-

Posts

5,503 -

Joined

-

Last visited

-

Days Won

59

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Posts posted by JBNeal

-

-

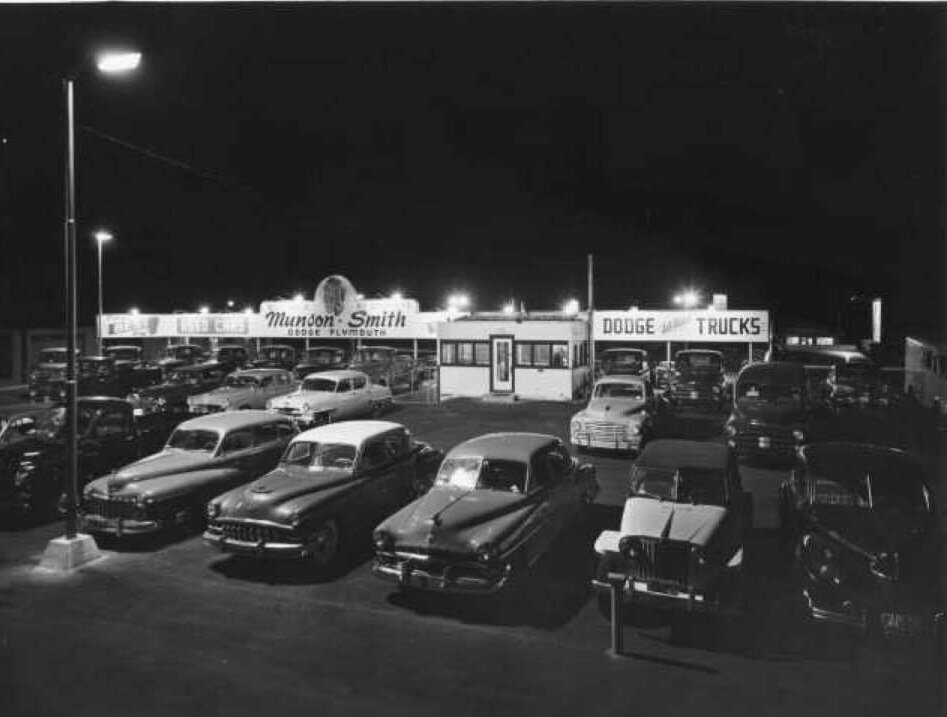

VINTAGEPIC:

saw a few Dodges available at Munson-Smith over on the FB

-

1

1

-

-

-

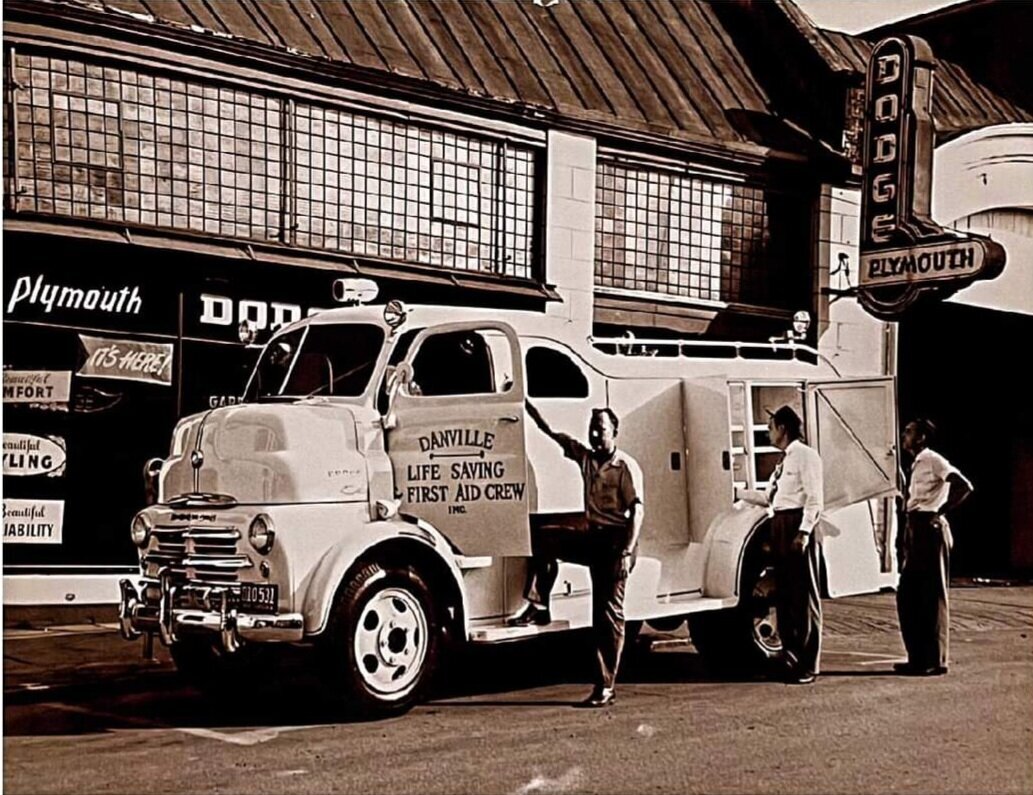

VINTAGEPIC:

saw this big Dodge on the FB

-

How'bout after running the vinegar cycle ya just fill up the cooling system with straight water...whenever I have done a flush where chocolate milk drains out of the radiator, I drive around for a day with straight water to flush out some more. Also cheaper if a leak springs up, then ya don't lose coolant just water.

-

4th gen Rams for years had an embossed blank on the HVAC box that could be upgraded by carefully cutting along the perimeter to add a cabin filter and a snap-in access door from the minivan. The 2015 Laramie Longhorn that I bought from my elderly neighbor was almost fully loaded but did not have that cabin filter, so I snagged a kit off eBay and made the magic happen.

I have replaced 2 heater cores on Ram 2500s, and it is a chore as the airbags have to be disabled, the steering column is dropped, and the dash is removed as an assembly...easier said than done and with a helper, but I managed to do both by myself out of necessity.

2nd gen Rams had an issue with a plastic adapter between the blend door motor and the blend door shaft. This adapter would develop a split so that the blend door did not rotate fully to completely seal off the heater core or the evaporator. Not easy to check unless HVAC box is disassembled. The symptoms would be heater that does not get very hot and AC that does not get very cold, yet engine coolant would be at operating temperature and AC pressure would be good. The QuadCab had this problem for years but Dad didn't say anything about it until I started driving that truck and asked...tore into it when the AC compressor bit the dust, replaced the busted adapter and kaput compressor, and it's been blowing ice cold or lava hot as needed for the last 7yrs.

-

Take that master cylinder to the hardware store and look for a NPT square head plug, preferably black pipe...brass could work, but why be extra

-

VINTAGEPIC:

saw this shiny big Dodge on the FB

-

VINTAGEPIC:

saw this Dodge available at Munson-Smith on the FB

-

AC performance check is in order from a qualified AC tech...if you've got a hole in that condenser or a leaky gasket spmewhere, then AC no worky. These newer systems seem more robust than the R12 days when they all seemed to leak over time. Before R134a came along, I remember asking several mechanics why R12 had to be topped off so much for a "sealed" system, and I was purty much told they all leak a little bit...YIKES. The last AC leak that I dealt with was 5 yrs ago on the QuadCab: hose retaining bolt apparently vibrated loose enough to break the seal, but gasket was still good, so every spring I crawl under the truck with a 10mm to retorque as required...so far, so good ❄️

-

VINTAGEPIC:

spotted the tail end of this Dodge on the FB

-

SURVIVOR:

saw this advertising Dodge near Henrietta...needs some work

-

1

1

-

-

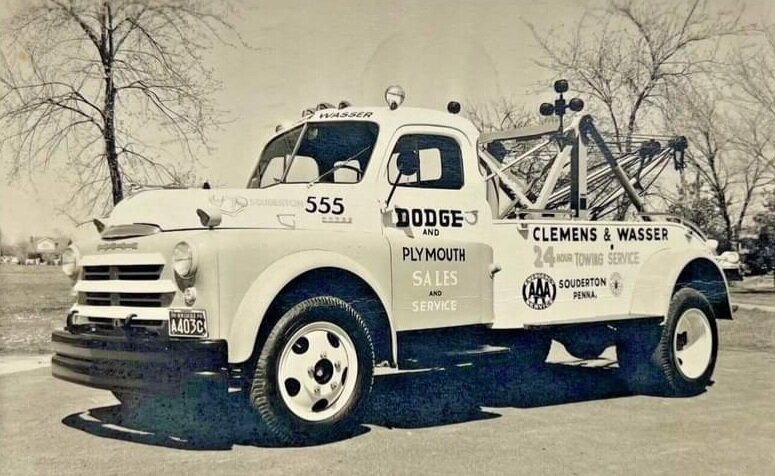

VINTAGEPIC:

saw this Dodge wrecker on the FB

-

VINTAGEPIC:

saw this Dodge on the FB

-

VINTAGEPIC:

saw this Dodge wrecker on the FB

-

1

1

-

-

On my first attempt to remove those 2 little bolts, the bypass housing flange ears busted all to pieces...not sure why, cuz I was taking my time and had applied Marvel Mystery Oil a few days prior, maybe that's just what they do. Anyhow, a local weld shop fixed that, then a few years later, I scored several NORS bypass housings and gaskets on eBay...the seller mentioned that he sourced this haul from a long ago closed down service station that he was cleaning out, so maybe these housings were known to be a common failure back in the day.

-

VINTAGEPIC:

spotted this Dodge on the FB

-

VINTAGEPIC:

saw this Dodge on the FB

-

this does not appear to be OSHA compliant

-

VINTAGEPIC:

saw this Dodge wrecker on the FB

-

VINTAGEPIC:

saw these Dodge wreckers on the FB

-

HOLLYWOOD:

saw this slightly modified '39 on Enterprise "Carbon Creek"

-

SURVIVOR:

spied this B-3 Panel south of Wichita Falls...needs some work

-

1

1

-

-

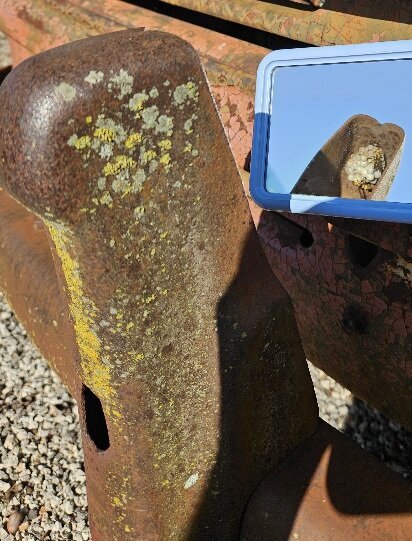

the yellowjackets take up residence in surprising places 👀

-

Vintage picture thread

in Mopar Flathead Truck Forum

Posted

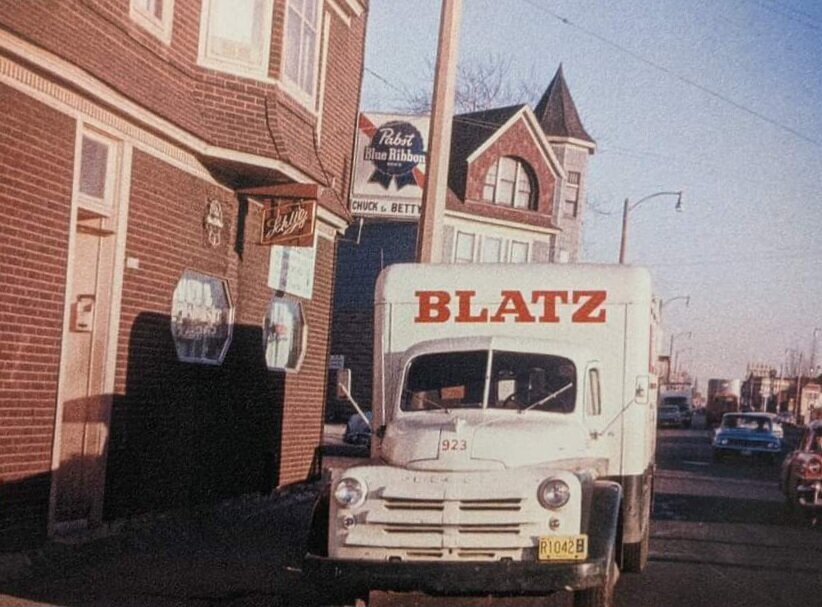

VINTAGEPIC:

saw this Dodge on the FB