-

Posts

369 -

Joined

-

Last visited

-

Days Won

2

CO54 last won the day on January 21 2020

CO54 had the most liked content!

Reputation

164 ExcellentProfile Information

-

Gender

Male

-

Location

Colo Spgs, CO

-

My Project Cars

1954 C1C6

Get her running again......

Contact Methods

-

Biography

Gotta be doing something

-

Occupation

Ask

Converted

-

Location

Colorado Springs, CO

-

Interests

Camping, Fishing, Restoration, Tinkering

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Thanks JB! Yup Brad, still plugging away here too.

-

I know it's been awhile since posting any updates on here, life with teenagers and adult kids never gets and slower. Yes the truck has made some serious progress. 99% of the body repairs are completed, the entire truck is in primer. The brake lines and master cylinder have been installed, I know it's been awhile since posting any updates on here, life with teenagers and adult kids never gets and slower. Yes, the truck has made some serious progress. 99% of the body repairs are completed, the entire truck is in primer. The brake lines and master cylinder have been installed, and bled multiple times, mounts for the replacement fuel tank have been fab'd and installed with the tank. The past few months have been moving pretty fast on little thing progress with the help of my son, who is finally taking a serious interest in the truck. We have now hit a snag that I swear I saw on the forum long ago. We are starting engine reassembly, and I'm looking for something like a step by step guide or list, the manual jumps all over the board without having a complete reassembly list. It's currently a completely stripped block, just looking for a general idea of best practices. Yes, I'll be move active when work, and life allows with kids in sports etc. I appreciate any all assistance. Eric

-

Ken, My running boards are in perfect condition. They are currently loosely installed on the truck frame for storage purposes. I'll try getting them pulled this weekend and getting some pics for you. It's dark by the time I get home from work.

-

The picture prior to the puddle on the floor shows the door lead repair in the upright position, I turned it hinge side down to let gravity do the work as it melted. The dent repair there really isn't to bad. It's the rust that has my concerns, especially in such tight clearance, complex corners etc.

-

Well, I'm still hoping for some input on the rust repairs that are needed. Fortunately, a day off with the MAP gas torch took almost 10#'s of lead off the door. Will be much lighter with a bondo fill instead, after further cleaning and prep is done. scratch marks are from the torch and paint scraper pulling more off.

-

double post, sorry

-

Well, it's been a hot minute since I've updated this build thread. Here's some updates, the steering box rebuild went well, after the teardown and cleaning it went back together without any more binding. Got it all painted and set aside for the time being. Since, then I started moving onto body panels 1 by 1. Cleaning surface rust and repairing large dents after talking with kids n wifey about what they'd like for the finished product, and they agreed to leave any pits from rust or minor dents to stay as long as there's no structural integrity issues. Keeps the character and farm truck history even when it's repainted. We're not after a show truck, just a truck to enjoy. As for body panels completed so far. The inner fender wells have been cleaned, primed and painted black (not original, I know) for a black engine compartment overall. The floor repairs to cab have been completed, the underside of the cab has been primed and sealed with a spray on truck bed liner. The front outer fenders, 3 hood sections, and grill have been cleaned and had major dents repaired to be primed for protection and storage. Everything with the exception of the cab is getting stored indoors after getting primed with rattle can heavy rusty red primer, all parts will get a rough sand and epoxy primer before paint to ensure total sealing. I've finally hit my 1st worse than thought issue. The driver side door. I've only started cleaning up the outside and this is what I found hidden under that patina, and an old school body filler. It's clear that I have some rust to cut out and replace with new steel, and that's a point of input that's needed given the locations and my limited skills on intricate body work. The second is the extra weight with the old school "lead bodywork repair", do I torch the lead off and see what's under it and possibly do the repair with bondo? Looking for some input and suggestions. Greatly appreciate you taking the time to read all my rambling and provide feedback. Eric Gonna try to get the pics to upload/link properly.....

-

Think I found my binding spot today! 2 of the 3 seals arrived and are installed in the main housing. While doing a dry fit with partial seals installed I found this part binding. Suspect a spot of old grease/dirt in there. The darn part I didn't want take apart now, needs tore down for cleaning and inspection. I did end up getting an O-ring (kinda fits) from Napa for the bottom part, and ordering gasket maker to cut another grease seal prior to installation. Still have some concerns with the pitting on the worm gear, but definitely less now what I've verified the binding is coming from. The corn grease arrived too, once I get this bugger marked and tore down, we'll go from there. Thanks. Eric

-

Don't have any JB Weld, but do have the POR-15 Epoxy Putty. Thinking about mixing up a really tiny batch to fill the void and then sand down to as smooth as possible. Will be holding on this until I get the daily driver back up and running. That's today's project.... I appreciate the input, and conversation. I'll post with updates as I get into it. Thanks again. Eric

-

Opened up steering gear box yesterday after getting some confidence from DrFate77, and a few others that post regularly with an abundance of knowledge. Prior to opening up, I noticed a rough spot at about 2 turns from a lock to lock of 5 turns. Soaked some parts overnight in cleaner, and sprayed the rest down with brake clean today. Found some pitting on the worm gear, but it's not rough or hanging a finger nail or micro fiber cloth. Should I be concerned??? Looking for insight. Truth be told, not wanting to have the ordeal or expense that Bkahler went through on his build with another country. Replacement seals for the housing already ordered along with the corn grease, will probably be looking for a universal O-ring for the last seal needed. Thanks. Eric Thanks again. Eric

-

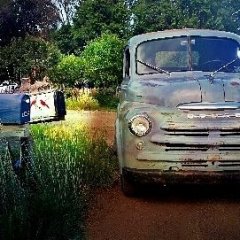

"Ran When Parked" 1954 Dodge C 3/4 Ton

CO54 replied to DrFate77's topic in Mopar Flathead Truck Forum

Well, I'll try getting some better pics, I did a test for 24 hours with my gear box and gear oil to verify a leak from the worm gear cover. I put the shaft at same angle as when mounted in the truck and filled with 90W gear oil (thinner than corn grease), no leaks. Continued checking and found a rough spot in the rotation at about 2 turns on one direction, when it goes 5 turns on lock to lock. Will be pulling it apart to inspect and see what's going on. Thanks for your pics and short write up on this style box. I'll do the same on my thread. Eric -

"Ran When Parked" 1954 Dodge C 3/4 Ton

CO54 replied to DrFate77's topic in Mopar Flathead Truck Forum

When you pulled the lower plate off with the horn wiring tube/outlet did you find an oil seal, or O-ring in there? The parts explosion of the gear box shows an "oil seal" on that tube. My casting #'s are: Gemmer, 2 88, 3DC03. -

My 54 C-1-C had a steel thermostat neck that was rusted out. As you mentioned in your t-stat thread, my truck doesn't have a heater either. It was just a straight neck coming out of the head.