-

Posts

7,238 -

Joined

-

Last visited

-

Days Won

82

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by JBNeal

-

VINTAGEPIC: saw this C-1 meat wagon on the FB...I reckon that mirror hasn't been used to find a loading dock yet 👀

-

I've rehab'd a gearbox while it was still in the truck...removed the top cover plate, removed the output shaft seal, flushed with diesel while cycling the gears, compressed air dry, cleaned output shaft for new seal installation, filled with corn head grease, cycled the gears a few times to displace the air, topped off grease while cycling gears again, applied thin layer of RTV as cover seal for installation, did the gearbox adjustments in those posted links, worked purty good. Yep, that looks like '52 👈

-

51 B3B build thread - after all these years

JBNeal replied to bkahler's topic in Mopar Flathead Truck Forum

I remember those ads Leadville Larry ran for years in the Hemmings...kinda wondered how much inventory he actually had, don't recall him showing any pics off but had to "call for availability" I went out in the arctic breeze this afternoon to eyeball that flatbed spare cuz that pic looks kinda familiar...studied the parts book too...I think that extra thread on those special bolts is to allow for larger tires and wider rims to be stowed safely. An alternative to that cotter pin is to use a roll pin...I reckon that once that carrier is installed, it won't be removed for a long time...back in the day, them extra threads would probably be mashed in a couple spots to keep that nut from backing off. -

if'n there is a plastic trim piece that says DODGE above the ignition keyswitch, it's a '53; if'n it's a stainless steel rectangle kinda shape, it's a '52. Corn head grease works very well in a properly adjusted steering gearbox, especially if the output shaft seal has been replaced...no more oil drips from that area. additional information - steering gearbox overhaul additional information - steering gearbox adjustments

-

I have limited experience with applying stains, but I noticed that stains applied in warmer weather appear to dry faster and more evenly. I stripped and stained an oak table that was originally painted multiple coats of black, did this in a small 1-car garage in February so I could run a propane space heater in there to get the temperature up in the 60s. I had read that getting the wood cleaned well and allowing to dry thoroughly was critical before staining, so I'd clean one day and let it dry for 2 days just to be safe, with the heater within 5 feet of the wood but not under it. The dark maroon-ish stain I applied dried somewhat evenly to look like red cherry like the gf wanted, but I could tell where I had slopped out too much stain and did not wipe off the excess fast enough...she commented that she liked the randomness of the grain accents or sumthin-ruther so as long as she was happy, I was fine with it. Anyhow, I recall doing a test stain on some scrap oak and it was a little tacky after 24hrs. I guessed that the 50ish degree air temp was too low so I cranked up the space heater to get it to stay in the 60s in that garage and the next test went well enough that I went to staining the underside of the table first to get my technique polished.

-

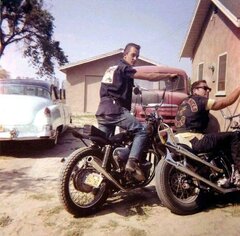

VINTAGEPIC: saw this B-1or2 parked on the FB

-

From the album: Vintage Pictures

-

Tucker body shop in progress

-

From the album: Vintage Pictures

-

From the album: Vintage Pictures

-

This corner of the Spring Special bed still has its black paint present, and it appears that the shovel strips are rabbited in and the bed washers are seated in counterbores. I believe both of these details serve a purpose: shovel strips lock into the rabbits to keep the boards from moving laterally, which might expose the gaps between the boards and the bedsides without the counterbore, any compression of the boards by the big washers could cause splintering around the washers, which could snag on burlap or paper feed sacks; the counterbore removes this risk by placing any splintering below the bed boards surface

-

VINTAGEPIC: spotted this B-3 parked on the FB

-

OUCH 👀 Can those cracks be welded? Did the machine shop find anything when they magnafluxed the block? Can't sat that I've seen cracks in this area before...

-

51 B3B build thread - after all these years

JBNeal replied to bkahler's topic in Mopar Flathead Truck Forum

Scratch that suggestion, I was thinking about something else...if ya lift the bed by the ratchet strap hooks, you can probably resist the bedsides from bowing by filling the bed with a temporary box by stacking some pallets in the bed, wedged in place with cardboard and/or carpet remnants. -

51 B3B build thread - after all these years

JBNeal replied to bkahler's topic in Mopar Flathead Truck Forum

How'bout: instead of pipe, ya fed nylon ratchet strap through them bed rolls...remove the ratchet, feed the nylon strap through the roll, tape some cardboard onto the strap to prevent chafing, put the ratchet back on, now you've got 2 hooks protruding from the bedside to latch onto place 2x4 strategically in between bedsides so that when lifting, the strategically placed 2x4 resists the bedsides from bowing inward...suspend in place with duct tape attached to lifting strap Is it pretty? Naw, but it's a one-time tooling use that ya minimize costs with readily available materials that can be disposed of economically. Duct tape: the handyman's secret weapon 🏆 -

high exhaust header temps on 230 engine

JBNeal replied to wiboater's topic in Mopar Flathead Truck Forum

The hood louvers reminds me of something that I tried awhile back. I tweaked the hood latch on the passenger side so that the front still hooked but the rear rode on top of the hook, leaving a sizeable gap between the passenger hood and the cowl. This kinda helped with the carb issues, but looked kinda funny. Once the weather cooled off, I readjusted so that everything was back to normal. That seal that was originally held in place with spiral shank nails into the cowl appeared to have been made out of canvas, and ran from roughly in between the upper door hinges. What if that seal was trimmed back so that there is no seal between the windshield wiper pivots? The cab has an integrated gutter along the top of the firewall, so any moisture that gets under the hood would shed towards the inner fenders. This gap in the seal could allow heat to escape the engine compartment, much like hood louvers without modifying the hood sheet metal. A replacement seal of foam rubber would compress a certain amount but would ultimately keep the hood spaced away from the cab and serve as anti-squeak; a small strip of anti-squeak would also need to be positioned on the cowl near the hood hinges. This might not solve all of the fuel boiling issues but it might help. -

Another necktie looking at a mashed Tucker

-

VINTAGEPIC: saw this B-1or2 grain truck airing out on the FB

-

From the album: Vintage Pictures

-

That black stuff might be sludge, who knows what quality of coolant was put in there or how long ago. On long dormant engines, I flush out with a garden hose, let to dry, then repeat...once the engine is running, let the cooling system go through several heat cycles with just water no antifreeze, this helps to boil out the engine and if there are any leaks, ya don't lose that pricey coolant. When the system goes through quite a few heat cycles and the water stays clear, then it's ready for proper coolant.

-

Check out the wall display at a good tire store...there may be an idea there that can be fabricated out of some scrap metal to make a tire hanger, cheaper than a rim and looks OK from 10 feet away

-

51 B3B build thread - after all these years

JBNeal replied to bkahler's topic in Mopar Flathead Truck Forum

grey beard documented his approach...this might or might not help: https://p15-d24.com/topic/3497-pilothouse-pickup-bed-reflooring/#findComment-424809 -

51 B3B build thread - after all these years

JBNeal replied to bkahler's topic in Mopar Flathead Truck Forum

If'n ya loosened the bolts on those L-brackets and rabbit the planks 1/16", could the planks be knocked into place? The bed sheet metal rests on those outer planks so I'd not want to remove too much material...I kinda figured them angle strips could flex a little, maybe even the sill plate a tad, and with that tight fit of plank between sill and angle strip, the L-bracket could be tightened back to complete that part of assembly.