-

Posts

29 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Matfirstattempt

-

Resurrecting and diagnosing…

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

@9 foot box just purchased a kd700 for the valves after reading JBneal’s post. I’ll pick up a set of thread chasers, for sure. I also need to remove a stud from the manifold that busted off. @Dodgeb4ya I’m pretty sure I saw bits of stuff (carbon) when I shined a light up from the manifold side, yes. I’m hoping that lapping will be enough. Do you think I need to cut the seats again? -

Resurrecting and diagnosing…

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

@Ivan_Bthats what I did - the light - and easily noticed issues. Noticed some space in cylinder 3 (the problem cylinder). So I’ll lap all, as you said, to be sure. there is some minor wear that can see but nothing drastic. Is there anything else I should adjust/replace while in there? on a side note - what’s the best way to clean this absolutely filthy grease sponge?! Foaming degreaser, a tarp for the floor and a hazmat suit? -

Resurrecting and diagnosing…

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

@Los_Controlim very certain the valves need attention. The way I look at it, with the head off, I might as well replace the valves and springs. You’re right, pulling the pan isn’t an awful idea either. Can I easily pull a piston and replace rings while keeping the crank in the engine? I’m farther than I’ve ever been in wrenching on an engine so I’m in complete noobie land. -

Resurrecting and diagnosing…

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

So in the saga of diagnosing the down cylinder, I pulled the head (man I love breaking this thing down and learning). So big question: is there anything I would see in the cylinder wall to indicate ring issues? I plan to check valve sealing with some solvent around the valve at the top of the compression stroke. Any thoughts on what else I ought to do here or next steps? Head removed 2.HEIC -

Resurrecting and diagnosing…

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

Yes, but I really wanted to see the tappet area. Pulling the manifold was my best sight to it. I do have a full gasket set. -

Resurrecting and diagnosing…

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

-

When I first bought this truck before Covid, I thought it would be a great project, and it was. The truck ran and then somehow it seemed I lost compression. Anyway, here I am in 2025 picking the project back up and I need some advice. I'm hoping that this is valve issue instead of a ring issue. I got the manifold off and to get good access to the valve windows. When I spin the fan, I can see all tappets moving. But I’m curious if that movement is truly going to tell me anything about the valves seating or if I need to pull the head? I really don’t want to if I don’t have to, but in this far in and id like to drive this truck a bit in the summer firing on all 6 cylinders. Any thoughts on how I can continue diagnosing without the head having to come off? side note: I never learned to wrench on engines - I’ve learned as I go. I’m impressed at how these engines worked, particularly the tappets and their rotation! Anyway.

-

And then there was smoke!

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

@clarkede yup, that’s a stuck valve! We had a baby last year and I’ve had a lot of woodworking projects that took over. I’ll be getting back into this project soon. Did you hit the spring back down?…did hit it perpendicularly to the valve stem? (Wouldn’t that cause damage?) did you take the fender off? Part of me wants to just rip into the truck but part of me wants to get running asap too. -

It's been too long since I've posted but my woodworking side hustle took a grip over my time and didnt let go. I haven't been able to get this up yet until now. Here's a video of the motor running at idle. There's a lot of wind noise from the fan - sorry about that. The head is getting taken off next week so I can actually see the valves work. Any initial thoughts on the video? Dual master will get replaced next week too along with new head gasket and cleaning the oil relief valve. The "doghouse" will get taken off as Los_Control mentioned.

-

Well, the woodworking business has slowed a bit and I'm going to take the time to put into the truck. Y'all know I've got either a ring or valve issue. I plan on draining the fluids, removing the head, inspecting what I've got and fixing it - valve, ring, etc - along with new seals. I also think I should check valve clearance - lots of ticking. I hear these are "typewriter" engines but it couldn't hurt to see how they are. Likely during the next month will be also 1) brake MC upgrade to DMC and lines 2) Kingpin replacements, 3) tie rod end replacements, 4) fuel tank float assembly replacement, 5) steering adjustment and fresh oil 6) handbrake clearance adjustment/lining replacement, 7) oil pressure relief valve cleaning. 8 ) distributor tune up and/or rebuild 9) Fix horn relay 10) add blinker switch 11) fix whatever is causing the excessive blowby - stuck/burnt valve, stuck ring, etc I'd like to get into the rear axel and replace the seals in it and the transfer box - seems to leak oil regularly from differential. I read the manual and it's intimidating for replacing all the seals. Any approaches or recommendations you have on the list above would be great. Lastly, one question: are there any fuses in these trucks? I can't find a single one and haven't read up on the voltage regulator yet. If there are no fuses, would it be a bad/silly approach to add any? Thanks for all your support and advice! Mat

-

Yeah, i found that site after posting and doing more digging. I think it's original. i know it's a B-2-B listed and the truck is a B-2-G but surely they may have used the same engines? I assume the TI is really T1. (not sure why 1 is beamed like a roman numeral)

-

@Los_Control - I once had a dishwasher that needed replacing. After diving in it became a $2,500 kitchen udpate. Who knows until we get there. As I messaged you also, there may be hole in piston 3. I'm not certain beacuse there's no knocking but the 16oz of Mystery Oil i dropped in #3 didn't stop till the bottle was empty! odd that it gave me 20psi though.... I'm looking closer to numbers because it looks like i'll be pulling heads and oil pan to clean up and inspect the engine. I don't intend to rebuild - i don't have the shop space or time to do that right now BUT I need to get gaskets all replaced and clean all the awful gunk off the engine block while I'm there inspecting this issue with #3. So, I need help interpreting the numbers: Serial Number: 8335412 Engine Number: TI72 (star?) 54509 (star?) Model listed as: B-2-G-116 What does it mean folks? I looked in the service manual and it doesn't say much about numbers, especially the engine number. The serial numbers are funky. I don't know what to make of the "116" either. Help?

-

@Los_Control yeah, right now it’ll be a week of soaking and running. I’ll see if I can get to cleaning the oil relief valve. I also have a fitting From the oil filter to the engine that needs to be looked at and sealed back up - lots of gunk/grime there. Coincidentally that’s by bottom of #3. I don’t know inner workings enough to know if could be connected to the cylinder problem. I’ll do a week of this, I’ll see if I’m getting much of a compression increase. If so, keep on with it. If not, will look at the valves. If not there, pistons and rings it is. Will let you know what I find.

-

Thanks guys for your advice! I Talked with my mechanic today also. He also suggested soaking #3in mystery oil for a few hours and then running/driving it for 5 minutes each day to try to get things loose. I’m only putting in a few teaspoons of Mystery Oil. Should I be using more? So that’s the plan for now, give it a week or better to see what that might do. Do another oil change next week to clean all the crud out and then try a compression test again to see if we have any improvement.

-

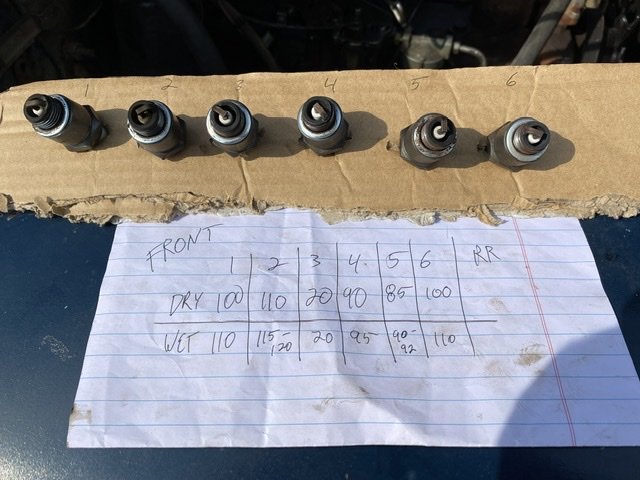

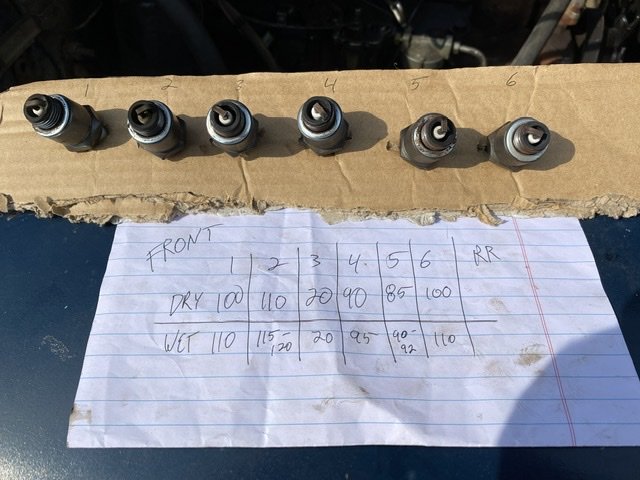

I posted a couple other threads On this - I took Alice on a 40 mile drive about 2 weeks ago. She Started to smoke the next day. Appears to be severe blow by from down tube. I did a compression test on her. See photo. since 3 had poor pressure wet and dry, I assume valves are a main issue. I don’t hear a knock on the engine but then again, I’m learning as I go. Am I on the right track? at 40mph on that drive, oil was consistently around 50-60 psi at the gauge. Another member on a different thread stated that was high and possible oil pressure relief valve issue as well. thoughts? I’d like to ease into this - not do a full breakdown if I can help it. I understand that I might not get a choice in that either. Where do I begin what else should I look for?

-

And then there was smoke!

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

Here’s a photo of the compression test today. *cue music* one of these things is not like the other....* Is it safe to assume rings are out on 3 if there’s lots of blow by and no compression? Maybe stuck valve since no good compression at all - wet or dry - in 3? There isn’t knocking or anything I would assume to be from a sever damage like a hole in the piston. Then again - noob at this, so it’s possible I’m missing something. thoughts? -

And then there was smoke!

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

UPDATE: I ran about 4oz of seafoam in the oil and then replaced the oil, oil filter, plugs, added a zinc additive. Plugs seemed relatively decent shape - limited if any fouling. I'm assuming it will take some time for any of these simple maintenance approaches to show relief of the smoke? I just took it out for a drive - seemed like it ran a bit quieter but then again, but I'm still a noob at this so what do I know, right? I did a compression test on the engine - the test gauge did not show cylinder KEEP the needle at a certain spot. (no my finger was not on the pressure release button of the guage). I assume this is a gauge issue, not the engine. When the needle moved, pressure was relatively consistent across the board on a dry test. I'll redo it here in a couple hours - dry and wet and post back numbers after a better break in. My oil pressure gauge increased running oil pressure to about 60psi or so at 40mph. The smoke that I'm noticing most prominent is coming from a pipe that shoots straight down from the engine along side or behind the exhaust pipe on the passenger side near the firewall and only points straight down. I looked at the service diagram but I must be missing where that pipe is labeled. Finding this label may help figure out where a problem could be. Any thoughts? Most notably, the smoke is prominent climbing hills or where the engine has to work a bit harder. -

Grease and gunk...so much cleaning...

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

@Plymouthy Adams - what’s your preferred way to protect? @Merle Coggins - you’re a wealth of knowledge my friend! I’ll check the shop manual for The oil cups. ill do this after I charge the oil and rinse the oil sock and air filter. Those seem like they’ll be messy... off topic but: any spark plugs to NOT use? My local parts dealer had ACDELCO plugs. I never gave a thought to plugs, until now. Suggestions? -

And then there was smoke!

Matfirstattempt replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

@Tooljunkie - thanks for your help. I need to run a. Couple miles today to take the recycling out. I’ll add it before I go to let it warm and get into the engine. Then oil change, plugs, and compression tests to follow. The an engine bay bath. ALICE IS GOING TO GET PAMPERED! -

I purchased Alice about 2 weeks ago and I love it! She’s a 1950 Dodge B2 stake bed. Alice and I took a drive earlier this week to see my mom a few towns over. I reckon it was the farthest she’s been in a long time. What a beautiful drive through the hills and valleys a of Wisconsin. Nothing too crazy, and no issues. Today I hopped in and took Alice to town (about 3-5 miles) but she was different. As I climbed a good hill I noticed that I had a lot of smoke in my exhaust. A white/blue haze. I pulled over and parked, took a look at the engine bay and noticed the oil vent cap had more exhaust coming from it than normal but nothing causing an issue. I took her back home and let her rest. Oil pressure is good. Engine temp is good. This seems to only happen under a load or at higher rev. The smoke isn’t coming during idle and no misfires or issues that I can hear (untrained to this age of engine). Im going to change the oil for fresh stuff. I will also replace the radiator fluid. I’ll change spark plugs and while I’m at it do a dry and wet test. My mechanic said to use a zinc additive to the oil. Anything else I should look for or consider?

-

When I first got my truck, I did a lovely deep clean of the interior knowing I had to tackle the engine bay. Like my exercise routine, I put it off and now am going to do a minor tune up and a few major items as well from the shop manual on the engine. There’s grease, lots of it. So, what’s the best way to tackle it? A hose to spray the main stuff off but then degreaser? Some say oven cleaner but is that too harsh? Some claim simple green is good. I don’t want to pull the engine or parts - I just want to clean it, linkages, trans, etc as best I can, find the leaks that caused the gunk, fix it, and get it reliable. Then, when I go to tackle a system, I’m not working through a thick layer of sludge to do it. So, how do you go about tackling an engine that’s not been cleaned for likely 3-7 decades?

-

Starting my B2C restoration.

Matfirstattempt replied to Bdblazer1978's topic in Mopar Flathead Truck Forum

@minicooper thanks for looking at it. Quick question: the link you posted for the part looks like it is a single cylinder - is it single or a dual master cylinder? -

@dcotant, Yeah, I remember Zach! Last name is Anderson. first is the first three of my handle. Zach hung out with Max and a few other guys I remember their faces but not the names. They weren't really in my circle - hell I didn't really have a circle. Anyway, ask most people in my hometown if they thought I'd be turning wrenches on a 70-year-old truck and they'd probably laugh at you.

-

That’s what I’m hoping for too. Building a driver that can do work. Maybe someday it’ll retire and I can make it a show winner, until then “no free lunch” at our ranch

-

That’s cool, this is Glenn and Betsy Thronson’s old farm. I played there a couple times as a kid. Knew them and still know Lowell well. I’ll see what we can work out for this summer. Thanks man