-

Posts

5,676 -

Joined

-

Last visited

-

Days Won

61

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Posts posted by JBNeal

-

-

If that truck is all original, it is a 6V positive ground electrical system. Using a 12V battery means that the charging circuit should be disconnected before the innards are fried. Pull the plugs out of the head and pour some diesel or thin oil in the cylinders to provide some lubrication.

Not to look a gift horse in the mouth, but ya might want to disassemble the motor to get an inventory of what has been done & what needs to be done. Since you've got the front clip off already, going through the motor & adjacent parts would be advantageous to getting the truck up & running reliably. Cleaning out the sludge & varmint poo & spider webs would be another reason to disassemble everything so that the engine runs smoothly in the future.

And take plenty of pictures, before & after. Ya never know when the noggin might slip and ya cain't recall why you have a coffee can of 'leftover' parts.

-

The shop manual refers to getting the door straightened out with a strategically placed block of wood and manual force...I straightened the doors on the '49 by lowerin' my shoulder and tee'n off, with a toobafor placed strategically between the door & cab...my shoulder was sore for a few days, but those doors are nice & true now.

-

The pan can be removed; I recommend jacking up the frame & pulling off the front wheels so the front axle will drop to give ya more room to work. You can pull the pan out otherwise, but it requires a great deal of jockeyin', finaglin' & cussin' to get it removed. The '49 had enough sludge in it to form a softball-sized glob, so cleaning out the pan (and the valve spring area) is worth the effort.

-

whut did ya do on the battery cover area? does that have a separate piece?

-

When in doubt, pull it out...the dist.tube is fed directly from the water pump, so inspection requires removing the pump. Removing the freeze plugs is a good idea because they can corrode from the inside out and form pin holes. Removing the freeze plugs in the '49 revealed total blockage on the bottom row of plugs with sediment that creeped up to the upper row. With the head & pump off and the plugs removed, I jammed a water hose in the dist.tube and poked at the sludge with a screwdriver while flushing...WOW there was a lot of crud up in thar. The trick in installing the new freeze plugs is to put sealant in the engine block seats first, then driving the new plugs into place. This oughta keep them plugs from weeping.

-

I had the same problem and was just as wary about tearing up my guage. But looking at the materials involved, I figgered I'd try cutting the line out completely and making a new one. Now you can put a wrench all the way around the ornery flare nut.

But first, the setup: the pickups have the gauge cluster that can be removed from the dash. Removing the other guages from the cluster, you now have a 'box' to clamp in a vise with wood blocks to keep from tearing up the cluster housing. Park the cluster in the vertical position so that you can see the gauge face & the flare nut. Using a small propane torch, heat the nut by passing the flame across the nut slowly, like once a second. Eventually, whatever crud is up in the gauge will start to ooze out. Keep an eye on the threads, crud might start bubbling out of them too. When that happens, put down the torch, pick up the wrench and see if that nut will budge CLOCKWISE...yep, try to tighten it first, this usually breaks any corrosion on the threads on the inside of the gauge. Then back the nut off slowly. If it hangs up, remove the wrench & apply more heat. The trick is taking it slow.

-

I hear ya, that first ride is a vindication run more than a shake down cruise. All the busted knuckles, dealing with the salvage yard crowd, parts desk jockeys & whutnot, that first ride makes all the work seem worth it. In a way I reckon we all like to see others' work progress cuz it's either a trip down memory lane or a road map of where we want to go. People who don't understand this will never understand the journey, they only want to admire the destination or sumthin'ruther.

-

Itellyawhut, that is one slick buggy...the checkerboard firewall, white wall bias plys, dual carbs & headers, and boy howdy don't it sound purty too...I like the clean look on this here Plymouth--well done!

-

my '48 1/2 ton has the 218 (Plymouth)+3spd, my '49 1 ton has the 230(Dodge)+4spd...the 230 has more lower end grunt, coupled with bull gears in the tranny & 4.89 rear end, and it just seems to run smoother at highway speeds. Changing a 218 over to a 230 is relatively painless.

-

The original truck radiator upper tank sits higher than the factory heater installation to keep coolant pressure (due to gravity) to force air out of the system. Essentially, the radiator drains towards the engine & heater. If the rad.upper tank is lower than the heater core, then coolant will want to drain from the heater to the radiator all of the time. So if an overflow tank is installed, it needs to be higher than the heater core & rad.upper tank. My concern is that with the heater higher than your rad.upper tank, then coolant will want to drain out of the overflow and the non-pressurized cap.

-

I'm leaning towards fabricating a 'tank' out of a piece of 3" pipe (possibly PVC) capped on both ends, with one end tapped with two fittings. One fitting would be a barbed NPT nipple for a rubber hose coming off of the overflow tube. The other fitting would be a vent of some sort...it's a work in progress

-

my '48 had the foam rubber, or at least a very degraded spongy rubber-like substance that I have stashed in my archive (aka paper box in the garage). My '49 had a bicycle innertube shoved down in there, I reckon to keep the rats out. My guess is that since the frame of these trucks is riveted rather than welded, there is a fair amount flex shown when taken off road. So they put some soft rubber around the fill neck to keep the cab from sawing into the tank when fording creeks or crossin' ditches or whutnot.

-

That looks sharp...one of my thoughts was to use that bed-liner-in-a-can stuff applied to the cab floor under a floor mat I picked up from Roberts. As I understand it, this applied material has a rubberized texture to it, which could absorb noise & provide an insulation layer (albeit a thin one). But I'm thinking this would be a more expensive approach rather than what you've done with this setup, and the benefits would be negligible.

-

Catch can, that's the ticket...I knew there was a term for whut I was thinkin'. Yep, pressurized systems use the overflow when pressure builds & whutnot. Putting the reservoir above the main reservoir would prevent siphoning and allow excess coolant to exit the radiator without makin' a mess like an excited dalmation.

-

Has anyone tried to install a radiator overflow tank for their flathead? I've seen a small cube tank at JC Whitney and O'Reilly's and wondered if anyone had tried to keep the pavement clean with a similar contraption. I stopped for gas with the 1 ton during the summer and it watered the pavement purty good...an old timer nearby quipped "yep, I got that problem too"...didn't know if he was talkin'bout himself or his buggy.

Anyhow, yeah I know this cube tank is plastic and would hardly look original. I was thinking that I could fab up a bracket to put in front of the radiator area or above the radiator under the hood. Maybe feeding a hose from the bottom of the radiator overflow tube to above the coolant level line...my concern would be that once the overflow began that it would siphon out the radiator eventually.

My aim is to keep this truck as close to stock as possible, but with small improvements to keep it clean, such as the PVC system and possibly this overflow tank. I've seen several of the paper air filter conversions and I'm leaning towards trying this...back in July 2008, I got in a hurry & forgot to tighten the clamp on the oil bath, and the first right turn I made at speed I realized whut I had done...

Constructive input is much appreciated

-

I reckon I spy an Airflow, a WD, some Willys Jeeps, a PH Deluxe cab, a 300F, a '68 Charger, a Wagoneer or Grand Cherokee, a Voyager, and then a loaded 300C...maybe the Omni, the Viper GTS & the Quad Cab Cummins were on the cuttin' room floor

-

Pulling the head might have jarred some gunk loose and there might have been some condensation with it. Just yesterday I pulled the water faucet out of the vacant rent house cuz it was practically new & the one in my house is leaking. The water has been shut off for 2 years, yet when I disconnected the supply hoses from the faucet, water comes out...and we had many a hunnert degree day here in the summer, so that water should have been long gone but instead it ran down my shirt sleeve on a 40 degree day.

-

Yep, looks like somebody pulled the spark plug and took a whack at a stuck valve.

Head gasket marks look like leak points, but why they are there is of concern. Check that head to see if it's gotten warped due to an overheated condition. Or the head was not torqued properly and the head gasket didn't seal up.

fyi, when I rebuilt the 230 in the 1 ton, several of the valves were gummed up stuck. I got them freed up & cleaned, and found that most of the valves rattled around in their guides. So I bit the bullet & replaced all valves & guides. It was a chore, but worth it...that motor purred like a tom cat at idle & pulled up any hill I aimed that beast towards.

-

After removing several antique tractors from their resting places in black dirt with locked up wheels & axle shafts, I noticed a couple of things. First you want to break the wheels free from that cement-like clay by lifting them up out of the ground, with the skull-bustin' tractor jack or a front-end loader and a chain. Be sure to get everything clear of the ground; in this case, I'm concerned if any part of the frame/drive train is submerged. If the tires are shot & don't hold air, then dragging the locked up wheel will break the bead seal on that rotten rubber and the tire will spin on what is left of the rim. Go slow & steady, cuz jerkin' stuff around yields shockingly bad results...watched a purty hefty chain break, and the sling-shot action it took since it was under so much tension just barely missed the guys head on the tractor that was doin' the pulling.

-

A decade of road-testing is plenty...

Those who think a formal education is a crowning achievement in one's life are sorely mistaken. Restoration of a unique antique automobile is THE crowning achievement...okay, getting married, having children, blah-blah-blah all that spiritual stuff is important too (and just as expensive).

What started as a photo-op for a diaper-clad red-head on the bumper of a '48 Dodge that had been in the family since new has progressed to the next big step of knocking the rust off and making the beast shiny again. I got it running after ten years of scraping cash & time together while blundering through high school & an engineering degree. Family squabbling ensued as the spoiled side of the family assumed this heirloom was 'given' to me in tip top shape and much peace-making diplomacy had to be pursued. Working through the Texas motor vehicle legal red tape of documented ownership was an exercise in patience & learning how to read disgruntled state employees. Debugging nagging carburetor & electrical problems was a good polishing of practical engineering fundamentals. Finding repair parts learned me real good on how to get creative with existing materials and a limited budget. In summary, many disciplines had to be mastered to bring this piece of American steel back to life.

Ten years ago, I got the '48 on the road, licensed, insured & inspected. Offended many folks when they offered to purchase my buggy for a miniscule fraction of the $$$ I had invested in it & I turned them down flat. I didn't want to do any cosmetic work until I had all the bugs worked out, and that finally happened last year when I replaced an intermittently foul-running carburetor with a NOS find from eBay and resolved the hot-starting problems. Didja know that even if the original big gauge cables look decent on the outside, that the indiviual strands corrode over time & build up a crippling resistance in the starter circuit? I sure didn't until I took some advice from the guy down at the starter & alternator shop.

The bias-ply tires are so worn now that they won't pass inspection, and it's been 10,000 miles on the rebuild, so everything has to be gone through per the shop manual directions. And the frame is bent from one of great-grandpa's three accidents he had before grandpa took the key away from him at the ripe old age of 90 back in '68. The bent frame has really showed up in the tire wear. Oil leaks are purt'near everwhar cuz of lack of properly located sealant in the motor & transmission areas. A couple of brake lines are weeping from inaccurate flaring technique. And I suspect the rear axle vent is plugged because of the gear oil that came out of the grease plug.

So I reckon it's time to take the next step and make Pappa's Dodge respectable. Doing research on this forum has really straightened me out on a lot of li'l odds & ends. Such as Wix 51010 oil filters that I've been using ain't right. The 218 Plymouth (!) that no one remembers having been swapped out has been running this filter since way back, cuz Dad remembers having to pull that messy perforated coffee can out when he was learning how to do his mechanic'n. There is a PCV system available for this motor, thanks to the P15-D24 downloads & member contributions. Setting the brake shoes can be done with a fabricated tool; bleeding the brakes can be done effectively by one person. And I can even jump start the 6V system with my Dodge diesel by simply disconnecting the charging circuit.

Let this be fair warning that I may be contacting a few of y'all for some technical information from time to time. I haven't committed this site's contents to memory yet, but I've read a majority of the threads & taken several pages of notes, cuz nobody likes to be asked a 'stupid' question. But I would like to thank all who have posted so far for providing a fountain of information.

When I did the initial mechanical restoration, I took plenty of pictures. Unfortunately, they were Polaroids that have since disappeared through a collection of mishaps. But I will be recording as much as I can this go around to go along with the documentation I've been collecting.

btw, the '49 1 ton went through a mishap last year thanks to Three-Tooth Timmy at the local tow truck establishment. Long story short, I have to replace the drag link, the steering box mounting bracket, and tie rods. Comparatively easy to accomplish...

Thank y'all again!

-

2

2

-

-

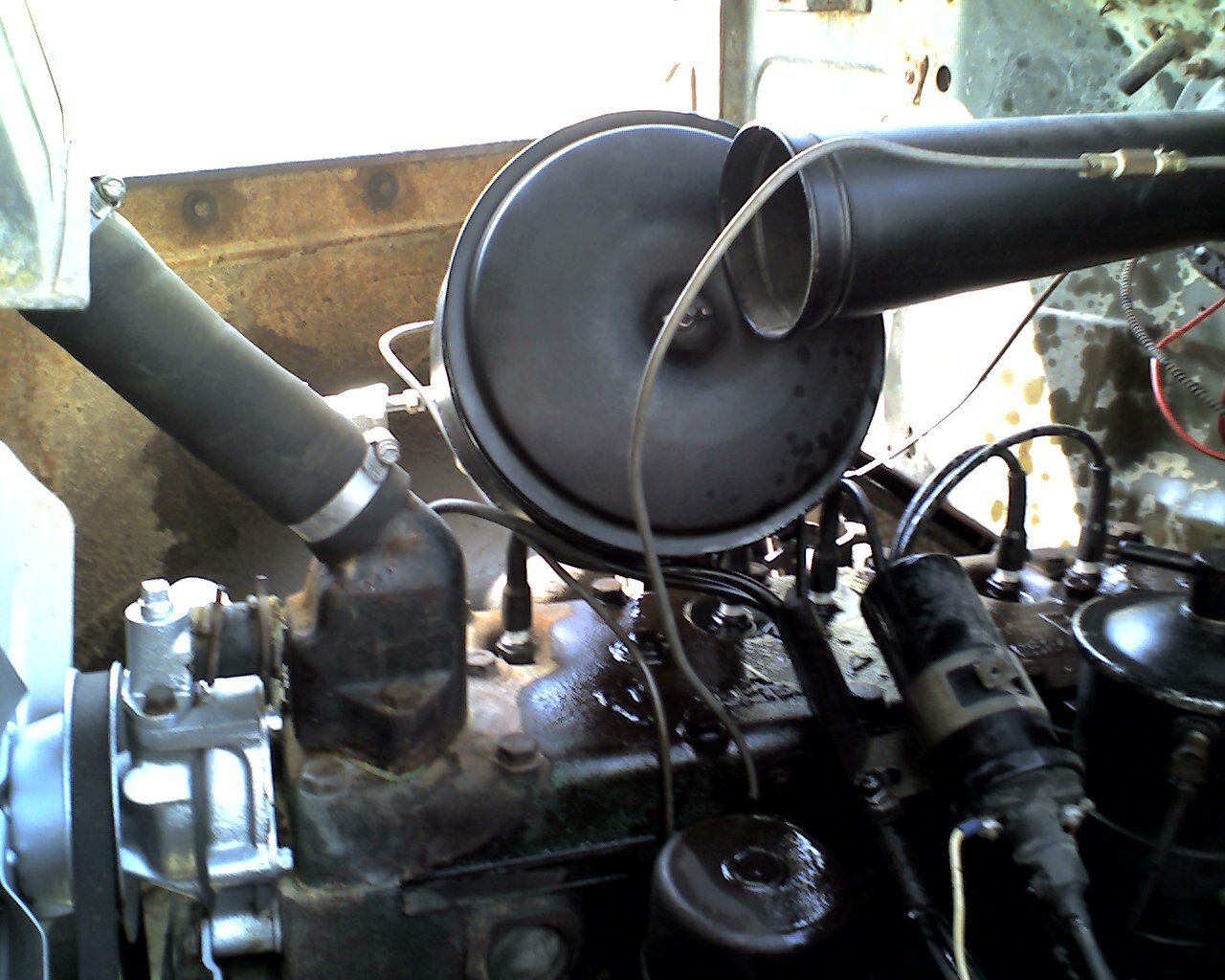

I've been contemplating the pcv system for the flathead and recall something out of place on the 230 that's in my 1 ton. When I found it, it had a crankcase filter (looks like p/n 627488) and no draft pipe, although it looked like it had some sort of tube on it at some point. This filter is standard on big trucks for that year, as well as all export trucks. The guts of the draft pipe crankcase filter are very similar to the guts of the oil fill tube crankcase filter. I have replaced the draft pipe crankcase filter with a donor draft pipe just to match it to the setup on the 218 I have in my '48 1/2 ton.

I recall that Chrysler's pcv system on the 318, 360, etc. pulled vacuum from both banks of the V8. One bank had the pcv valve that used a vacuum port from the air cleaner body. The other bank had a crankcase filter that used a vacuum port form the throttle body.

Knowing this, I'm wondering if the flathead needs a filter between the pcv valve and the crankcase. I'm thinkin' that sludge might build up in the pcv valve & the lines and restrict vacuum.

Anyhow, the next time I'm at the parts store I'm gonna try to get some better ideas on what's available that could work. I'll post pics & p/n's with any 'breakthroughs'.

-

If the vacuum port is open, then the fuel mixture metered by the carb is being made too lean. Plug that port (I've used a brass hex head plug I found at the hardware store), readjust your carb to get the idle speed at its leanest mixture, and see what happens.

first start in 15-20 years help

in Mopar Flathead Truck Forum

Posted

When I first started working on my '48 after it sat by the barn for 20 yrs, I filled the cylinders with diesel and let it sit for a week or so. By then, the diesel had seeped past the rings and into the oil pan. I repeated this a couple more times, and by the end of the month the motor would turn over, but with some difficulty.

After pullling the head off, I found that there was some surface rust on the cylinder walls. So I took the motor apart, sanded the surface rust off by hand, and cleaned the engine innards thoroughly before putting it all back together with new rings & bearings. New battery cables on the starter & battery were put on, and that motor spun fairly quick with the 6V battery.

Even with the engine compartment left intact when the truck was first parked, moisture still got into the cylinders past the valves that were open. Humid days over several decades caused enough oxidation to make the clearances inside the motor super tight, so getting the engine back within clearances made things go better.