Pauls46P15

Members-

Posts

22 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Pauls46P15

-

You'll be a fabricator when your done. I have a '46 Club Coupe and It came with the pedal on the right in that picture. I had to get new floorboards and I got them from The Plymouth Doctor back then. I just popped in the upper end into the linkage arm and bought some threaded ball-studs and nuts on ebay. Then I measured the location on the new floorboard and drilled 2 holes at the needed places on the floorboard. I popped them into the pedal. I also just spray the sockets on the pedal with WD40 and they press in real nicely with a minimum amount of thumb or finger force.

-

I found the Trostel pages very helpful in general seal installations. They have really good .pdfs documents from seal lists, seal installation, Type of seals illustrations, and Causes of premature failure. Trostel Oil Seals :: All Seals (allsealsinc.com) https://www.allsealsinc.com/trosel_oil_seals.htyou how to install the sealsml .

-

I will just look at the dimensions for these seals and see which one is closest to my needs. I thought Bernbaums had it all figured for those years and those makes.

-

I was unaware that the word M6 was specific to the semi auto transmission. I just thought it stood for Manual 6 cylinder.

-

I am not that familiar with all of the special names associated with the manual transmission used on the 6 cylinder. I just thought it was just shorthand for the basic design, which looks like the Borg Warner transmission was used on early Jeeps used in the military. I believe Chrysler Corporation just used this transmission as one of the 'hard parts' in the building of their cars.

-

The felt side goes outside the seal towards the brake drum and the rubber end of the seal goes toward the bearings, is this correct?

-

The part number of the sealsI received were T115 the one with cotton on one side of the seal, and T115A the one with the metal ridge on one side of the case. The T115A is coming under being used on the 1947 Dodge Truck, Desoto.Sorry for the confustion.

-

I received the T134A part first as the T134 part I ordered this time, this is the smaller id one with the metal ridge on one side of the seal case. I sent them a pic of what they sent me and they said this was not the part and they sent me the T134 part with the cotton on one end. This is more like the T134 I recieved previously and I wrecked it when trying to put it in about a half a year ago. It had so much cotton on one end that I removed some of the cotton at that time and tried to install it. I don't recall seeing any numbers off of the seal that came with the transmission originally.

-

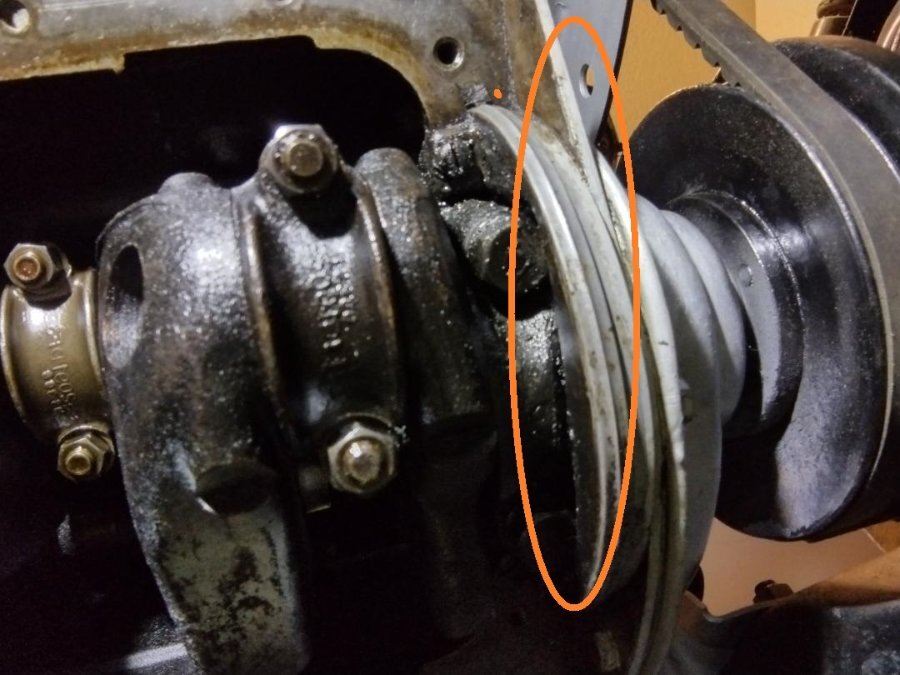

I am replacing the tailshaft seal on my manual 3 speed transmission on my P15C Club coupe. The seal I got from Andy Bernbaum is part number T134 with cotton seal on one end and rubber seal on the other end all in a metal case. This seals inner id is too small to fit on the e-brake drum inner shaft that fits over the tailshaft splines. this seals od is a little oversize with the tail shafts inner diameter but looks like will probably fit when tapped into the tailshaft housing. The other seal that Andy Bernbaum sent me was part number T134A. This seal is in a metal case with a rubber seal on both ends but with a protruding ridge on one side of its case. Its inner diameter fits perfectly on the e-brake drum inner shaft but the seals outer diameter is visibly smaller than the tailshafts housings inner diameter and doesn't even touch the inner diameter by about an 1/8 of a inch. Do I have a mix of tailshaft housing and e-brake drums or is the T134 part number seal just going to stretch its inner diameter to accomodate the e-brake durm inner shaft? I am confused. I did originally try installing a T134 seal from Andy Bernbaums origiinally and I failed to seal the tailshaft and mainshaft adequately.

-

Thank You Sam. These links nailed it completely. I appreciate your help.

-

I am in the middle of replacing the oil pan gasket set for my 1946 Plymouth. There is an additional Fel-Pro Installation Tips" which mentions the Fel-Pro supplied O-ring and cutting off 2 sections 1.125 inches each from that O-ring and using the pieces in the main cap groove the tip says: Use the O-ring supplied to fabricate new front main cap seals. Cut 2 sections of the O-ring to approximately 1.125 inches in length and lay in the cap groove. My question is where is the cap groove that gets covered by 1.125 inches. I can see what I think are two grooves running along the end plate which I think is the cap groove plate that is attached to the main front cover of the engine. There were two 3 1/2" O-rings supplied and their length is 10 11/16 when cut. The two O-rings when cut are long enough to run along the the entire length of the two grooves. So what am I missing? thank you, Paul

-

'47 era Dodge D24 Front Hood Support positioning?

Pauls46P15 replied to hbpaints's topic in P15-D24 Forum

Looks that way to me too. The bolts are offset to one edge more than the other. They're definitely not centered. -

On my '46 P15 there was a worn out pad about 1/8' thick piece of rubber in between the 2 metal plates. I found a radiator rubber spacer for Ford F1 pickups on www.dennis-carpenter.com for 48 -52 Ford Truck Part #: 8C-8124-A. I bought that one,cut it to size and added another bolt hole. It is thicker, but I haven't put the rest of the sheetmetal back on to see if there will be a problem with alignment of the mouting holes with the radiator side frame bolts. This type of support pad was the technology back in that period when the designs of cars and trucks were evolving from the smaller body and frame sizes of the 20's and 30's to the body and frame sizes leading into the 50's and 60's.

-

Thanks everybody I will report back when I get them running.

-

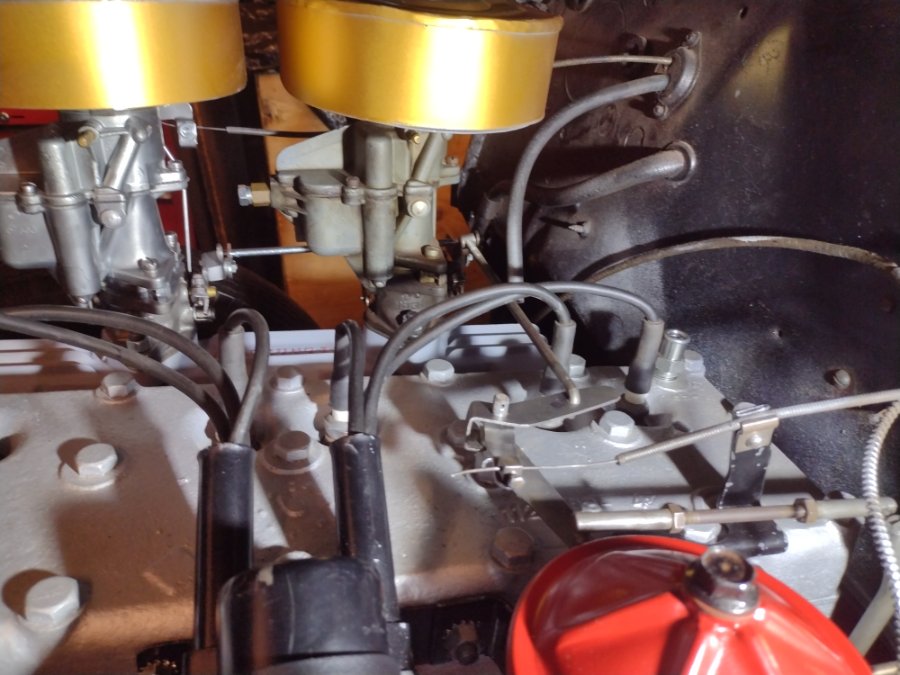

I think the setup now which is pull will work now. The throttle plate is partially closed which the Plymouth service book says occurs at idle and it opens gradually with acceleration. This setup is static right now since I still need to add fuel line and wiring

-

Cool ?. So the push or pull would be just a matter of turning the carbs 180 degrees on the manifold and connecting the throttle rod to the other end of the one carb side cam with the joining rod connected to the opposite end of the carb side cam. On each carb.

-

-

I have dual carbs on and offenhauser manifold. Fuel lines to the front of engine. Using stock gas pedal and linkage. Should the final accelerator rod push the side cam on the carbs or pull the side cam on the carbs when the gas pedal is pushed down.

-

ok thank you all for the advice.

-

So the outers are the same part as the inners. Outer right to inner right outer left to inner left?

-

In detailing my 1946 P15 Super Deluxe Club Coupe, I have found the tie rod ends all have cracked boots and are leaking grease. Are the outer tie rod ends the same part numbers that are used on the inner steering tie rod ends located by the steering box?