-

Posts

7,182 -

Joined

-

Last visited

-

Days Won

79

Posts posted by JBNeal

-

-

-

I heard that radio and HVAC knobs are making a comeback by popular demand...the Laramie has a drop-in oil filter element which I kinda chuckled at when I 1st saw it, but I appreciate after years of doing oil changes...of course there's a trick to not making a mess, but it's way easier to swap out than the spin-on filter on the QuadCab; that one marks its territory every time 👈

-

1

1

-

-

-

-

welcome aboard...watch out for the passive aggressive trolls, there's an assortment on here...but there's also an assortment of knowledgeable ppl that are able to share helpful information without being condescending cuz they're more interested in fixing up things than patting themselves on the back 👈

-

-

-

Arm orientation for assembly on the B-1 wiper motors is easy...to get wrong. I am convinced that these wiper motor assemblies were put together with tooling because without some consistent frame of reference, it is easy to get the arms off by one or several teeth. This is something that I alluded to in that link I posted.

After trial and error, I found that it's best to orient the arms parallel during gearbox assembly. Leaning the arm pivots on scrap lumber allows the arms to find vertical orientation. Then add the gears and hardware in the gearbox.

The park feature in the electrical circuit will orient the arms at the correct angle once the motor is energized. It is also best to clean thoroughly then assemble the gearbox dry to verify correct arm orientation. Once verified, remove the gearbox cover and fill with disc brake wheel bearing grease.

Operate the gearbox for 10-15 minutes to let the grease work behind the gears, preferably with the motor in the vertical position. Remove gearbox cover and top off grease as desired cuz who knows for sure how much air should be in there...there is a leather grease seal on the motor shaft that will take that promised article to explain how to possibly replace.

Ya don't want to overfill the gearbox or grease will seep past that seal into the windings (also something that I address in that future article). What I did was cover the gears, which left an air gap. With operation, the grease moves around the gearbox, sticking to the gears as well squeezing out of the teeth. After a period of disuse, the fresh grease slowly flows down to establish a new level. From experience, this type of lithium grease will begin to dry out after 10 years and will require replacement to keep the wiper motor amp draw low.

-

-

-

-

-

-

-

That switch with the spade connections looks like it came from a newer vehicle.

-

-

-

-

-

-

-

-

-

.jpg.c58c60753aef4527ede450d87b051e52.jpg)

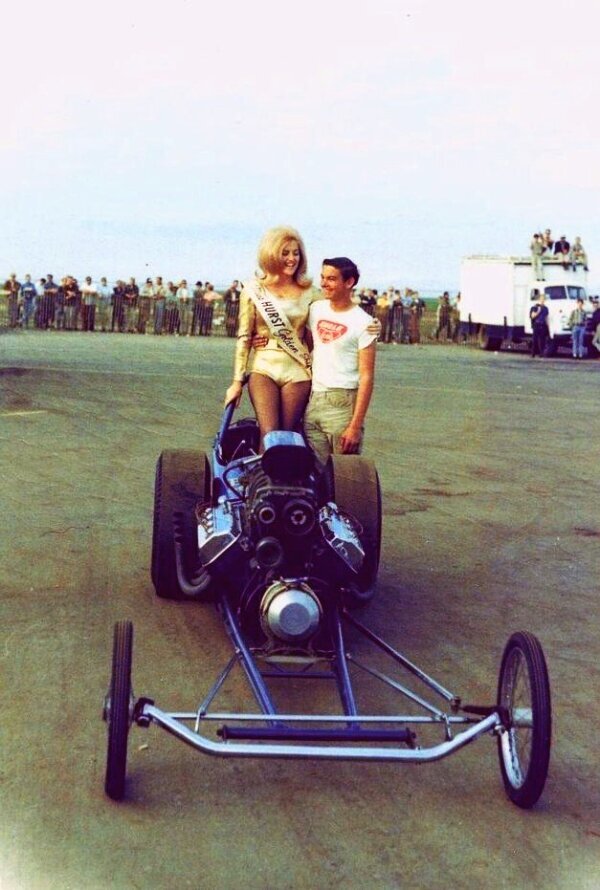

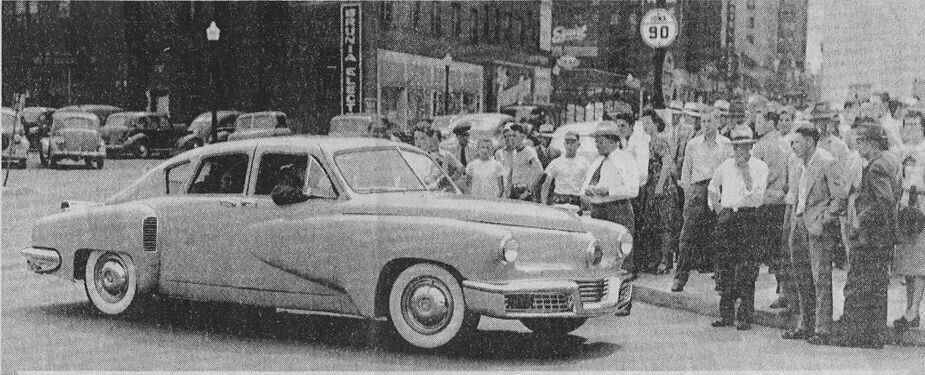

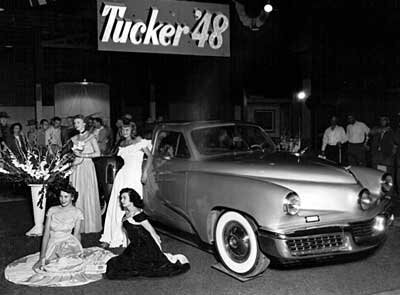

Vintage picture thread

in Mopar Flathead Truck Forum

Posted

VINTAGEPIC:

spotted this B-3 at the parade on the FB