Single Carb Intake, Dual Carb Intake, Triple Carb Intake, why not more ?

·

· For Decades I have listened to people talk about Flathead Mopar 6 Cylinder Engines in terms of intakes, what is the best carb configuration for their particular situation.

Discussions on putting two carbs and those who claim to be sure that is too much carburation or that it will use to much fuel. Then every once in a while the discussion of 3 carbs comes up, and that almost always sparks the debate on how it would take a race motor to need it, or how the engine will bog, or run poorly. In the last 20 years with a good friend of the AoK boys coming across a huge stash of 2 barrel carter weber carbs which were designed for slant six engines, the discussion on utilizing a 2 barrel instead of two singles comes up.

I just smile, but then I know that when the stash of 2 barrel carter webers were found, its finder put them on his website as a carb for a flathead mopar. Its amazing how a market can be created and how quickly – “this is the way to go” spreads like rapid fire, without as much as any background check into something.

But 1st, let me go back to the 1st time I heard the discussion on multiple carbs vs a single multi-barrel carb, or put another way, comparing that “old technology carter ball and ball vs a modern 4 barrel carb”..

It was about 45 Years ago, when I 1st heard someone in a conversation with my Grandfather and my Dad, suggesting they knew a lot about Flathead Mopars and were sporting a 4 barrel carb on a homemade intake.

This gentleman had played with flathead Ford v8s and had came across a Dodge 2 door sedan from the mid-50s. He was suggesting he had built the ultimate flathead Chrysler Engine and he was one of those guys that whatever he had at the moment was just the best and the only way to go.

Well after my Dad explained he had far from the ultimate flathead Chrysler, and that his wife’s daily driver (my Mom) was good enough to kick his ass, Dad pulled out my Mom's pickup. It was sporting a bored out 265, with a cam, a factory dual intake and exhaust with a pair of carter ball and balls, and an a833 4 speed tranny. After a little bit of fun that really wasn't much of a contest, licking his wounds sort of speak, Mr "Ultimate Flathead Chrysler" started down the road of excuses when Grandfather shook his head and cut him off at the pass.

Grandfather like my Dad were automotive Engineers, and Grandfather literally knew more about Chrysler Flatheads than any person alive. Given he saw the very 1st flathead roll of the line in Windsor, Ontario Canada in 1935 and saw the last block cast in 1959, he had some pretty good credentials to give a lecture.

What is explained in a few minutes was not only how the flathead engine worked, but why the engine this gentleman had came with only 1 carb failed to perform.

Most think that 1 carb was put on the engine and that it has sufficient carburation for the engine, and if it needed more, Chrysler Engineers would have put more on.

On a basic level that is true, but what engineering was building was an engine to a specific HP, torque and fuel consumption target and not to get the most out of the engine, make it as efficient as possible or even have it run to anything close to 100% optimum performance.

By Optimum performance I am not talking maximum hp or maximum rpm or optimum fuel mileage on a vehicle.

Grandfather then explained that in fact when Chrysler was faced with the need to meet a 5 ton truck specification for dump/plow trucks asked for by Canadian Municipalities during the winter of 1950, that the requirement had filtered to engineering in late 1950. They developed the 265 ci motor which was 3 7/16" bore and 4 3/4" stroke and have dual carbs and dual exhaust on them, which was what was in Mom’s pickup.

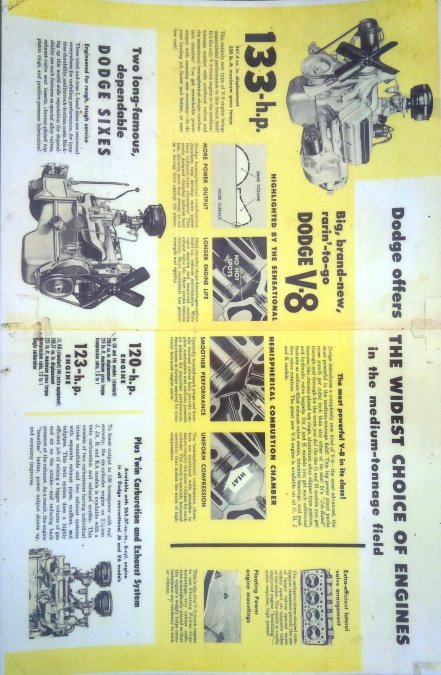

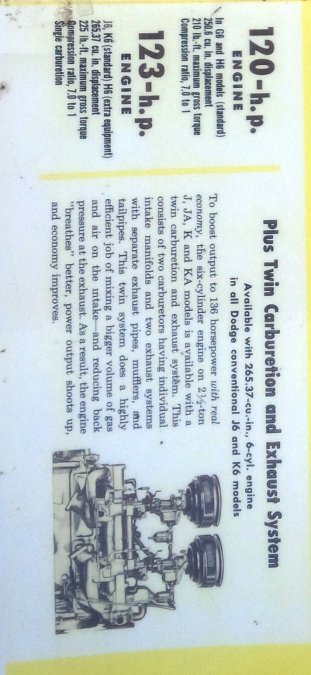

Few realize that that engine actually had more hp than any other engine on the market. I will attach the picture of the poster that was on Grandfathers office at the time. I gave it to George Asche Jr years ago. In any case you can see the hot v8 mopar had in 1952 was 133 hp and the flathead 6 had more hp. As an aside Grandfather with the cam grind out of the 1952 Chrysler that engine exceeded 150 hp at the time, but given the time, energy and money that have been invested in the new Hemi v8 that was never going to see the light of day on any marketing information.

That engine and the fact it had a factory intake, immediately became a stock car favorite in the 1952 season, when Mopar dominated stock car racing everywhere it landed.

In any case Chrysler didn't just put on a second carb on it because they needed more carburation. By then Chrysler already had Carter building Ball and Ball carbs from 85cfm - 425 cfm each and we now know they had a 625 cfm carter ball and ball single barrel carb if they needed it.

The reason for two was the basic issue, some would call flaw, but Grandfather would call basic restriction to taking the engine to the next level. I say that folding back to the earlier point that Chrysler was building engine to a spec of "x" hp, "y" torque and "z" fuel consumption.

The flathead 6 build by Chrysler has 3 Siamese intake ports, each of which feed two cylinders. Setting aside the exhaust for a second, and keeping in mind that an engine is really just a giant vacuum pump, putting 1 carb in the middle of the block, basically over the middle intake port feeding cylinders 3 and 4, means that if all cylinders are the same in compression ratio and ability to create vacuum and suck in a fuel mixture coming from the carb, then cylinder 3 and 4 are going to get more fuel than the intake ports feeding cylinders 1 and 2 or 5 and 6. Yes Chrysler made intake modifications to help that, but they again were not trying to make the perfect engine, just have it meet specs required.

As a little aside if your look at intakes from the 1930s through to the 50s you will notice Chrysler Engineers raised the level of the carb. With the Dual Carb truck intake it also was raised further with governors placed under the carbs. The height of the carb mounting above the intake posts can easily be seen to rise from the 1930s to the 1950s.

Its also why if your look at some of the aftermarket dual intakes made in the 30s and compare them to say the 3rd generation Edmunds in the 50s you will notice a huge difference in height. The raising of the carbs and providing a smoother run from carb to the intake ports saw huge benefits in performance. Of course maybe buried in the story is the fact that early intake was designed for a marine application where quick rev was far more the desired trait than was torque. When the intake was moved to an automotive application you would find a quick rev with the clutch engaged, but disengaged there is a significant loss in torque and it will actually burn more fuel than a single carb.

But back to my story, if we now add the exhaust component into your stock Mopar flathead (or L-head) which depending on what year engine and what vehicle, has the single exhaust exiting at one of a few different locations. For this discussion lets say it exits at the back as does the post ww2 cars. What you find is as the cylinders push out exhaust there is almost no restriction or back pressure at cylinders 5 and 6, but there is a great deal of back pressure at cylinders 1 and 2.

So here we have the most back pressure making it tough to push away the exhaust and actually the front intake port receiving the least amount of fuel.

While the engine meets specs with no problem, its clear that if you can balance the exhaust, by having 3 exhaust cylinders exit through 1 exhaust pipe and the other three through a 2nd pipe, you can better balance the exhaust back pressure. We sort of glossed over the fact that while there are only 3 intake ports, each cylinder does have its own exhaust port. Something that changed with the introduction of the slant 6, which had 6 equal intake runners each feeding a cylinder.

Back to the flathead, if we can better distribute fuel to balance the opportunity for each of the 3 Siamese ports to get fuel, then the engine will run more efficiently.

So if you were to take a big block 25 1/2" engine, and anyone of them, not just the 265 and put the factory dual carb and dual exhaust setup on it and then put on the appropriate carter ball and ball carb on it, it will gain hp, torque and improved fuel mileage. The reason is it runs more efficient. The same takes place with the 23 1/2" USA small block which has the same intake and exhaust configuration, although slightly smaller ports.

If you take it one step further, putting 1 carb on top of each intake port, you can provide the optimum amount of fuel efficiency for the engine.

Back to our 4 barrel friend, putting on a large carb just provides a further opportunity to over fuel the center siamese intake port. When he hammered the throttle it was actually not able to burn all of the fuel in the middle two cylinders and was “bogging” ,until it could gain enough RPM to use some of the fuel.

When he was running against Mom’s pickup which had more balanced back pressure, and a better distribution of fuel he had no chance even if the engines were internally the same. Of course they weren't but that is another story.

Years later when we created the AoK triple intake, we placed the first intake on an almost rock stock 201 ci motor. It had been rebuilt stock, although required to be bored out 10 thou to clean up cylinders. Beyond that it was a stock cam, intakes etc. With 3 of the smallest CFM carter ball and ball carbs on board and headers made from a stock exhaust systems, the car ran smoother, had better acceleration and got 6 miles per gallon better highway mileage over the single carb and single exhaust. In the end, it is just a myth that you need some bored out, cammed up engine for 2 carbs and a full race motor for 3 carbs.

The reason why Chrysler didn't run 3 carbs was simple. 1) The cost of 3 carbs was no inconsequential 2) They could meet the HP, Torque and Fuel useage targets with 1 carb. The exception was when there was a time window where the dual carb, dual exhaust 265 ci motor was released, but with overhead valve v8s and Hemi's coming shortly after the multiple carb flathead life-cycle was short lived.

There is a bit more it than that. I have glossed over a bunch of the engineering parts of why you don't just put a carb directly to each intake port with no equalization tube, but I am sure you get the drift.

Unlike a v8 where you might try and make carbs progressive because your feeding a intake plenum that equally or close to equally feeding all 8 cylinders, the flathead engine has 3 intake ports each feeding 2 cylinders so progressive carbs just are not effective. On the flathead Mopar, with either 2 or 3 carbs you want them to produce the exact same fuel to feed each of the Siamese ports exactly the same. Its not progressive in terms of additional barrels or carbs, its progressive by pushing on the gas peddle.

The key is making sure both or all three carbs are identical and that you have linkage that operates all of them exactly the same.

Its a common misconception that they must be hard to keep synced. We have engines with tens of thousands of miles on them with multiple carbs and are never adjusted. George Asche's 1929 Desoto that he has owned since 1950 likely has an unbelievable amount of miles on it and likely the carbs were only touched when George has redone the engine. I own vehicles with 100,000 + miles on them and the linkage for the dual carbs has never touched. That has a lot to do with just how good Carter Ball and Ball carbs are..

We also get asked quite often about modifying the block to provide 6 intake ports, or using webers or other carbs, or running fuel injection. Dad and Grandfather with too much time on their hands, as my Mother would say, did modify a couple of engines to provide 6 intake ports. There were several intakes made including one with an 18" runner set on it, one with 6 side draft webers and one with modified hilborn fuel injection.

At the end of the day, with various levels of success, nothing seems to outperform an Edmunds triple carb intake with riser blocks and 3 matched 1952-56 Truck carbs on them and maybe with some jetting changes. Of course, since then we have developed a couple of new cam profiles and of course the AoK triple which utilizes better and modern casting technology, as well as better flow bench testing and computer modelling that neither Chrysler or Eddy Edmunds had. Have we thought about digging out the 6 intake port block that is still in Dad's shop, well yah we have, but that is another project and a blog entry for another time.

-

9

9

-

2

2

22 Comments

Recommended Comments