-

Posts

367 -

Joined

-

Last visited

-

Days Won

4

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by dgrinnan

-

Both upper and lower. I think they are the same. The truck was missing the shocks and bolts. I have new shocks but need the actual bolts to go on the threaded stud to secure them in place.

-

I will be surprised if anyone knows but I will ask. Bolt size and thread for the studs the front shocks mount to? I will probably have to make my best guess and grab a few different sizes and test fit them.

-

New guy on the forum, having troubles finding parts

dgrinnan replied to Slikk's topic in Mopar Flathead Truck Forum

What is his Facebook. I did a name search and could not find him -

New guy on the forum, having troubles finding parts

dgrinnan replied to Slikk's topic in Mopar Flathead Truck Forum

Desert Valley Auto Parts. www.https://www.dvap.com/ They have two locations. They had a reality show on Discover but it only lasted one season. Here is the phone number with the location that has two 1947 Dodge 1/2 ton that should have the springs you are looking for. There is not much left on them. They are pretty rough. Dodge trucks 1-800-798-2465 A second salvage yard is http://www.rockymountainrelics.net/ the problem with them is it is mostly a one man operation and he is semi retired. He does not take an form of electronic payment. He will ship and item but you have to mail him a check first. Once he has the check he will send the part. It seem a little shady but I took a chance. I had to mail the check to his house (bells and whistles going off). My parts did show up the following week. You must be very clear about what you want I would put it in writing in an email. (970) 686-2926 -

Okay, I suspected it was performing double duty as a breather and filler tube but wanted to confirm. Thanks everyone for the feedback.

-

So I remove the oil filter lid and pour the oil in there?

-

I never ever thought this was a question I would have to ask. Where is the oil filler on a 218 flathead. Ignore the red arrow.

-

I will start out light. Thanks for the tip.

-

You could be correct. If I zoom in and squint there might be some indication of a tail on both of those small circles indicating a 6 and 9. That would make since. I might take a scotch pad and lightly hit that area to remove a little of the paint and see if anything is revealed.

-

I have a 1947 Dodge truck. It appears a previous owner has installed a flathead six 218 from a 1953 car. I used an engine decoder link posted in another thread on this site but I am confused by the numbers stamped on the engine. See the pic. If I read the decoder correctly this is clearly a 1953 Plymouth car engine. P24. It is the numbers after that I am confused about. Every example picture I have seen contains the engine code, the star as a separator and then a string of numbers between a star and the end. My number has the small o separators???? Has anyone seen this and know how I should read it?

-

No replacement engine needed. The flathead started. I had a guy that has been working on these old vehicles for 56 years stop by. My first issue is the distributor shaft bushing is worn out and there is too much play in the shaft allow the timing to vary as much as 2-5 degrees. My carburetor also needs rebuilt. With all these problems we were able to get it to start and run. We had to hook up a 12v battery to get the engine to spin fast enough. Now that I know it runs and it actually sounded pretty good I still have some work to do. I have pulled the distributor and the carburetor. Both will be rebuilt. Once that is done, we can fine tune everything.

-

Update. Flathead started. I had a guy that has been working on these old vehicles for 56 years stop by. My first issue is the distributor shaft bushing is worn out and there is too much play in the shaft allow the timing to vary as much as 2-5 degrees. My carburetor also needs rebuilt. With all these problems we were able to get it to start and run. We had to hook up a 12v battery to get the engine to spin fast enough. Now that I know it runs and it actually sounded pretty good. We have pulled the distributor and the carburetor. Both will be rebuilt. Once that is done, we can fine tune everything.

-

Timing is not the concern. I have never had a distributor pulled out and just wanted someone looking over my shoulder. i don't want to rush and thought it would be good to have someone helping me double check everything. I will have the flathead running this week. I am only speculating about replacement engines in case once I fire up the flathead I discover there is some un-repairable internal damage that might have been the reason it was parked to begin with. None of this scares me. I just like to double and triple check before I commit so I don't have to redo anything,

-

Okay, based on the feedback I think I am okay. To answer DakotaFrank's question the flathead does have a similar set up. I also a 54 Chevy 1/2 ton with a 235 and they are similar. I just didn't know if we had to be at a certain position. Sounds like as long as TDC is confirmed the location in the distributor is what it is.

-

I am positive I am at top dead center. In addition to the timing marks being under the pointer I had the number one plug out with my finger over the hole. It pushed my finger off the hole when it came around to TDC. The reason I am concerned is the position of the rotor which should be pointing to the number one cylinder of the distributor is sitting at about 4 o'clock. That might be okay. I just want to confirm it's not an issue. I know the firing order. Locating the other wire locations on the distributor is easy once I am confident I have number one identified.

-

First thread is about wiring and identifying the correct location. I have read you can have the distributor 180 degrees off. I think the procedure for installing the distributor is a different process. I get that wrong then I could be pointing at number 6 thinking I was pointing at number one. Step one, get the distributor install correctly then step two, follow the process identified my first thread.

-

I found the timing marks. The issue was I was looking in the wrong location of the pulley. I thought I had number one cylinder top dea center but I didn't. Once I got it in the right locatioin and cleaned the surface they were there.

-

I did a search. I am sure this is documented somewhere but I could not find it. I have a 218 in my 47 WC I am trying to start. It has been years. It looks like the previous owner just randomly plugged in the spark plug wires into the distributor cap. The distributor was loose and I have no faith it was drop into the engine in the correct postions. I do have the engine sitting at zero degrees top dead center. When I seat the distributor, how can I tell I do not have it sitting 180 degrees off. I can try it in the position it was in before I pulled the dirtributor out (50-50 shot)but if there is a way to check it before I button everything back down it might save me some work.

-

I was hoping there was something there. I we try to clean up the pully.

-

Am I looking at the wrong location for timing marks. I am assuming the triangle pointer is for setting timing but I can find timing marks anywhere on the pully. Should there be marks on the pulley?

-

My goal is to get my current flathead running. I posted the question thinking ahead just in case it has a major issue once I fire it up. Been sitting for 15-20 years.

-

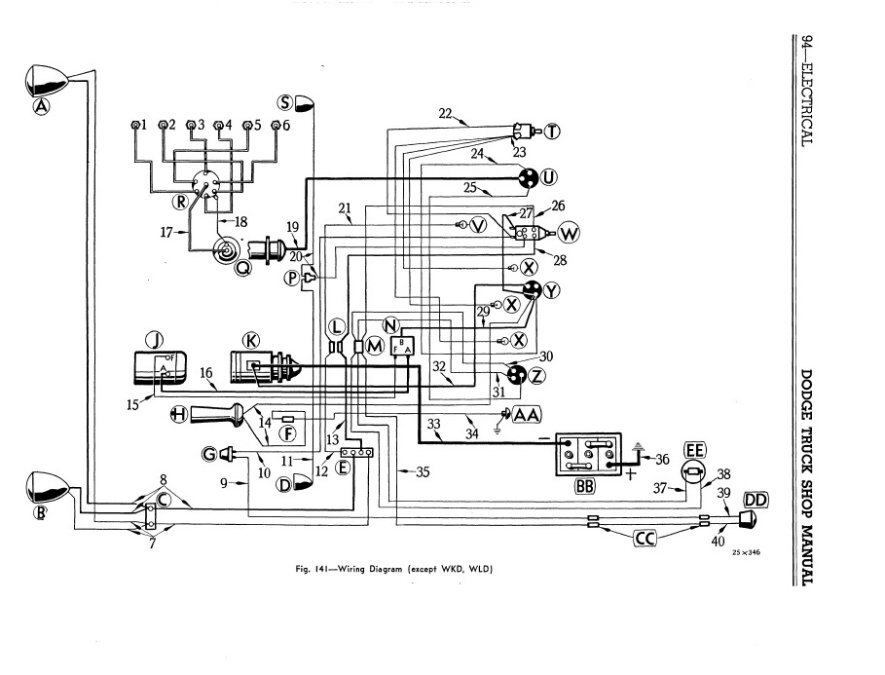

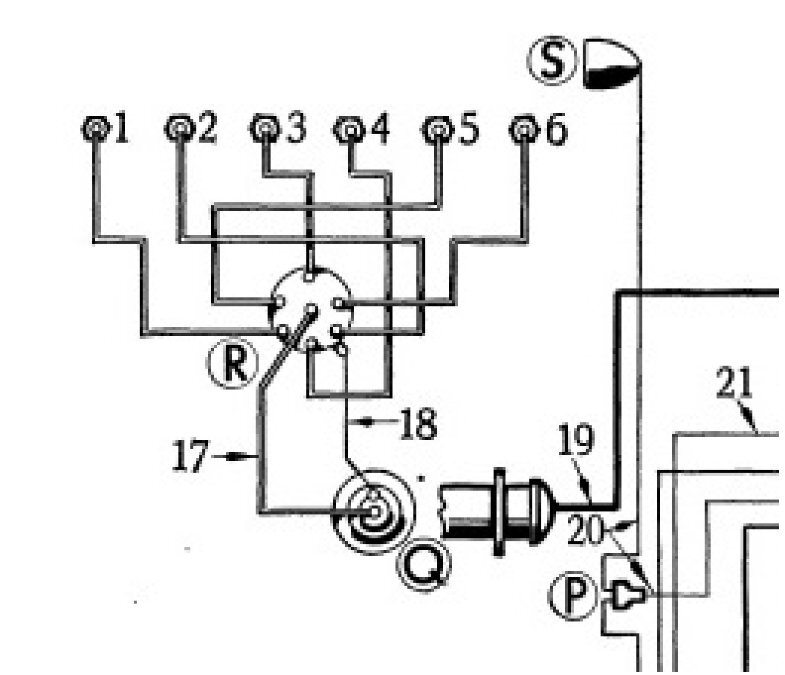

I am trying to start a truck that has not been started for years. I have installed a new wiring harness, new voltage regulator, new points, new condenser, new coil, new rotor and plugs. I get 6.53 volts to the distributor coming from the distributor to the wiring terminal on the outside of the distributor. With the key turned on if I open the points I get a spark. New gas tank, fuel line and fuel pump. Just from cranking the engine it has pumped gas up to the carburetor. I know I am getting fuel. I have also given it multiple shots of starting fluid. When I try starting the vehicle it acts as if it is not getting any fire. I have seen diagrams from different sources and they show the cylinders number different. They also show the cylinder numbers in the distributor in different positions. The attached picture is from a 1941-1947 Dodge_W_Series Truck Manual. My interpretation is if you are standing on the driver side of the vehicle looking at the engine It shows the number one cylinder at the front of the engine and the number one terminal in the distributor at 8 o'clock progressing to number 6 at the rear of the engine. This is opposite to what I have seen in other sources. It's also a completely different position in the distributor for each of the cylinders than other sources. Can someone confirm this is correct or post a correct diagram showing the correct cylinder location and distributor cylinder location? This giving me a firing order of 1, 5, 3, 6, 2, 4 but I am not sure what is marked as number one on the distributor is accurate. If not, number one is not getting spark when it is suppose to.

-

Just a follow up. It took some real finger dexterity but I was able to get the cable attached and once it was on it did have clearance from the emergency brake bracket. Close but it clears it.

-

If you have any computer skills, picture software and a printer you can make your own decals. Scan your best speedometer face. Use the image software to clean it up and make it darker. You can print your own decals. Any office supply store sells sticker paper that will work in your at home printer. I printed my own speedometer decal for my 47 WC because I could not find any ready made. They turned out great. I could only find them for later years. It took me 30 minutes and a pack of sticker paper is about $5-$8.

-

Have any of you replaced the flat head six in your 47 WC 1/2 ton? I am not looking for some high horse power conversion, just wonder what engine swaps you might have done. What matching standard shift transmission did you use.