-

Posts

381 -

Joined

-

Last visited

-

Days Won

2

Everything posted by PT81PlymouthPickup

-

I can hardly believe I found this engine advertised on Craigslist. It was in the back of a service station brand new still in crate from Chrysler listed as military surplus. The fellow who sold it to me said his dad bought back in the 1960s? This Mopar flat-head 230 turns over easily, complete with manifolds, carburetor, distributor, water pump, generator, starter, flywheel, and bell housing. I had been looking for a good core for rebuilding in case the one in my 39 PT81 ever failed catastrophically. It's doubtful I will need it, but I couldn't pass this up for $1500. If I could identify what this was intended to fit, I might sell the NOS parts that will not fit my truck. I must admit, it almost breaks my heart to this. I imagine it may have been intended for Dodge Power Wagons of some sort? I think these engines were used in some pretty big military vehicles? T2I4SR-4488 Not sure if the I is a one or a capital i ? Looks like a capital i in photo. Anyone have any way of identifying what this would have been installed in?

-

Lets see pic of your trucks

PT81PlymouthPickup replied to Ken_Hart's topic in Mopar Flathead Truck Forum

T2I4SR-4488 Not sure if the I is a one or a capital i ? Looks like a capital i in photo. I'll start a new posting. This one is supposed to be for truck photos. -

TRUCK MASTER CYLINDER UPGRADE ADVICE

PT81PlymouthPickup posted a topic in Mopar Flathead Truck Forum

I am in process of converting to front disc on my 1939 Plymouth 1/2 ton pickup. I've read where several have had good luck with the Jeep master cylinders. The AC Delco #18M957 (95-2001 Jeep Cherokee) has been successfully used by a few on here for disc / drum systems. This master cylinder has a angled reservoir which on the 95-2001 Jeeps the masters were angled up. When mounted level on our old trucks they can't be filled correctly and look wrong albeit they may work OK. Anyhow, I found another master cylinder that appears to be exactly the same with a level type reservoir. AC Delco #18M802 (97-2006 Jeep Wranglers and some Dodge Dakotas) Anyone have any experience with these? Sure looks like it may work? -

Lets see pic of your trucks

PT81PlymouthPickup replied to Ken_Hart's topic in Mopar Flathead Truck Forum

Not sure, but definitely military vehicle. Perhaps a Dodge Power Wagon. I think these engines were used in some fairly large trucks? I have documentation with a bunch of numbers. I imagine someone could reference it? -

Lets see pic of your trucks

PT81PlymouthPickup replied to Ken_Hart's topic in Mopar Flathead Truck Forum

I can hardly believe it, but I recently found a brand new from Chrysler 230 flathead still in the crate. Military surplus complete with manifolds, carburetor, generator, starter, water pump, flywheel, and bell housing. I doubt I'll ever need it, but could not pass it up for $1500. It was sitting in the back of a service station since the 1950s. Turns freely. -

Lets see pic of your trucks

PT81PlymouthPickup replied to Ken_Hart's topic in Mopar Flathead Truck Forum

Here's a few snap shots of my 39 Plymouth PT81. Been working on it since 1979. Still not done. 12volt system, Halogen headlights, Borg Warner T5 transmission, Mid 80s Jeep posi traction differential, Currently working on converting to front disc brakes. -

Jerry, I have not been able to locate Charlie's instructions yet. I'm hoping to find them which would be helpful in my decision. You are correct about the master cylinder bore. I rechecked mine and it is 1 1/4". I measured incorrectly the first time. Are you using DOT3 or 4 fluid? I was using DOT5 silicone and have had some weird things happen. I'm planning on returning to DOT3 / DOT4 after I upgrade the brakes.

-

Thanks Jerry for your reply! Please don't go to any pains, but it would be interesting to know your mc bore dia. I have been reading incessantly about brake systems and the mathematics involved only to become more confused. When I ask the companies who are selling the conversion kits, none of them seem willing to recommend a master cylinder and prop.valve? I do know for certain that a dual mc split system is safer if a brake line or hose should rupture you still have some braking. So far of the kits I've looked at, Charlie's (Rusty Hope) looks the best to me. The one thing I'm uncertain about is the inner bearing spacer. It appears by spacing out that inner 1.250 I.D. bearing, it may not engage on the spindle completely? Might you recollect? Do you have any complaints about the Rusty Hope setup? Did you have any issues with the retaining nut and cotter pin? Sorry for all the questions. Regards, Steve

-

Jerry, Yes, just about everyone tells me split master cylinder with Prop. valve in order to be safe with disc / drum brakes. Does your truck stop well? Can you lock up the brakes? (Please don't go and test on the highway) I would think with the original master cylinder (1-3/8" dia. bore) you would have to stand on your brake pedal? Steve

-

Thanks Campton 1941 and thanks Jerry Roberts Are either of you guys using combination, proportioning, residual or metering valves of any kind to address bias? Also, were you able to mount your original 16 inch wheels without interference? Question for Campton: Would you know the piston diameter of your Corvette master cylinder? Very much appreciated your responses. Steve

-

I'm wondering if anyone out there is driving a 1939 - 47 Dodge or Plymouth pickup with upgraded (front discs / rear drums) brakes? A couple years ago I installed a Borg Warner S10 T5 trans behind my Flathead and a 1986 Jeep Cherokee 3.55 differential along with it's drum brakes and that all went OK. I also installed a Master Cylinder from the same 86 Cherokee in my original bell housing location. It sorta worked, but too much pedal travel which I believe is due to the smaller (.9375) M.C. bore? The original M.C. had 1.375 bore. I'm now considering converting the front drum brakes to disc. The Rusty Hope setup has my attention, but I'm hoping to talk to someone that may have done this before. The more I read about brake engineering and about the myriad of issues others have had modifying brake systems, I'm hesitant to start buying any parts. Not wanting to offend any purists, I have gone to great pains to keep my truck visually original and have all the parts to go back if I wanted to. I'm hoping to make it a bit safer stopping now that it goes a bit faster at lower rpm. I want to keep my original wheels as well. I've been reading for days on several sites trying to find trucks similar to mine with the brake modifications and how they perform. No luck so far. Perhaps I'm not searching correctly but haven't found much regarding 39-47 dodge / Plymouth pickups. Any advice would be much appreciated!

-

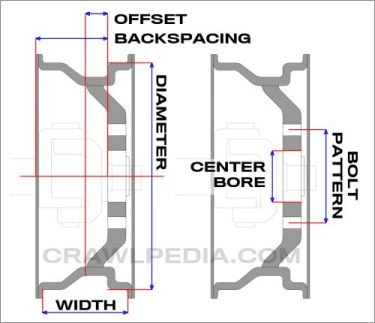

Greetings! Anyone know if there are any 16 inch wheels (either new or used) that would go on these trucks and are a bit wider to accept modern radials? I'm also hoping that I could use the original hub caps and trim rings. I think bolt pattern is 5 X 4.5. Also it's difficult to measure the offset and backspacing without removing the tires. Anyone have this info? I'm hoping to install a set of Michelins 215/85/R16. Anyone drive one of these trucks with radial tires? Any advice would be much appreciated! Regards, Steve Lowe

-

Flathead 6 engine identification

PT81PlymouthPickup replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

Thanks Reg! I couldn't find anything refering to the SR-4488? Do you have any idea what SR stands for? I'm fairly certain this engine will bolt right into my 1939 PT81 pickup? Just slightly larger cubic inches. My original engine was 218 cu. in. -

Hello, Need help identifying an engine I've come across with engine number T214 SR-4488 still in a crate. Crate is marked as Army surplus. Anyone know how to identify this number? It is a 23" long block. I'm considering purchasing for my PT81 1939 Plymouth pickup as a spare. Any information would be most appreciated. Year? Cubic inches? Regards, Steve

-

Now that's funny Jerry! I remember that phrase too. Has the engine in your Dodge ever been bored for oversized pistons? I just read where that could contribute to harmonics? I can't remember exactly how much, but I know my engine is at least .030 over. Thanks for the compliment! I tend to over do things, and it's bugging me I can't get a handle on this.

-

Thanks Jerry for the information! It reads just like what my engine is doing. I have read other articles that led me to believe a damper might solve my issue. What is confusing me, is that if undesireable harmonics was an issue, why didn't Chrysler Corp. install them on all the inline flatheads? It sounds like there were more L6 flatheads without them than with them? Engine balancing and harmonics are evedently two separate issues. An engine could be balanced to perfection and still produce undesireable harmonics. It's more of a Physics anomoly of the engine designs. Some engine designs are more prone than others. I was thinking I could possibly adapt a smaller diameter damper which would allow me to get a belt off and on, but I also have read that these dampers are specifically designed to counteract known harmonics of different engine designs. So, not being an automotive engineer, it might be a waste of time? The high frequency vibration I have is minimal and only occurs shortly on acceleration. I think a lot of people might not even notice it? Overall, my truck runs really well. There is also a possiblity that something else in my driveline could be causing or exasberating this vibration. Perhaps, as one responder to my posting indicated I'm just being too fussy? Using anecdotal evidence only, I surmise that all of the mopar L6's may have had this issue. Chrysler Corp. may have installed the dampers on the higher end Chryslers and Plymouths? I'm thinking my best course of action is to reinstall the original crank pulley and get back on the road. I'll pay closer attention to details of how and when the vibration occurs which might lead to solving this mystery? Does this sound logical?

-

Jerry, I was afraid someone would ask that question. Lols! At this point, I'm not sure of anything! It's been 37 years (1979) since I rebuilt this engine. I think you're correct that orignally it would have come with a 201? I'm completely sure it was not the original engine that came with the truck when I got it. There was a engine replacement tag on the firewall and there were / are no numbers on the block where they should be? I'm fairly certain at the time we rebuilt the engine we were able to deterimine it was a 218. I cannot remember how. Perhaps casting numbers? Anyhow, Yes, this engine could have come from a later model car that had a harmonic balancer? I've heard by some that it would make a difference and others say not? Some say they were added only for extra smooth running on the higher end cars? I really don't know what the facts are?

-

Hey Jeff! You must be older than I am if you remember linked belts on old cars. Lols! Your comment got me to thinking. I just read that the reason they used the wide belts on early vehicles was to dampen vibrations. Not sure if that's a fact or how that works? I have been using a cogged belt on my truck. I'm wondering if perhaps a solid belt would be a better choice? You're definitely right Jerry! I'm just too lazy to make the pulley if I can't keep it on there.

-

At the full diameter there is only about 1/32 inch clearance. Even with a flat positioned downward the belt will not fit. Wow! Don, you really did some serious work there. I had to modify one cross member to get the T5 to fit, but at this point, I'm not willing to modify the front cross member for a harmonic balancer that might not fix my vibration problem anyhow. I'm disappointed there was not enough clearance. It would have been a simple job for me to adapt or turn a pulley. I'm surprised that you were able to weld a flange to your balancer without melting the rubber or throwing it out of balance? Did you have it re vulcanized after welding?

-

Thank you all for your inputs! It is most appreciated. I'm new to this site and very glad to have found it. Quite amazing to find so many still have interest in vintage Mopars. I agree there are several factors that could be suspect in my vibration issue. At this point, it is a process of elimination. The fact that it is not a serious vibration, I'm fairly certain I could run this truck for years without any major issues, but being fussy, I would like to get rid of the vibration. My harmonic balancer plan has come to a complete halt. I have discovered that the outside diameter of the mopar harmonic balancer made for these engines is just too large to work on the truck. It barely clears the cross member which does not allow enough room to get a belt on. So, I'll focus on flywheel and pressure plate. And! Yes, I know, I might still have a problem after that which could be in the engine. If that's the case, I'll attempt to locate a rebuildable core and put together an engine more precisely than I was capable of 30+ years ago. I began this post hoping to find someone that may have installed a balancer to L6 mopar in the 39-47 trucks. I'm not sure why, but Chrysler's engineers certainly installed them on some of their car engines. One thing for sure! The vintage mopar balancer will not work on the pickups.

-

I don't believe so? But, I could be wrong. I had this vibration when I first restored the truck years ago. I suspected the driveshaft back then. The old cross and ball joints that came with my truck are technically a constant velocity joint, but they were worn and need of replacement. The holes where the bearing shafts pressed into the drive shaft ends were elongated. I carefully engineered a new double cardan driveshaft and installed it including setting the correct pinion and drive shaft angles while also installing a new differential at the same time. The vibration I now have is exactly the same as it was before the transplant. So, I'm pretty certain the problem lies elsewhere? I believe I've narrowed it down to engine, flywheel, or pressure plate? But, having worked on mechanical stuff for a long time, I'm really not certain. Weird stuff can happen! And, Yes, it's is usually simple once you figure it out. I'm struggling figuring this one out.