-

Posts

197 -

Joined

-

Last visited

-

Days Won

8

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Semmerling

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

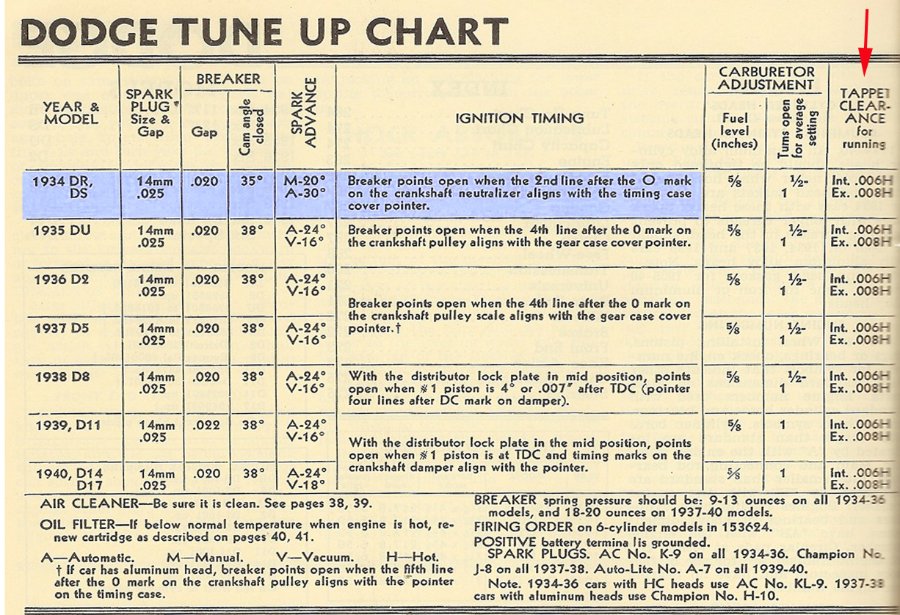

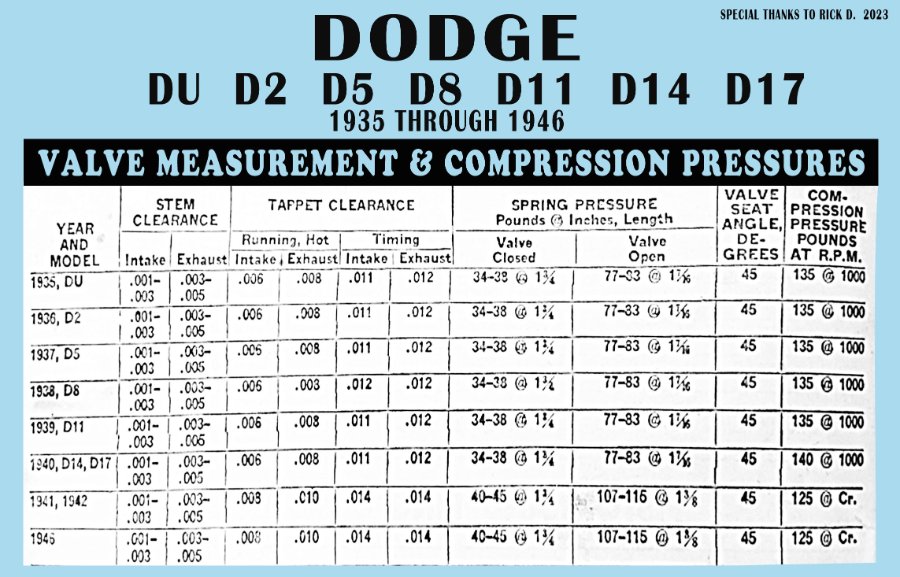

John, I have a good amount of early Dodge material. Here is one showing valves lash as low as....well take a look- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Duplication- 42 replies

-

- 1

-

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Flathead 6 - Head Torque both Initial and Maintenance

Semmerling replied to Semmerling's topic in P15-D24 Forum

First off, thanks to all for their thoughts. I used the font because I had a whole crate of the font, well everything except capital "K" left over from a "don't be boring" mandatory event I had to attend. The best news so far is three fold, first that it looks generally serviceable, secondly that PDF makes a difference and thirdly that DHS is still of the mind that the masses can read. By any description....winning. It is unclear as to how material is moved into the Tech tab. -

Flathead 6 - Head Torque both Initial and Maintenance

Semmerling replied to Semmerling's topic in P15-D24 Forum

Appreciate you taking the time to respond. Here is the graphic in PDF, even with medium bicubic downsampling PDF barely makes the 3MB hurdle The bigger problem with PDF is that this site requires a download as it appears it cant actively show and enlarge a PDF online. Not sure PDF actually helps the real problem, that being clearly seeing and enlarging a simple jpg. This was made Photoshop. PDF DODGE HOW TO TORQUE HEAD.pdf -

Trying to produce another unified and simplified graphic document on the subject of torqueing the head. These are a series for my kids to return to as required In this case, one would download to be able to read it as there doesnt appear to be the means to see it in a larger format here. It prints out to standard page size. Let me know if it looks in order.

-

Different way to do static tappet adjustment on flathead six.

Semmerling replied to MarcDeSoto's topic in P15-D24 Forum

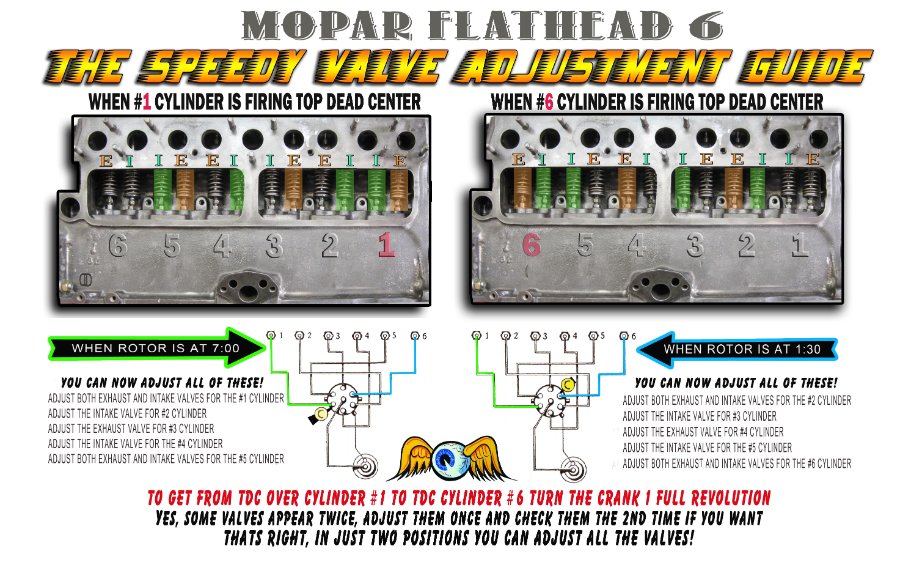

True, but the important part is to not confuse between the FIRING TDC and the EXHAUST TDC. The graphic reveals the relationship between a PROPERLY set-up distributor and the cylinder entering FIRING TDC by a quick observation of the distributor to know which is which. It is 100% correct. -

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

No problem Sam, we have a solution for that! Special thanks to Jim Paulson at Causeway Castings for making up these "Cylinder Number" cases for me. They are only $113 but do not have the means to support a manual fuel pump.- 42 replies

-

- 2

-

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

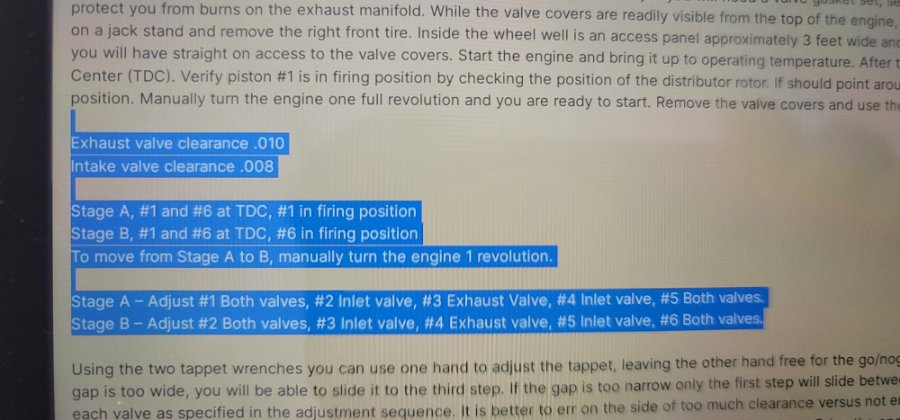

Marty.....you missed the other one to be exact....check out #5 Ok lets take some time here.... Marty, nobody is catching that as it isn't a mistake. this guide allows you to POSITION (the big ARROWS) the TDC on only two (2) cylinders and do ALL the valves. Sometimes you can do BOTH of a single cylinder's exhaust AND intake.......and sometimes its just an exhaust or just an intake. Now you don't have to do it this way.....but you can. Again, position it in TWO specific TDCs positions.....and do all the valves. You can also just move from FIRING POSITION to FIRING POSITION and do each cylinder at TDC too. - Yes.....there are single valves that come up as ADJUSTABLE in more than one position. This is not a "new" discovery, it is almost a 100 years old. For those that didn't read the first page.... Stages matter...... THIS IS THE EXACT TEXT FROM THE TECHNICAL PAGE RIGHT HERE AT P-D -------------------------------------------------------------------------------------------- Exhaust valve clearance .010 Intake valve clearance .008 Stage A, #1 and #6 at TDC, #1 in firing position Stage B, #1 and #6 at TDC, #6 in firing position To move from Stage A to B, manually turn the engine 1 revolution. Stage A – Adjust #1 Both valves, #2 Inlet valve, #3 Exhaust Valve, #4 Inlet valve, #5 Both valves. Stage B – Adjust #2 Both valves, #3 Inlet valve, #4 Exhaust valve, #5 Inlet valve, #6 Both valves. ------------------------------------------------------------------------------------------------------------------ Leroy..... Start from the top. This guide is helping those that want to understand TDC, factory shop manual valve adjustments how and why it is done. You don't need TDC because you are doing your adjustments quite differently than the factory shop manuals. TDC is not needed, neither is wiping the oil off your feeler gauge, etc. etc. You have a technique that takes time to master.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

I appreciate your comment, this guide is attempting to help those trying to do a standard valve adjustment. I mentioned this in the very 1st paragraph. You had mentioned that you didn't pay much attention to the poop sheet. That is completely understandable as you do your adjustments without concern for TDC. "Unless I missed it I didn't see any info on the guide about which cylinder is #1 unless we are supposed to assume the #1 cylinder on the left is the "front" of the engine. To make it more confusing, #1 is on the left in the Rotor diagram but on the right in the (unnumbered) illustration of the valves!" Distributor Side = #1 cylinder IS on the LEFT (it is properly and plainly numbered) and it IS in the front On the Manifold side = #1 cylinder IS on the RIGHT. Nothing confused about it......unless your engine has the distributor and the manifolds/tappets on the same side.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

FIRST ILLUSTRATION We see the engine from the distributor side We see the wires coming from the distributor to each cylinder We see them all numbered in cylinder number order left to right The first illustration requires knowing the cylinder order in proper left to right series Why? So that the common mistake of distributor wire to proper plug can be checked as well. SECOND ILLUSTRATION - The Manifold side We are concerned with TDC as it moves from cylinder to cylinder in FIRING ORDER We begin with the cylinder Firing Order marked #! as that is TDC - it is extreme RIGHT Then move to cylinder Firing Order marked as #2 as this will be next TDC- it is 2nd from LEFT Then we move to cylinder Firing Order marked as #3 as this will be TDC - it is 3rd from RIGHT Etc. Etc. Etc. The Red Number are at the point of where the adjustments will be made.....the tappets.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

1. Going to say no to this one. RED NUMBERS mean FIRING ORDER. See #2 2. Whereas you are certainly correct that this diagram is for a correctly set distributor. You are also correct that the distributor can be set in incorrectly and (knowing the firing order) one can make up for the error. HOWEVER - The diagram solves the dilemma by exhibiting and requiring the viewer to follow the wires FROM the distributor TO the plugs, thereby showing proper distributor setup AND EXHIBITING PROPER CYLINDER NUMBER ORDER. Good minds should see any alternative pathing and then think "not what I have, what is up with that?" For a simplified guide to standard procedures we should establish the right way in a manner that reveals a deviation. No doubt you are right they can set it up wrong. That is a different Speed Guide subject matter. Appreciate you taking the time.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

You are absolutely right. ALL FIXED SEE THE !ST ENTRY IN THIS THREAD- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Many thanks for that Bob- 42 replies

-

- 1

-

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Man what a fabulous video on valves. Thank you so very much.

I changed the very first sentence on the whole thread to point folks to your video. -

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Keith and Sniper, many thanks very helpful both..- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Keith would you be so kind as to drop the links right here for those that might follow? Much appreciated.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Rick many thanks, much appreciated and confirm my manual as well. Dave, nobody will ever say that you cut corners. My kinda guy.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

In approaching helping people that do not have the depth and breath of mechanical experience that professional practitioners or even the casual weekend warriors have the process has to be reasonably stream lined. By and large the best that P15 has to offer is lost because of an abysmal search engine. Anybody that has used it, really spent time with it knows this. I can go on at length that absent the ability to tell the search engine not to allow certain words ("-PVC") means all is pretty much mishmash. Many good people have come forward with some very good material over the years but much of it is presented from the perspective that relies on fairly good competencies and skills. That is great for the 72% of the curve that is over 65 but it makes bringing forward the next generation much more difficult. Hammering the feeler gauge - Of course it hammers the feeler gauge, but that isn't why some folks do the "pogo." The best of them do it because they actually have done it enough to actually come closer to getting it right. Those people are not the ones that are going to do the majority of of it by the Factory Shop Manual." "Better to hear it than smell it" - That also came from folks right here. It's a practical statement on "if you hear it, adjust it properly as just getting rid of the sound may later make you get rid of the block." Snugness thing is a wipe off the oil kind of issue, feeler work unless its dripping in oil and on a "pogo" is what it is. Comments by 9-Foot-Box are of the very best kind. He offered up the last missing part of these guides, that being, the EXACT FACTORY RECOMMENDED SETTINGS broken down by engine types/year/options etc. I have what I need from my manuals, but I remain curious what others might think. If I had access to that information I could do one of the following: - Set it all out properly in a SIMPLE table right here and find the means to get it to the "How To" section and pray that the search engine finds a better search engine in the future. - Distill all of it down to 5 or 10 groupings that deal with the 2 standard deviations crowd of crankers, grinders and deckers. - Come to find that the vast majority of it all breaks down to .009ish for intakes and .011ish for exhaust. Your thoughts on drawers and feelers - Better yet, take a 12" piece of something and mount the right for your rig right on it. That way you can easily work it either through the wheel well porter or whatever. I've seen them with the Intake feeler on one end and the exhaust feeler on the other. The business about ever, repeat ever, feeling the need to change the adjustment is what this is all about avoiding. These should last 10,000 miles or more. My car has been in the family for four generations and, outside of the rebuilds, 11 adjustments. The important point to my mind is doing it well once in a long great while. Not sure how we got from "If LOTS of highway driving" to "2 hours" but we did. Trust me when I say that making up these guides takes more time than adjusting the valves ever did over the last 90ish years. Appreciate the comments.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

I appreciate the chance to correct it. Thanks for letting me know. Stages matter...... THIS IS THE EXACT TEXT FROM THE TECHNICAL PAGE RIGHT HERE AT P-D -------------------------------------------------------------------------------------------- Exhaust valve clearance .010 Intake valve clearance .008 Stage A, #1 and #6 at TDC, #1 in firing position Stage B, #1 and #6 at TDC, #6 in firing position To move from Stage A to B, manually turn the engine 1 revolution. Stage A – Adjust #1 Both valves, #2 Inlet valve, #3 Exhaust Valve, #4 Inlet valve, #5 Both valves. Stage B – Adjust #2 Both valves, #3 Inlet valve, #4 Exhaust valve, #5 Inlet valve, #6 Both valves. ------------------------------------------------------------------------------------------------------------------- At the proper stage (see the two ARROWS) in the guides, do you still see a problem? Given that, reviewed and corrected SIMPLIFICATION should result in something that actually supports learning, It sure beats overly complex and highly subjective, scattered everywhere information. Or worse, not understanding why something is correct, lets see if we can finally improve on that.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

On that very topic, I returned the INTAKE to .008 and the EXHAUST to .010 with a note about highway speed. I think the we are close here, did you see any errors?- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Very helpful and very welcome. My concern is teaching those that do not understand the basics. Your work is fabulous, but in some ways inaccessible. Let me ask you directly, is the information on the guide a made up above correct? And if it is, should we also provide the following image as well. Lastly, what would have been the factory recommended gap for a 1934 Dodge DR. Many, many thanks for taking the time to reach out.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

I am asking if the document is correct if one was to do it following the prescribed process in the manual. Without knowing which is EXHAUST and which is INTAKE, that is the best video of how to stick thin metal into moving metal pieces on the web.- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with:

-

Adjusting valves - Speedy Mopar Flathead 6

Semmerling replied to Semmerling's topic in P15-D24 Forum

Good points, we'll add.. - take the spark plugs out - Turn clockwise using a starter handle for TDC. Is there anyone who might be able to offer up a simplified I/E gap by engine year/type?- 42 replies

-

- adjusting valves

- valves

-

(and 1 more)

Tagged with: