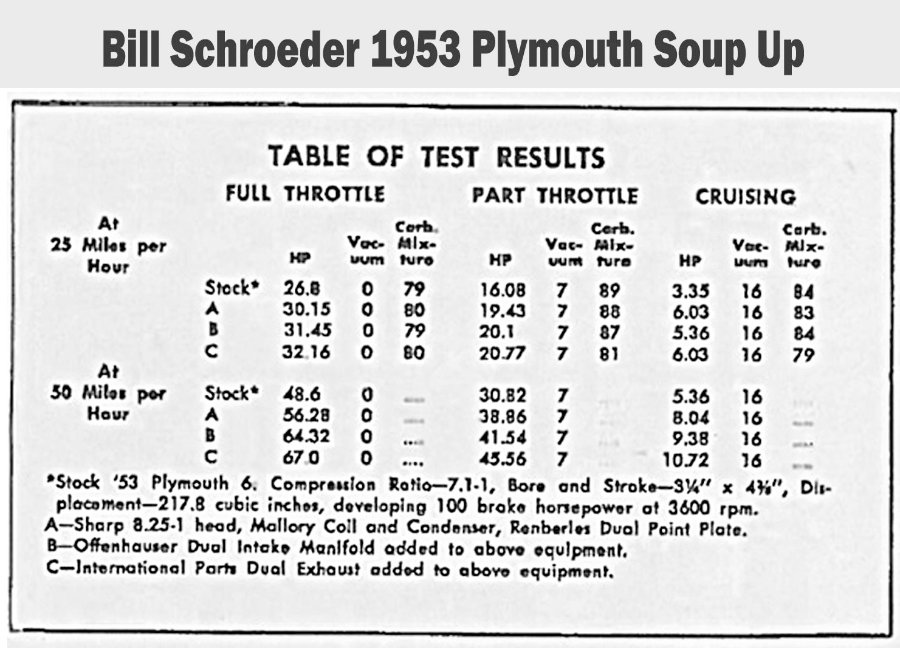

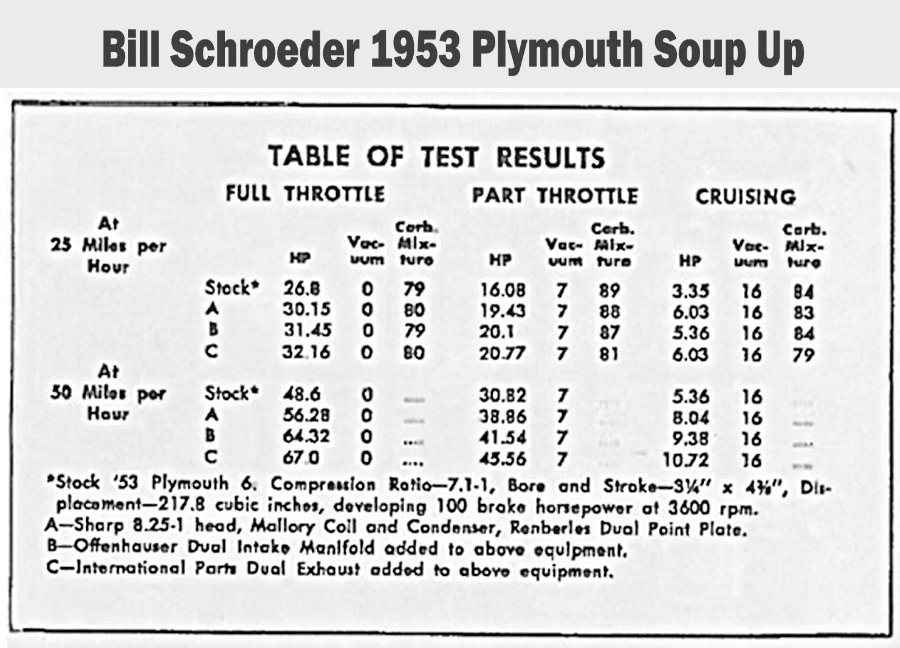

There is not much head snap in any of this, but there may very well be some strong pull up a hill that would simply not be there prior to some or all of the mods mentioned. I would agree with the idea that compression leads the parade. As I had mentioned elsewhere, IMO the next in line would be fixing the known design or production limiters that impact the stock engine. One would want to follow the flow. There we would find the exhaust manifold of the earlier 6's, mine certainly is there. Whether one exhaust pipe or two is, as Sniper points out, dependent on diameter of those pipes, muffler, etc. etc. Both the original fuel pump and the single carbs on many are all one would need at one atmosphere. The case for two or three might come into play for efficiency or response. As has been proven in countless multicarb Static Racing event, there is little doubt that attributable horsepower gains appear to be proportional to three important things. First, if the hood is up. Second the number of people looking at the engine under that hood and lastly the alcohol content or anyone speaking. But, when we add additional atmospheres, carburation is imperative. Probably the best case Fi or a new crank and ignition starts about there too. And then Octane says hello. And only then, when all that is accomplished is one really in a position to answer the Big Question, namely "Is Using a Stand Alone Intake without Exhaust Heat responsible for the Ice Typhoon Winter Storms we now see?" I know a couple of people who if given enough time can make a pretty compelling argument that the answer is YES! How do I know about all this and speak with such authority? I read it in a magazine or maybe it was here...honestly I really don't remember. Aside from that.....whatever Loren says is OK by me.

- 17 replies

-

- 4

-

-

- dual carbs

- hot rod

-

(and 3 more)

Tagged with:

-

Here is how I went about solving the problem of providing light in the case of a night time emergency. The result allows me to be able to payout enough cord to reach all four wheels and a just about everywhere else. When not in use it provides a very warm and diffused interior floor light. The finished unit hangs off of the passenger side interior panel and cant be see without getting down and looking under the dash. The light holds all the payout wire perfectly and is very stable. The main light head is a small round chromed utility light with a real early faceted glass lens that looks about right and take a standard bulb that provides enough light without blinding me, something that I can't stand about LEDs. I found it on Ebay an early 3" mercury switch light that would most likely have come out from under a hood as motion fired off the on switch. The mercury switch was removed and I replaced the old bulb mount with a new version that could take modern incandescent or LED bulbs. The.piece that makes this all possible is also readily available on ebay. It is a modern, small aluminum cell phone holder that has the unique characteristic of folding flat and still having two hooks to hang it up. I am confident those hooks were not there to do what I needed, but what a find. The hinge is excellent and remain quite stiff. Buy the one that looks exactly like this. Fresh cloth wire to reach everywhere on the car and couple of new holes and bolts and it was all to together. This light can also hang from the Rumble Seat side wall giving that area great light as well. I finally attended to a rats nest of wire stretching back 3 generations and wire up a new toggle switch just in the series just for this light. Nice, easy and fast project.

-

- 17 replies

-

- 1

-

-

- dual carbs

- hot rod

-

(and 3 more)

Tagged with:

-

Sniper, many thanks. Those are about what I would have expected and alluded to in the first entry of this thread. His results will undoubtably be proportionally better than what can be expected out of my engine model (1934 vs 1953.) As I just finished with a full rebuild it is about as good as it will ever get when I am done for a motor running on a single atmosphere and stock crank. For those that just want to see the article and its four pages, I'll post the four pages as photos and reveal the final detail charts so kindly mentioned by Greg.

-

Greg, First, thanks for taking the time to direct me to downloads. I searched every way I could and, unfortunately, nothing came up as you described. Under the a search for "Duggan" came "The best thing you can do for your engines performance is to boost the compression ratio. This assumes the rest of the engine is in good working order. .030 to .050 milled from the cylinder head will put your compression ratio up a point and a half or so. With this change you can also advance the timing a few degrees for better throttle response. You can also open up the intake and exhaust ports to match the gasket hole sizes. The 201 is never going to be a neck snapper, but it can be made more lively through these inexpensive modifications." that you yourself wrote back in 2021. I would agree with what you stated as a general rule. Having said that, where there are design limitations in a particular engine, more can be done. In the case of my engine model that would include the exhaust manifold (notoriously constrictive to the first two forward cylinders) and piston design and their rings. I have generally found that the search function at P-d is, well, disappointing. "...This article was submitted by member Mark Duggan, if you can't find it you might contact him to see if he has it as a pdf file he might e mail. There is also a chart for all flat head sixes illustrating the compression ratio changes that occur through planing or milling cylinder hea..." You again....NO CHART "Give member Mark Duggan a shout or check his profile on this site. He started a face book page for 40s to 40s chryco convertibles. Don't know how.much traffic it gets but there may be some resources and info for convertible specific issues. Welcome, enjoy your ride." You again....NO CHART "...Member Mark Duggan refreshed one a few years ago, he probably can steer you towards parts sources and maybe some tips and things to look out for." You again....NO CHART "...Member Mark Duggan did a rebuild on the one in his p15 shoot him a private message, he can tell you how and what to look for. He found all his parts on line. Most 9f 5he faults are electrical. Although there can be issues with internals, the usually are wear rather than damage. In the download..." You again....NO CHART In fact there are around 10 instances of you mentioning Duggan....and not one from him. Might you have that article and would you please consider reposting it? Thanks.

-

Boom! Fabulous

-

Full transmission rebuild is almost done. I was able to find NOS parts of the 1934 free wheeling transmission and am in the middle of a full rebuild. And there. folks, is a real story. As some of you may be aware the free wheeling transmissions had some very interesting attributes, interesting enough that approximately 11 states outlawed their use and required that the freewheeling system be dismantled. Most systems were dismantled by removing the cable that ran from the FW vacuum system and manipulated the tranny side lever that controlled the FW Clutch Ring Fork. But there are any number of unusual approaches to stopping the FW system to work. Here is one that stopped it cold.... but had impact! Weld the FW Clutch Ring to the FW Shell and Shaft! What is the impact? Harmonic vibration if you do a quick and dirty job and the nasty surprise of not being able to separate the TWO part Main Shaft, as the clip is UNDER the now welded FW Shaft housing. So the WHOLE stripped shaft is mounted up in a lathe and a cut is made right behind the welded bearing. We then can get to the clips, etc. strip the rest of the tranny and set about Fixing the FIX with unmolested/welded parts. No small feat as those parts are simply some of the rarest of all the Dodge transmissions parts. Oregon Bill kindly came to the rescue and everything I needed was made available. The end result will end up with totally NOS interior and the FH fork being restricted at the case exterior.

-

General update.... Work is well underway. What I am up to know is duplicating the stock Dodge DR throttle actuator that comes off of the cross-over firewall (Driver side to Passenger side) linkage and provides the actuation of the dual throttle linkage. The 1934 DR has a really nice design that allows for not only the foot accelerated to be delivered but the hand throttle from the dash as well. That hand throttle allows for setting the engine speed for warm up as well as a very early form of cruise control. In the original single carb set-up, the throttle pushes the carb mounted link UP....and the dual carbs require pulling DOWN. Now most folks just take off the original throttle actuator and don't get to use the hand throttle. I want the exact same functionality so.......the new mounting plate will take the original throttle actuator and REVERSE the direction when it interfaces with the dual set up. Pics to follow, but for those that have never seen the 34 actuator....here it is on the single.

-

FT, Those headers are manufactured as requested by Red's Headers in California. These are not stainless as the bends required are too tight to be made with stainless, they are mild steel. What you see here have been coated by Jet Hot in their standard silver. I hope that helps. When you see them you will be struck by how beautifully they are rendered and how tiny they are. All flow and conflict issues with pumps etc are finished.

-

That is impressive mileage and helpful for those that run the FENTONS. Can we see the proximity of the manifold to the fuel pump side of the block? I've seen a good number of them and would like to see how you managed it all. I would imagine that you have had no issues running the heater block. My early point is not about running it, its about not needing to run it. Look forward to the pics and much greatly appreciate your post

-

I am not building headers, I like you I'm trying to find appropriate sources and talking to people along the way. When I come up with a solution set of choices, I'll be sure and post it out. As to the issues surrounding heating intakes, it is just one man's opinion to consider. Time to get back to work.