-

Posts

430 -

Joined

-

Last visited

-

Days Won

3

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Jocko_51_B3B

-

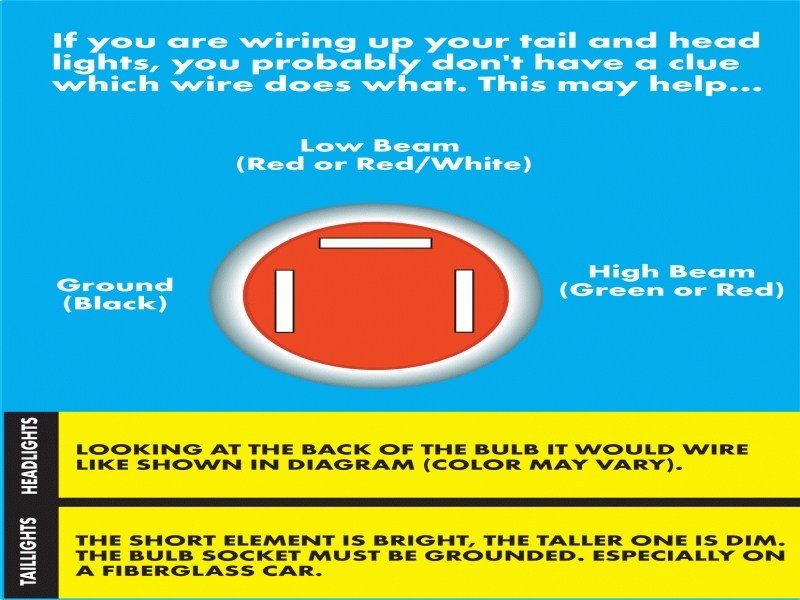

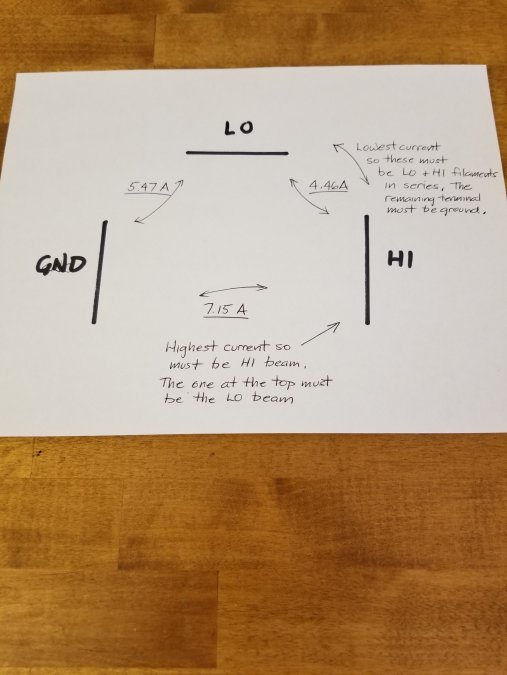

Tooljunkie, I think you are right. I went to this site: https://wiringforums.com/3-prong-headlight-wiring-diagram/ and found this diagram which matches your photo. But I like to make sense out of things myself so I tried this; I measured the current through the three pin combinations using a DMM. My battery is at 6.21 Volts. I got the following current readings between the pins, 4.46A, 5.47A, and 7.15A. The lowest current must be flowing through BOTH filaments. The next highest must be flowing through the LO beam to ground. The highest current must be the flowing through the HI beam to ground. Here's what I got:

-

That's what I'm trying to determine, which terminal is HI, LO, and GND. If my markings are wrong (which is what the Wagner tech gave me), then it's a good thing I didn't trust the Wagner tech. What is the industry standard?

-

Relays and Fuses for Pilothouse Trucks

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

I thought these were a good deal: https://temcoindustrial.com/catalogsearch/result/?q=CN0364 I'll use one for the HI beam, one for the LO beam, one for the horn, and one for a spare. -

I originally tried measuring resistances between the terminals with a Fluke and got 0.2, 0.2, and 0.3 Ohms, but the readings were jittery so I didn't really trust the numbers. The 0.3 was probably both filaments in series, but the 0.2 and 0.2 didn't help me tell the difference between HI and LO. Then I called Wagner who makes the H6006 headlight and they gave me the terminal designations as I marked them in my photo. But I like to crosscheck things so I started this thread anyway rather than take Wagner's word without question. Sure enough, Plymouthy got back in about two minutes to verify Wagner. Now I feel better. Here's perhaps a better photo which makes the terminals clearer: Again, these markings are wrong! Here's how it should be... LO at the top. GND to the left. HI to the right.

-

Thanks Very Much. I figured this terminal arrangement was standard, but I searched all over the internet and called several vendors who sell this exact headlight and couldn't get a straight answer out of anyone. You answered in about two minutes flat!

-

I have 6V Wagner H6006 headlights for my B3B. Is this the standard terminal arrangement for this type of headlight? First off, these markings are wrong! Here's how it should be... LO at the top. GND to the left. HI to the right.

-

Relays and Fuses for Pilothouse Trucks

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

Styles, A horn relay sounds like it might be a good idea, but how essential is it? Headlights could be on for hours, but horns only get energized for a second or two. Just wondering. -

Relays and Fuses for Pilothouse Trucks

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

JB, I took a look at your CAD drawing and I stand corrected about the original wiring having no short circuit protection. Your diagram made me get out the book and check things out a little better. I didn't know that the small box hanging off the headlight switch is a breaker. Same for the device stuck onto the wiper switch. The only thing I noticed was that my shop manual rates the wiper switch breaker for 12A instead of 30A. I wonder if it's a good idea to check the breakers by briefly applying 6V across them. Your CAD drawing is nice! I had put an almost identical diagram together with photocopies, scotch tape, and with pencil lines going all over the place. Your drawing is a whole lot better to work from. I recommend it for anyone adding turn signals especially. -

Pilothouse truck owners know that an original Pilothouse electrical system is not complex compared to a modern vehicle. it also has some shortcomings that could be dangerous over time. It has no fuses or relays. Full headlight current goes through the headlight switch. There are no turn signals or flashers. My 1951 B3B electrical system was trash when I bought it so I'm replacing it almost entirely. I'm replacing the wiring completely with an original reproduction harness. I'm keeping it 6V. I'm keeping the original generator and the original headlight and panel switches which still work fine. I want to install headlight relays for the low and hi beam headlights to take the load off the headlight and dimmer switches. I'm going to install a Signal Stat 900 turn signal/flasher unit. I've installed dual filament 6V bulbs in the front parking lights and tail lights so I'll have full turn signals front and rear, front parking lights, and brake lights (of course). I'm familiar with how to hook up headlight relays, but I'm getting down to some nitty gritty questions... 1. Can someone suggest good quality 6V headlight relays? 2. Where are the best locations in the circuit to include fuses (and what values)? In other words, what loads would it be wise to protect with fuses? 3. Does it make more sense for Pilothouse trucks to use inline fuses in various places or to install a fuse panel on the firewall? (A fuse panel seems like it would add extra wiring and complexity although it would look nicer.) 4. Is it better to use circuit breakers for the headlights instead of fuses? Any other wiring/circuit suggestions/ideas are very much welcome. (Better to get some experienced advice before trying to re-invent the wheel.)

-

Piston Markings -What's Going On Here?

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

It would be great if I could find a nice block with a T306 engine code, but Plymouths seem to be the most common. I'd go with a Plymouth block if I had to. Being a purist is nice, but you gotta do what you gotta do. -

Piston Markings -What's Going On Here?

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

I'm not trying to drag this out forever, but here are two more pictures of this same engine that I think might shed some more light on its overall condition. The first picture shows the end of the water distribution tube which doesn't look like it's corroded badly at all. The same photo also gives me a peek into the water jacket at the #1 cylinder wall which also looks pretty good to me. But the best indication for me is the second picture below which shows the female threads for the coolant drain valve. The engine block I have in my truck right now only has two good threads left. This one has ten. That tells me that the water jacket should be in pretty good shape. I asked the seller specifically for a picture of those threads. I realize that nothing beats a personal inspection followed by a total teardown. -

Piston Markings -What's Going On Here?

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

Thanks Plymouthy. He wants $400 for the engine, but I'm pretty sure I can get him down to $350. Unfortunately, the seller lives about 575 miles away near Knoxville Tennessee and he says it's too much trouble to ship it to Illinois. If I lived closer to the seller I'd take a dial bore gauge there myself. I don't like buying anything without a personal inspection, but neither do I want to make an 1150 mile round trip to look at a bad engine so I really appreciate getting as many opinions as possible - especially from this forum. In the meantime I'm keeping my eyes open for something closer to home. -

Piston Markings -What's Going On Here?

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

When I first contacted the seller, he sent me the pictures below. I messaged him again and asked him to check the top of the pistons for oversize markings. Instead he used something to scour off the top of the pistons and sent me the pictures I posted at the beginning of this thread (so I could see the piston tops for myself). I don't think he scoured the cylinder walls, just the piston tops. So, my main question is this; with no oversize markings on the pistons, is it possible this engine has never been bored oversize? That would seem too good to be true. I any case I would absolutely tear the engine down and rebuild it. I'm just trying to determine if I this block has never been bored out based on the lack of piston markings. -

I'm considering buying this 218 engine out of a '53 Plymouth but I'm wondering what these piston markings mean. Three of the pistons have no markings at all. The other three have a TD and an NG stamped on them. Since the pistons aren't marked with an oversize number (like .030) does it mean the pistons are necessarily standard size? Also the fact that the pistons don't all have the same markings has me scratching my head. The different piston markings tells me the engine must have been taken apart before, but why all six pistons weren't changed out together makes me wonder what's going on. Do any of you more experienced engine builders have any educated guesses before I spend my hard-earned money? The owner says the engine turns over just fine. I just don't like having unanswered questions - especially when cash is on the line.

-

Cab Center Window Glass Installation

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

I like the weed trimmer line idea better than using a fiber string. Trimmer line would be less abrasive to the rubber and should pull out and around with less friction. I'll remember that for next time. Good idea. -

Cab Center Window Glass Installation

Jocko_51_B3B replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

Thanks to everyone who responded with window installation tips! I was able to install the center window. I used some string and a plastic pry tool from HF. I had a helper hold the window from the inside. If I ever do this again, I'll try using a slightly thicker string (maybe 1/8 inch thick) to reduce the chance of cutting the rubber or breaking the string. The string I used was only .090 because that's what I had laying around. -

I was able to get the cab corner windows in myself, but the center window is giving me a hard time. I bought some hemp rope at the hardware store to try the old rope trick, but that was no help at all. Maybe hemp is the wrong type. Maybe the rope was the wrong size. Who knows? Anyway, someone on this forum probably knows a good method for installing the center window. I searched the Pilothouse forum but didn't see any posts about this. Nothing about this specifically on Youtube either as far as I can tell.

-

My B3B didn't come with a cowl vent screen. Should it have one? If so, how should it be secured to the vent?

-

Flathead block coolant drain plug

Jocko_51_B3B replied to rottov's topic in Mopar Flathead Truck Forum

I have a related coolant drain valve problem. I was able to remove the old valve and replace it with a new one. But - no doubt due to corrosion inside the coolant passage - I saw that there were only 2 to 3 pipe threads left in the block to screw the drain valve into. I put some Permatex sealant on the valve threads and it's holding, but I really don't trust it. I wonder if there is something that can be done to repair the block and restore the pipe threads. I'd feel much better with six or seven threads in there. Or is there some other clever way to make the valve secure and leakproof rather than resorting to JB Weld? -

Unfortunately I don't have pictures, but the machine shop took the block back and stitched the crack which corrected the leak so far. Time will tell. When I first bought the truck the block was OK - no coolant in the oil (the oil wasn't new either). The problem first showed up after the re-sleeving. When I put the engine together I was very careful to follow the torque specs for the head bolts and to torque them in the correct order. The only other source of stress on the block would have been when I put it back on the frame with a cherry picker by using four head bolts, but I doubt that would crack the block.

- 27 replies

-

- welch plugs

- coolant

-

(and 6 more)

Tagged with:

-

Any opinions out there regarding the best kind of coolant to use in these old cast iron engines, IAT, OAT, or HOAT? Should it contain silicate or not? From what I've read, some coolants contain silicate, and some don't. I'm not even sure why silicate is added. One of my textbooks says that silicates can cause extra wear on water pump impellers although my B3B won't be driven that much anyway.

-

Well, I found the problem. There was a fine crack along the top of the block near the #3 and #4 cylinders. Since the intake and exhaust manifolds were not yet installed I first saw evidence of the crack when I pressurizing the cooling system and saw coolant slowly accumulate inside the #3 #4 exhaust passage on the side of the engine. How coolant got into the oil from up there I'm not totally sure. I had previously had all six cylinders re-sleeved because there was some serious pitting in the #6 cylinder wall and because all six were already .060 over . I'm sure the crack occurred during the re-sleeving work although I can't prove it. With hindsight, if I had to do this again I might not re-sleeve all six cylinders, just the badly pitted one. Also, I would have made sure to have a magnetic particle test performed after any re-sleeving work and before putting the engine together. That might have saved me a ton of trouble and a truck load of wasted time. I'm not an expert on re-sleeving one of these engines, but I'm guessing it puts a lot of stress on the block, but what do I know?

- 27 replies

-

- 1

-

-

- welch plugs

- coolant

-

(and 6 more)

Tagged with: