-

Posts

32 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by Jared Duramax

-

The cab mounts are done the fender to cab brackets are made all the interior bracing has been cut out and the cab brace blocks are done now it is time to start working on the hood. I am going to make it a 1 piece hood and remove the upper brow and turn it into part of the grill.

-

Look at Truck-Lite they make really good DOT approved lights. https://www.truck-lite.com/lights.html

-

I’ll have to keep that in mind.

-

I am starting to look for a new bench seat does anyone have any recommendations? I don’t plan on using the original I would like to put something nicer instead.

-

Looks great how much fighting did you have to do to get the doors to line up correctly after all the cutting?

- 640 replies

-

I got the cab squared to the frame, the front clip apart, and hammered out majority of the dents. I rust converted the inside of the fenders then re assembled the clip. It took a long time to get the fender to door gaps correct. Radiator crossmember, front clip gussets, and fender to cab brackets are next on the list. This cab and clip has been a pain to get everything set right. What is everyone’s opinion on rust converting products?

-

Thanks this is my first car build so I am kind of flying blind learning as I go. I am just outside of Charlotte in Monroe.

-

No the floor and firewall is 1/8” plate and it will have a 3”x3”x3/16” tube sub frame with cross members for the seats

-

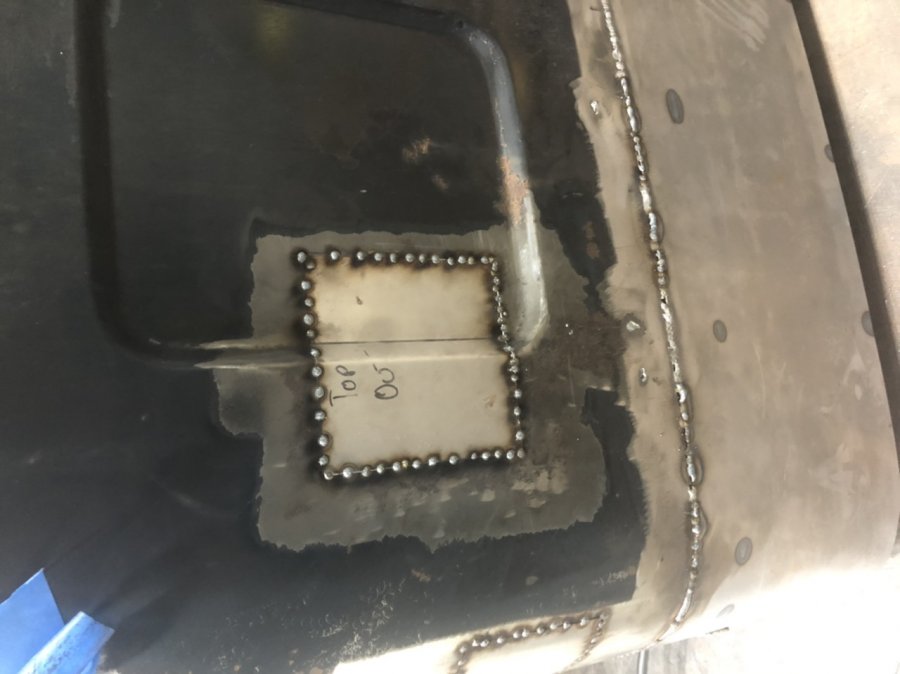

Front cab corners done, gas door filled, patch panels done, lower cab radius done, floor needs final welding then back onto the truck for the cab mounts.

-

It will have a 10’ flat bed

-

Back onto the frame for fire wall and floor mock up.The fire wall and floor is made with 1/8” plate. Then onto the table to square the cab and welding in the floor and fire wall . Everything is drawn up on the computer then CNC plasma cut then bent on the press brake.

-

-

I have the motor trans and cab mocked up for alignment along with the motor mounts and transmission mounts fabricated

-

I got the cab off the excursion and the motor and trans pulled. Ready to start the install of the 5.3 LS and 4l60e trans.

-

I got this truck about 5 years ago and it was supposed to be a restoration but after tearing it down I found this was not going to be a good candidate. So it sat in my garage in parts until I figured out a good plan. During that time I have been collecting lots of parts and ideas. I came across a 2000 Ford Excursion that was 4wd for $500 and I knew this would be my best start. The original frame was not square and was beyond repair.

-

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

Well it has been a while but i have made some progress. The doors are being rebuilt right now (the lower eight inches), the frame is stripped and i am working little by little on cleaning, welding, priming, and painting. The motor is torn down other than the # 6 piston which is seized so badly i can not get it to move with a 6lb hammer. Once I get it out the block will go to the machine shop to be decked, bored, and hot tanked. Overall the truck is in much worse shape than i thought it was in and i am seeing my august 24th initial test drive to dinner day coming a lot faster than i was hoping it would. Update: I just knocked the #6 piston out and the cylinder wall is so pitted that you can take a screw driver and knock holes into the water jacket. so it looks like this block is trashed i guess i will be on the look out for another block. -

My original factory wheels are to far gone for repair and need to be replaced I am wanting to put a set of rocket booster wheels on in 18" but I am having a hard time figuring out what the backspacing needs to be. I will be running factory suspension and drum brakes. Any input would be great Thank You

-

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

Well it looks like I am finally going to get a break on the weather this weekend and I will get almost all of it disassembled and ready for media blasting. I will get pictures of the progress. I am in the market for new wheels and what backspacing is everybody using? -

Compression readings and assessment

Jared Duramax replied to Jeff Balazs's topic in Mopar Flathead Truck Forum

If I were you i would be pulling the engine out and going through it. If the engine is still in specs i would just re ring, hone, re bearing and shave the head about .050" to gain a bit of power but not so much to the point of possibly dropping reliability. I would have the valves ground and get a neway seat cutting kit and do the valve job your self. I rebuild lots of flathead equipment engines that just have low power from years of use and it never takes much to get all the power back. I wouldnt do an engine swap because then you are into swapping transmissions and then it takes the originality out of the truck. -

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

I am looking for a set of steel B2 style -

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

Im on the search for the grill louvers does anybody have a suggestion on where to find some? -

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

https://www.boltdepot.com/fastener-information/materials-and-grades/bolt-grade-chart.aspx Here is a link to bolt identification markings this is extremely handy when digging through an assortment of bolts. -

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

Buying another has always been my go to answer that's why I am trying to avoid that. Good news is I am a mechanic for a profession and I have lots of experience with flat heads. Hopefully I can get the engine pulled Monday and tore down to start a parts list. -

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

So far I have removed all the old wiring, Washed the truck and started taking some of it apart. ( i need to come up with a better parts storage system before i get to far any suggestions?) -

Start Of Another Project

Jared Duramax replied to Jared Duramax's topic in Mopar Flathead Truck Forum

Based on the title I am going to go with it is all original mileage.