-

Posts

5,090 -

Joined

-

Last visited

-

Days Won

58

desoto1939 last won the day on October 31 2024

desoto1939 had the most liked content!

Reputation

1,485 ExcellentAbout desoto1939

- Birthday 05/25/1951

Contact Methods

-

AIM

desoto1939@aol.com

-

Biography

Have bicycled across the USA in 1976 from Williamaburg Vir to San Fransico Ca

-

Occupation

retired software Quality Assurance analyst

Profile Information

-

Gender

Male

-

Location

Valley Forge, PA

-

Interests

Colleting old Cross reference catalogs to support the antique Moapr cars and Trucks Have scanned these an put on Compact disks. Bicycle collecting and Bicycle touring

-

My Project Cars

1939 Desoto 4 Door Sedan that has been judged as HPOF with the AACA.

Converted

-

Location

Valley Forge PA

-

Interests

own a 1939 Desoto 4 dr sedan

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

purchased two GE 4030 Sealed Beam 6volt headlight bulbs

desoto1939 replied to desoto1939's topic in P15-D24 Forum

But here is the big issue. AACA permits the cars that are being judged for Junior 1st, 2nd and 3rd place trophies and also Senior 1st along with Grand National cars that should not have the lens with the nubs that they can pass the judges with these nubs. AACA standards are that are car is to be represented as if it just came off the showroom or dealers lot or backlot. I have brought this to the attention or the CEO Mr maskowitz about this issue. He could care less and stated that they do not know every car. Two years ago at the Hershey fall car show there was a 1951 Chrysler Royal 6 that had a recent Senior Grand National badge attached to the front of the car, BUT this car also had the incorrect headlight lens with the three nubs. Next to this same car was a 1950 Desoto that had the correct Autolite Bullseye bulbs and then down the row was a 1953 DeSoto that also had the correct bulbs. I pointed this out to Mr Maskowtiz. My point is that if the car is a Senior Grand National winner to me that tells me that the car has been judged by the most experience judged and have gone over the car with a fine tooth comb. Also since it is a senior Grand National the car owner then can increase the selling price. But a poor guy that does purchase the car would be paying top dollar for the car and would have incorrect parts on the car. The AACA judging standards have gone down hill so do not always thig that a judged car is correct and also far from being perfect. I also offered to come to the Hershey AACA headquarters and do a presentation on Headlights and also told this to Mr Moskwotz but he and the AACA have never answered my opportunity to educate them and to update their judging manual. But there profess to be the experts on judging of restored cars. Just posting the facts that I know and have first hand knowledge of seeing AACA judged vehicles. Rich hartung Desoto1939@aol.com -

I went to a local swap meet held by the South Jersey AACA club on Sunday. There were a lot of venders. I was able to purchase two GE 6volt 4030 sealed beam headlight bulbs. Refer to the attached pictures. When looking at the front of the bulbs you will notice that there are NO alignment TIT molded into the front glass part of the bulb. Starting in 1940 the sealed beam bulbs did not have the aiming tips. The aiming tips started with the 6006 6v bulbs that were starting to be manufactured around 1955/56. Mopar used the 4030 bulb from 1940-1948 as standard equipment and then in 1949 -55 they used the Autolite Bullseye bulb. I came home and cleaned up the bulbs and tested them on my 6 battery tester and both low and high beams worked. So I am ready, if I ever want to convert my 39 Desoto over to sealed beams, but the conversion trim is totally different than the original rectangular trim. But at least i have the correct period correct bulbs and I also have the correct adapter and conversion sealed beam internal components for the car. Oh, and I only paid $5 for the two bulbs. Not to rub it in or not. Just wanted to provide some education if you have a mopar car/truck from 1940-48 so tha you can have the correct period headlight bulbs installed if you are going for points judging. I did a presentation at the National Desoto convention on headlight so this is how I can document what is and is not period correct. see the pictures below. Rich hartung Desoto1939@aol.com

-

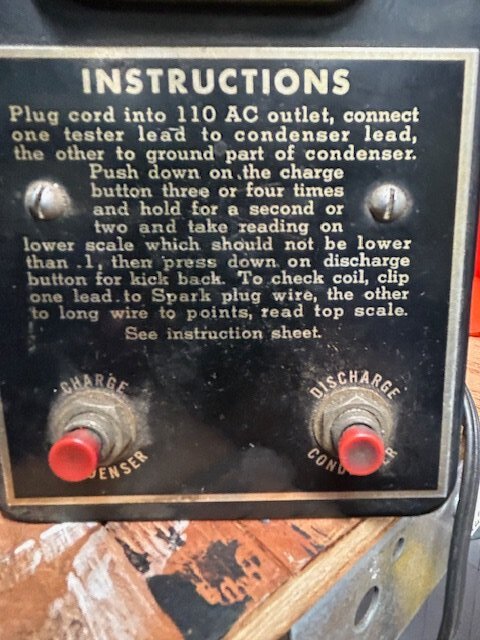

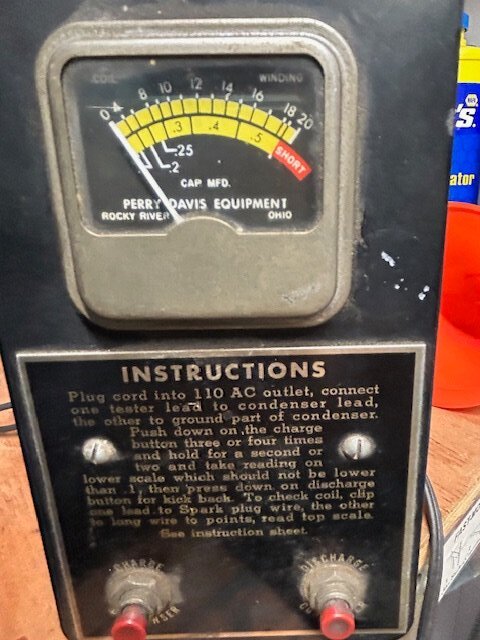

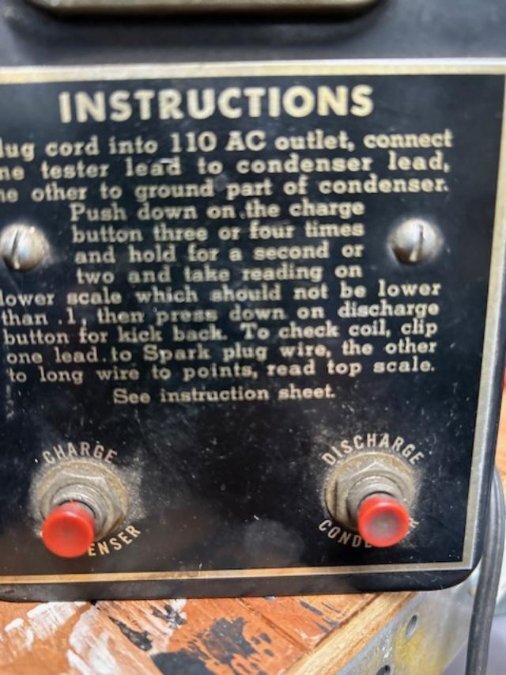

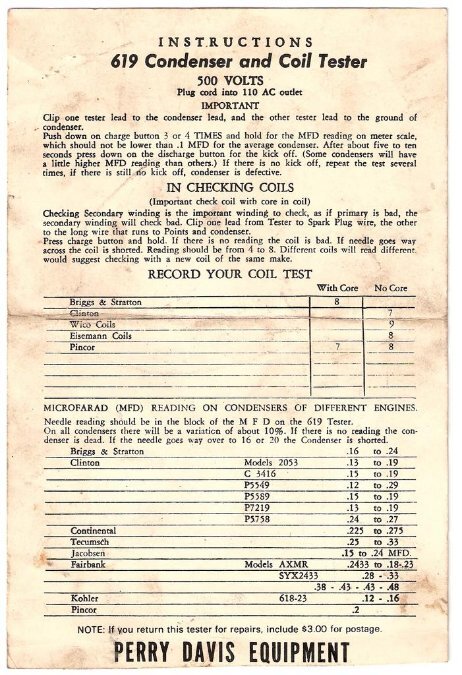

I went to a local swap meet held by the South Jersey AACA club on Sunday. There were a lot of venders. I was able to come home with three great purchases. 1st found a Perry Davis Coil and Condenser testing. I know how to work the condenser testing part. But, i can read the instructions on the front of the tester. I have a question regarding the testing of the coil You plug the tester into an electrical outlet. Connect one lead to a spark plug and the other lead to the wire coming from the coil which would be my postive wire going to the distributor. Then i assume you should get a reading on the upper scale on the tool. When testing a condenser you have to press the charge button on the left get the reading for the MF, Micro Ferrets reading then discharge the condenser. But when testing the coil do I have to do the same process or not and also does the ignition switch need to be turned on so that the current is now completing the circuit from the coil through the distributor to the spark plugs. I want to make sure I have this setup correctly and then do not want to destroy any of the electrical parts and the original coil that is in the firewall. I have never done this test so trying to figure out how to properly perform the test safely. I purchased the tool for $10. Not a lot of money for a diagnostic tool. refer to the attached pictures of the tool and the instructions on the tool. Any help is appreciated. After getting the tool to work I will post pictures of the readings that I get on my 39 Desoto. Did a search and found an instruction sheet on the coil tester. Hook up the two leads and then depress the charge button to get your reading on the scale. But nothing stating to turn on ignition and or to depress the discharge button. What is everyones opinion.

-

Doug: Glad you figured out the issue. So what fuel pump number solved the issue? Hey are you planning to be coming to Hershey this fall, if you do please stop by our vendor spot at OAD 7&8. Looking forward to seeing you again. Rich Hartung desoto1939@aol.com

-

in your car if the car was made in the US it will have the 23 inch block and head. So are you wanting to go to the bigger 25 inch block and engine that were used in the Chrylser/Desoto cars? If you go this route then you might have a very tight fitment issue. Rich Hartung Desoto1939@aol.com

-

Sonny: Have you removed the top of the carb to verify that gas is getting into the bowel and that there is no sediment or dirt in the bowel of the carb. If the move the throttle linkage does gas squirt down the body of the carb. Coulb also be a stuck needle valve that operates the float. Also check the float to make sure it does not have any holes. Would the car also need a ballast resister since now going to 12 volt? Rich Hartung desoto1939@aol.com

-

If looking at the post above this one and refer to number 13 you will notice that the vibration dampener and the pully can come as a complete unit. refer to number 47 on the grid below. The numbers on my grid are also factory number and come from a Mopar vender Tristate catalog that the Mopar supliers used and is the same as the michell catalog number. When I replace the vibration Dampener and pully is was a single unit that already had the hub on the unit. Rich hartung Desoto1939@aol.com

-

You will use an r-1 radiator cap if you still have the original radiator. here is a picture of the cap. Rich hartung desoto1939@aol.com

-

You are correct that you DO NOT use a pressure cap on the radiator. The radiator should have an overflow tube and these older systems are self leveling. Fill the rad with water and then run the car until it gets up to temperature. The rad will burb out the excess water and it seeks its own level which willbe approx 1 inch down from the top, just keep it maintained at that level, sorry, we are not metric here in the states, and we drive on the right and not left side of the road, just kidding

-

Here is a page from my tristate mopar venders catalog on the vibration dampener. Hope this helps you. Rich hartung desoto1939@aol.com

-

I sent you a PM and I have the kits and housings for the 40 Plymouth. Rich Hartung

-

I am looking at maybe purchasing a 1956 Dodge Coronet Coupe with the V8 engine. The car is yellow and white combination. Interior is very good. overall body condition is very good no cancer from the pictures. Chrome looks great and would make a great diver car and also being 12 volts. What are some of the areas that i should be concerned about, Trans, rear, engine, etc. Looking for input prior to making an offer or even considering the car. Thanks for any input. Rich hartung desoto1939@aol.com

-

I am looking at maybe purchasing a 1956 Dodge Coronet Coupe with the V8 engine. The car is yellow and white combination. Interior is very good. overall body condition is very good no cancer from the pictures. Chrome looks great and would make a great diver car and also being 12 volts. What are some of the areas that i should be concerned about, Trans, rear, engine, etc. Looking for input prior to making an offer or even considering the car. Thanks for any input. Rich hartung desoto1939@aol.com

-

Check the metal tag that still might be attached to the generator and or starter motor. The color of the tag should be red and this indicates that it is 6 volt. If the tag has a green background color then it is 12 volt. Also same with the volt regulator. Verify and double check all of these prior to installing the battery. I would think that the car was never converted to 12 volt. You will also need to purchase a drum puller to get the rear drums off the tapered axle. When you get to the point of doing this contact us again so we can walk you through the process. Rich Hartung Desoto1939@aol.com

-

The only way to find out if the clutch is toast is to remove the starter motor again and inspect it. Lets hope that you did not damage the ring gear and grind away any of the teeth. Let us know what you find after removing the starter motor. Rich hartung