-

Posts

197 -

Joined

-

Last visited

-

Days Won

8

Semmerling last won the day on June 28 2024

Semmerling had the most liked content!

Reputation

137 ExcellentProfile Information

-

My Project Cars

34 Dodge DR

Converted

-

Location

New England

-

Interests

the car

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Not a solution....not if you want it to work properly. Won't be doing that for all the reasons I've already spelled out for you. When you do your Asche Duals you can tell us all how you resolved issues. The difference between you and me is that I actually finished my project and worked through the various issues with some truly helpful people who stepped forward and were actually quite illuminating on what they had for both open and closed issues. You finish you project and then you can tell us all about what you did to make it all come together and post here so that posterity can actually learn what you did and why. You can take the time to post the pics and write it all up. Until then, Sniper, you are just that guy that takes 2 seconds to type some vague snide snippet comment. Nothing I've shown here is complicated....you have no idea what complicated looks like in engines. You just hate people who actually finishing something and then take the time to help others understand how they went about it. Sniper....perfect name.

-

I certainly want you to be more confident about what I wrote....so lets see if the following helps. Potential Claims...lets state that properly. I made the following observations, recommendations for a solutions....since you used "any" well lets do them all. 1. The Chrysler B&B designed carburetor vs. Carter B&B designed and built carburetor. The following comes from one of it not the most knowledgeable living carburetor specialists. 50 years and 140,000 carbs have passed through or are in his hands. The the Senior B of B&B died, his son, Jr. B of B&B, went to work at Chrysler and designed a carburetor that was built by a sub of Carter named Penberthy Carb. It is the ONLY carb to preload the idle that made it on Chrysler products. They are the only carbs with pre-load that were made, period. That carb ends up being used primarily for, as I said on stationary agricultural and industrial equipment. The failings of that carb are what was laid out to me and that which I posted here. Like it or not....all are the facts. 2. The Idle Pre-set issue that many contend with needs to be fixed and in a way that allows for the lightest pedal, linkage and firewall actuator ('34) possible. The whole Idle set issue of these carbs is but one of many problems that earn it the reputation of the guy that has made a successful career of fixing carbs. It is one of a handful of carbs that he strongly recommends not be used and tries hard not to even suggest that they be rebuilt. For all the reasons stated...those are the facts. I have spoken to a good number of people that have real difficulty with the pre-set issue, some on this board. When doubling or tripling these carbs, the pressures double or triple and the result is very noticeable. No surprises here....all of that are well known facts about these carbs. 3. Single Spring or multi springs, use single spring. The proper way to resolve this issue is to toss these carbs and go with any other good well designed carb of the period that isn't THESE carbs. But, I went as far as to make these carbs work with all the caveats, conditions, risks and requirements as laid out. I showed how a single quality spring can be used. How it can be tuned for the idle state and, in doing so, keep the lightest possible pedal, linkage and pressure on the on-board actuator. Now lets say that I want to SOLVE this issue with these carbs as an engineer. I would remove the accelerator shaft enlarge it and use torsions springs externally. So, that was done. The force was SO GREAT that the torsion spring was set aside as requiring (no surprise here) attributes to be incorporated into the base casting. Counter weight? Whereas a torsion spring used in a lateral transfer will wear uniformly, a counter weight does not. It is subject to it's mass being shifted by aberrant movement on the linkage...bump perhaps, does not insure constant force, would be complicated to make adjustable and would require nothing as simple as I showed here. 4. The spring weakens over time. As you well know, any spring kept under tension weakens over time. That weakening can be static state can de reasonable calculated and is accelerated and less calculable by heat (present), vibration (present), work flex (present), etc. In EVERY OTHER carbs application of the period, the carb is at rest at idle and does not have this problem. 5. The Efficiency of the Chrysler B&Bs I have listened to a number of people explain in certain terms and that I myself have stated a number of times, that I believe my car has never run better in regard to starting, acceleration, especially under load on hills on in a higher than optimal gear. I have also head enough stories that one of the potential benefits of duals is better gas economy. Those stories are regularly told and I always ask the carbs used and the distances traveled. Never, not once was the story relayed to me more powerfully that by the carb expert, who simply made these statements. The people that specifically wanted efficiency and had the means to properly judge it by maintaining reasonably uniform speeds over long distances all found a potential maximum savings of 15%-20% and firstly, non of them used these carbs by design and secondly, these carbs do not have the build attributes either by internal dimensions or mechanical attributes (jet, venturi, float design, accelerator pump, etc.) either by design or adjustment to make the list. According to those I spoke to who would know, the Chrysler B&Bs run rich. I don't see this as a problem as the money spent on the duals would buy more gas than consumed for a long time. The last thing that I expect is for this block, these carbs, this drive train, weight to be efficient. 6. Low walls on the Chrysler B&Bs Look at them. Sniper, I for one look forward to you finishing your 6 project and reading about what you have learned that worked and what you had to over come and how you did it. I have only been working on this car the 30 years as a hobby, but I try to give back as much as I can. My real passion was supercharging Dodge's V10s 25 years ago. So its been really 5 years of dealing with improving the performance of cars with less torque than the wheel nuts of the V10s. Hope this helped, thanks for taking the time to express your concerns. I would say lastly, that a number of people I spoke to have stopped writing here at P-d because of the idea that it is a hostile place is legion. They still come on to read, but they will not write and some of them have actually finished their projects and they run really well and have a great deal to offer up. I'm not saying that your entry by itself was lacking in clarity of what claims you found to question, nothing like that at all....

-

There are obviously a whole host of reasons. But I'm going to suggest the following. If you, like many other people, are finding that you can get out and go to the car and gently press the on-carb actuator lever just the slightest bit towards idle set and it settles right down then the following comes into play. Your carbs have to be generally clean, your linkage has to be generally clean and lubricated, and if all that is the case then this....

-

Andy, what head is that please.

-

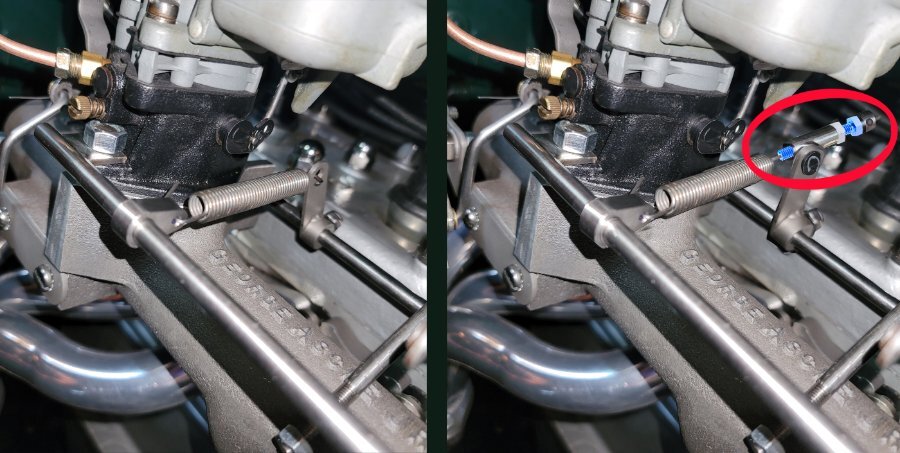

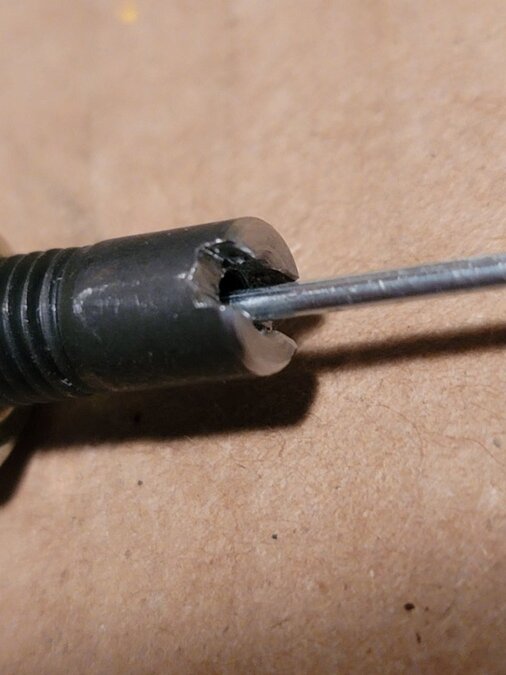

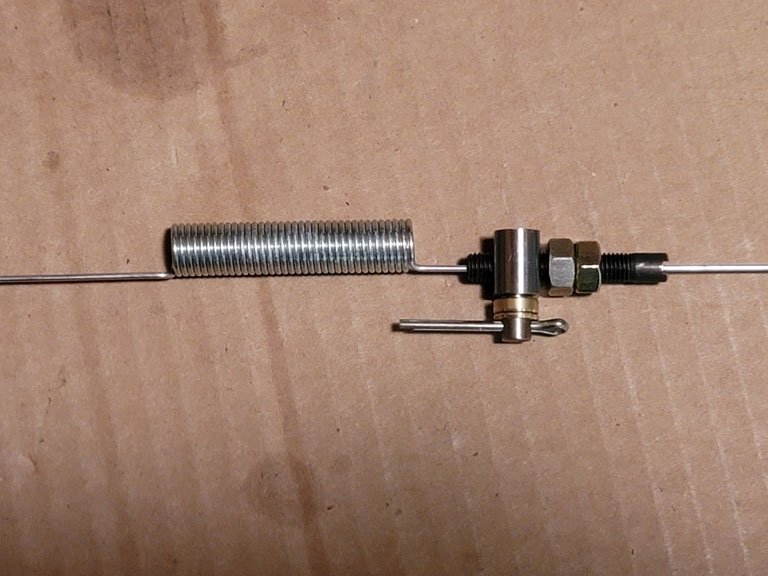

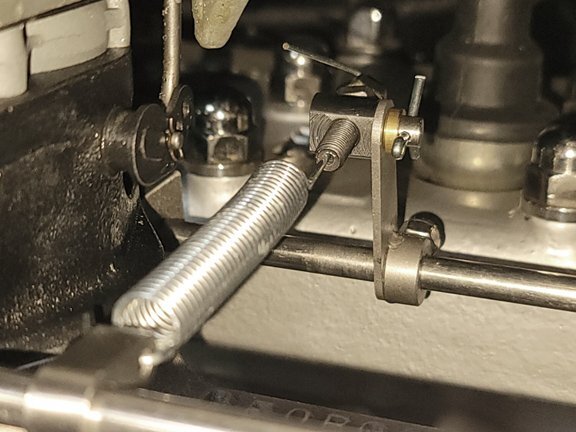

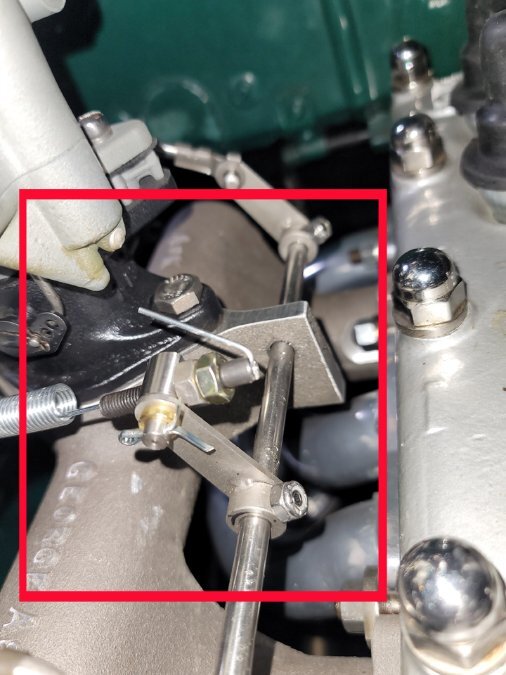

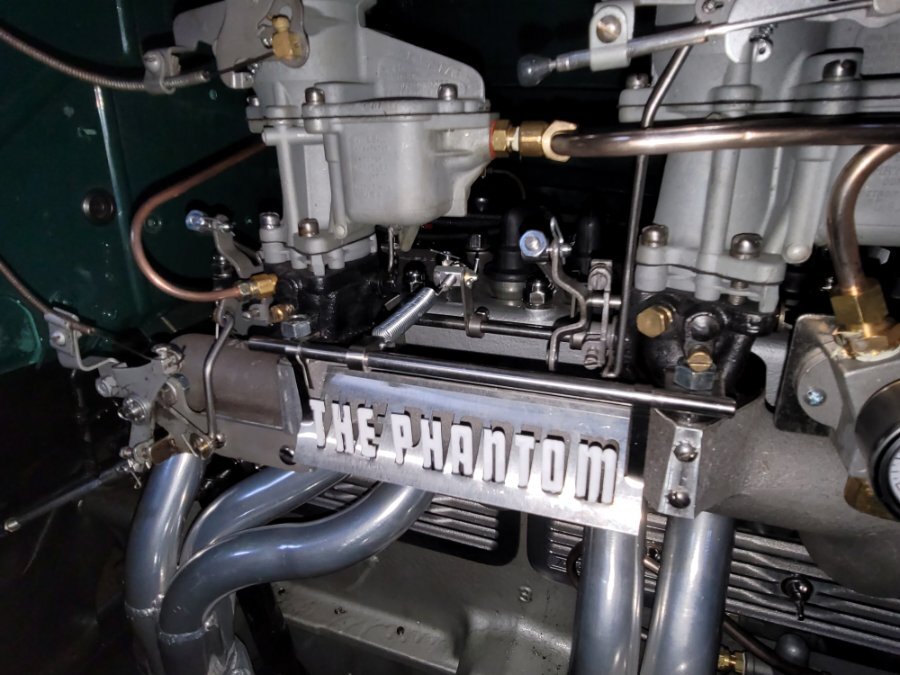

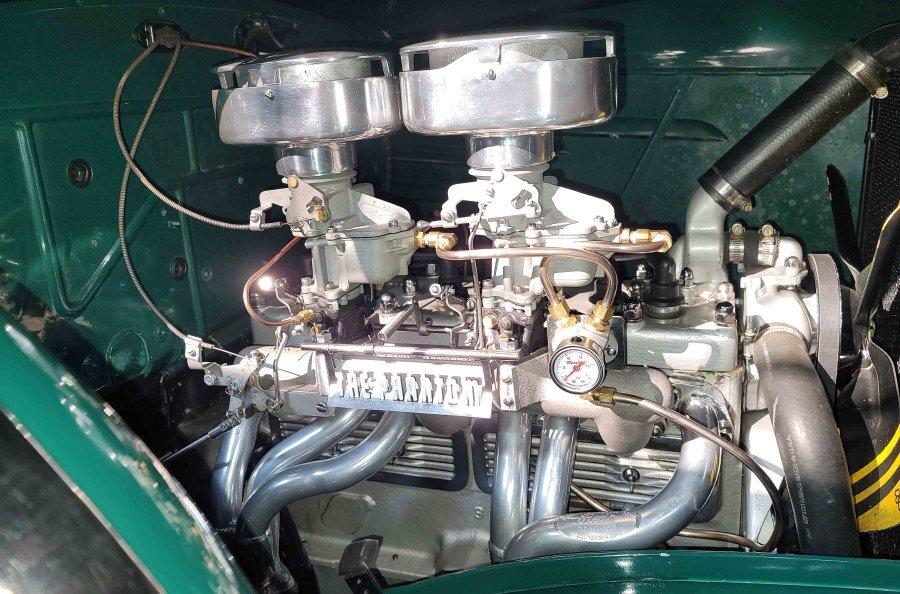

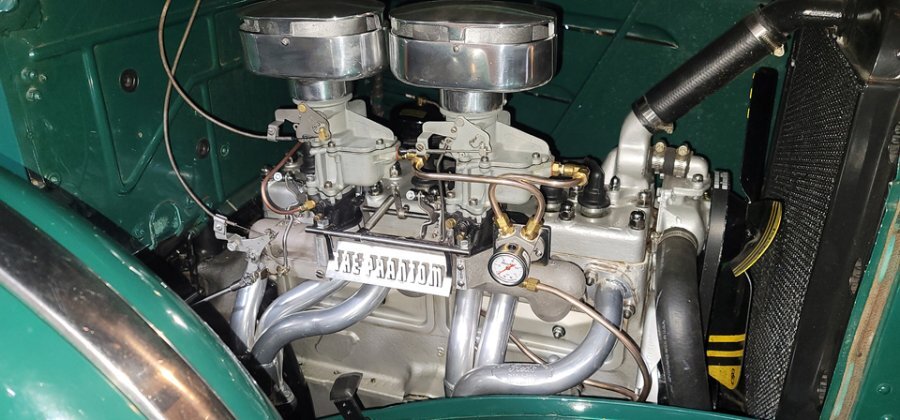

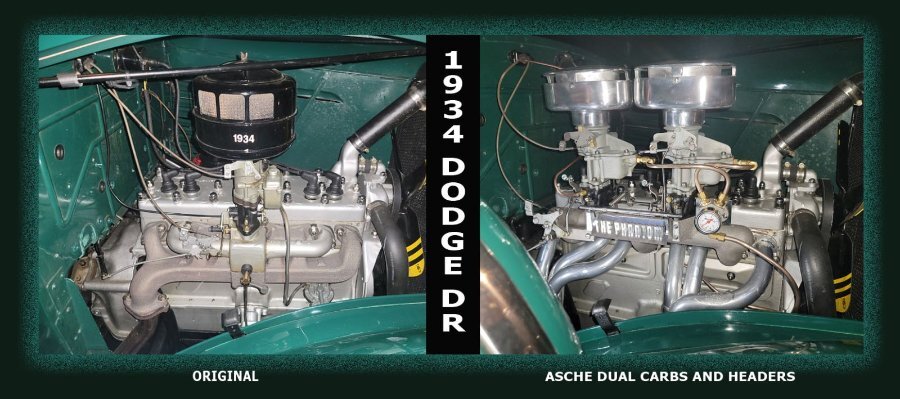

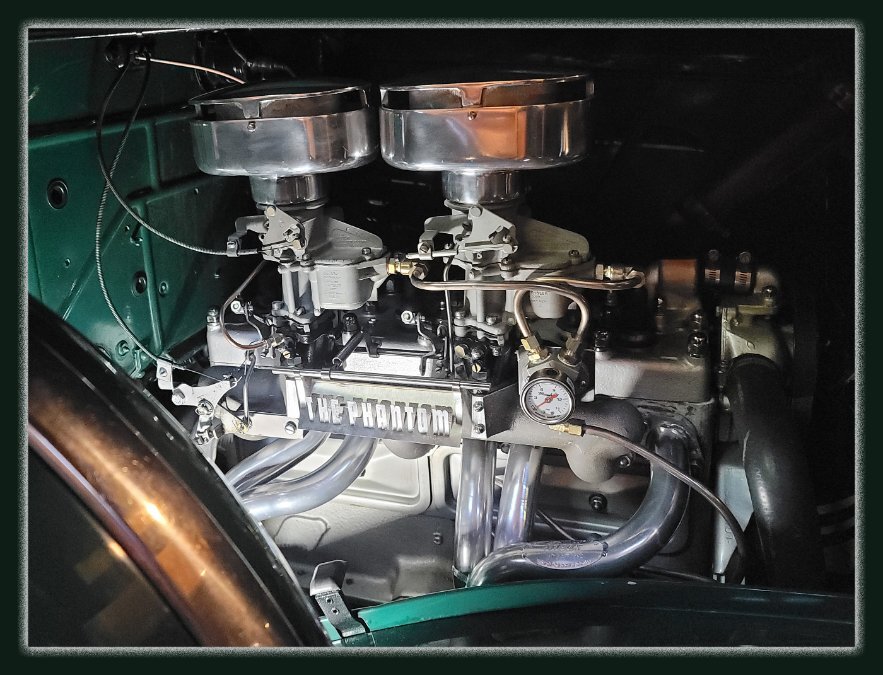

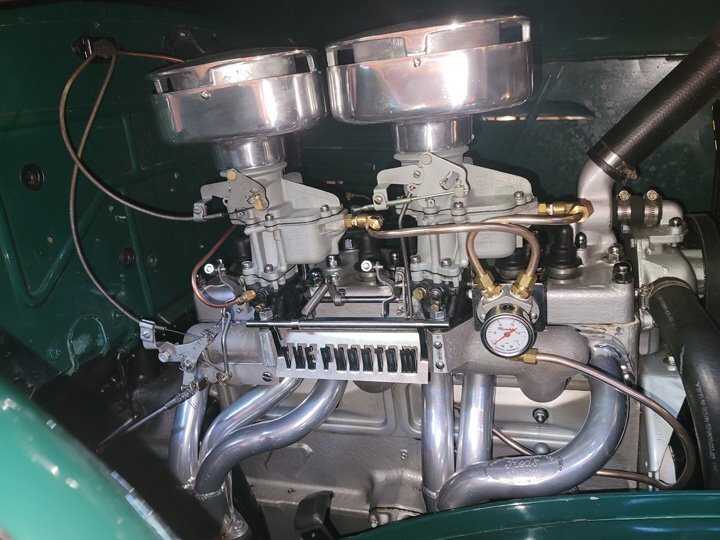

This thread is to show all interested members, my final solution to how to properly and efficiently maintain the considerable forces on the dual’s throttle actuator so that, while in idle state, just the right amount of force is applied and is fully user adjustable over time. I designed this because, over relatively short periods of time, the return spring will weaken. This is because return spring pressure is never relieved and always working, fatiguing the spring. This new design allows the user to simply adjust the exact amount of spring force required and keep adjusting it as the spring weakens over time. Moving the spring arm in the linkage is not a solution. It will eventually chew up the main shaft geometrically increasing failure risks. One can now get perfect returns and greatly reduced pedal pressures. Here is the digital representation of the adjustable return spring device , I do for these types of projects. Notice that one end of the spring will be bent as a hook on whatever your static hold is. The spring’s other long straight end is inserted into the threaded shaft and comes out the other side where it is bent and retained in a slot. This is much better than the single set screw holding the arm itself on to the main linkage shaft. That threaded shaft runs through an unthreaded (smooth bore) body that attaches to the linkage arm. The whole assembly can free rotate on the arm, which is more efficient than a direct spring attachment, easing the pedal pressures as well. One simply adjusts the two nuts to accurately dial in the exact force needed to keep both carbs in idle. When the spring slacks over time, one can quickly tighten it up instead of changing the linkage arm on the main shaft. It works perfectly and resolves the idle pressure problem and attends to the pedal pressure dilemma. Lastly, with all the adjustment provided you can make a flat facing on the linkage main shaft and set the arm in place forever. We now have reduced the chances of a catastrophe to close to zero. The Real Deal..... So why is all of this important? I had a conversation with one of our members about the choice of carburetors on the Asche Dual Carb system that I have been writing about recently. He is one of the Nation’s most experienced vintage carb gurus, having had over 60 years experience. His questions “why did you choose that carb model?” My answer was “those were the carbs that George sent along with the intake.” To which he said “I thought you would say that and that makes sense as that particular carb type was found on Dodges in a dual configuration. I like your fabrication work but those carbs are the worst carbs of that period.” The carbs you see are NOT Carter Ball & Ball. This carb model is a Chrysler B&B design produced at a sublet of Carter’s, the Penberthy Carb plant. Carter did sell a very few of these carbs to Studebaker and International Harvester for a small number of their truck offerings. They are a unique, proprietary design that we find nowhere else. Know this, the Chryslers primary use for these carbs ended up being for stationary motors on agricultural equipment and industrial applications. Take that to mean, the engine may blow up but it won't be on public roads with passengers. Only Chrysler designed a carb with positive idle pre-set, every single other carb made for cars in this era avoided this issue. They also only have 4 screws to hold the top casting to the bowl resulting in warpage that can cause fuel leakage at the top gasket. The vacuum piston is brass but sits within a zinc alloy chamber, although not common, it can hang up. Lastly and perhaps most importantly there is a spring that loads the accelerator pump. That spring can provide uneven squirt. That spring is preloaded by the linkage and it is that load that is the heart of the idle set problem. George was correct in using a Chrysler product, and the only one ever offered as duals for a Dodge. And, as I have stated a number of times, his carb preparation was excellent, it still leaves the user with a significant problem that is perhaps one of the reasons why we see so few disciplined, stable, clean and finished examples of finished duals and triples with these carbs. George’s intake is a well designed and well executed intake with all the features one would want and most “period” intakes simply do not have. It’s all about flow folks, flow. Now let me be clear and fair here. I run these Chrysler B&B duals and they run better than my single carb. But what they will never be is as safe and fuel efficient as the vast majority of other dual carbs choices. Here are the reasons why... 1. These carbs will never rest in idle state like every other carb manufactured throughout the period without direct intervention to overcome the pre-load problem. The “pre load” constantly wants to roll the actuator into a high RPM mode and it takes dedicated force, delivered to the linkage by way of a return spring system, to avoid that. What this means, and meant at the time, is that a failure of the linkage return spring means rapid acceleration with all the consequences of that. Whether parked....low speed driving...or highway speeds, if the return spring completely fails your motor will race to destruction if you do not immediately recognize the condition and if you don’t TURN OFF THE MOTOR...5-4-3-2-KaBoooom! Now if you are thinking, “run more springs!” well, work it through. It takes the exact amount of force to keep the duals in idle state. Any more than that and it only adds to an already heavy pedal. Anything more than the exact, required weight, wears the throttle linkage, work against your foot, destroys whatever pedal sensitivity you would consider normal and runs a higher risk of pulling the throttle linkage spring arm loose from the main shaft or the other side linkage, or pulling through the Allan key. Multiple springs in this case means multiple weaker springs. Once you drop in strength to the "other" spring, it may be too late. Multiple springs means ZERO chance of adjustment. Don’t do it. One wants to be able to ADJUST the spring tension to the exact point that holds the duals in idle. Remember, if the spring weakens, you will know by the higher idle.....it is the risk is of gross failure of ALL return pressure that will destroy your engine. You want the strongest single spring, and be able to adjust it multiple times to its perfect weight as the spring weaken and stretches over time. Some of you have probably already figured out what attending to collective idle set with “Triples” of this carb would be like at the pedal when properly adjusted. Dragster, sure, one stomp and you are off. Driving? Not so much. 2. This model carb has a wider footprint of flange size #3 (2 15/16.) In my case, my original carb was an early model carbs flange size #2 (2 11/16 EX-22 ’34 Stromberg). The Chrysler B&Bs are less efficient to the point where dual carbs of this model give you a fraction of the anticipated “gas efficiency” gains that is one of the hallmarks of running duals on earlier intakes. Let me be clear here, if one were to take the earlier, smaller Stromberg and make them duals and set them on George’s intake, they would send the larger, less efficient Chrysler B&B’s home to Momma in tears. It does mean that one would have to use a reducer on George’s intake to run earlier carbs. This is not a considerable issue. It also means that, where as the Chrysler B&Bs have a dual arm on the carb’s throttle actuator, the Stromberg do not. As a result the throttle linkage would work differently with the car’s own pedal actuator pulling up an intermediary linkage connect to both carb’s actuators. This is not a considerable issue either. 3. The top of these carbs has a very low wall to set an air cleaner on. Compression ring types will come right off. The solution is to run multiple Allen set screws low on the ring. George’s intake has a design attribute that is really excellent. Unlike many other period deigns for the straight 6, George’s comes out of the block and rises up tall creating velocity. Know that that translates to a higher vibration forces as the engine’s vibration at the top of the carb is magnified. Higher walled carbs manage those forces easier. Carbs with center holds are best, but compression side mounting does work reliably. Having said that, I am currently in process of restoring two Stromberg EX-22s. One is a 1934 and the other a 1935 as the ’35 introduces a vacuum tap in the base. Will I go as far as swap them in? One instance of anything close to a run-away-idle set is all that it will take.

-

Double carb and split exhaust/ pro and cons

Semmerling replied to GTfastbacker's topic in P15-D24 Forum

GT, we all would like to know what the duel intake and exhaust system you have are. Please do let us know. -

Double carb and split exhaust/ pro and cons

Semmerling replied to GTfastbacker's topic in P15-D24 Forum

You have already gotten some good advice. There is a good deal more to read here, though getting to it takes way too much work. My opinion...on your questions... Wondering how much is the effect installing this components? The engine is stock. A disciplined built out of the intake and the exhaust will have significant enough results that you will not want to run without it ever again. 80% of that will be simply improving the exhaust flow and the other 20% is all intake improvements. Know this, I figure about 25% of the people that own the intakes actually end up setting them up. Like whomever you bought your truck from, they own these speed parts but do not put them on. Why? Some don't actually finish anything, others don't stop working on upgrades until they work well, most seem to never actually start. What carburetors are the best choice for this application? Just about anything other than a Chrysler B&B (designed by the son of the founder of B&B and build by Carter) they are NOT a Carter design as Carter would never design a carb like these. Though rarely talked about, they are perhaps the worst carb of the period as per a man with 50 years of being one of the leading carb experts in the country. The reason why is complicated but is a combination of spring loaded accelerator pumps, a larger #3 flange footprint that is less efficient as compared to any of the #2 carbs, and a nasty pre-load at idle, and a host of other issues. Can you make them work? Yes you can. Are these Chrysler B&Bs used as dual with Dodge? Yes, limited models and briefly, the vast were used on stationary motors in agriculture and industry. Can you get them to perform, yes but you can do better. But regardless of which you use, they must be completely rebuilt and completely identical. If they are, with maybe a thousandth drill out of the idle tubes, they will work very well. Sniper is exactly correct about adjustments past idle speed and mix. And the air cleaner thing is a complete non issue if they are identical and free flowing filters. The linkage, a proper linkage, has to be able to adjust BOTH carbs on-board throttle actuators for high rpm matching. Regardless, the Chrysler B&B's will not deliver much fuel economy in dual set-ups. Try dual Stromberg carbs if you have access. I am currently setting up a pair of EX-22s one '34 and the other is a '34 base with a '35 lower to get the vacuum tap. I expect them to outperform the ones you see below. That will require quite a bit more work, from the flange difference, throttle actuator and linkage required, etc. etc. etc. As mentioned, nothing is going to come close to injection and mapping, but one has to use oxygen sensors and a whole lot more....not on these blocks for me. Cast header = using an electric fuel pump. Way way too close to the stock manual pump. I wanted to use my manual pump safely so I passed on the Fenton cast copies and went with real headers. Will the auto choke working with double carbs? On duals, one only needs to choke one of the carbs. I have only had a manual choke model so I can't answer the auto question. Makes it sense to do this without changing the head or milling it off? Not really sure any of it makes sense. I didn't do it to make sense. You can improve the performance of your engine and you can even enjoy the process but unless you start with the cam, performance is all at the margin. Start better? Yep. Run better, yep. Accelerate up hills, yep. All that is possible without changing you heads.....but it all all helps. Exhaust?...BIG. Dual carbs? With the right duals you might get 15% more efficiency on a Long drive in high gear. Speed Demon? Nope. My head has been milled. -

Yes, for both gas and brake lines as seen in road cars that are sometimes show cars. The big "big no no" is confusing the nickel copper fuel lines with pure copper lines. They are extremely strong and durable, resists corrosion and wear and, as importantly, resistant to heat. Volvo, Audi, BMW, Aston Martin, Porsche, etc. etc. etc. etc. Been about 20 years now......try them, all the benefits of steel and a whole lot more. George Asche Dual Carbs is a very well designed and made set-up. Takes more than a spoonful to set it up properly but is well worth the work. See the other write ups on this site. For both go and show....

-

Rusty, I really enjoyed how you went about thinking through this linkage. Really excellent out of the box thinking. Super well done.

-

For what it is worth, I'll offer up the following observations on this 10 year old thread as it is the kind of question that is timeless. 4 generations of working on the same 1934 Dodge DR convertible means that I have rebuilt the engine 2 of the 3 times it was done. Everything was stock for all three times. And then I asked the very same question right here on this forum a year or two ago and went to work. Here is what I have come to realize. 1. Freely up the exhaust flow is by far the single greatest improvement that can be made that is reasonably inexpensive and if you do it, get the highest flowing exhaust system you can. No "pinches" in the pipe casting, try to use direct in-line run right out of the head and before any bends or redirects. Nothing that is so poorly designed it impacts the mechanical fuel pump (which can easily run 3 disciplind carbs. Recognize right off from the start that when you take off the stock exhaust you are essentially opening up the intake manifold's bottom and that will require impactful decisions to the intake as a whole as well. Be realistic in your expectations of what these engines can actually deliver in regard to modern performance standards. Past the exhaust, there are very few and relatively limited and expensive alterations that will have to be done with every increase in horsepower and measureable performance improvements coming at a very high $$$ to speed ratio. 2. A single well tuned carb can deliver all the gas you would need to run your engine in all but a heavily modified engine. 3. If you aren't willing to improve the cam, then you are never going to get the potential out of these block. The only reason to do the cam work is to commit your self to doing everything else as Plymouth Adams properly addresses earlier in this thread as well as fuel and lightening. 4. Dual are nice to look at. Triples are nice to look at. Only one has the potential for any kind of efficiency improvements and, unless you are driving 300 miles, you won't notice it at all and the expense to get the savings would buy your more fuel than you probably will spend in 2 years of real driving. Which one? Triples. Pick the one you like the looks of as efficieny is marginal if at all. 5. Do not confuse Carter B&Bs with Chrysler B&Bs, most do. The later is a wholly unique in design and can only be set up for efficiency with access to a dyno and then some of the best minds on topic say its marginal. The later also suffers from an idle state design flaw that is impactful, resolvable and wholly unique in ALL of carburation world. Chrysler B&Bs would be your best choice ONLY if you want to run twins that actually were once originally offered. Reread #4. 6. As Don mentioned earlier, The exhaust makes a difference and the presentation can be greatly improved. In fact, if you do a really excellent job squaring everything away, standing still your can will be clearly capable 0-60 in a manner directly correlated to the IQ of the person listening to you, which in many instances with be under 4 seconds on pump gas going up hill. So...why would does one do it. For me it was an improvement in acceleration going up hills. Static state, open hood performance saw a remarkable increase of close to 200% Was the project worth it? Absolutely. All that and this....

-

I can help you. That intake has a wider main shaft than the Asche intake. Based on my experience (written up recently) you may need more than George. More importantly your intake has no flexibility as to the distance the main rod can be set from carbs. Asche intakes can be drilled (if one does not ask George to do it, he may have a static jig) with some flexibility as to side-of-intake and distance and even height from the carb's own on-board throttle linkage. This can matter greatly. The Dodge Thickstun has fixed tabs limiting both the main shaft's height and distance to the carbs. This is not an issue IF the resulting throttle linkage is well thought through. The Carter B&Bs are a challenge setting up a linkage on because of the preloaded IDLE set. - Dimensions of the linkage set. The dimensions of the adjustable arm coming off of the throttle linkage main shaft and the piece representing the 2nd final arm-to-on-board carb's linkages is critical to applying uniform return spring values that can overcome B&B preload and get a repeatable full IDLE return. The larger the "bent knee" of those two pieces at IDLE set, the greater the spring's force is in getting to true IDLE set. Most of the people I talked to do not have it. It is why you see the few full set up we do see with multiple springs, all of that loading up the pedal. I spoke with a guy today that actually lifts the foot accelerator UP with his toe to get to 700rpm idle and has been driving with that for a while. - The arm coming off the main shaft that is the mount for the return spring(s) dimension and angle to spring at full IDLE set is critical - The Spring(s) weight and length is critical as is placement in regard to a balance on both carbs. George makes his own critical pieces (The two (2) final pieces that run from the on-main-shaft throttle arm to the carb's on-board throttle) and you will have to as well or at least account for proper length and FINE adjustment for both carbs. A great deal of energy is lost on lousy linkages, clevis is better than turn tabs as they allow for twice the rotation adjustment. The two off the main shaft throttle arm's height, if off the shelf, have real limitations as does not using a rotating bronze insert through that arms hole to support the spring. Etc. etc. etc. Can it all come together and run better than anything you have ever had, absolutely! Is it easy with Carter B&B and duals? That depends on understanding and creating a great linkage set. If you want to talk about it, easier than writing about it let me know and I'll get you my number.

-

In order to finish off the Asche project I went about figuring out how to design a 3D laser cut stainless badge for the engine. I though maybe somebody might find this interesting. About 4 hours of time mostly in carefully getting the letters out of the background field. It was a nice break for a change. It worked out perfectly and surprised me how the letters flash nicely. It hangs off of the 5/16 rod return spring piece I mentioned in my video last week. Trying to keep up in both worlds.....