Search the Community

Showing results for tags 'flywheel bolts'.

-

My 218 is mostly together and this morning I was in the process of mounting the flywheel and torquing the flywheel bolts to 55 ft-lbs per the shop manual when I started to feel the last bolt give out. Sure enough, the bolt thread had stripped out. I guess it was just an old worn out bolt that I should have replaced before installing the crankshaft. Has anyone else had this happen and what would be the best way to fix this problem? I'm sure the original style bolts are unavailable. Would any grade-8 hardware store bolts be OK if I grind off one corner of the head to make them fit? Last but not least, why on earth did Dodge not design the flywheel to be bolted on from the flywheel side??? What a pain.

- 20 replies

-

- flywheel

- flywheel bolts

- (and 3 more)

-

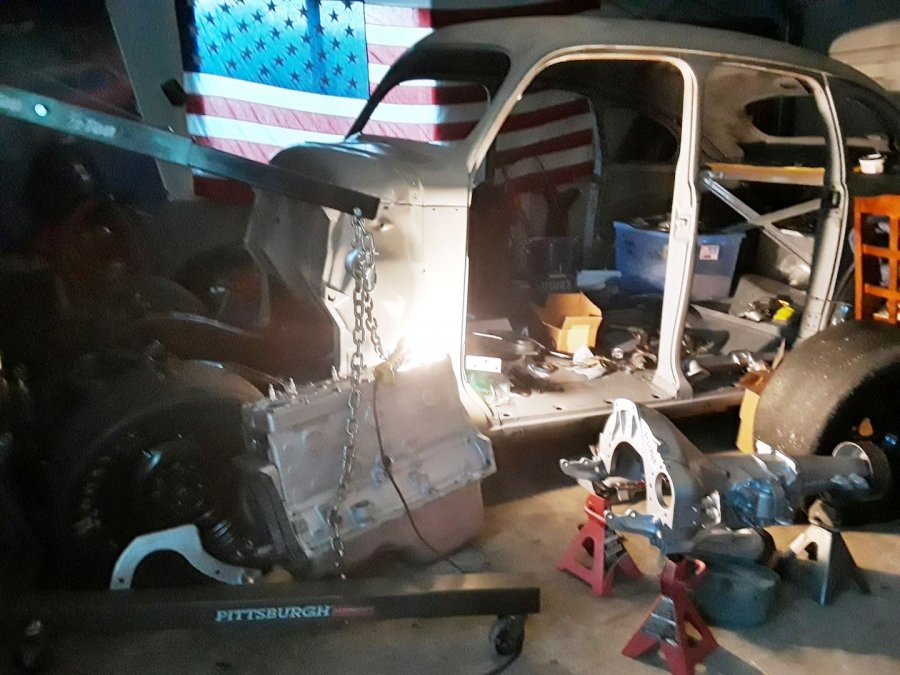

Hello everyone on my favorite forum! I have miss placed the spacer/ bushing that fits on the crank to make the flywheel bolts not turn! The parts book says it's a bronze piece, but no dimensions listed. (for my P15C) It's been about a year and a half sense I removed it, and I did place it in a safe location. But with all that life has brought to me this year, I cant seem to find it. I know this is a small issue to create a new topic for, but I cant install the trans and motor into the car without it. And I'm ready to see what it looks like in the car, after restoring the frame (even the factory date painted 68 years ago) and dropping the front and rear springs. So does anyone have photos of this or specific dimensions so I can have one machined?? Thank you for your time. Vince McLellan

-

I am installing a 4 bolt flywheel off a 218 onto an 8 bolt crank off a 230. Had both machined and balanced plus had 4 more holes punched into the flywheel so now its an 8 hole flywheel. Did not notice till now but the crankshaft does not have a ring inside the flange to hold the flat of the flywheel bolts. Its smooth. I checked the original 218 crank to be sure and it has a raised edge that catches the flat of the flywheel bolts. Even so I got all the bolts tightened down to 70 lbs, but 2 of them keep spinning. I have tried wedging various tools in between the flat and the crank but cant get ahold of them. Thought about putting a tack weld on them but never tried anything like that. If anyone has any suggestions, -- how did the bolts on this type of crank keep from spinning?