-

Posts

72 -

Joined

-

Last visited

-

Days Won

4

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by kridgleyud

-

Thanks for the pointers. Going to out to car this weekend to take a look at pedal range vs carb fully open and pull the plugs for any signs there. exhaust is dual manifolds into a single 2.5, so larger than original. I'm going to check the vac advance as well and rev in neutral if previous don't show cause.

-

Looking for guidance/help/thoughts. 1940 dodge sedan back on road after resto. Dual carbs, vac advance working, langdons HEI, 12V, mechanical fuel pump, fresh rebuilt motor, 3 speed column shift and ford 3.55 rear. She accelerates through 1st, 2nd and into 3rd fine ... But I find there is not enough throttle left to push past 2,000 rpm in 3rd. Flat roads, tops out at 48-50 mph at 2k per cellphone gps. I feel like she should have some more room left to go past that, but pedal is to the floor. She'll cruise there for miles without issues. Where to look first, directions, tips? I see folks here say they can cruise at least 60 without issues. Not trying to race her around town, but feels dogged.

-

Update for Feb. Last sheet metal installed, carbs rebuilt and balanced, fitted modern light sockets around the car for 12V bulbs. Put wheel spacers on rear wheels to bump them out a bit. Last bits are headlight wiring, tie in fog light (using as turn signals), and wipers. Then head onto motor vehicle inspection for my tags and I'm ready to cruise. Now I'm on the hunt for some odds and ends. Period front tag holder to bumper guard, usable hubcaps, and passenger side front side panel ornaments (just under hood).

-

For me, I was in the market for a new project. I knew I wanted it to be pre-war and my wife said it needed to be 4 door. So my 1940 D14 fell into my lap and it's been a loving relationship ever since getting it ready for the road. First tags under my ownership coming in the next few weeks.

-

So with COVID, I've been home and that has been wonderful for the old Dodge. Fall/winter has been focused on getting paint laid down. I used the TCP Global single stage acrylic urethane, high gloss with great success, I really like this paint, it lays down really nice and leaves a good shine when cured. Then moved onto wiring, dash, interior (new covered seats), adding seat belts for the kiddos. Can finally say that the test drive went well - now moving onto reassembly of panels and trim work. For the colder portion of the winter I plan to get her ready for tags in the spring and FINALLY be able to cruise and show. Planning to trailer her up to Watkins Glen for a nice family getaway this September.

-

My 1940 D14 will be tagged for the first time since I've owned it 5 years ago come this spring. I'll be there!

-

So, another good weekend on the 40. If I can figure out the video posting part of this, I have a video of her running as I checked out gauges, exhaust, gears, etc. As with all steps forward, there are always things that set you back. This time, the water pump bypass was cracked so there's a coolant leak. Very cheap for new, so there's one on the way before running for too long. Tach came, so I test fit this into the area to the left (or right for RHD'ers) of the gauge cluster. Also test fit in the modern radio control. I have no intent on reusing the old mopar 802 since I'm 12V and they're very far gone to rebuild. The amp unit is a small brick that mounts under the dash, piked it up from Woodys Custom Shop and I'll use a bluetooth marine switch to control. This is a little better than a cable from my phone to cable, cleaner. The speaker will be a dual channel 5 inch speaker to mount in original location. For the old radio control knob holes, I plan to drop in LEDs for turn signal indicators. Last bit before closing up the floor was to make a bracket to hold a mechanical brake switch. I'm not a fan of the pressure switched plumbed into the lines as it's one more place to leak and any servicing of the switch will not break the circuit. I mounted this between the clutch and brake linkage on the frame. Next up is the motor break in (once coolant leak is resolved), test drive in and out of garage then onto the painting.

-

Hey andy, love what you did to your 40, seen a lot on this site and advice you gave really helped me out as well. I'm installing a little 52mm tach in that unused area of the dash between wheel and door. Once it's in and radio is set up, I'll post an update.

-

Update, over the last week or so I was able to make up the exhaust. For this, I just ran of the headers into a single pipe back, through a glasspack and out the original location at the rear. I reinstalled the dash to work through the shifting linkage and that's adjusted good now. For the first fire-up and drive out of the garage, I also reinstalled the gauges after refurbishing the cluster. Original glass had almost no lettering left so it was stripped, painted, sanded and I used my wifes vinyl cutter for the background. The original speedo was also very bad off, so I picked up a 30 speedo with really good shape color filter and face and adapted that onto the 40 body. Came out pretty good I think. When reinstalling the gauges, I learned about the unique (to me at least) fitting for the oil pressure gauge, so that's the last thing stopping the start up and low speed test out of the garage. I have that now, so hopefully this weekend I can milestone this build thread with a nice video for you all, we'll see. Throttle pedal rod was also installed, finally got that right and spring locations worked out. I also started working out the radio and decided to add a small tach into the dash. I'm going to use the original radio knob locations for turn signal indicator lights and where the actual radio was, put in a bluetooth radio remote (small control panel with like 4 buttons to work hidden radio) and mount the hideaway radio under the dash wired to a 2 channel speaker in the original location. Floor closed up, upholstery fellow quoted work, new tires ordered and then paint coming up next. Once she's painted we'll get cracking on wiring, interior and glass, and alignment before inspection. She's getting close. I have a goal to get out to the later summer/fall cruises with her and enjoy it as I address the more cosmetic stuff.

-

@Los_Control Thanks for the photo ... the trucks ran the linkage to the pass side of the block, the cars ran it to the driver side and across the head. I've seen on later model cars where there its a hinge or pivot on the firewall. Mine looks as is there is a rod that connects the bell crank on the left side of the motor to the pedal. I have a rod that looks the part, I'm just not sure how it goes into the firewall area. There is a tab bolted onto it with no indication of fasteners. Here is what I can tell, looking through all the tear down photos, you can see the rod headed toward the firewall.

-

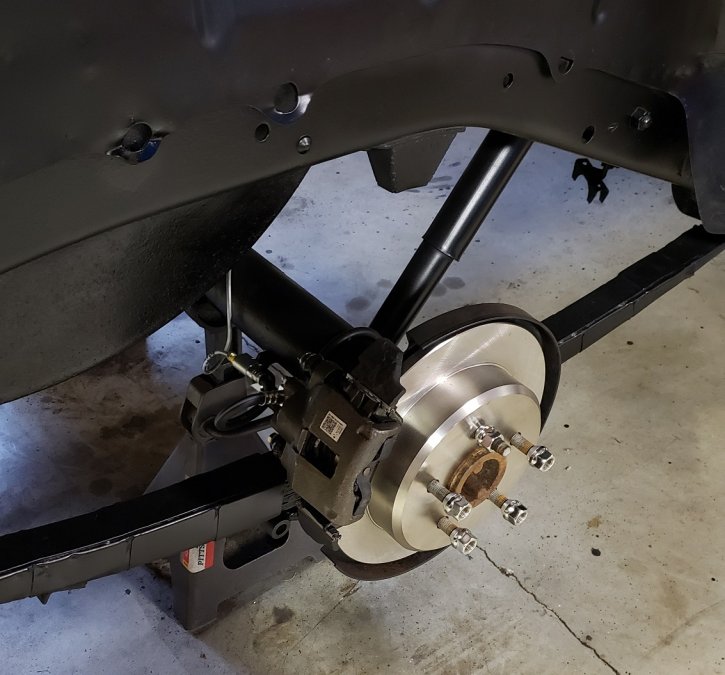

Hello all. It has been a long road and the project took the back burner for a while. But, here is an update on where the build is now: - Rear replaced with a 98 ford 8.8 with disc brakes - Engine buttoned up, repainted silver - All the body rust repaired and sealed, fuel tank repaired and installed - Front disc brake conversion (Scarebird) finished and pedal assembly reinstalled - Trans reinstalled, clutch linkage and shift linkage reconnected - Front and rear brakes plumbed, bled and tested - New wiper motor installed from Newport (great kit) while dash is out On the list of things to work out are: - How the heck the throttle linkage from pedal gets to the side of the motor to the bell crank ... no pictures from my books on how this linkage is made ... I have a rod, but can't make out how this attached .... it can't be solely supported by bellcrank and floor board, can it? - Prime and paint - Wiring - Exhaust work ... looks like it's not possible to run true duals all the way back given the battery box and left side mounted fuel tank ... only have a small opening between tank and spare tire well to run tubing and this is not big enough for duals. If anyone has info on they did it around the tank and spare tire well, I'd be happy to see but everything I've seen, it's too tight

-

Quick update for those still following this build ... I know it's been a while. Motor is back in the car and all oil leaks have been addressed ... crank had odd hole in flange, some fittings loose, oil filter can was leaking ... all set now. Current set back is what I believe is timing. I reset the timing to #1 TDC prior to trying to start ... got some detonation and figured I was 180 out, adjusted for that ... same thing. So I decided to check the valve movement via the springs with the front cover open ... my intake valve is not moving on #1, seems to be stuck for some reason ... Next steps ... quick compression and leak down test then pull the heads off and see what that shows me ... was rebuilt a while ago and has been sitting for almost 2 years now so could be some stuck valves.

-

So the expansion plug in the crank worked out well ... no more leaking from the rear and with plugs out, starter rotating the flywheel I saw the pressure gauge jump right up to 25-28 psi ... BUT! Also noticed some oil coming from the #3 and #4 cylinders (apparent from the plugs being removed). After cranking starter like this for a bit on and off ... some small oil drips coming from the headers ... this makes sense if there was oil in the cylinders and being blown out the exhaust valves. I'm hoping this was because the motor was sitting upside down and rotated in that position while I was working through the crank flange and rear seal. however, I'm starting to not trust anything on this motor anymore and think I should do a compression test to make sure the rings are OK. Am I being paranoid with this, or should I start her up and see if it goes away? It's never been run to temp or broken in yet, so maybe there's some oil getting by until it's run at RPM and able to get hot ... on the other hand I don't want to ruin anything either. thoughts?

-

@Robert Smith I believe this one has the electric wiper motor installed as well.

-

Figured I would post the solution I used ... I found a dorman expansion plug that matched the bore ... drove this in with some permatex and it seated nicely. Re-installed the flywheel, bell housing and starter and cranked her with no load to check oil pressure .... got it now! no leaks! She's going back in the car as soon as my new clutch disk comes in from Nashville and I'll get her started on frame. Video when all goes well

-

Hello all. I did some investigation as to where this oil is coming from and I found the issue. The bore into the crank flange for the pilot bearing and trans input shaft is too deep. Not sure what happened to this crank before I had it, but it was machined out for some reason ... now I'm worried what else I'm going to find. It's so deep that is broke into the oil passage for the rear main bearing journal. Who in for world would machine anything out of this???? Here is some pics of what I see ... picture into pilot bearing bore / picture shining light into bore and looking down at main bearing surface ... you can see the oil passage light up. I'm going to pull the crank out next and take to the machine shop to see what they think ... I'm thinking I'll need to regrind a crank I have in an old motor and replace all bearings to match. But ... maybe it's possible to plug this area behind the pilot? That's optimistic ...

-

@thebeebe5, thanks for sharing this. It may likely be coming from this seal again ... the rope seal I took out, in my original pic didn't look very good. I have the best gasket on the way as it's very cheap through EGGE. I plan to replace is no smoking gun other than this is found. Again, really thankful for the feedback and experience shared and have to trust the word of your engine builder.

-

Thanks for the thoughts all. I've got her on a stand (crate really) so I can look at further. Plan: 1. Remove pressure plate and clutch disk, use starter and bellhousing to crank and look around ... 2. Remove bellhousing and starter and flywheel and look at plugs/seals on rear again for wetting @thebeebe5, I was with the understanding that the rope seal in the bolt-on retainer was a direct swap with the newer neoprene seals. Curious, what machining is required for this seal to work? The pic shows both .. I did install the flange inward as that's what the manual showed, its just flipped in my pic. @greg g, there is a plug in place of the oil pressure gauge line at block that would normally run to the firewall. ... But, going to re-check all seals and plugs to make sure they're sealing.

-

@Merle Coggins I'll check these while it's out .. .didn't see any signs of oil here last time but I'll definitely look again. @Andydodge Sure did! I'm stumped really ... but with her out maybe I'll see something I couldn't before.

-

Experts ... I need some help! Bought a rebuilt 218 from and Dodge truck to go into my 1940. If you followed my build thread you'll recognize the issue. Months ago before winter I put the motor on the chassis, cranked the starter without plugs and had a BAD oil leak from the rear of the motor. I pulled it back out and replaced the rear main seal (bolt-on type) and new oil pan gasket. This weekend I put her back onto the chassis and tried again ... cranked starter without plugs and what happens ... oil to about 20 psi and nothing higher ... more leaking out of the back. Pulled her back out with oil this time; into the garage again to see if I can find out where this oil is coming from. Here is the seal i took out last time versus what I replaced it with ... Any thoughts as to other sources for oil coming from the back of the block? All seals and plugs look intact on the back of the block ... any chance it could be coming from the crank at the pilot bearing?

-

Just saw this thread and thought I would share my experience. I'm in Delaware, so not apples to apples. I bough the car from a fellow in PA, who bought from another fellow in TX. The PA title I got with the car has the serial number on it (located inside the pass. door pillar), but my local DMV would not use it. The car was not drive-able, so when it came time to get my Delaware U-Title, they sent out an employee (inspector, number looker-at-er, i dunno what his title was). But he told me my new title would be using the engine ID and I was surprised, but said that's what DE did. When I asked what to do if I ever replaced the motor, he said to just mount (rivet) a plate on the firewall with the old engine number. Since the original engine was replaced and I'm not usually one to trust a state-workers word, I'm keeping the engine until after my U-title gets converted into a real title and gets it's tags and registration ... just in case!

-

@Tom Nice looking car there! Looks solid. It's starting to get pretty cold out here, but I was able to get the front end done before moving her back into the garage. I'm going to pull the motor next and figure out where this oil is coming from and rest her back in there. I'll do the cam break in on the frame then move onto my planned winter projects. My wiring harness just showed up and I've started looking whats needed to get the gauges restored. Any questions or odds and end parts you need, feel free to ask away. Keep us posted on your progress too! -Kev

-

alright everyone ... was thinking about this all day at work, so crawled under there to take another look. I attached a pic of the rear seal area ... not as wet as I thought, hard to see now where it was coming from. It's soaked up around the starter as i look up into the bellhousing. Is it possible it's not the rear seal or oil pan? Not sure what else could leak back here. Next, I think I'll get a helper to hit the starter for me as I look at where the oil might be coming out from. I was at least able to determine it has the outside the block style seal ... is that really all there is? Or does this have the rope inside as well? 1950 Dodge truck motor, 218.

-

To be safer I used the chassis as the test stand. Burns me up a little to have to backtrack but it's not that bad. Pull motor, bellhousing and clutch back off, drop oil pan then I can tackle the seal. Big bummer is that the clutch disk was exposed to the oil. Not sure if there is a way to save it or if I'll need a new one?

-

was hoping to post some good news ... but I've got a set back ... used an old oil pump with drive gear off to prime the passages, was able to get pressure on the gauge but noticed an oil leak ... dripping from the clutch cover. Was hoping it was the oil pan or something ... well it appears the rear main seal is leaking, flywheel and clutch are all wet with oil. bummer, but it is what it is ... so I'm going to start getting ready to tackle that, motors coming back out.

.thumb.jpg.78d6c0802c54e2d4382e1ae232fa93e6.jpg)

.jpg.5668f4d199702ac3220b21685087d051.jpg)

.jpg.bb6fecc83a13831daf27999a80002a3f.jpg)