-

Posts

10,373 -

Joined

-

Last visited

-

Days Won

21

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 55 Fargo

-

How about considering a 230, and make some decent power

-

Whos the boss? you the wife or the car.........

-

I think you would be surprised what a hi perf 265 can dish out, compared a 218 or 230. Engine dressup items while look good to those who like it, does not mean the engine has been built for a balance of max power and driveabalitly or just plain outright power designed for WOT use in racing or tractor pulling etc. Just ask George Aasche, building these engines since 1949, in 1954 he hit 142 mph at the Daytona flying mile with his 265 powered 1929 Desoto roadster.

-

cooling tips for pilot house trucks

55 Fargo replied to gramps1951's topic in Mopar Flathead Truck Forum

Lets remember this is a modern engine designed to run at a much higher temp than a flathead 6. If he is running a 195 t/stat, what temp do yall think he will run at in hot weather, easily over 200f, now with 50-50 coolant, and a 14-16 lb rad cap, and no puking boiling or heat related issues with the fuel and/or engine detonation , what exactly is the problem here? -

Chrysler Flathead Hi- Perf and Racing

55 Fargo commented on 55 Fargo's blog entry in The Chrysler A833 Overdrive Trans Conversion Blog

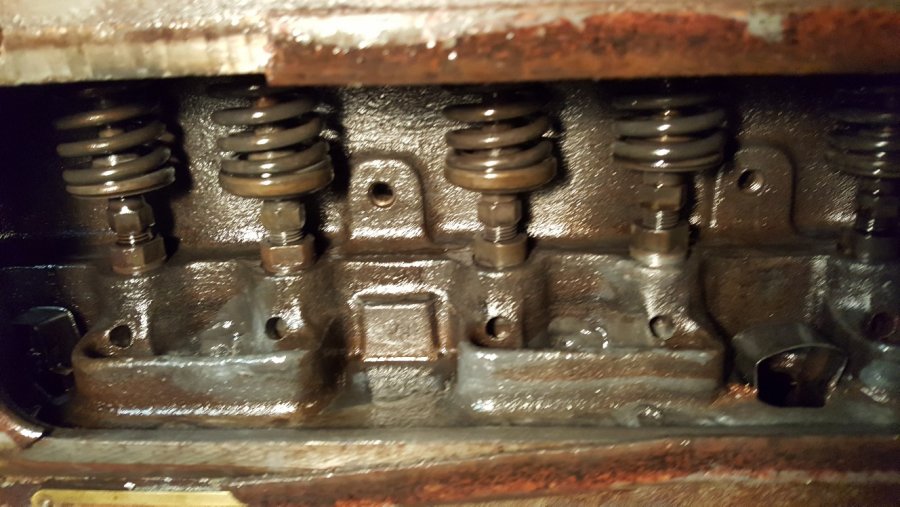

Well its fairly simple on a cam profile for an industrial engine destined for a "combine" low RPM torque, how much different than say a truck profile I do not know. These engines are rated at 95 hp, but at a much lower RPM than 3600. Okay some close up pics, cyl 6 has a bad rust pitted spot, that cyl might clean up with a honing, but it could very well be a boring candidate. Not as good as I was told, but would only believe after my assessment. Lifter chamber is quite clean... -

cooling tips for pilot house trucks

55 Fargo replied to gramps1951's topic in Mopar Flathead Truck Forum

would be normal using a 195 t/stat, and this engine would be designed to run hotter than a flathead. I would like to see it running at 185-195 though.... what t/stat is in there 195? they sell 160 and 180 t/stats for tis engine too. -

cooling tips for pilot house trucks

55 Fargo replied to gramps1951's topic in Mopar Flathead Truck Forum

Okay so engine, all water jackets clean and clear? T/stat verified, not that it will make it hotter necessarily, unless it's only opening a small amount. The rad, good flow, and in good condition, is it's capacity up to snuff for your locale? If not a bigger rad, might be the ticket. Does it need a shroud? Timing? too late will make heat. Driving habits, and rpm and load, higher loads, higher RPM =hotter engine temps. if the water jackets in the block are clear, and no exhaust gases leaking into a water jacket, I would bet on a rad problem..... -

Chrysler Flathead Hi- Perf and Racing

55 Fargo commented on 55 Fargo's blog entry in The Chrysler A833 Overdrive Trans Conversion Blog

Okay so picked up the engine last Saturday, and hauled it home. I pulled the head, lots of carbon, and cyl 6 had some moisture o the valves, and the cyl got a little rusted on the top 2 inches. I lceaned up all, and oiled the cyl walls until I get a chance to deal with it. The valve chambers, the valves and top of combustion chambers cleaned up nicely. The underside of head cleaned up too. -

Rather than having an EDGY head, I would much rather spend the money on custom "pistons", cam and/or cam grind. I do not see the big advantage of an aluminum head, other than eye candy for most users. I have discussed this with the Flathead King George Asche Jr., he does not see any or much advantage to an aluminum head over a milled cast iron head. Power can be made in a lot more ways than a head, on a l head engine, an OHV a different movie, power is really made in the head(s)

-

Now here are some great looking engines, and more traditional looking. I am not a big fan of an assortment of "Billet" trinkets plastered under the hood, these engines are all go, not just show. Here is mine, my style, I love old Edmunds heads, but not overly partial to an Edgerton head...

-

No, we did not follow that practice.... sounds like your truck is 1 ton rated...my GVW is only like 5000 lbs on my 1955 Fargo 108 wb 1/2 ton. In the USA some jurisdictions used an engine serial number, we did not....

-

Mopar For Mopars Solutions Blog

55 Fargo commented on 55 Fargo's blog entry in The Chrysler A833 Overdrive Trans Conversion Blog

Okay today picked up one of the 265 engines. It looks good, lifter chamber clean as whistle, has compression, oil while dark was clean and not full of metal flakes or anything. Plugs don't look bad either. I asked a lot of questions, Gent I bought it from purchased it 25 years ago from an old Farmer, he either had his engine rebuilt or bought a rebuilt engine from Piston Ring Machine in Winnipeg. It was installed into a Massey combine and used 2 seasons then the combine had other issues so the machine was scrapped, but the farmer did not want to scrap a rebuilt engine, so pulled it.... The big plan is to hopefully use this engine without a rebuild, but shave head and install a wilder cam. This will be coupled to a Chrysler A833 trans, no T5 for this baby..... -

Yes this would be reason enough. I did not think as another you needed just points and plugs so you figured time for a rebuild. My 228 engine is down on power and compression too...

-

I kept reminding myself to ask you to check this, and had it on my mind, bad on me should have asked you about this right away. Glad you found it, and this wire has been a problem for many others...

-

T5 Topic now eh....LOL not an engine though Okay be aware of the choice of this transmission, early S10 NWC transmissions had a 4.03 1st gear and a .86 5th over drive, kinda useless, unless you are running say 3.08 rear gears. The other S10 NWC transmissions had 3.76 1st gear, and a .73 overdrive, so you better have at least 3.55 rear gears for the 5th overdrive. And if you are running 3.73s or 3,90s, the 3.76 1st gear is also geared low, and you would be shifting before you get across an intersection All things need to be considered, you just don't buy a donor T5 and hope for the best, and unless you have bucket seats, you will not want the tail shaft shifter style either.. WHICH T-5 TO USE S10 The S10 T-5 has garnered most of the attention due to its favorable shifter location. The S10, however, was a NWC unit through 1992. There are two basic gearsets available in the S10 T-5: 1st - 4.03 2nd - 2.37 3rd - 1.49 4th - 1.00 5th - 0.86 1st - 3.76 2nd - 2.18 3rd - 1.41 4th - 1.00 5th - 0.72 As a general rule of thumb, regardless of engine, ALL S10 T-5 prior to 1985 received the 4.03 gear set, while ALL S10 T-5 after 1986 got the 3.76 gearset. The S10 T-5 was also available in the equivalent GMC T-truck. The speedometer changed to electronic with the 1990 model year, however, some 1989 model T5 came with electronic speedos if they were equipped with the optional digital dash. These can prove problematic for swaps, but output shafts & tail housings can be swapped with cable-driven speedo models. There is some evidence that certain types of early electronic speedos can be converted to mechanical, but I have no experience with this. There are also cable converters out there, but they are not inexpensive. While not very common, the Astrovan T-5 is worth mentioning. With an offset shifter that can be replaced with an S10 shifter, it makes a good candidate for swaps too. The 4-cyl vans used the 3.76 gearset, but the ratios found behind the V6 are better than the S10: 1st- 3.50 2nd - 2.14 3rd - 1.39 4th - 1.00 5th - 0.78 Tag Numbers: S/T Truck 4.03 Gearset 010, 012, 013, 014, 033, 042, 043, 055, 056, 057, 058, 146 S/T Truck 3.76 Gearset 107, 108, 110, 136, 145, 186, 191, 192, 193, 201 Astrovan 3.76 Gearset 170, 180, 190 Astrovan 3.50 Gearset 101, 148, 149, 164, 179, 189 MUSTANG Introduced in 1983, the T-5 arguably gained its fame in the Mustang 5.0. The first to take the step up to WC in 1985, Ford used the T-5 through the Fox-body & SN-95 chassis ending in 1995. The strongest T-5 available was found in later Mustangs and available through Ford's Motorsport & SVO operations. Available with a few different gearsets, the most common gearing was from 1985 through 1995: 1st- 3.35 2nd 1.99 - 3rd 1.33 4th - 1.00 5th - 0.68 The other V8 gearset used was the NWC 1983-84: 1st - 2.95 2nd - 1.94 3rd - 1.34 4th - 1.00 5th - 0.62 Ford rated their T-5 anywhere from 260lb/ft to 335lb/ft depending on the application. In 1989, stronger alloys were used upping the torque rating from 260lb/ft to 300lb/ft. The 310lb/ft rating belonged to the 1993-94 Cobra spec T-5 and an aftermarket-only Z-spec T-5 was available with 335lb/ft. The late-model (1994-95) 3.8 V6 T-5 was rated at 265lb/ft, had the slightly longer input shaft, and had the following ratios: 1st - 3.35 2nd - 1.93 3rd - 1.29 4th - 1.00 5th - 0.73 Ford did use the T-5 in later V-6 Mustangs, but there is very little data on them. I do not have a list of production tag numbers, but they are challenging to swap due to their linkage-based shifer and lack of a slip-yoke using a flanged mating surface. I have never held one of these in my hands, but I suspect they could be used in many swaps with a remote linkage and a different driveshaft. Tag Numbers NWC V8 034, 065 3.8 V6 220, 236 V8 260lb/ft 126, 165, 169, 141 V8 300lb/ft 199, 204, 208, 246, 218, 219 Z-spec 335 249, 251 SVO 200, 202 Cobra 239, 242, 253

-

Play in steering 54 dodge truck

55 Fargo replied to tattooman43's topic in Mopar Flathead Truck Forum

Gear lube, if the box doesn't leak? If you have a John Deere dealer nearby go and buy, "Corn Head Grease" http://www.greenpartstore.com/John-Deere-Special-Purpose-Corn-Head-Gun-Grease-AN102562.html or this product, http://www.penriteoil.com.au/products/steering-box-lube -

Play in steering 54 dodge truck

55 Fargo replied to tattooman43's topic in Mopar Flathead Truck Forum

Yes do an adjustment as per "shop/service manual". But also make sure your tie rod ends, drag link, are all in good shape, without play. In fact the entire front end, king pins and tie rod ends, need to be slop free. The steering box if not too worn can be adjusted, and make sure it's full of lube, if it leaks use some very thin grease such as John Deere corn head grease, its got the viscosity of mustard.. -

Short more 4 sport, long more door charm....LOL Shorty is kool, long is long.......

-

A 230 with the right gearing should be 70+mph all day long. What on earth did your engine builder do wrong? I would think a well rebuilt engine should have been good for a 100k. Mismatched Carter B&Bs would not be a good thing, a matched set in good shape, are a great mix especially the large truck types I have with about 400 CFM combined. I also have a 265 waiting for the ultimate build. Even with my tired 228 engine I now have, it launchs and cruises quite well with the AoK racing intake, exhaust and Carter B&B carbs..

-

Hey all, anyone have a disc brake bracket pattern for the trucks with 10 inch drums? I am looking to do an experiment, and want to have a pattern....thanx

-

Tremclad Red Oxide Primer after 1 week, sand off easily blocks nice.. This product is manufactured by the Rustoleum corporation in Canada direct to rusty metal alkyd primer..

-

A smoother ride 54 dodge truck

55 Fargo replied to tattooman43's topic in Mopar Flathead Truck Forum

I would also look at the "scrub Line" on your flipped set-up. If you want a modern ride, then clip it, bag it, or buy a modern vehicle. These old trucks ride okay, but are still trucks, much like older CJs. What Flaming has done will give you a lower stance and softer ride, but as far as changing how an I beam front axle handles and steers, it aint like IFS no way, no how, Man............. -

Well on non servo brake systems such as the Chrysler Lockheed brake systems, dual wheel cyls do the following, each shoe is independent and forces itself into the drum opposite of each other, making for a far better braking then a 1 wheel cylinder that only pushes the brake shoes out on the tops against the drums, as the bottom of the shoes are anchored to the backing plate. Bendix type self energizing brakes force the shoes into the drums, almost floating and the shoes move and seat into the drums, if I am explaining this right. Lots of semi trucks have drum air brakes with dual wheel cyls for the front brakes 1 for each shoe... Search on Google lots of good info, and even on this site. Chrysler went to bendix type brakes in around 1962, as was the rage for the big 3...

-

1924 first year for hydraulic Chrysler brakes, Well in the 1920s to 40s this was a great braking system, far better than Fords mechanical and Chevrolets eventual "Huck" brakes in 1936. Ford eventually for the 39 or 40 years adopted their own version of a Lockheed hydraulic braking system, but did not use front dual wheel cyls, like Chrysler did, which is a big upgrade over a single wheel cyl brake. These brake systems need to be set-up, and adjusted for best results, which brings in special tools and equipment to achieve this as we both know. The bendix type servo self energizing, install and adjust, as long as drums shoes, hardware and hydraulics are in good working order all is well. There is no special equipment for adjusting shoes to a drum, a more superior system that all the big 3 followed before the advent of the 1970s disc brake updates. Those of us who drive on snow and ice, as well as loose gravel, know this to be true, and you learn to brake accordingly, ABS brakes now are designed to compensate for this type of driving environment...

-

Yes sir, but the Lockheed type brakes are not self energizing. They are non servo type, anchored shoes, they do not at like bendix type self energizing drums, which are a better design and still used to this day on the rear brakes for many cars. The dual wheel cyl lockheed brakes re better than the single wheel cyl lockheed brakes too, and work very well when in a good state of repair. Drum brakes were used on a lot of big cars with power boosters for years and right into the 70s, so they work, maybe not as well as more modern disc.