-

Posts

165 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Posts posted by Fargone

-

-

18 hours ago, nkeiser said:

I didn't have to do any "real" machining. If any, the only thing I had to do was polish to OD down a little bit to fit inside the TO bearing. For that, I just used emery cloth and elbow grease. It was pretty close, so it didn't take much. The only other thing I did was cut it to length.

Great sounds straight forward enough, my bushing is on it's way to me as we speak.

-

On 8/23/2019 at 5:41 PM, nkeiser said:

My pickup doesn't have the same crossmember that your's does, so I didn't have that issue. There were lots of other "opportunities" along the way though. The transmission mounting bolts are 9/16", so I had to modify the adapter plate and find some place that had 9/16 bolts. I had to order a bronze bushing to account for the input shaft and throw out bearing diameter differences https://www.amazon.com/gp/product/B00IG7PONW/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 I mentioned the linkage issue, but that could have been solved if I would have found OEM linkage instead of after market. All of the information and websites that have parts for Hurst shifters cater to after market and don't deal with OEM which of course are all unique.

I enjoy fabrication, so I had fun tweaking the shifter to fit. It still needs some work as it has a little slop and can be a knuckle buster going to third.

I've been doing some micrometer checks on the input shaft and throw out bearing dimensions and it looks like the bushing would have to be machined down a few thousands. Did yours fit without machining?

-

I'm hoping you guys have some images of the completed 4 speed swap. I'd love to see how your floors turned out. What shifter boot style you're using. For this conversation I don't think it matters if was a T5 swap on an A833. I'd just like to see how cool they turned out.

-

On 9/15/2019 at 11:08 AM, 52 ram said:

Hey guys, been awhile since I've been on..... Life..... I need some help. I just snapped the end off the column shift rod on my B3. Any one have a line on a replacement one ? I'm not sure if welding and maching the old would be strong enough ? Any help would be appreciated !!!

In my stack of spares I have one from a 1951 Fargo 1/2 ton (not sure if they are the same). Do you have a picture of yours?

-

On 9/16/2019 at 8:05 AM, Dave72dt said:

The closer the shifter can be placed to the floor, the smaller the hole in the floor has to be and the shorter the shift handle can be. With a mostly flat floor in these trucks instead of a tunnel, you'll likely want that shifter moved up.

Thanks for the feedback, I'm going to reinstall the trans for another mock up session. I really don't want a giant hole in the floor.

-

25 minutes ago, Old CWO said:

I would think the solution you see in SmokeyC3's photo is going to be the easiest to sort out. It appears the shifter is moved straight forward just like your option "A," but it looks like he fabricated a bracket to move the lever itself to the center of the truck. Not sure if that added leverage makes the Hurst type shifter mechanism any sloppier, perhaps he can chime in. I know the Dodge trucks with factory A833s have the lever in line with the shifter - mechanically sound, I just don't like the way it looks in the older trucks.

Where would option "B" place the shifter mechanism? It looks like it might fall right in the center of the floor board which would be sort of difficult to cover up without a tunnel or gigantic boot. Both of those options sound unattractive and add work for no good reason.

Kudos to you for tackling this! I have always disliked fiddling with external linkage shifters and tend to shy away from transmissions that use them.

I can't speak for the guys that have raised the shifter, but there is a long distance to the floor from the shifter I'm guessing that's why they raised it. I'm also guessing that leaving the pivot point low makes for a rather long throw in the gear changes. Not sure that's why I'm asking.

-

On 9/7/2019 at 6:36 AM, 55 Fargo said:On 9/4/2019 at 12:59 PM, Old CWO said:

I like that you moved the lever towards the center while modifying. It looks more correct for a pickup truck that way.

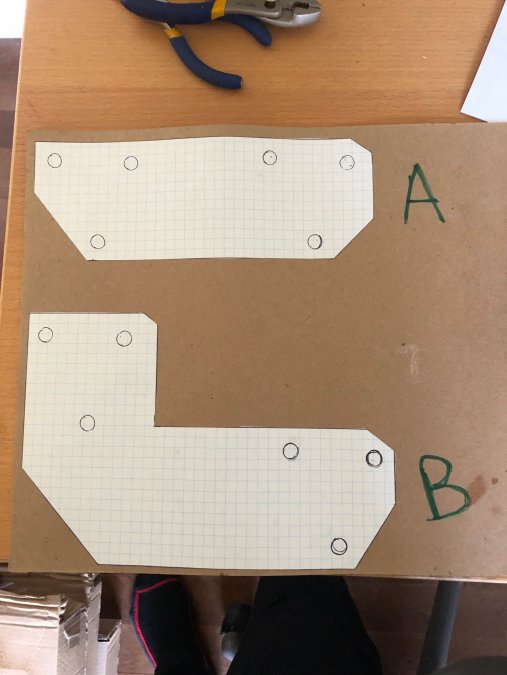

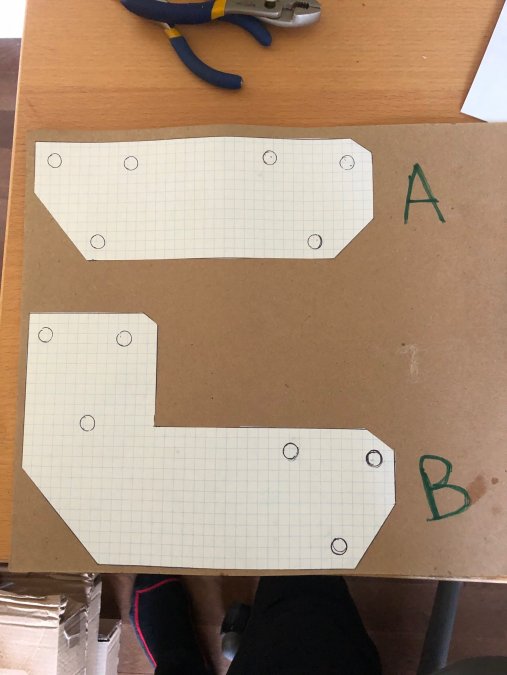

Sorry about duplicate post but I meant it to be a quote for you two guys. Ok I've spent some time coming up with templates for moving shifter forward. Option "A" is a straight forward move of roughly 5 1/2" toward the bellhousing. Option "B" is more complex moving not only forward 5 1/2" but up 3" as well.

I'm inclined to the more simple approach, but I'd like some feedback on why some have raised the shifter position. Both choices obviously involve a modified shifter and shift linkage. Option "A" appears to involve less potential for shift linkage problems.

-

Ok I've spent some time coming up with templates for moving shifter forward. Option "A" is a straight forward move of roughly 5 1/2" toward the bellhousing. Option "B" is more complex moving not only forward 5 1/2" but up 3" as well.

I'm inclined to the more simple approach, but I'd like some feedback on why some have raised the shifter position. Both choices obviously involve a modified shifter and shift linkage. Option "A" appears to involve less potential for shift linkage problems.

-

15 hours ago, tanda62 said:

That is a sweet looking setup! What are the plans for exhaust?

The exhaust is split stock manifolds, if you look close you should see them in the pictures I've posted. I'll be doing dual exhaust not sure what size yet. I'm guessing something in the 2" - 2 1/4" range nothing too fancy or loud. I want it to rumble, but not be a nuisance to the world.

-

2 hours ago, Mike36 said:

Where did you get those air cleaners?

Aok contact Tim Kingsbury he's a member of this blog.

-

I changed the air filter setup after some input from Tim. This setup is much less restrictive. It will require some extra work but that's the way things go.

-

1

1

-

1

1

-

-

17 hours ago, Old CWO said:

Sexy.

I would very much like to have a dual carb set up someday, but those triples are absolutely bringing the wow.

Is that using the stock truck throttle linkage?

The custom linkage was part of the package. George fabricated the whole works. I will be using the stock gas pedal and throttle cable, at least that's the plan.

-

Top notch wiring job!

-

1

1

-

-

I did some mock-up work today, so as promised here's some photos of the tri-power setup with split exhaust. Tons of thanks go out to Tim Kingsbury and George Asche that made this set up possible. As you can see there is a small hole in the firewall and I've still got more carving to do to clear the rear carb, linkage and air cleaner.

-

6

6

-

-

On 8/27/2019 at 3:52 PM, Old CWO said:

It is bemusing how some folks get their hackles up over the A833 vs T5 vs other transmissions debate. I just don't get it...

Fargone, thanks so much for posting photos of the A833 swap. it's always great to see what you might be getting yourself into with a job like this.

What tire size and rear gear ratio do you plan to use?

I've swapped in a 96 Jeep Cherokee diff. I cant recall the exact ratio but I believe it's around 3.73 or 3.54.

-

On 8/23/2019 at 5:41 PM, nkeiser said:

My pickup doesn't have the same crossmember that your's does, so I didn't have that issue. There were lots of other "opportunities" along the way though. The transmission mounting bolts are 9/16", so I had to modify the adapter plate and find some place that had 9/16 bolts. I had to order a bronze bushing to account for the input shaft and throw out bearing diameter differences https://www.amazon.com/gp/product/B00IG7PONW/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 I mentioned the linkage issue, but that could have been solved if I would have found OEM linkage instead of after market. All of the information and websites that have parts for Hurst shifters cater to after market and don't deal with OEM which of course are all unique.

I enjoy fabrication, so I had fun tweaking the shifter to fit. It still needs some work as it has a little slop and can be a knuckle buster going to third.

Thanks for the info on the Isostatic Industries AA-1715-3 P/M SLEEVE 1.254 X 1.753 X 3 bushing

-

On 8/22/2019 at 5:31 AM, 55 Fargo said:

Have you bolted up the A833 yet?

Does the bearing retainer fit with your truck bell?

Or have you not mocked it up yet?

So I had a lot of fun / difficulty getting my transmission into my truck and now I know why. The hole in the adapter plate for the transmission snout is a few thousands too small. I checked the clutch plate for correct splines and fit, I test fit the plate to my bell housing, but I never slipped the plate onto the transmission to make sure it slid on freely. It did not. Once I pried the trans out and removed the plate it was quick task to resize the plate with an air grinder. It was a very small amount of material to remove, but now she slides right on like butter.

-

On 9/3/2019 at 12:29 PM, cavisco1 said:

GM used this same transmission with GM’s own 10-spline input shaft, input bearing and retainer:

o 1981 to 1986 Chevrolet 2- and 4- wheel drive pickups and Suburban (3.09:1 ratio first gear)

o General Engines designated this transmission code MY6.This may open up some options for tailshafts and shifters. I will leave further research to you.

It's not really the same transmission, other than internal components it does not fit this application. The Aok adapter plate between the bell housing and trans is not compatible with the GM version.

-

1

1

-

-

12 hours ago, 55 Fargo said:

Looks good.

What bell is that? What engine you running?

See the A833 is bolted on top 2 holes to bell, what about the bottom 2 holes?

Sorry I missed the second part of your post. The engine was the original 237 flathead 6 now its 251ish the bell housing is the original 1/2 ton unit for the 3 speed column shift. I have the Aok adapter plate the trans bolts are all in. You had the same problem I currently have, I'm glad to see it's been done before!

-

-

23 hours ago, SmokeyC3 said:

Off topic vehicle ,but I did this one. The bracket has to be beefy enough or it will flex and eventually break. Shift linkages took some fiddling and they weren't all correct on the first try. The reverse link has some pretty hard bends that flexed when shifting so it got a gusset plate added. With a little patience it's doable.

Awesome job man!

-

23 hours ago, Plymouthy Adams said:

your shift rod will need to be modified to the correct length as gauged in neutral position each tranny lever and with the shifter neutral and cross over also pinned..from there it is a simple cut to length and thread as needed...when you do this type of changes to a set up you must be prepared for these events and have the tools needed or at least available to you to complete the task...

My thinking was to reposition the shifter with a custom bracket to the approximate position of the centralized factory shifter and maybe raise it an inch. My hope is the shift rods will not require NASA to resize. If I maintain the shifter position relative to it's existing position (moving it forward only, not left or right) I should only have to shorten the rods not rebend or get overly fancy with design. That is my hope anyway.

-

20 hours ago, 55 Fargo said:

This is totally factory 1979 D100

Good to know thanks.

-

I have a bought several items on Kijiji but I haven't tried for this item, excellent idea. The problem is I don't think the item exists. The mighty internet is full of data but lacking in actual facts, photos and measurements of the A833 transmission. I can not find a photo of the short trans with the forward shifter position. I will try Kijiji for the item and another complete trans and shifter combo.

S10 Frame Swap

in Mopar Flathead Truck Forum

Posted

This is a cool project idea, I'll be following you. I was on Code 504 website and I'd be curious if they ever considered making a conversion package so you could use an original flathead 6 (I will be contacting them). I've got a lot invested in my engine build and tranny swap. If I could drop that into a modern and lowered chassis I'd really be intrigued. Good luck and keep us posted please.