Search the Community

Showing results for tags 'Crankshaft'.

-

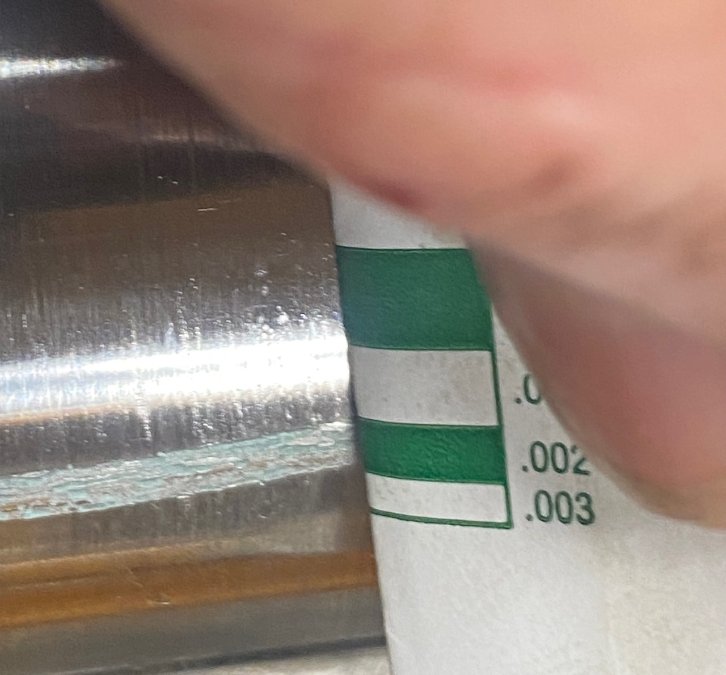

I've finally got to the main bearing install on my rebuild of the '56 230ci motor. The machine shop didn't need to do anything to the main journals or con rod journals except polish them. They were ground .020 on the previous rebuild and my Bernbaum bearing set was also 0.20 over. I followed @keithb7's video and plastigaged the mains and they all came out .002 clearance. Spec is .0005-.0015. Should I worry?

- 25 replies

-

- crankshaft

- main bearings

-

(and 1 more)

Tagged with:

-

Hey all, I just wanted to heap some praise on a crankshaft shop I've used couple of times. For you who are in the Dallas-Fort Worth metroplex area, there is a shop called Tripple 'N'Gin, (yes, that's the correct spelling) and the guy, named George, has done some excellent work for me. A while back, I took him my 265 crank to have the rear seal surface welded up and ground smooth, and he did a fabulous job, leaving absolutely no sign of the deep pitting that had been there. You couldn't even tell it was welded - it just looked factory original. Other shops in the area had said that portion of the crankshaft was too narrow for their grinding wheels, but this gentleman has many different sizes/widths. In fact, a big local crankshaft repair shop had sent me to him, saying they sub out a lot of their work to him, and that he always does a great job. As best I can tell, he's just a small, one-man show, but I like that even better. Well, fast-forward several months, and I haven't gotten around to installing the crank into the engine yet, and although I had it covered with a plastic bag, some humid air had found its way under the bottom of the bag and onto the bottom couple of journals and seal surface. As it turns out, it was mostly just light surface rust, but I wasn't able to satisfactorily polish it myself, and I thought it might need welding again, so I took it back to George a couple of days ago. He looked at it and said it only needed a good polishing, not welding, and he polished up all of the journals right there on the spot (I was expecting to have to leave it with him). He then coated each journal with a thick, oily substance, to keep them from corroding again. To top that off, after spending about a half-hour with me, he didn't even charge me anything. I tried to give him something, but he wouldn't take it. Now my crank is back in shape, and I thought I owed it to him to spread the word about his good work and honesty. I don't think he has a website, but he is on Facebook. His number is (972)259-2474. If he's away, you can also try his cell phone, which is (214)529-2436. Both numbers are published on his business card and his Facebook page, so I don't think there's an issue with me posting them here.

-

I am working on a 1937 Dodge 1/2 ton pickup with a 218ci 6-cylinder. The engine number stamped on my block is: T38-8085. The engine spun the #2 rod bearing and cracked the crankshaft. I have located a crankshaft and set of rods out of a 1953 Dodge B4B with a 218 ci engine, and I am hoping to use this crank as a replacement. The B4B engine is stamped with T306*I57323*. Unfortunately, I do not have the crankshaft casting numbers readily available. My question is, are these crankshafts interchangeable? Or can this only be determined from the crankshaft casting numbers?

- 2 replies

-

- engine

- crankshaft

-

(and 2 more)

Tagged with:

-

After nearly 35 years the 218 came to life in my 1941 P11. Everything is going great with it. I have put a few miles on it but would like to drive it more. The crankshaft pulley wobbles and i really don't want to drive it a lot until I get this repaired. Mine is the stamped steel pulley. The 218 is out of a 1952 Plymouth. I was looking through the "store" here on this website and they have a pulley and hub listed for the 218/230. My question is will this work for my application or they not interchangable. I use the wide belt, about 5/8 wide. I know I could try to straighten it out and I may end up going that route but not sure yet.

-

I have a '47 Plymouth and am wanting to go with the narrow belt crankshaft and water pump pulley. My question is, what cars came with the 2-piece crank pulley with the narrow belt? I was hoping to leave the hub in place and just replace the outer part. Thanks, Dan

- 12 replies

-

- crank

- crankshaft

-

(and 1 more)

Tagged with:

-

Well, after 4 months, I finally got my block and other engine parts back from the machine shop. They ground the mains .040" under and supplied me with matching bearing shells. I used the plastigage method to check the clearance, and they all measure .001", right in the middle of the specs (.0005" - .0015"). When the caps are bolted on snug, not even torqued down, turning the crank in the block is very difficult. I have to put a pipe wrench on the front snout bolt and use a 4' long cheater bar to get it to turn (with one foot on the engine stand). Even with this effort, its only a few degrees at a time. With the caps torqued it's pretty much impossible. The addition of rods and pistons won't help, either. I'm worried if I continue with assembly and get the engine back in the truck, then try to start it, it won't turn over. Should I take the crank back to the shop or count on my 6 volt starter to wind up this baby?

- 14 replies

-

- crankshaft

- engine

-

(and 1 more)

Tagged with: