-

Posts

50 -

Joined

-

Last visited

-

Days Won

1

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 48 New Yorker

-

FrankenSpark experiment: I'm going to run the following spark plug set up in my New Yorker (323.5ci) for a while to see what the different ranges yield....why not? After a few hundred miles, I'll pull them and compare. The Autolite 306's are (resistor) one step hotter than the 295's (no resistor) and the NGK B4's (no resistor) are approximately 2 steps hotter (equal to the Autolite 308's (resistor). I've heard NGK's are superior to what I've been using (Autolite), so I'm going to give them a try. I've checked everything else, ign, carb, timing etc. I think the PCV setup I've installed has fundamentally changed the mixture in a way that can not be easily "leaned out" without re-jetting the carb.... recall this engine had moderate blowby. That's something I'd rather not do....yet. Where would I find an assortment of jets?....which one to use? .....lots of trail and error. The "plug trail" may give an answer more quickly with less expense. I'll keep you posted.... Btw, the PCV valve I've used is marked 2257 and I believe it to be a Fram FV333, which is sized for a 318ci Chrysler/Plymouth/Dodge engine....approximately close in size to 323.5 in ci. "IT'S ALIVE...."....(and remember.....there's always Egge for replacement pistons)

-

Wagoneer: To answer your questions in order: I think we are parallel in our repairs. I had the vac advance rebuilt by Terrell Machine DeLeon, TX years ago and it's still doing ok. I did get my material from SMS....I was warned that it might take a while to get, but they filled the order in about 2-3 weeks....I'm very happy with the quality....but not cheap.... I think it also comes in a blue/green combo, there is an even more rare, a Navajo pattern (see photo), but I don't know if they carry that. The steering w/the Cocker radials is still somewhat heavy during parking, but better....once under way moderate effort.....don't expect Chrysler's (later) full" time steering" --- I have a DeSoto with that....and can park it with 1 finger. The radials cornering grip exceeds the capabilities of the suspension....it will really heal over before sliding. There is a highway gradual sweeper turn near me which I drive often....over time, I gradually took it faster to see what the limits were.....can't recall the speed, but when Geezr started to drift, it was very gradual, tail slightly out and controllable....the kind of thing ya do only once....just to see.... Re: breaking.....Coker's grip very well for stopping, but I haven't done any (intentional) panic stops....for fear it would pull to one side or the other...very tricky to adjust, even with the Ammco Brake tool. My speedo with these tires (7.60R-15) still reads about 7-9 mph fast. I tried everything short of pulling the engine to free up the piston rings to minimize the blow by...and it has worked to some extent....still got some, but manageable ......ATF + Acetone cocktail.... sitting in the cylinders over a couple of days...re- apply as it will drain into the sump....then drain .....don't run it with that brew in the crank case....fresh oil and filter....takes time....maybe an occasional Berryman's B12 chaser in the gas once in a while......

-

Greg G: Thanks for the good info... I'm now an expert at popping the top of the carb off to check stuff (float level...etc). I'll check out what you've suggested..... Narrowly avoided a real headache......during my rebuild of the AAVS2.....I decided to use my compressor to blow out a bleeder (looks like a long needle).....damn thing shot out of my hand when I hit the air... finally found it .....about 4 hours later....stuck in my bench grinder.....don't know where I'd locate another .......at least I found it.

-

Wagoneer: Thank you for the complement. "Ol Geezr" was originally delivered to Carter's Garage in Centrailia WA (this from the id plate info that I sent to Chrysler Historical). Strange part is.....the firewall ID plate reads DeSoto, but has all the correct info for the car. I think it was owned by a woman who did not drive much, currently has about 34k miles, and is rust free (other than surface rust. Unfortunately, I don't think it was garaged as the chrome is shot and it's been repainted twice from it's original Heather Green (see door jams).... I refer to it's present color as medium Bile. My guess is that it sat for years, and as a result, the oil control rings either got "lazy" or are carboned up, hence the blow-by, doesn't use an inordinate amount of oil tho'. I've had the head off, but didn't remove any pistons. One shows some pitting that I think occured as a result of a leaking head gasket many years ago; and a couple of cylinder walls have some slight pitting as well, again maybe water intrusion. I recently got the seats done and treated myself to the Highlander option (original was dark green)....see pics. Next projects are the door panels and headliner......and finally paint, and back to original Heather Green.....hopefully in the next year or so. For anyone who remembers my prior posts, I had complained about heavy steering and opined about getting electric power steering.....which is impossible as I've learned, because I have chosen to retain the 6v pos ground electrical (you need 12v neg for electric).... I've keep the 6v pos, but upgraded to a 6v alternator....(a very good and $$$ reasonable upgrade). The car came with L78x15..... a Freighliner steers easier. The solution to the steering was to buy a set of Cocker "Bias Ply Look" radials (wide whitewalls). Even though the recommended size for a '48 is 8.20x15, I chose to go with the 47's size of 7.60x15 because they were narrower. Radials tend to grip better making them harder to steer, but this is offset by the fact they are quite narrow. It still steers heavy when parking, but is manageable - I'm happy. 2 issues with the Cockers tho' ....two tires were defective - sidewall blisters, (exchanged free) and they are very hard to have mounted because they come tightly wrapped.....the bead would not expand enough to catch the rim.....had to leave them in the sun with bricks in them to spread the bead....what a pain.

-

Yup, did that with vac gauge and confirmed with a tach ....found the highest smoothest idle after backing out the idle speed screw to drop the idle..... then adjust the mixture...then reset idle to 500ish.... Re: spark plugs, I guess no one uses 308's. An additional FYI, I replaced the coil with a new one thinking the old one may have had an intermittent problem....the new one is (correctly) not internally ballasted....

-

Thanks for your replies: Chrysler1941: It's timely you should mention "timing w/a vacuum gauge. I just tried that a while ago without getting definitive results. My vac is nice and steady @ about 18-19"....problem is, when I dialed in more advance it never got to a point where it dropped off.....signaling me that there was too much advance...in fact I ran out of "room" to advance (the advance unit hit the block preventing it's further movement). At that point, I "guesstimated" that I had dialed in about 10 to 12 degrees of advance....far too much...so I reset with my timing light to 4. Most of what I've read here say no more than 3 to 5 degrees max... The cold start issue may be part of the problem as well as my driving habits .....mostly slow around town driving.....not much highway.....fyi...no oil on the plugs....just soot. GregG: No black smoke, but sooty tail pipe and strong burnt gas smell (bicyclists hate me)..... I've modified my air cleaner to take a standard Fram paper element (see pics)....and I think the flow is ok....maybe I should try w/o it for a while. Heat riser is free and moves easily....clunks when I open/close throttle quickly. You're point about the carb circuits is a good call....but one I've avoided because I don't really know how I could diagnose and fix it.....re-jetting????....so I've kind of avoided thinking about it. I've had the Stromberg apart several times for cleaning and rebuilding (have another as a backup) and I feel that I've cleaned out the passages as well as possible.....using a very fine wire, soaking and compressed air. I've replaced the Sisson with a manual choke, so I'm confident it's not hanging up. Also, added some heat shielding to prevent "hot soaks" b/c of alcohol/gas issues. One other thing....up until recently I have a 3 year old 6v battery that was getting tired...now replaced. Perhaps I wasn't getting a strong spark....New battery makes it start a lot quicker....much less cranking....FYI I have copper core wires and new points/condenser too.

-

I've got a 48 New Yorker 8 that runs quite well. Currently running the spec'd Autolite 295's gapped at .025, but they become sooty after a few thousand mi. The engine has moderate blow by for which I've installed a PVC system (based on the factory reto-fit plans). Other stats: timing: 4 degrees adv., valves I.008/E.010, dwell 29 degrees. I'm thinking that the recirculated vapor might richen up the mixture causing the sooty plugs. (the carb Stromberg AAVS-2 has been recently rebuilt and has correct original jetting). To fix the soot problem, I was thinking of going to the hottest plug available, the 308 (2 steps hotter than 295)....does anyone have any long time experience using them? I tried 306's not much better than the 295's. Also, the 306/308's are resistor plugs, not spec'd for the 48, and the gap is spec'd @ .035".....vs .025" for the 295's To recap: Anyone have experience with 308's in a Chrysler 8/ 6 or Dodge/Plym 6? .....what gap do you use? Thanks all. FYI my old Motor's manual lists the correct plugs as follows: 46-48 Chrysler 6/8 = AL (Autolite) A5 49-50 Chrysler 6/8 = Al (Autolite) AR8

-

Muffler for a 48 Chrysler New Yorker - 8 cyl.

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

Hi John: Yes the 41 Buick is a maroon 2 door sedanette (fastback) that I purchased about 15 years ago from a guy in Chicago. It was owned by a "little old lady" who put about 20k mi on it. She sold it back to the original dealership in '57 when she could no longer drive. The owner of the dealership kept it in his collection until the mid 90's and stipulated in his will that sales manager's son should be given the first shot to buy it from the estate. The son who worked at the dealership part time as a youth, first asked to buy it......in 1957. Patience rewarded.- 5 replies

-

- oem muffler

- chrysler

-

(and 3 more)

Tagged with:

-

I'm trying to find a stock type oem muffler to replace the one on my 48 Chrysler New Yorker 8 cylinder (which I believe, is longer than the 6 cyl model). That would be the larger front one, as they came with a front and rear (mine only has the front). I want to replace it with a quiet oem type, no Flowmasters, Smitty's etc.... When I say oem type, I don't mean an actual NOS oem; I mean a new muffler in the oem style. If anyone has a older cross reference guide, could you post it on line? My current muffler has the following markings on it, but no brand name: T 777 and W 757 659. I've searched the web with those numbers, but nothing comes up. Thanks, David in Santa Cruz Below are the specs for my muffler, the dimensions are approximate: total length 38" body length 34" circumference 19 1/8" cross section 8 inlet num + location = 1 center outlet num + location = 1 Rt. side inlet pipe diam 2.38 (outside measurements) outlet pip diam 2.18 " " muffler shape oval

- 5 replies

-

- oem muffler

- chrysler

-

(and 3 more)

Tagged with:

-

Thanks to all who responded. Just to clarify, (I should have worded it differently), I'm pulling vacuum directly from the intake manifold; the fitting is in the manifold under the base of the carb, not the carb itself. Re: vac @ 17-18 rather than 19-21, I may have an intake leak...I've noticed some "oil moisture" around the bottoms of the intake manifold runners where they attach to the block. I figured this was due to my adding a closed PCV system to minimize some blowby vapor at idle. I've tried using a propane torch to find the leak... (unlit ) as well as soapy water....haven't found anything yet. Again, what I'm trying to figure out is why my idle is not dropping (as it should) when I go beyond the timing "sweet spot"..... the RPMs just keep climbing with more advance....not what I expected to see or want to happen. I think I've got my timing dialed.... it runs quite well at 2• BTDC , for a total of 4 degrees advance over what the manual says (2•ATDC). The odd results of the vac test have become more of a matter of curiosity as to why I'm not getting the results I expect with the vac gauge. I'd like to be confident that I'm doing it right, so I can use this method in the future.

- 7 replies

-

- new yorker

- timing

-

(and 3 more)

Tagged with:

-

Having some difficulty setting my timing using a vacuum gauge on my 48 New Yorker 8 cyl…..and could use some guidance. I’m trying to find the timing “sweet spot” rather than just rely on the book specs. I’ve attached my vac gauge to a non-ported vac source at the carb base…(it usually reads about 17-18”)… then adjust my idle as low as I can get it…about 350 rpm or so….to keep the mechanical advance from kicking in. Did not disconnect vacuum advance because it is not supposed to activate at low RPM. Next, the procedure is to advance the timing until you get the highest rpm...just before it drops of. The problem is the more I advance, the more RPM I get…until I can’t turn the distributor any further (about 12-15 degrees (which I know is way too far). What should happen, is that at some, point the RPM should decline when the timing is too far advanced…but it doesn’t. I would expect the RPM “fall off” to show excessive advance, but that’s not happening….(FYI, points are set to specs and read about 28 degrees of dwell). The manual calls for 2 degrees ATDC, but with modern fuels I’ve been told most people run about about 2-4 degrees advance; I’m currently at 2 degrees BTDC based on my timing light. Can anyone tell me what’s going on?

- 7 replies

-

- new yorker

- timing

-

(and 3 more)

Tagged with:

-

M5 Fluid Drive - coupling capacity and observations

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

Hey.....I've got two Dynaflows both are fast ...............................................leakers.- 11 replies

-

- fill

- fluid coupling

-

(and 3 more)

Tagged with:

-

M5 Fluid Drive - coupling capacity and observations

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

If you really want to see how well a Fluid Drive performs against a stick, view the video below from the :43 sec. mark. I’m absolutely, positively sure they didn’t speed up the film for that sequence ….nope….nope….nope….- 11 replies

-

- 1

-

-

- fill

- fluid coupling

-

(and 3 more)

Tagged with:

-

M5 Fluid Drive - coupling capacity and observations

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

MarcDesoto: I would try a local "industrial oil distributor" or on line Granger or Zoro, see links below, however my best price was from a local place called Toro Watsonville CA. ≈$100/5 gal pail. https://www.toropetroleum.com/ https://www.grainger.com/product/MOBIL-Mineral-Circulating-Oil-4ZF36 https://www.zoro.com/mobil-mobil-dte-light-iso-32-5-gal-104743/i/G0808272/?gclid=CjwKCAjw7O_pBRA3EiwA_lmtfhAEUUY-lyh571MNrjK5ofbfSxnrtkI-9QW6xqePSIATZLI2PfoPfhoCiAQQAvD_BwE&gclsrc=aw.ds- 11 replies

-

- fill

- fluid coupling

-

(and 3 more)

Tagged with:

-

M5 Fluid Drive - coupling capacity and observations

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

The M5 is not as much of a slug as some think it to be. I think the problem is that few people really know what to expect regarding acceleration because they’ve never used the correct fluid…. it’s a case of “I’ll put in whatever oil I found and now the car moves and shifts….problem solved”, and the result is how they think it’s supposed to perform. Wrong. My reasoning: Let’s say that the original fluid will last about 10 years before it starts to deteriorate (well beyond the length of time Chrysler engineers felt/hoped an owner would hold on to their car). Sooo, in my case (’48 New Yorker) my fluid would have been due for replacement around 1958…. Since they stopped making the stuff in the mid 50’s, everyone has been using something yellow or red that would pour…..ATF, 10w oil, Tractor Fluid, Vitalis, oil&vinegar etc. I just compared two very similar oils in everyday driving and one gave much better acceleration than the other. The DTE 24 with a few additional additives was inferior to the DTE Light Circulating Oil. My point is this: — Very minor differences in oil formulation can make a big difference in how an M5 tranny car accelerates and preforms...if you've never installed the right stuff, how would you know how it's supposed to perform? My 48 now keeps up with around town traffic easily given it’s weight and horsepower…135hp/≈3900 lbs. If you decide to try Mobil DTE light circulating oil, use the product number to prevent confusion: Mfr part#. 104743 As to the current uses/specs of Mobil DTE Light Circulating, see the product data sheets attached below. DTE Light, Medium, Heavy Medium & Heavy pds.pdf- 11 replies

-

- fill

- fluid coupling

-

(and 3 more)

Tagged with:

-

M5 Fluid Drive - coupling capacity and observations

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

Marc: The Mobil DTE 24 in your ebay post is not what you want. While it won't damage anything, you won't the the correct performance out of it. Its additives make it a bit too slippery; which makes the tranny feel as if it is slipping/sluggish. Chrysler1941: Both Mobil DTE24 and the correct Mobile DTE Oil Light Circulating oil are ISO32. The easiest way to get the correct Mobile oil is to ask for it by the manufacture's model number which is Mfr #: 104743- 11 replies

-

- fill

- fluid coupling

-

(and 3 more)

Tagged with:

-

Just got finished replacing the oil in my M5 Fluid Drive…after 12 years. Unfortunately, when I first got my Chrysler New Yorker, I installed the “slightly” wrong oil; “Mobil DTE 24 Hydraulic …. should have been “Mobil DTE Oil Light Circulating Oil” - manuf. part number 104743. Mobil’s naming scheme is confusing, however my mistake allowed me to compare both blends. The DTE 24 has additional additives, but IMO, was more "slippery" and didn’t accelerate the car as quickly as the DTE Oil Light Circulating 104743 -- while not fast, I’d say that it’s much more “sprightly”. The only downside is that the DTE Oil Light comes only in 5 gallon pails…. and it ain’t cheap….I found it locally for about $100…well, at least I’ve got a 30 year supply…. A few observations: - the fluid coupling of an M5 takes exactly 25.5 cups or 6.375 quarts. - instead of using a rag to keep the plug from falling into the bell housing, I used a thin piece of aluminum sheet to make a tube that fit in the fill hole.... left more room for the socket wrench. - make sure the car is level. On my first refill years ago, didn’t realize the gentle slope of my street… under-filled the coupling by 3 cups. This time I used a level and jacked the back end. - a DIY slow drip system is a lot less fatiguing, allows you to walk away while it’s filling…see photos. - Jame Douglas deserves a round of applause for his research into the correct oil for our Fluid Drives, he got it right. David in Santa Cruz

- 11 replies

-

- fill

- fluid coupling

-

(and 3 more)

Tagged with:

-

ignition points: recommend a manufacturer

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

Thanks to all who responded about the points and condenser question. Since no current manufacturers are mentioned, I guess I can conclude there's no one who produce quality stuff. Fortunately, as suggested, there's ebay for NOS Autolite parts -- which I'm going to try. Re: T120's suggestion.....good idea, I've also considered using 3M Silicone Paste....anyone tried it? https://www.3m.com/3M/en_US/company-us/all-3m-products/~/3M-Silicone-Paste/?N=5002385+3293194053&rt=rud Now.....the rest of the story.....I had a Pertronix set up, (including Flamethrower coil) which I installed about 10 or so years ago. At that time, after consulting with a Pertronix engineer, I wired it according his plans with the resistor for the M6 Fluid Drive tranny. Didn't have any problems.....but it never seemed to "out perform" a good set of points, (other than not having to replace them due to normal wear, but I really don't mind that.....retired with time/interest for maintenance and wrenching). Once running it performed well enough, but it remained hard starting, requiring a lot of cranking (even with a fully charged battery)....just felt I wasn't getting a strong spark... Read elsewhere, that Pertronix liked a full 6 volts plus at the coil to run best...checked and was only getting about 3.6v at the coilI, so I ran a wire from the neg side (hot) of the coil to the 2nd lug on the starter (the lug that is only hot during cranking; it's connected to the sisson choke). Pfffffffft.....after the putrid smoke cleared, I made the decision to return to points.....don't try this at home folks.- 6 replies

-

- distributor points

- recommendation

-

(and 3 more)

Tagged with:

-

Hi All: I've read several posts about poor quality replacement ignition points and condensers. Seems like a lot of them are made in China and fail quickly. Can anyone recommend a quality brand that they have had experience with? Conversely, can you also let me know which brands are junk? I'm running an Autolite distributor model 1GT-4201-1 in a Chrysler New Yorker flatty 8.....don't need the part number (although if you've got one-- great), just want a brand/source for a quality set of points and condenser. Thanks, David in Santa Cruz.

- 6 replies

-

- distributor points

- recommendation

-

(and 3 more)

Tagged with:

-

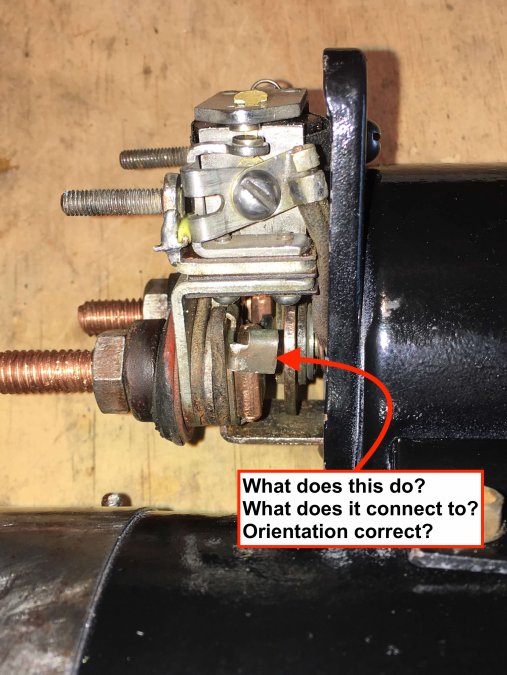

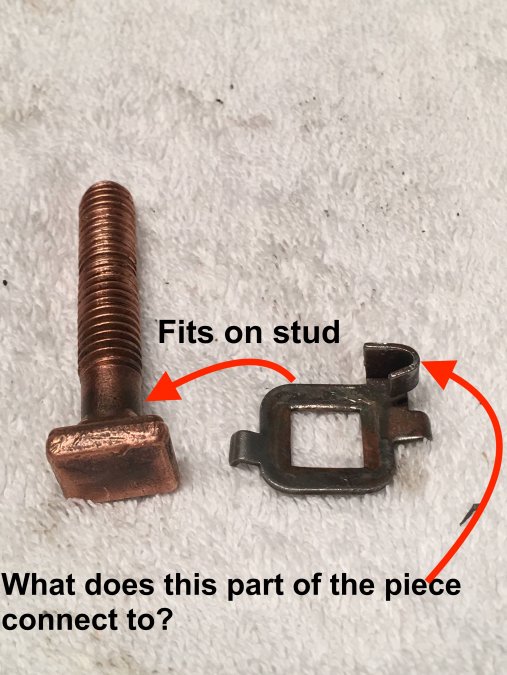

Help identify what this part does and its correct orientation

48 New Yorker replied to 48 New Yorker's topic in P15-D24 Forum

Thank you Dodgeb4ya, your photos confirm I have the "ring" in the correct orientation. As to the purpose of ring's tab....it looks as if it should be crimping a wire or making contact with something....but does neither. I'm thinking that the "tab" exists only because it may have been cheaper to manufacture....probably used in other solenoids and simpler to use one stamping rather than tool a new part. Possibly its purpose here is just to shim up the longer copper stud so that it sits lever with the shorter stud when contacting the round plunger. This must have been a real stumper....only one reply. Any other insights? Still haven't got the starter to work yet. Gonna go over everything again to see if I missed anything. -

What you see is the starter solenoid from my '48 Chrysler New Yorker 8 cylinder. I need help identifying what the "ring like" connector (that rides on the terminal stud) does and its correct orientation. Some background: the starter quit, so I started troubleshooting. I found the winding for the solenoid relay (with yellow wires) was defective, so I rewound it. Now, it tests out fine....points close when energized with 6 volts to the contact studs. The solenoid also seems fine... pulls the plunger in when current is applied to the wire leads. There is continuity between both terminals of the relay and also between both terminals of the starter coil . Tested out the starter motor and that tests out ok too, spins right up when current is applied directly to its terminals. So all three parts, relay, solenoid and starter motor work - individually. When everything is put back together, the solenoid won't engage (won't throw the gear into starting position), nor will the starter spin.....can't figure out why. Thinking the "ring like" connector may have something to do with it. My question is this: (see photos): what does that tab on "ring like" connector do? What is it supposed to contact? Is it in the correct orientation (it can be rotated around when loosened). When I removed the battery studs, this contact piece was twisted around and was making contact with the copper disk. This is because as I loosened the nut the stud rotated, and the contact piece with it, so I don't know it's correct orientation. Anyone got an exploded diagram? I'd really appreciate any help you can give me on this as I'm really stuck.... Thanks, Daivd in Santa Cruz

-

I'm replacing the clutch and various elements of the Fluid Drive unit in my 1948 Chrysler New Yorker 8 cylinder and I need some advice. History and questions: The carbon seal and the copper bellows (40-51 "1st style") are leaking and need to be replaced. The carbon is pitted and the bellows has a pinhole leak in it. I have been able to locate, but have not yet purchased, the "1st style" which I have heard is inferior to the "2nd style" (51 - ?). Will the "2nd style" fit my "1st style" Fluid Drive unit. Is the upgrade to the '2nd style" is worth the effort so far as reliability is concerned? I probably put about 2000 miles per year if even that. I was told that if I use the "2nd style" seal, I would have to get the large retaining coller nut, which on the "1st style", is soldered/glued to the accordian bellows assembly....is this correct? If so, does anyone have a source for BOTH the later carbon seal, sleeve AND the large retaning nut? Does anyone have a photo of the "2nd style" seal complete? Finally, how do I remove the front most bushing/bearing (the smaller one that supports the fluid coupling)? The chrysler manual shows an extraction tool, but I don't have one, and all other attempts have failed to remove it. Thanks David in Santa Cruz

-

Ready to get rid of the electronic ignition

48 New Yorker replied to 47heaven's topic in P15-D24 Forum

I've had some "crap out" issues with my Chrysler New Yorker like this and have compounded the problem by trying to relate it the most recently changed item on the engine. Sometimes I'd be right, sometimes wrong. Here are some things I'd check (some of the things that bedeviled my flathead) -fuel line at carb--I wrapped the fitting with yellow teflon tap to cure a leak and a small chunk wound up intermittently clogging the fuel line. -low charge on your 6v battery. I have a Pertronix ignition and it MUST have a strong battery with a good charge or the unit will not fire off. -check your throttle shaft for wear....at high rpms the fuel mix may be fine, but at idle the throttle shaft may be leaking and leaning out the mixture. A nice fat dab of grease on the shaft end may seal it temporarily. -check the vacuum advance plate to see if it (or a wire) is shorting out as it rotates. Just a few thoughts for now, back to my hectic life (not) in CA. David in Santa Cruz -

Thanks all for your suggestions. I went a slightly different route. After seating the plugs I had them tack welded with a "soft" weld with low heat. If I should ever need to remove them I can simply "dremel" away the welds. This should keep the little buggers from flying off. See photo. David in Santa Cruz.

-

I need some sage advice about rebuilding the king pins on my 48 New Yorker. I'm having trouble getting the welch plugs to stay in place. I've read that they fall out quite often leaving the bearings/kingpins exposed to dirt as well as letting grease drip out before it gets to the bearings. I've cleaned up the seating surfaces because they were a bit nicked up. I installed the welch plugs (which are very tight fitting) and got them to seat properly, then flattened their domes, but when I pump in grease the plugs lift out. Got any suggestions? If all else fails I was thinking of attaching them with a couple of tack welds or using some JB Weld. I don't anticipate having to rebuild the king pins again because of the low mileage I plan to put on the car. Thanks. David in Santa Cruz