-

Posts

36 -

Joined

-

Last visited

Reputation

15 GoodProfile Information

-

Gender

Male

-

My Project Cars

1962 Fury

1946 P15

Contact Methods

-

Biography

Retired teacher

-

Occupation

retired

Converted

-

Location

West Virginia

-

Interests

Phonographs, Radio, Clocks cars

Recent Profile Visitors

597 profile views

-

Wow, very nice car! Can't remember the last time I saw one.

-

jfish started following Baby Moon style hubcaps

-

I want to get a set of Baby Moon style hubcaps for my P15. I had a set that popped on over the 3 or 4 bumps (attaching points) that sit on a 9" circle but they are gone and I don't know where they came from. The wheels are 15" and have a 4.5" bolt circle. I don't know if the wheels are stock or if they came came off a Ford (for instance). What should I order? Thanks See the picture below:

-

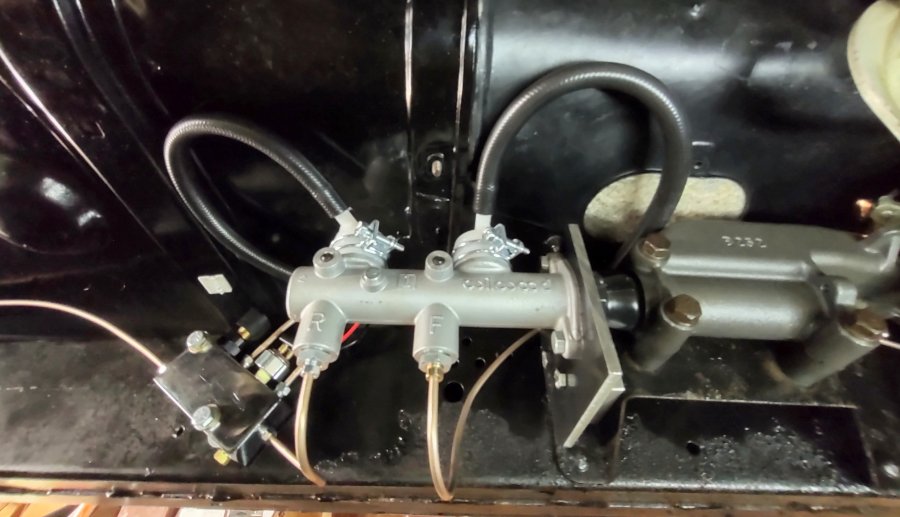

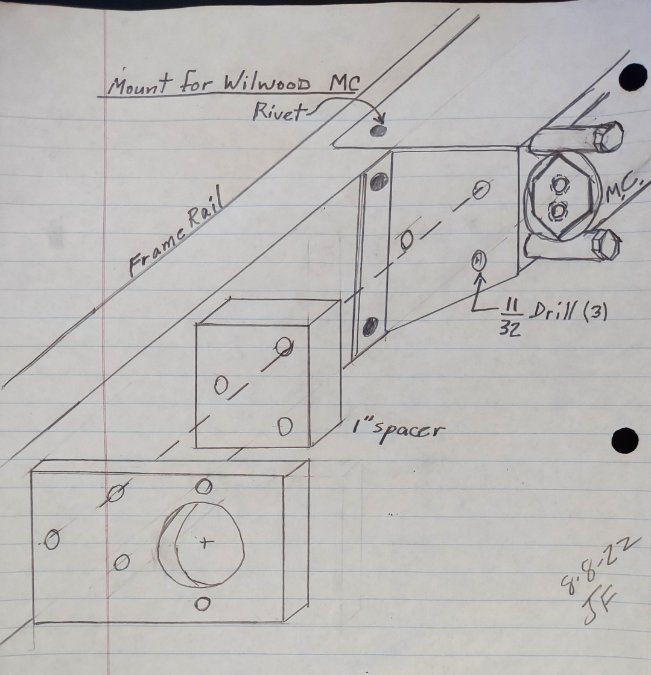

Would be a major project to remove and modify that arm! According to Wilwood, if one system fails the MC requires 50% to 80% of its stroke to START building pressure in the remaining system. 50% would probably be OK. In any case as you said, these brakes will be way better than the old brakes!

-

The existing brake pedal arm is 10.5" long and the short arm that pushes on the MC is 1.5" for a 7:1 ratio. I think to get up to 1.1" travel the shorter arm needs to be longer (not easy to do) to about 1.8". Would also make the pedal harder to push by about 20%. Yes I think this could be a problem if one brake circuit failed.

-

No, it's not binding. If I remove the brake pedal pad, I can pull on the brake pedal arm from under the car until it passes thru the floor of the car and the arm is horizontal. At that point the new MC has bottomed out.

-

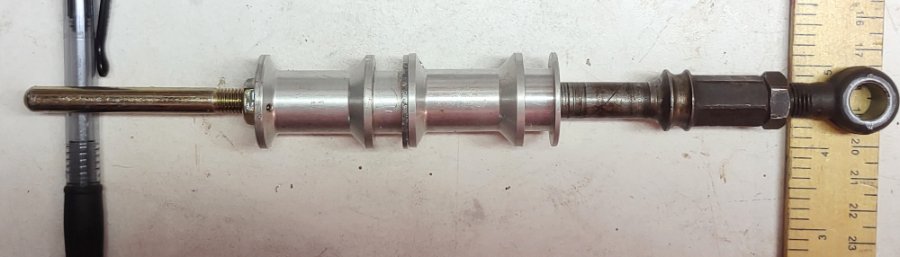

I am using 2 pistons from the Mopar MC and the Mopar connecting rod along with the Wilwood connecting rod to actuate the new Wilwood MC. I tapped the end (5/16-24) of one of the pistons to take the Wilwood connecting rod. Not related to this but so far I can only get about 0.9" of travel at the Wilwwod cylinder. Wilwood says you should be able to totally bottom out their cylinder for safety and that requires about 1.1"

-

Me too. Just trial and error I guess. Never done it.

-

Another way to release the latch is with a 12" long screwdriver inserted thru the left grill and aiming up at a 45 degree angle as shown. Sorry this forum turns about half my photos sideways.

-

Speaking of Fuel Pumps 6 volt eletrict booster...

jfish replied to James_Douglas's topic in P15-D24 Forum

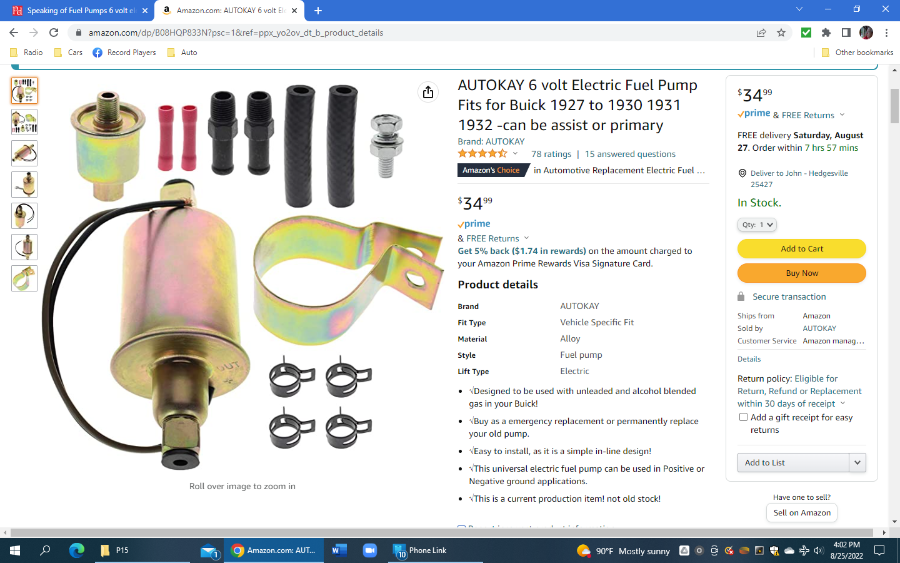

This one is 6 volts Pos or Neg ground. Don't know why it only lists Buicks. I have it installed on my P15 but not run it yet. -

-

-

-

Good news. My wheels clear the disk brakes! The 15" long Cadillac Seville hose fits OK and you can get it on Amazon if you search BH36845 for $12. Sorry the pictures are sideways but there does not seem to be any way to fix it.

-

Here is the picture. The Bernbaum lug screw is on the right. What's left of a rivet is in the middle and an old lug screw is on the left.

-

Two points here: The old hubs are pretty thin near the edge so I was able to cut down the OD with a grinder in about 20 minutes. I bolted the wheel, probe rotor and old hub together using the lug screws I had. The old lug screws were a few threads short of full engagement in the hub. Newer lug screws I had from Andy Bernbaum fully engaged the hub's threads. Will attach a picture later.