bkahler

Members-

Posts

1,936 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

After 30 years I wonder if the condenser is up to snuff. Did you replace any of the components inside the distributor, what about the cap and wires? Age has a way of breaking things down. True story. When I bought my B3B in 96 I drove it around the block and then up onto a trailer for transport. The steering was really really tight on turns. Fast forward 25 years and as I was rebuilding the front end I realized that whoever had the truck before me replaced the kingpins and bushings but didn't grease them! I ended up just greasing the kingpins and they now turn nice and smooth. Yes, there is an adjustment nut. You have to be careful just how much you adjust it. Before adjusting it I would suggest replacing the grease/oil in the steering gearbox with cornhead grease. That's a great looking truck!

-

That would definitely eliminate varnish in the carb. I'm guessing the gas was new/fresh. Did you do any work to the ignition system? What happens when you put the front end on jack stands, does the steering feel smooth or tight? I'm guessing tight kingpins can cause issues with steering. No bulb probably explains why the gauge doesn't work. Hopefully someone can/will explain the process of getting the bulb replaced. Got any pictures of your truck?

-

First thing I would try is adding a can of Sea Foam to the gas tank and going for another drive. I've found Sea Foam to be an amazing product for gummed up carburetors. How old and hard are the tires? You can test the temp gauge in a pan of boiling water. That would give a definitive answer as to whether the gauge is good or bad.

-

You and me both!

-

That is the look I was hoping to achieve. Could you provide info on the brand of stain and info on the flood deck oil? Thanks! Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

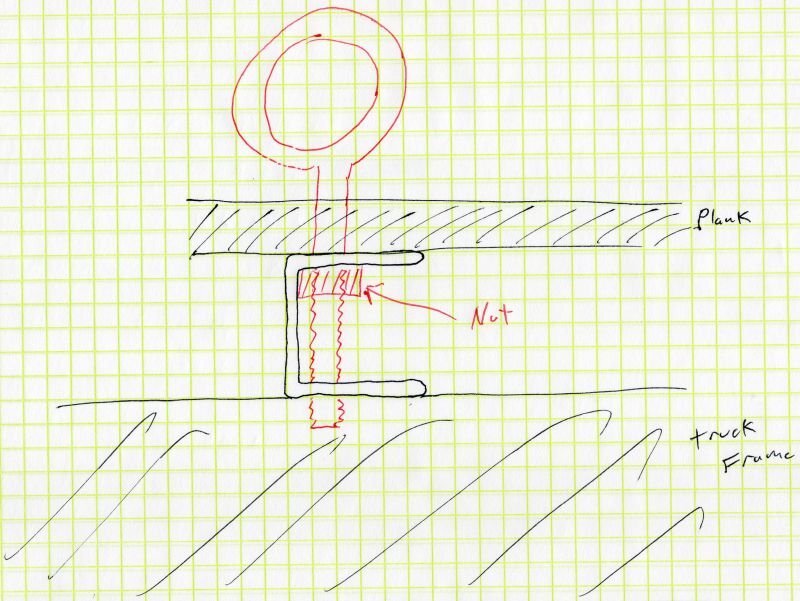

Can someone explain how this particular spare tire hanger rod is supposed to be setup? My assumption is the hanger assembly should hang parallel to the frame so the spare tire is squeezed evenly. The main thing I'm confused about is the castellated nut does not engage with the cotter pin when the hanger is set for the size of tire that I have. My truck was missing the entire hanger assembly when I bought it so I picked this one up from a used parts supplier. On the bottom side of the rod in the picture there was NOT a nut that came with it. I have since added a nut so that the rod is clamped solidly in place, otherwise without the bottom nut the rod was free to wiggle around. As far as the cotter pin goes, should I just bend it so it won't come out? Or should I drill another hole in the rod so it can pin can engage the nut? -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

-

This is the Trailer Hitch I installed. It's a Class III hitch. The truck frame is 40" wide and this just fit that perfectly. I just added a couple of 1/4" side plates to the frame and drilled a lot of holes in the plates for mounting. I didn't add any holes in the frame. Specification: Gross towing weight capacity: 5,000 to 8,000 lbs. Tongue weight capacity: 500 lbs. Receiver tube size: 2"

-

Well, here's an update as to what's been happening with the bed saga To start with, the wood I've been trying to use is Cypress which would have been fine if it had been quarter sawn. Instead, it was flat sawn and immediately after planing it to thickness I started having issues with the grain opening up, so much so that you could catch it with your fingernail. The bottom line is the quality of the wood did not make me happy at all. Next, I'm assuming you all noticed the gray color of the finish I applied. I was told when I bought the stain that it would dry darker, i.e. closer to flat black, it obviously did not. At this point I decided to re-coat the gray stain with a different stain that was labeled Total Black. It was touted to be able to be applied over an existing stain, unfortunately it did not apply well over the gray stain. It's been over a week and it is still tacky to the touch. I'm not a painter at all so I'm sure my methods had a lot to do with the poor quality finish. I finally bit the bullet and decided to scrap the existing Cypress planks and go a different direction. I talked with Steve at DCM Classics about the plank kits he sells and I've decided to go with his Ash plank kit. The kit has the boards routed for the shovel strips and the large washer holes are countersunk. I hemmed and hawed for a while about rabbiting for the shovel strips but decided in the end to just go with it the kit as is. I should have it in a week or so. So that lays to rest the decision on whether to countersink and rabbit 😄 With work on the bed on hold for a while I decided to tackle adding a hitch to the truck. To me, a truck without a hitch isn't really a truck I ended up buying one of those universal receiver hitch assemblies and custom fitted it to the truck. The top of the receiver tube is about 2" below the bumper and the center of the hitch is about 14" above the road. I have no real plans to use the truck for towing but I have several trailers that I'm always moving around and I think the truck would be suitable for short trips. Having four wheel disc brakes sure won't hurt matters any. Anyway, the hitch installation is done, I just need to add the wiring connector and connect it to the tail lights.

-

Those are going to be some stout running boards

- 717 replies

-

Yeah, his picture clearly shows countersinking and rabbiting for the shovel strips. I kind of get the impression Dodge built beds both ways. My truck had a piece of plywood on top of the remnants of what I believe was the original wood and there were no rabbits and no countersinking. I kind of like the utilitarian look of no rabbits and no countersinking.

-

Spring special

-

Nice work. Looking forward to seeing the completed running boards.

- 717 replies

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Dang, that's a great idea! If done properly the eye bolts wouldn't be a problem. The eye bolts can be fastened into place as shown in the picture below. The protruding threaded section would guide the bed into the holes in the frame as it's being lowered. I think I'll attempt this approach first. I've got eye bolts that I can use which gives me a no cost solution Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

To be honest, I don't even want to think about disassembling it and then reassembling it. The risk of scratches, drops, etc is more than I want to deal with. I figure the factory assembled the beds in a separate location, trailered or moved them to the factory floor and lifted them into place. I think it is probably a lot easier to crawl around underneath the bed during assembly on sawhorses than if it was sitting on the truck frame. I would think lifting into place would be the most efficient for them. -

I replaced the sockets the same way. It just so happened the sockets that I bought had a tab for connecting a ground wire which made it easy to take care of the ground issue. I like the idea of the sliding plate. That was my first thought when you started describing your problem. Should be quick and easy to do.

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

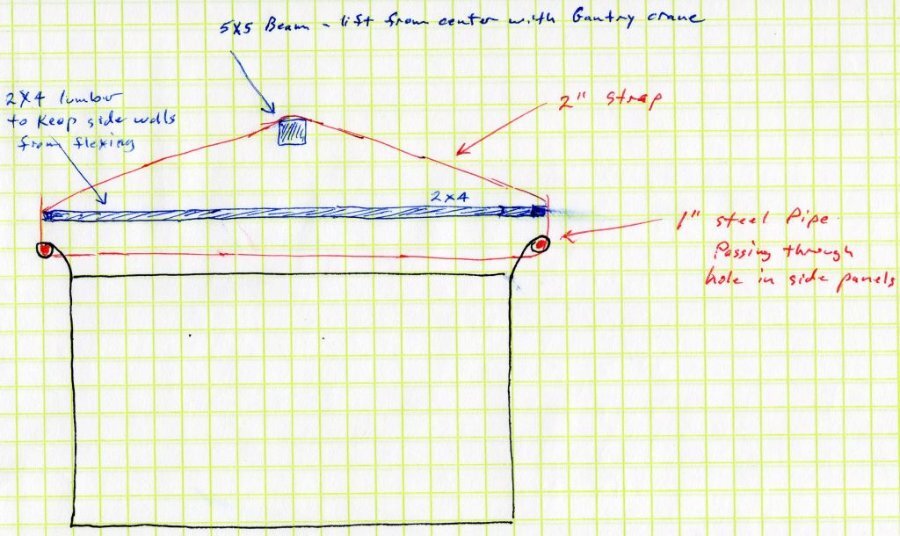

EMT would definitely be cheaper than pipe. I'm going to look into JB's suggestion of straps and see what happens. Thanks! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Deforming the sides is my biggest worry. I would much prefer the hoist, assuming I can get the rigging in place properly. Possibly this weekend, we'll know for sure -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I like the strap idea! That saves me the cost of the pipe and the longer 2" x 12' sling straps that I was going to have to buy. The ratchet straps would also give me better adjust-ability than the sling straps would have. Not sure what you mean by "duct tape attached to lifting strap" I don't care if it's pretty if it gets the job done. Heck, I ain't pretty and I always (well almost always!) get the job done....😄 -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Stacking like you described is something I've thought about, but I keep coming back to my problem of having enough floor space on the sides for setting up 4 saw horses. If I could come up with the room, what did you used to support the bed? The side panels hang down lower than the bottom of the bed floor causing interference with the cross pieces sitting on the saw horses. Did you place smaller chunks of wood under the bed to raise it up? -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Now that I'm getting close to completing the bed assembly it's time to figure out how to lift it onto the truck by myself. Here's a sketch of how I'm thinking about going about doing the lifting using my gantry crane. I have everything on hand but the 1" steel pipes. I'll either have to buy some or borrow from someone. The reason I'm thinking about using the 2x4 lumber is to keep the tops of the side panels from bowing inwards during the lift. When I was lifting the bed on one end while I was working on the L brackets I noticed the tops of the panels were bowing inward slightly. I was using 5/8" rebar at the time for lifting the end and while the rebar was ok, the bowing bothered me. So, I think using 1" pipe and 2x4 spreaders will solve that issue. Thoughts?