47 dodge 1.5 ton

Members-

Posts

406 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 47 dodge 1.5 ton

-

Noticed that I didn’t answer your weld question fully, I had mine Tig welded using phosphorus bronze rod, peening only with weld hammer. Then stress relieving in oven at two intervals 1st 1000 degrees held at 30 min and 2nd was 850 degrees held at 1 hour hold time. Slow air cooled with ceramic heat blanket. Also took a picture of the LP kit that I recommend for small shops(there are other options).

-

All cracks should be ground approx 45 degrees “V” for a “full penetration weld”, problem is having enough access to grind the internal areas. Brazing is fine and has been done for years with acceptable results. An “LP test is using Liquid penetrant dye to check for surface defects (google this to get a full understanding, very important for good results). I could go in detail but may take a page or so. I stuck mine in the oven for stress relieving and air cooled. I have the temp and hold time written down at the shop but can get that to you. In my experience, bead blasting really is used for wearing surfaces and parts that stretch to smooth sharp corners for reducing “stress points” not so much for this application other than cosmetics(can’t hurt though).

-

The welding should be completed first, then machining as heat can cause things to warp. My recommendation is; clean, LP test (this will show all relevant linear cracks at the surface) pre-heat, weld, controlling inter-pass temperature, LP, stress relieve, LP, machine all surfaces flat, spot face all holes, and LP again for verification. Repeat all steps if(when) manifold cracks during this process!

-

I haven’t before heard mentioned about the Canadian plow trucks, neat information. Just wanted to add that it showed 136hp advertised with the dual carb/exhaust set up on the 265cu motors. I have seen larger flathead dodge trucks with them as well, they look a little different. I almost bought one by mistake, they would not fit the 25” engines. Be very cautious to who does your welding on cast iron as there really is no weld procedures qualified for repetitive results (cast iron only has a tensile strength requirements and not chemistry for the elements per ASTM meaning it is not as controlled by different foundries, each one may have their own pour sheet requirements). Some people are just good at repairs, I would look for a well seasoned welder!

-

Come on, who could possibly want (2) old, worn out Carter truck Ball & Ball carbs with all that sloppy linkage to keep managed, along with keeping gaskets tight, listening to (2) noisy tail pipes and having to avoid water puddles with the front right tire!!? Now —in exchange, you could have a late model Holley (2) barrel with an electric choke that according to some, makes up to 200hp (w/just carb) and maybe a special pop here and there! Enjoy your set-up! Kevin

-

Most Likely off a 265 truck motor. If you change your mind about ownership, I could use as my exhaust manifolds have some cracks.

-

Nice Data, I wonder if there is something put together for the 25” heads?

-

265 IND dismantle

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

I drove the combine 30 miles home, ran in the “r” part of “normal” the whole way. Remember this thing never turned over 1950rpms a day in its life. It ran cool for sure. -

265 IND dismantle

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Do you happen to know what the differences are to the later truck head or a picture of the chamber? I thought there was a post here but only see the 23” heads. Or— is the only difference in CC’s? I’m on a hunt now for one and see what turns up. One difference is the hole is not through to cylinder 6 like my 237 1947 head. Wish I could just pop that off for a comparison but don’t want to go that route yet. -

I pulled the head tonight to see where improvements can be made. Top of pistons is flush with top of block, head is flat to piston (no recess), head gasket measures .047” thick. Cam has .375 lift both valves, top of valve to block measures .425”. Head max valve depth pocket measures .495”. This motor has a tremendous amount of build up behind the valves. Motor has never been pulled down for overhaul. Pictures to follow.

-

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

-

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

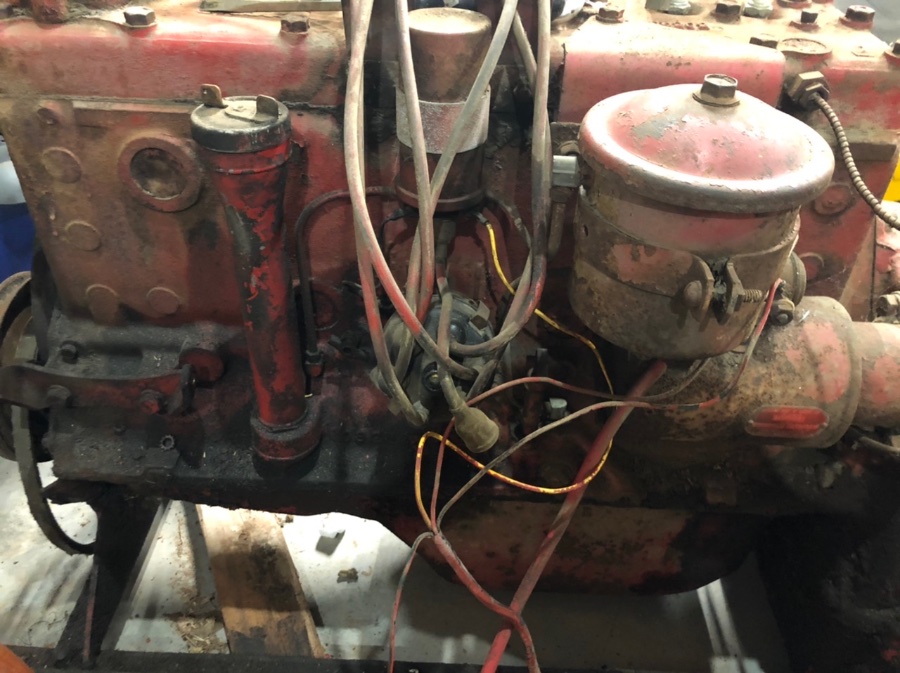

This one is bypass I believe, nothing special. I’ll grab a picture of the left side when I get in the shop. Does anyone have the ‘56 and later 250/265 Truck Head casting number and where that number is located? -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

I just looked at the oil pan on the 237 still in the truck. Think I’m in luck here either way. -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

-

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

-

265 Hi comp pistons

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

55 Fargo— Do you have their contact that can be shared on here? I am most likely having block cut at a min of .060” oversized, I have been looking for a head and have not came up with one at this time. If new forged o/s pistons are under a grand, I may go that direction and on shave the head/block minimal at this time unless needed later. Thanks for the replies. Kevin -

Who makes the best piston set for approx 8.5-9.5 compression ratio? Or is there another option that is used? Thank you, Kevin

-

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

They are some really cool pictures. You must be up North to still be cutting ice, I used to work at an ice house here in PA. Checked compression on the 265 today, 1 cylinder was down to 95psi, others were 120-125 with starter. Not bad for sitting a while and the oring broke on the last hole which may have something to do with the 95 reading. -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

I am going to use the truck moving round bales, apple crates, and maybe pull some equipment back and forth between farms. The heaviest pc is a backhoe. And yes, this is still my toy. -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

So is the opinion just to rebuild the 265 stock then or maybe not touch it at all pending the compression test? I want to use the truck some, and be reliable. The truck has 7.5 x 20’s and 5.625 rear ratio. 55mph would be good. Checking the compression tomorrow. -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Well, that’s not what I was hoping for as with that being said, no real advantage of a bigger cam then I guess. Are there pistons available somewhere to raise compression without cutting a bunch from the head? -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Do you know what the safe zone that would be recommend? I thought they were HP rated at 3600 RPM’s? It seems any information is very limited on these. I spoke to a recommend guy on here through e-mail that is located in CA about cam regrinds. He is currently limited do to the fires. I didn’t think it appropriate to ask a lot questions as he has many issues that are more relevant. So— just need to get a plan that’s going to work and makes sense for my old truck. My goal is just a little more hp than the factory 136, don’t lose any torque and a little more RPMs. I am not after a cheap build as I could have went another direction, just something that is reasonable. Thank you for any thoughts, Kevin -

265 identification

47 dodge 1.5 ton replied to 47 dodge 1.5 ton's topic in Mopar Flathead Truck Forum

Does this match any casting numbers for a 265? There is another post that has casting numbers and nothing matches from what I can tell. Is this a good head to rebuild regarding flow or would a 1947 237 head be any better? Would this be a sodium filled valve motor? I don’t see anything different about the oil filter so guessing it’s not a full flow system. Should this crank need any modifications for turning up to 4500 rpms? Just trying to decide what direction to go on a rebuild mainly, 237 and this crank/rods or 265 stamped block, maybe head? Both engines run, 237 is down on compression, haven’t checked the 265 stamped motor yet. And wanted verify all parts would interchange like the distributor, cam, oil pump. -

I have a 25” motor from a Massey super 92 combine and the numbers don’t match to what I have read. The block is stamped top left corner IND 265 space 20459C, same as Chrysler tag located under manifold. The casting number above starter is 1402529 and a backward C. The head has 08202 cast on the top. I am trying to determine what I have to start with. My understanding is that the motor has never been apart and the combine was bought new about 1960. Thank you, Kevin